Beruflich Dokumente

Kultur Dokumente

Tables

Hochgeladen von

Chika OlvianiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tables

Hochgeladen von

Chika OlvianiCopyright:

Verfügbare Formate

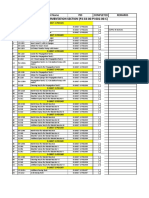

TABLES

May 2011

103-87668

Table 2-1: Fuel Analysis, Highlands EnviroFuels

Design Values

Sugarcane Bagasse

Parameter

Specific Gravity

Heating Value (Btu/lb)

Heating Value (Btu/gal)

Heating Value (Btu/scf)

Ultimate Analysis:

Carbon

Hydrogen

Nitrogen

Oxygen

Sulfur

Ash/Inorganic

Chlorine

Moisture

Sorghum Bagasse

Wood

As Fired

3,900 (as fired)

Dry Basis

7,800, dry

As Fired

3,900 (as fired)

Dry Basis

7,800, dry

(Dry Basis)

4,250, wet

Natural Gas

1,020

24.8

3

0.2

20.4

0.06

1.52

0.02

50

49.6

6.0

0.4

40.8

0.12

3.04

0.04

NA

23

2.75

0.32

20.9

0.11

2.8

0.12

50

46

5.5

0.64

41.8

0.22

5.6

0.24

NA

49.6

5.87

0.4

40.9

0.07

9

0.21

30 - 50

Note: values represent average fuel characteristics, see Appendix A for detailed summary.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-1, A-1 Fuel Specs.xlsx

May 2011

103-87668

Table 2-2: Biomass Boiler Design Parameters, Highlands EnviroFuels

Parameter

Value

Unit

Boiler

Hours of Operation

8,040 hr/yr

Basis

Based on 335 days of operation

Maximum Steam 24-Hour

Maximum Steam 1-Hour

250,000 lb/hr

275,000 lb/hr

Highlands Ethanol

Based on 110% of 24-Hour steam rate

Net Enthalpy

1,247.1 Btu/lb

See Appendix A

Thermal Efficiency (Biomass)

Thermal Efficiency (Natural Gas)

68 %

82 %

Boiler manufacturer

Estimate

Total Heat Output Required

2,506,671 MMBtu/yr

Based on net enthalpy and 335 days/yr

Sugar Cane Bagasse

Heating Value

Heating Value

Sugarcane Harvested

Bagasse from Sugarcane

Sugarcane Bagasse

3,900

7.8

1,074,091

22

236,300

Btu/lb, wet

MMBtu/ton

Tons

%

Tons

See Appendix A

Calculated

Based on heat output requirement

Fagen Engineering

Calculated

3,900

7.8

984,584

24

236,300

Btu/lb, wet

MMBtu/ton

Tons

%

Tons

See Appendix A

Calculated

Based on heat output requirement

Fagen Engineering

Calculated

Sweet Sorghum Bagasse

Heating Value

Heating Value

Sweet Sorghum Harvested

Bagasse from Sweet Sorghum

Sweet Sorghum Bagasse

Wood

Heating Value

Heating Value

4,250 Btu/lb, wet

8.5 MMBtu/ton

See Appendix A

Calculated

Natural Gas

Heating Value

1,020 Btu/scf

See Appendix A

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-2, 2-3, 2-12, 2-13.xlsx

May 2011

103-87668

Table 2-3: Maximum Fuel Usage for the Biomass Boiler, Highlands EnviroFuels

Fuel Type

Heat Inputb

Maximum 1-hour/3-Houra

Biomass - Sugarcane Bagasse

- Sorghum Bagasse

- Wood

Natural Gas

Maximum 24-Houra

Biomass - Sugarcane Bagasse

- Sorghum Bagasse

- Wood

Natural Gas

Annual Average

Heat Output Fuel Firing Rate

(MMBtu/hr)

504.3

504.3

504.3

249.0

(MMBtu/hr)

458.5

458.5

458.5

249.0

(MMBtu/hr)

343

343

343

204

(MMBtu/hr)

312

312

312

204

64.66

64.66

59.33

244,118

58.78

58.78

TPH

TPH

TPH

scf/hr

TPH

TPH

53.94

244,118

TPH

scf/hr

(MMBtu/yr)

(MMBtu/yr)

1,843,140

1,843,140

0

0

3,686,281

1,253,336

1,253,336

0

0

2,506,671

236,300

236,300

0

0

TPY

TPY

TPY

MMscf/yr

Maximum Wood Firing (10%Wood / 90% Bagasse)

