Beruflich Dokumente

Kultur Dokumente

Cosmetics Acceptability

Hochgeladen von

radule021Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cosmetics Acceptability

Hochgeladen von

radule021Copyright:

Verfügbare Formate

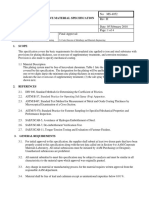

Tier II Documentation

Work Instructions

Title:

Department:

COSMETIC ACCEPTANCE CRITERIA

QUALITY ASSURANCE

Revision History

Change Notice /

Dev. Number

Description

Old

Rev.

Date

100-229

Initial Release

1/16/09

100-277

Revised Para 5.0.2

06/29/10 I/R

Reviewed and no changes required

06/02/11

Title

Originator

Department Head

Revised By

Documentation

Coordinator

Authorized Signatures

I/R

Date

Robert Davies

1/16/09

Kirit Patel

06/29/10

George Sheldon

06/29/10

George Sheldon/Kirit Patel

06/29/10

Document Number

FRM 120-007

New

Rev.

WI190-004

Revision

Page 1 of 18

Rev I/R

EPE Work Instructions

Title:

1.0

Date Issued:06/29/10

1.0 Purpose PURPOSE AND SCOPE

1.0

2.0

3.0

The purpose of this document is to establish cosmetic acceptability and nonacceptability criteria for customer shippable parts, assemblies and final products that

are purchased or consigned to EPE Corporation for value added assembly.

RESPONSIBILITIES

2.0

Quality is responsible for maintaining this document and the content. Quality applies the

information contained here in or as it is modified and agreed to between EPE and the

customer to determine material compliance with this document.

2.1

Program Manager is responsible for providing Cosmetic Specifications to EPE

Customers prior to value added assembly.

2.2

Purchasing/Buyer is responsible for communicating cosmetic criteria/requirements to all

Suppliers of EPE Corporation.

2.3

Manufacturing Operators are responsible for assessing questionable material

conformance with this specification

SURFACE COSMETICS

3.0

General Inspection Requirements:

3.0.1 Cosmetic inspection at EPE Corporation or its suppliers shall use the TIME and

DISTANCE method of inspection as described in different sections of this

document.

3.0.2 The Cosmetic standards defined in this Workmanship Standard shall be used for

training personnel, checking surface quality produced by any process and used

in making Accept/Reject decision.

3.1

Viewing Conditions:

3.1.1 All inspection will be made under normal artificial lighting, unaided and viewed in

a manner that duplicates the typical end use of the product. During cosmetic

inspection, only visual qualities (appearance) of the part surface shall be

considered. Surfaces shall be viewed without the aid of magnification, at an

angle approx. 45 to normal of the surface to be inspected.

Document Number

FRM 120-007

WI190-004

Revision

Page 2 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

3.1.2 The following are Inspection criteria:

3.1.2.1

Inspection shall be conducted using the unaided eye.

3.1.2.2

Viewing distance shall be 18 or 24 as specified by surface class.

3.1.2.3

Viewing angle shall be 45 to the surface.

3.1.2.4

Light source shall be by cool white fluorescent light; the light source shall be

positioned and distanced to provide optimal viewing and minimized glare and

shadowing of the sample.

3.1.2.5

In the case where black light or other special lighting is required to detect or

accent defects, the specifics specified in this procedure shall prevail, except

where exempted in writing by the customer

3.1.2.6

Where subjectiveness intervenes in the assessment form/fit/function shall

take precedent or where available 3rd party decision (including) but not limited

to the customer/end user shall prevail.

.

3.1.3 General Guidelines

3.1.3.1

Codes

Viewing duration shall be based on part size as well as complexity.

Class A

Class B

Class C

Viewing Distance

450mm (18 in.)

450mm (18 in.)

600mm (24 in.)

Viewing Time

10 seconds

5 seconds

3 seconds

Viewing Area

3.1.3.2

Discernable variation from the guidelines specified within this document shall

be grounds for rejection.

3.1.3.3

Class A surfaces shall be manipulated during inspection to achieve

maximum reflection of a light source. Class B and Class C surfaces shall

NOT be manipulated during inspection. Refer to Class A, Class B, and Class

C viewing condition figures below.

Document Number

FRM 120-007

WI190-004

Revision

Page 3 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

Class A (Viewing Conditions cool white light):

Class B (Viewing Conditions cool white light):

Document Number

FRM 120-007

WI190-004

Revision

Page 4 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

Class C (Viewing Conditions cool white light):

Document Number

FRM 120-007

WI190-004

Revision

Page 5 of 18

Rev I/R

EPE Work Instructions

Title:

4.0

Date Issued:06/29/10

SURFACE CLASSES

4.0

The following assumes the item being viewed is an assembled unit as it would appear

in an operational environment. Assemblies utilizing unlike materials on the same

viewing surface (e.g. plastic handles and fasteners on a sheet-metal panel) will have

the same cosmetic class standard applied from the applicable material tables. When

viewing separate components it must be understood which surfaces correspond to the

classification below.

4.0.1 CLASS A - Highly decorative surface in constant view of the customer.

4.0.2 CLASS B Moderately decorative surface in occasional view of the customer

without the unit being removed. Examples include but are not limited to the top

and sides of rack-mounted chassis, rear faceplates.

4.0.3 CLASS C Non decorative surface not readily visible to the customer except

when the unit is moved.

5.0

PLASTIC PARTS

5.0

Acceptable Criteria:

5.0.1 Acceptable Class A, Class B or Class C defects should not affect FIT or

FUNCTION. In such cases affecting fit or function, the parts are automatic

rejects.

5.0.2 For General inspection requirements and viewing conditions reference

beginning with Section 5.3 (Various materials- Surface Cosmetics)

5.0.3 This spec. applies to parts with inserts and parts resulting from post molding

operations.

5.0.4 50 sq. inch area in the Tolerance Table is the limit for the number of defects

found acceptable within the surface area. For larger surfaces the number of

defects allowed increases proportionally. Clustering of more than two defects is

not acceptable.

Document Number

FRM 120-007

WI190-004

Revision

Page 6 of 18

Rev I/R

EPE Work Instructions

Title:

5.1

Date Issued:06/29/10

Texture:

5.1.1 Molded texture specs are the default plastic textures adopted by EPE

Corporation.

5.2

Defect Definitions:

5.2.1 Protrusion A raised area on a surface (blister, bump, ridge or gate mark)

5.2.2 Discoloration Change from original color or inconsistent color within the same

part

5.2.3 Burns Black specs in the surface of the part due to overheating

5.2.4 Splays Marks from gases or voids in the surface of a part.

5.2.5 Flow Marks Wavy or streaked appearance of a surface.

5.2.6 Haze Cloudiness on an otherwise transparent part.

5.2.7 Pits Small craters on a surface.

5.2.8 Specks Small pieces of material stuck to the surface.

5.2.9 Scratches Shallow grooves forming lines on the surface.

5.2.10 Phantom Scratches Light surface marring, visible through manipulation, but not

from all angles or sides.

5.2.11 Sink Depression on the surface.

5.2.12 Knit/Weld Line A visible line formed at the intersection of material flow.

5.2.13 Blush Inconsistency in surface gloss.

5.2.14 Parting Line/Flash A visible line and or raised surface on the part formed at the

intersection of (2) mating surfaces of the mold.

5.2.15 Texture Variation Visible variation of texture from within the same part.

5.2.16 Mold Release Spray lubricant used for ease of part release from the mold.

5.2.17 Color Variations Color of part appears different from color sample chips.

5.3

Tolerance Table: (Plastic parts Surface Cosmetics)

5.3.1 The total number of defects per surface shall not exceed the acceptable limit.

Use the Table below for training inspection personnel and making

Accept/Reject decisions.

Document Number

FRM 120-007

WI190-004

Revision

Page 7 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

Defect Type

Protrusions

Class A

Not Acceptable

Class B

Class C

Qty 2 (Max) per 50 Sq. Area. Max Dim: .010

Sq A x .015 H

Qty 8 (Max) per 50 sq. Area.

Max Dim: .020 Sq. A x .030 H

Discoloration, Flow marks,

Haze, Burns and Splay

Not Acceptable

Qty 4 (Max) per 50 Sq. Area. Max Dim: .010

Sq. Area.