Sugarcane Bagasse

1,658,826

Sorghum Bagasse

1,658,826

Wood

368,628

Natural Gas

0

Total

3,686,281

1,128,002

1,128,002

250,667

0

2,506,671

212,670

212,670

43,368

0

TPY

TPY

TPY

MMscf/yr

Maximum Natural Gas Firing (30% Natural Gas / 70% Bagasse)

Sugarcane Bagasse

1,215,145

Sorghum Bagasse

1,215,145

Wood

0

Natural Gas

1,041,553

Total

3,471,844

826,299

826,299

0

854,074

2,506,671

155,788

155,788

0

1,021

TPY

TPY

TPY

MMscf/yr

Normal Operations (100% Bagasee Firing)

Sugarcane Bagasse

Sorghum Bagasse

Wood

Natural Gas

Total

Notes:

Maximum 3-hour heat input based on 275,000 lb/hr steam rate; maximum 24-hour based

on 250,000 lb/hr. Fuels may be burned in combination, not to exceed total heat outputs.

b

Heat input and output rates are calculated based on the design parameters shown in Table 2-2.

a

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-2, 2-3, 2-12, 2-13.xlsx

May 2011

103-87668

Table 2-4: Specifications for VOL Storage Tanks

Fuel Ethanol

Storage Tank

1

200 Proof Ethanol

Storage Tank

2

Off-Spec

Tank

3

Denaturant/Gasoline Tank

4

Corrosion

Inhibitor Tank

5

Yes

Yes

Yes

Yes

No

Ethanol

Ethanol

Off-Spec Ethanol Product

Gasoline (4.5% of ethanol for

denaturant)

Methanol, xylene and ethylbenzene

Internal Floating Roof

Internal Floating Roof

Internal Floating Roof

Internal Floating Roof

Vertical Fixed Roof

Tank Height (ft)

52.0

32.0

32.0

32.0

8.0

Tank Diameter (ft)

58.0

25.0

25.0

25.0

7.0

Tank Capacity (gallons)

1,000,000

100,000

100,000

100,000

2,300

Throughput (gal/yr)

36,000,000

36,000,000

3,600,000

1,620,000

2,700

Turnovers per Year

36

360

36

16

Tank Description

Tank ID No.

Subpart Kb Applies (Yes/No)

Tank Content

Tank Type

See MSDS in Appendix D for corrosion inhibitor speciation.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-4, D1-D3 Tanks.xlsx

May 2011

103-87668

Table 2-5: Ethanol Process: CO2 and Distillation Scrubbers

Manufacturer and Model No.

Vogelbusch (or equivalent)

CO2 Scrubber

Inlet Flue Gas Temp (F)

Inlet Design Flow Rate (acfm)

Scrubbing Liquid

Scrubbing Liquid Flow Rate (gpm)

Recirculation Liquid Flow Rate (gpm)

Ethanol Removal Efficiency (%)

Distillation Scrubber

Inlet Flue Gas Temp (F)

Inlet Design Flow Rate (acfm)

Scrubbing Liquid

Scrubbing Liquid Flow Rate (gpm)

Ethanol Removal Efficiency (%)

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-5 to 2-9 APCD.xlsx

77

4,566

Process Water

64

101

98

77

120

Soft Water

4

98

May 2011

103-87668

Table 2-6: Boiler Control Equipment Parameters: Wet Sand Separator (Cyclone)

Manufacturer and Model No.

Wet Cyclone (or equivalent)a

Inlet Flue Gas Temp (oF)

Inlet Design Flue Gas Flow Rate (acfm)

Moisture (% Volume)

Cyclone Diameter (ft)

Cyclone Height (ft)

No. of Spray Nozzles (Cyclone)

No. of Spray Nozzles (Inlet Duct)

Total Water Flow to Nozzles (gpm)

Pressure Drop (in H2O)

Overall PM Collection Efficiency (%)

a

Vendor for the Biomass Boiler Cyclone not yet selected.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-5 to 2-9 APCD.xlsx

510

256,832

18

22

35

5

9

713

9

80

May 2011

103-87668

Table 2-7: Boiler Control Equipment Parameters: Electrostatic Precipitator

Manufacturer and Model No.