Acceptable

Pits and Specks

Not Acceptable

Qty 4 (Max) per 50 Sq. Area. Max Dim: 0.06

Dia. x 0.15 Dp (Pits) Max Dim: 0.06 Dia. X

.015 H (Specks)

Acceptable

Scratches

Not Acceptable

Qty 4 (Max) per 50 Sq. Area Max Dim: 0.25 L

x .020 W

Acceptable

Phantom Scratches

Not Acceptable

Qty 4 (Max) per 50 Sq. Area Max Dim: 0.25 L

x .020 W

Acceptable

Sink Marks

Not Acceptable

Qty 2 (Max) per 50 Sq. Area Max Depth:

0.005

Acceptable

Knit/Weld Lines

Not Acceptable

Qty 2 (Max).

Acceptable

Max Dim: 0.002 Wide

Blush

Not Acceptable

Acceptable

Acceptable

Parting Lines/ Flash

Not Acceptable

Flash: Max Dim: .005 protrusion from base

surface.

.010 Max

Mismatch/Step: Max Dim: .005. Diff from

one surface level to another

Texture variation: Visible

variation on the surface

Not Acceptable

Acceptable

Acceptable

Mold release on surface

Not Acceptable

Not Acceptable

Not Acceptable

Color Variation

Not Acceptable

Not Acceptable

Acceptable

6.0

SHEETMETAL PARTS

6.0

Acceptable Criteria:

6.0.1 Acceptable Class A, Class B or Class C defects should not affect FIT or

FUNCTION. Any cosmetic defects that negatively affect fit or function of the part

or assembly shall be rejected.

6.0.2 For general inspection requirements and viewing conditions reference Section 6

(Surface Cosmetics).

6.0.3 This spec applies to both Pre-Plated and Post Plated parts.

6.0.4 50 Sq. inch area in the Tolerance Table is the limit for the number of defects

found acceptable proportionally. Clustering of more than two defects is not

acceptable.

Document Number

FRM 120-007

WI190-004

Revision

Page 8 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

6.0.5 Fingerprints: No fingerprints, whether they penetrate the plating or not, are

allowed in Class A, B or C. (Wear appropriate protective garments)

6.1

Defect Definitions:

6.1.1 Rainbow effect Zinc plating may have discoloration or the rainbow effect.

6.1.2 Rust/ Oxidation Chemical reaction of exposed metal with oxygen (air).

6.1.3 Discoloration Any change from original color, intended color or inconsistent

color.

6.1.4 Scratches Visible but cannot be felt with thumbnail. Please consult your

Quality Engineer or Process Engineer if you have product specific questions

regarding Acceptablility.

6.1.5 Gouge Surface imperfection, deeper than a scratch, penetrates into plating,

often with raised edges.

6.1.6 Plating Marks and Runs Visible inconsistencies in the surface due to the

plating process. Such as bleed outs, water runs and hook marks. Any mark, pit,

scratch or gouge, should not penetrate the plating.

6.1.7 Marks Pits, sanding or other marks on base material that remain visible after

coating.

6.1.8 Non-uniform gloss Areas that have insufficient or excessive gloss.

6.1.9 Grease or Oil Used in the process and left on the surface (not cleaned).

6.1.10 Lint/Grit/Speck/Dust Any unintended substance in the coating or on the surface

6.1.11 Pits Small craters on the surface.

6.1.12 Tooling Marks Normal process marks created by forming dies. These marks

are consistent on all parts and located at the formed area. All other marks are

not defined as standard tooling marks. Depth of tooling mark can be visible but

cannot be felt with thumbnail.

6.1.13 Surface Finish (Texture) A pattern (texture) produced by abrasive media. Such

as a belt-sander that produces a grained finish and an oscillatory sander that

produces an oscillated finish. GRIT size must be specified on individual part

drawing.

6.2

Tolerance Table: (Post-Plated Sheet metal parts) (Surface Cosmetics)

Document Number

FRM 120-007

WI190-004

Revision

Page 9 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

6.2.1 The total number of defects per surface shall not exceed the acceptable limit.

Use Table below for training inspection personnel in making Accept/Reject

decisions.

Defect Type

Class A

Class B

Class C

Rainbow effect

(seen on Zinc

Plating)

Not Acceptable

Acceptable

Acceptable

Rust/ Oxidation

Not Acceptable

Not Acceptable

Acceptable on sheared edges.

Touch up allowed for rust spots on

surfaces up to 0.25 Dia.

Discoloration

Not Acceptable

Acceptable

Acceptable

Gouge

Not Acceptable

Not Acceptable

Not Acceptable

Scratch

For scratches which are within

0.25 L x .015 W

For scratches which are within

0.25 L x .015 W

Not to Exceed Standard Manufacturing

Practices*

Surface Area

10 - 20

21 - 50

51 200

201+

sq in.

sq in.

sq.in.

sq. in

# of

Scratches

Allowed

0

0

0

4

For Scratches which are within

0.50 L x 0.005 W

Surface Area

10 - 20

21 - 50

51 200

201+

sq in.

sq in.

sq.in.

sq. in

# of

Scratches

Allowed

0

0

0

1

Surface Area

10 - 20

21 - 50

51 200

201+

sq in.

sq in.

sq.in.

sq. in

# of

Scratches

Allowed

3

6

10

20

* Please check with specific NPI team

member if there are questions re:

Acceptability.

For Scratches which are within

1.00 L x 0.005 W

Surface Area

10 - 20

21 - 50

51 200

201+

# of

Scratches

Allowed

sq in.

sq in.

sq.in.

sq. in

1

2

3

7

Accumulation of scratches

not to exceed 2.5 in

length/200+ sq. in.

Surface Area

10 - 20

21 - 50

51 200

201+

sq in.

sq in.

sq.in.

sq. in

# of

Scratches

Allowed

1

2

3

7

Phantom Scratches

Not Acceptable

Acceptable

Acceptable

Plating Marks and

Not Acceptable

Qty (2) Max per 50 Sq Area

Acceptable

Document Number

FRM 120-007

WI190-004

Revision

Page 10 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

Runs

Max Dim: .06 W x .5 L

Non-uniform Gloss

Not Acceptable

Acceptable

Acceptable

Grease or Oil

Not Acceptable

Not Acceptable

Not Acceptable

Grit/Dust/Lint/Speck

Not Acceptable

Acceptable

Acceptable

Protursions

Not Acceptable

Acceptable

Marks/Pits

Not Acceptable

Acceptable

Tooling Marks

Not Acceptable

Acceptable

Acceptable

Fingerprints

Not Acceptable

Not Acceptable

Not Acceptable

Surface Finish:

Visible variation in

texture from the

approved sample.

Not Acceptable

Not Acceptable

Acceptable

6.3

Tolerance Table: (Pre-Plated Sheet metal parts) (Surface Cosmetics)

6.3.1 The total number of defects per surface shall not exceed the acceptable limit.

Use the Table below for training inspection personnel in making Accept / Reject

decisions.

Defect Type

Rainbow effect

(seen on Zinc

plating)

Rust/ Oxidation

Class A

N/A

N/A

Class B

Class C

Acceptable

Acceptable

Not Acceptable

Acceptable on sheared edges.

Touch-up allowed for rust spots on

surfaces up to 0.25 Dia.

Discoloration

Gouge

Scratch

N/A

N/A

N/A

Acceptable

Acceptable

Not Acceptable

Not Acceptable

For scratches which are within 0.25

L x .015 W

Not to Exceed Standard Manufacturing

Practices*

Surface Area

10 - 20

21 - 50

51 200

201+

sq in.

sq in.

sq.in.

sq. in

# of

Scratches

Allowed

* Please check with specific NPI team

member if there are questions re:

Acceptability.

3

6

10

20

For Scratches which are within

1.00 L x 0.005 W

Surface Area

Document Number

FRM 120-007

WI190-004

# of

Scratches

Allowed

Revision

Page 11 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

10 - 20

21 - 50

51 200

201+

sq in.

sq in.

sq.in.

sq. in

1

2

3

7

Accumulation of scratches not to

exceed 2.5 in length/200+ sq. in.

Surface Area

# of

Scratches

Allowed

10 - 20 sq in.

21 - 50 sq in.

51 200+ sq.in.

Phantom Scratches

Plating Marks and

Runs

Non-uniform Gloss

Grease or Oil

Grit/Dust/Lint/Speck

Protrusions

Mark/Pits

Tooling Marks

Fingerprints

Surface Finish:

Visible variation in

texture from the

approved sample.