Factory Sales (or equivalent)a

Model No.39R-1330-3712P

Inlet Flue Gas Temp (oF)

Inlet Design Flue Gas Flow Rate (acfm)

Moisture (% Volume)

Inlet PM Loading (lb/MMBtu)

510

256,832

18

0.41

No. of Precipitators

Precipitation Type

Total Number of Fields

Total Installed Collection Area (ft2)

Gas Velocity (ft/s)

Specific Collection Area (ft2/1,000 acfm)

Power Consumption (kw)

Pressure Drop (in H2O)

Pollutants

Particulate Matter

a

1

Rigid Electrode

4

71,656

3.66

279

121

0.5

Inlet

Loading

(lb/MMBtu)

0.41

Vendor for the Biomass Boiler ESP not yet selected.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-5 to 2-9 APCD.xlsx

Outlet

Loading

(lb/MMBtu)

0.015

Control

Efficiency

%

96.3

May 2011

103-87668

Table 2-8: Boiler Control Equipment Parameters: Selective Non-Catalytic Reduction System

Manufacturer and Model No.

DNTa (or equivalent)

Flue Gas Flow Rate (acfm)

NOx Reduction Reagent

256,832

19% Ammonia

Ammonia Injectors

Ammonia Flow Control Section

Pressure Drop (in of wc)

6

1

0.8

Inlet

Loading

(lb/MMBtu)

0.25

Pollutants

Nitrogen Oxides

Notes:

a

Vendor for the Biomass Boiler SNCR system not yet selected.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-5 to 2-9 APCD.xlsx

Outlet

Loading

(lb/MMBtu)

0.10

Control

Efficiency

%

60

May 2011

103-87668

Table 2-9: Boiler Control Equipment Parameters: Dry Sorbent Injection System

Manufacturer and Model No.

Factory Sales (or equivalent)a

Model No. T-268

Inlet Flue Gas Temp (oF)

Inlet Design Flue Gas Flow Rate (acfm)

Moisture (% Volume)

510

256,832

18

No. of Injection Fans

No. of Feed Hoppers

No. of Pulverizers

No. of Classifiers

Reagent

Dry Sorbent Injection Rate (lb/hr)

Pulverizer Motor (hp)

Classifier Motor (hp)

Blower Motor (hp)

Pollutants

HCl

SO2

a

1

1

1

1

Trona or sodium bicarbonate

219

40

8

20

Inlet

Loading

(lb/hr)

37

64

Outlet

Loading

(lb/hr)

1.8

16.0

Vendor for the Biomass Boiler Acid Gas Removal System not yet selected.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-5 to 2-9 APCD.xlsx

Control

Efficiency

%

79

75

May 2011

103-87668

Table 2-10: Physical, Performance, and Emissions Data for the Fermentation CO 2 Scrubber

Parameter

Performance Data

Ethanol Production (gal/yr)

Ethanol Production (gal/day)

Scrubbing Column Control Efficiency (%)

Hours of Operation

Emission Factorsa

Uncontrolled Ethanol (lb/hr)

Controlled Ethanol (lb/hr)

Uncontrolled Other VOCs - Total (lb/hr)

Controlled Other VOCs - Total (lb/hr)

Value a

Basis

36,000,000

120,000

98.0

7,296

Highlands Envirofuels

Estimated

Design Value

Maximum

770.4

15.41

180.0

3.60

Design Value

Calculated

Calculated

Design Value

Emission Calculation - Speciated a,b

Maximum Uncontrolled Emissions

(lb/hr)

(TPY)

Maximum Controlled Emissions

(lb/hr)

(TPY)

Pollutant

Factor (%)

Description

Ethanol

Ethyl Acetate

100.0

78.0

of ethanol

of other VOCs

770.4

140.4

2,810.4

512.2

15.41

2.81

56.21

10.24

Acetaldehydec

19.8

of other VOCs

35.6

130.0

0.71

2.60

Methanol c

2.2

of other VOCs

Total VOC

Total HAP

4.0

950.4

39.6

14.4

3,467.1

144.5

0.079

19.01

0.79

0.29

69.34

2.89

Based on data from Highlands EnviroFuels, 2011.

Example Calculation - Ethyl Acetate:

Hourly Average: 3.6 lb/hr Total Controlled Other VOCs x (78 % Maximum of VOC / 100) = 2.81 lb/hr Ethyl Acetate

Annual Average: 2.81 lb/hr Ethyl Acetate x 7,296 hr/yr / 2,000 lb/hr = 10.24 TPY Ethyl Acetate

Hazardous Air Pollutants (HAP).