N/A

N/A

Acceptable

Acceptable

Qty (2) Max per 50 Sq Area

Acceptable

Max Dim: .06 W x .5 L

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Document Number

FRM 120-007

0

0

1

Acceptable

Acceptable

Not Acceptable

Not Acceptable

Acceptable

Acceptable

Qty 4 (Max) per 50 Sq. Area Max

Dim: 0.06 Dia. x .010 H

Acceptable

Qty 4 (Max) per 50 Sq. Area Max

Dim: 0.06 Dia. x .010 DP

Acceptable

Acceptable

Acceptable

Not Acceptable

Not Acceptable

Not Acceptable

Acceptable

WI190-004

Revision

Page 12 of 18

Rev I/R

EPE Work Instructions

Title:

7.0

Date Issued:06/29/10

DIE CAST PARTS

7.0

Acceptable Criteria:

7.0.1 Acceptable Class A, Class B or Class C defects should not affect FIT or

FUNCTION. In such cases as affecting fit or function the parts are automatic

rejects.

7.0.2 For General Inspection requirements and viewing conditions- reference Section

3 (Surface Cosmetics).

7.0.3 This specification applies to all RAW and PLATED die cast parts and to parts

resulting from post casting operations.

7.0.4 50 Sq. inch area in the Tolerance Table is the limit for the number of defects

found acceptable within that surface area. For larger surfaces the number of

defects allowed increases proportionally. Clustering of more than two defects is

not acceptable.

7.1

Defect Definitions:

7.1.1 Growth Expansion of casting from aging

7.1.2 Heat Checking Fine cracks, veins or fins of any length

7.1.3 Sink Depression on the surface

7.1.4 Porosity Holes or voids (blow holes, pits, underfills)

7.1.5 Protrusions A raised area on a surface (blisters, bumps, ridge and gate).

7.1.6 Specks Small particles stuck on the surface.

7.1.7 Scratches Shallow grooves forming lines on the surface.

7.1.8 Weld Line A visible line or mark on a surface of any length.

7.2

Tolerance Table: (Die Cast parts) (Surface Cosmetics)

Defect Type

Class A

Class B

Class C

Growth

Not Acceptable

Qty (2) Max Dim: .10 Dia. x .015 H

Acceptable

Heat Checking and Sink

Not Acceptable

Qty (4) Max Depth: .03 (sinks/cracks)

Acceptable

Max Height: .015 (fins)

Porosity, Protrusions and Specks

Not Acceptable

Qty (4) Max Dim: .05 Dia. x .15 H

Acceptable

Scratches

Not Acceptable

Qty (4) Max Dim: .02 W x .25 L

Acceptable

Document Number

FRM 120-007

WI190-004

Revision

Page 13 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

Weld Lines

8.0

Not Acceptable

Qty (4) Max Depth: .008

Acceptable

WET PAINT & POWDER COAT COSMETIC SURFACE FINISHES

8.0

Acceptable Criteria:

8.0.1 All classes must exhibit good workmanship and meet requirements (as specified

per customer product drawings and/ or specifications) for color, gloss, texture,

and film thickness and adhesion.

8.0.2 Wet paint touch up is acceptable as long as it meets the Class B and Class C

defect criteria in the Tolerance Table.

8.0.3 For general inspection requirements and viewing conditions reference Section

3 (Surface Cosmetics).

8.0.4 50 Sq. inch area in the Tolerance Table is the limit for the number of defects

found acceptable within that surface area. For larger surfaces the number of

defects allowed increases proportionally. Clustering of more than two defects is

not acceptable.

8.1

Defect Definitions:

8.1.1 Debris Foreign material and objects

8.1.2 Dents Local material impressions

8.1.3 Gouges Material removed or displacement in a local area resulting in the

removal of paint and/or base material.

8.1.4 Scratches Shallow grooves forming lines on the surface.

8.1.5 Phantom Scratches Light surface marring, visible through manipulation, but not

from all angles or sides.

8.1.6 Orange Peel Surface condition caused by an irregular waviness of a paint

finish, resembling an orange peel texture.

8.1.7 Paint Runs Caused by excessive paint in a local area not drying uniformly.

8.1.8 Discoloration Non-uniform color.

8.1.9 Light Coverage Inadequate paint coverage.

8.1.10 Texture Variation Visible variation in texture on the part surface.

8.1.11 Blisters Areas of local air entrapment or non-adhesion

Document Number

FRM 120-007

WI190-004

Revision

Page 14 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

8.1.12 Stains Spots or uneven color on the surface due to defects in material or due

to poor cleaning.

8.2

Tolerance Table: (Wet Paint & Powder Coat finishes) (Surface Cosmetics)

Defect Type

Class A

Class B

Class C

Debris including Fibers

Not Acceptable

Qty (3) Max. particles of less than .040

Dia. X .015 H per 50 sq. inch area

Acceptable

Dents

Not Acceptable

Qty (3) Max. dents of less than 0.040

Dia. Per 50 sq. inch.

Acceptable

Gouges

Not Acceptable

Not Acceptable

Acceptable. Must not

penetrate base metal.

Scratches

Not Acceptable

Max. of 4 - .025 L x .015 W per 50 sq.

inch area

Acceptable. Must not

penetrate base metal. Touch

up NOT required.

* Wet paint touch up may be required.

Phantom Scratches

Not Acceptable

Max. of 4 - .025 L x .015 W per 50 sq.

inch area

Acceptable. Must not

penetrate base metal. Touch

up NOT required.

Orange Peel

Not Acceptable

Not Acceptable

Acceptable

Paint Runs

Not Acceptable

Not Acceptable

Acceptable

Light Coverage

Not Acceptable

Not Acceptable

Acceptable

Discoloration

Not Acceptable

Not Acceptable

Acceptable

Texture variation: Visible

variation on the surface

Not Acceptable

Acceptable

Acceptable

Blisters

Not Acceptable

Not Acceptable

Not Acceptable

Stains

Not Acceptable

Not Acceptable

Acceptable

* For items denoted by * contact Process Engineer to determine if touch up of this defect will be allowed. For

touch up to be performed on a Class A or Class B surface it must be approved by the Customer.

9.0

PRODUCT MARKING:

9.0

Acceptable Criteria:

9.0.1 Acceptable Class A, Class B or Class C defects should not affect FIT or

FUNCTION. In such cases as affecting fit or function the parts are automatic

rejects.

9.0.2 For General Inspection requirements and viewing conditions- reference Section

3 (Surface Cosmetics).

9.0.3 This spec applies to all Product Marking processes such as Product ID labels,

Silk Screening, Rubber Stamp, Laser and Chemical etching etc. However, this

Document Number

FRM 120-007

WI190-004

Revision

Page 15 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

spec does not provide criteria for Class C surfaces. The markings on a Class C

surface such as barcode labels (i.e. serial number, deviation number or CLEI

code labels) and the compliance labels are intended to provide information and

shall be inspected against EPE Workmanship Standards.

9.1

Defect Definitions:

9.1.1 Label is loose and falling off Label not properly adhered to surface or does not

stay in designated location.

9.1.2 Label Edges / Corners dog-eared or not fully adhered to surface. Example:

Label edge peeled up.

9.1.3 Misapplied Label on the product. Example: Label is not parallel or perpendicular

to the product edge.

9.1.4 Mis- registered text or graphics. Example: Text or graphics is off or not parallel

to the label edge.

9.1.5 Mis-registered silkscreen text or graphics on product. Example: Silkscreen text

is off edge or not parallel to the edge of product or to the label edge.

9.1.6 Scratched Label Shallow grooves forming lines on the surface.

9.1.7 Phantom Scratches (Abraded label Light surface marring, visible through

manipulation, but from all angles or sides.

9.1.8 Scratched or Abraded Silk Screening Shallow grooves forming lines on the

surface.

9.1.9 Stray Spots and Print Voids Typically the spots are round or oval in shape.

Several small spots clustered together can appear as a single spot and should

be considered a single spot.

9.1.10 Variable Line width of text or graphics Print imperfections appearing with line

width variation.

9.1.11 Illegible Text / Smudged Ink/ Non-Permanent Ink Can be problem with ink or

post-print handling resulting in smears.

9.1.12 Ragged Printed Edges Print imperfections with ragged profile

9.1.13 Filled Text Example: Ink-filled txt (i.e. the letter O may appear as a dot).

9.1.14 Ink Non-Opacity Example: Ink is translucent (i.e. you can see through the ink).

9.1.15 Incomplete Characters Example: The letter R appears as a P.

Document Number

FRM 120-007

WI190-004

Revision

Page 16 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

9.1.16 Pin Holes (Blistering in Silkscreening) Blistering resulting in pinholes in the

silkscreeining.

9.1.17 Inconsistent Ink Color Color of ink appears different with a part when

compared to other parts in the same production lot.

9.2

Tolerance Table: (Product Marking) (Surface Cosmetics)

Defect Type

Class A

Class B

Label loose or falling off

Not Acceptable

Not Acceptable

Label edges/ corners dog-eared or not fully

adhered.

Not Acceptable

Not Acceptable

Scratched Label

Not Acceptable

Not Acceptable

Phantom Scratches

Not Acceptable

Qty (1) Max Abrasion of

less than .25 L x .020 W

per 5 sq. inch area

Scratched or Abraded Silk screening

Not Acceptable

Not Acceptable

Misapplied Label on the product. Example:

Label is not parallel or perpendicular to the

Acceptable within 1

degree

Acceptable within 2

degree

Mis- registered text or graphics. Example:

Text or graphics is off or not parallel to the

label edge.

Acceptable within 1

degree

Acceptable within 2

degree

Mis-registered silkscreen text or graphics

on product. Example: Silkscreen text is off

edge or not parallel to the edge of product

or to the label edge.

Acceptable within

degree

Acceptable within 1

degree

Variable line width of text or graphics.

Line width within 5%

Acceptable

Line width within 10%

Acceptable

Stray Spots and Print Voids

Not Acceptable

Qty (4) Max. spots or less

than .008 Dia. Per 5 sq.

inch area

Illegible text/ Smudged Ink/ non-permanent

ink

Not Acceptable

Not Acceptable

Filled Text

Not Acceptable

Not Acceptable

Ink non-capacity

Not Acceptable

Not Acceptable

Incomplete Characters

Not Acceptable

Not Acceptable

Class C

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

product edge.

Document Number

FRM 120-007

WI190-004

Revision

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Refer to 9.1.3

Page 17 of 18

Rev I/R

EPE Work Instructions

Title:

Date Issued:06/29/10

Pin Holes

Not Acceptable

Qty (4) Max. spots or less

than .008 Dia. Per 5 sq.

inch area

Inconsistent Inc color

Not Acceptable

Not Acceptable

10.0

Refer to 9.1.3

QUALITY RECORDS

10.0

11.0

Refer to 9.1.3

N/A

ASSOCIATED/RELATED DOCUMENTS

11.0

N/A

Document Number

FRM 120-007

WI190-004

Revision

Page 18 of 18

Rev I/R

Das könnte Ihnen auch gefallen

- Catalogue FARETE International Club 2019Dokument46 SeitenCatalogue FARETE International Club 2019radule021Noch keine Bewertungen

- Ds Lc15dx enDokument3 SeitenDs Lc15dx enradule021Noch keine Bewertungen

- SSAS2.81 Magnetic PropertiesDokument2 SeitenSSAS2.81 Magnetic Propertiesradule021Noch keine Bewertungen

- Rivnut Mechanical Properties 1Dokument1 SeiteRivnut Mechanical Properties 1radule021Noch keine Bewertungen

- Styli Catalog 13B PDFDokument100 SeitenStyli Catalog 13B PDFradule021Noch keine Bewertungen

- CV1 - PR - B - Mipa TDSDokument2 SeitenCV1 - PR - B - Mipa TDSradule021Noch keine Bewertungen

- TDS Ep100-20Dokument2 SeitenTDS Ep100-20radule021Noch keine Bewertungen

- Solidworks Inspection Data SheetDokument3 SeitenSolidworks Inspection Data Sheetradule021Noch keine Bewertungen

- Training Brochure UK en HexagonDokument28 SeitenTraining Brochure UK en Hexagonradule021Noch keine Bewertungen

- Developments - Cont'D: Mechanical Engineering Graphics MECH 211Dokument139 SeitenDevelopments - Cont'D: Mechanical Engineering Graphics MECH 211radule021Noch keine Bewertungen

- Electrodeposited Coatings of Zinc With Passivation On SteelDokument4 SeitenElectrodeposited Coatings of Zinc With Passivation On Steelradule021Noch keine Bewertungen

- Rohs Implementation: OutlineDokument16 SeitenRohs Implementation: Outlineradule021Noch keine Bewertungen

- English Manual of NTR83Dokument47 SeitenEnglish Manual of NTR83radule021Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- TDS Ru5black 000 EngDokument3 SeitenTDS Ru5black 000 Engphistore19Noch keine Bewertungen

- Nammaaaa 000031Dokument147 SeitenNammaaaa 000031mohammad qaruishNoch keine Bewertungen

- Type D3 MV Sprayer 1Dokument4 SeitenType D3 MV Sprayer 1lavascudoNoch keine Bewertungen

- Basics of Cold FormingDokument51 SeitenBasics of Cold FormingPrakash RNoch keine Bewertungen

- Dau Sprinklers TYCO - TY315Dokument4 SeitenDau Sprinklers TYCO - TY315hungNoch keine Bewertungen

- Chromium Plating On Abs PlasticDokument11 SeitenChromium Plating On Abs PlasticMohammed Shafi AhmedNoch keine Bewertungen

- NPCS ListDokument2.034 SeitenNPCS ListdevilgentleNoch keine Bewertungen

- CCI Notes: Silver - Care and Tarnish RemovalDokument5 SeitenCCI Notes: Silver - Care and Tarnish RemovalVitor RodriguesNoch keine Bewertungen

- 2 Battery2006Dokument110 Seiten2 Battery200622t22t22Noch keine Bewertungen

- Electroless Silverplating Chapter From Electroless Plating - Fundamentals and ApplicationsDokument22 SeitenElectroless Silverplating Chapter From Electroless Plating - Fundamentals and Applicationssaikat_cepNoch keine Bewertungen

- 4310M-4310M HCF12 LM PDFDokument1 Seite4310M-4310M HCF12 LM PDFlatinocomm2009Noch keine Bewertungen

- Unit-4 Roto PDFDokument70 SeitenUnit-4 Roto PDFKristianto Mathers IIINoch keine Bewertungen

- Sample 2Dokument6 SeitenSample 2Er Sarvjeet YadavNoch keine Bewertungen

- Xylan CoatingDokument3 SeitenXylan Coatingsidhesh870% (1)

- MS-4052 Rev. HDokument4 SeitenMS-4052 Rev. HGuri GuriNoch keine Bewertungen

- Technical Data Sheet: H.E.N.E. Hard Chrome ProcessDokument5 SeitenTechnical Data Sheet: H.E.N.E. Hard Chrome ProcessLuuThiThuyDuong100% (1)

- PDFsam - B 355 - 11 (2016)Dokument8 SeitenPDFsam - B 355 - 11 (2016)mike.jensen0581Noch keine Bewertungen

- PTR HARTMANN Testing Technology CatalogueDokument244 SeitenPTR HARTMANN Testing Technology CatalogueRangit RayNoch keine Bewertungen

- Large Size Conveyor ChainDokument156 SeitenLarge Size Conveyor ChainManatchaiSanNoch keine Bewertungen

- Art:10 1007/BF03215469Dokument11 SeitenArt:10 1007/BF03215469Cicero Gomes de SouzaNoch keine Bewertungen

- About Finishing and Lacquering of Metal ClosuresDokument2 SeitenAbout Finishing and Lacquering of Metal Closuresshalin_mbaNoch keine Bewertungen

- Rod Ends, Sphericals, Rolling Element BearingsDokument33 SeitenRod Ends, Sphericals, Rolling Element BearingsJose BaronNoch keine Bewertungen

- Braided Cable SpecificationDokument32 SeitenBraided Cable SpecificationmansurscribdNoch keine Bewertungen

- Engineering Chemistry IDokument5 SeitenEngineering Chemistry Isenthil kumaran mNoch keine Bewertungen

- Comet Gland CatalogueDokument12 SeitenComet Gland CataloguePrabhudatta KarNoch keine Bewertungen

- A New (Better) Approach To Tin Whisker Mitigation: Craig Hillman, Gregg Kittlesen, and Randy SchuellerDokument8 SeitenA New (Better) Approach To Tin Whisker Mitigation: Craig Hillman, Gregg Kittlesen, and Randy SchuellerHokuto No KenNoch keine Bewertungen

- Metal ProductDokument119 SeitenMetal ProductFloriana AyumurtiNoch keine Bewertungen

- Astm B633 - 2011Dokument6 SeitenAstm B633 - 2011mpk8588Noch keine Bewertungen

- 0 Catalogo Completo Alfalaval IntercambiadoresDokument304 Seiten0 Catalogo Completo Alfalaval IntercambiadoresFrancisco RodríguezNoch keine Bewertungen

- Setting Up of Electroplating Unit For The Fabrication of Agricultural ToolsDokument18 SeitenSetting Up of Electroplating Unit For The Fabrication of Agricultural ToolsKumar SahebNoch keine Bewertungen