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-10, 2-11 Ethanol Process.xlsx

May 2011

103-87668

Table 2-11: Physical, Performance, and Emissions Data for the Distillation Vent Scrubber

Parameter

Performance Data

Ethanol Production (gal/yr)

Ethanol Production (gal/day)

Scrubbing Column Control Efficiency (%)

Hours of Operation

Emission Factorsa

Uncontrolled Ethanol (lb/hr)

Controlled Ethanol (lb/hr)

Uncontrolled Other VOCs - Total (lb/hr)

Controlled Other VOCs - Total (lb/hr)

Value a

Basis

36,000,000

120,000

98

7,296

Highlands Envirofuels

Estimated

Design Value

Maximum

79.20

1.58

1.20

1.20

Design Value

Calculated

Design Value

Design Value

Emission Calculation - Speciated a,b

Maximum Uncontrolled Emissions

(lb/hr)

(TPY)

Maximum Controlled Emissions

(lb/hr)

(TPY)

Pollutant

Factor (%)

Description

Ethanol

Ethyl Acetate

100.0

78.0

of ethanol

of other VOCs

79.20

0.94

288.92

3.41

1.58

0.94

5.78

3.41

Acetaldehydec

19.8

of other VOCs

0.24

0.87

0.24

0.87

Methanol c

2.2

of other VOCs

Total VOC

Total HAP

0.026

80.4

0.26

0.096

293.3

0.96

0.026

2.78

0.26

0.096

10.16

0.96

Based on data from Highlands EnviroFuels, 2011.

Example Calculation - Ethyl Acetate:

Hourly Average: 1.2 lb/hr Total Controlled Other VOCs x (78 % Maximum of VOC / 100) = 0.94 lb/hr Ethyl Acetate

Annual Average: 0.94 lb/hr Ethyl Acetate x 7,296 hr/yr / 2,000 lb/hr = 3.41 TPY Ethyl Acetate

Hazardous Air Pollutants (HAP).

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-10, 2-11 Ethanol Process.xlsx

May 2011

103-87668

Table 2-12: Maximum Short-Term Emissions for the Biomass Boiler, Highlands EnviroFuels

Regulated

Pollutant

1-hr Averages

Sulfur Dioxidej

Sugarcane Bagasse

Emission

Activity

Maximum

Factor a

Factorb

Emissions

(lb/MMBtu)

(MMBtu/hr)

(lb/hr)

0.078

Nitrogen Oxides (uncontrolled)

0.25

Carbon Monoxide (cold-startup)

3.0

504

e

39.1

Sweet Sorghum Bagasse

Emission

Activity

Maximum

Factor a

Factorb

Emissions

(lb/MMBtu)

(MMBtu/hr)

(lb/hr)

0.14

504

126.1

0.25

183

550.2

6.5

504

e

Emission

Factor a

(lb/MMBtu)

Wood

Activity

Factorb

(MMBtu/hr)

0.075

504

70.6

504

126.1

0.25

183

1,192.1

6.5

Maximum

Emissions

(lb/hr)

37.8

Natural Gas

Activity

Emission

Factor a

(lb/MMBtu)

Factor

(MMBtu/hr)

Maximum

Maximum

Emissions

Emissions

(lb/hr)

for all fuels

(lb/hr)

0.00059

249

0.15

70.6

249

34.18

126.1

504

126.1

0.14

183

1,192.1

0.00059

249

0.15

1,192.1

3-hr Averages

Particulate (PM)

Particulate (PM10)

0.015

504

7.6

0.015

504

7.6

0.015

504

7.6

0.0075

249

1.9

7.6

0.015

504

7.6

0.015

504

7.6

0.015

504

7.6

0.0075

249

1.9

7.6

Particulate (PM2.5)c

0.0098

504

4.9

0.0098

504

4.9

0.0098

504

4.9

0.0075

249

1.9

4.9

0.078

504

39.1

0.14

504

70.6

0.075

504

37.8

0.00059

249

0.15

70.6

504

126.1

0.25

504

126.1

0.25

504

126.1

0.14

249

34.18

126.1

183

1,192.1

0.082

249

20.5

1,192.1

Sulfur Dioxidej

Nitrogen Oxides (uncontrolled)

Carbon Monoxide (cold-startup)

0.25

3.0

183

550.2

6.5

183

1,192.1

6.5

VOC

0.017

504

8.6

0.017

504

8.6

0.017

504

8.6

0.0054

249

1.34

8.6

Lead

9.60E-05

504

0.048

9.60E-05

504

0.048

8.4E-05

504

0.042

4.9E-07

249

1.2E-04

0.048

Mercury

1.38E-05

504

0.0070

1.38E-05

504

0.0070

3.6E-06

504

0.0018

2.5E-07

249

6.3E-05

0.0070

6.0E-04

504

0.30

--

249

--

0.30

Fluorides

Sulfuric Acid Mist g

504

0.30

6.0E-04

0.0038

504

1.9

0.018

504

Particulate (PM)

Particulate (PM10)

0.015

Particulate (PM2.5)c

Ammonia h

504

0.30

6.0E-04

0.0069

504

3.5

0.0037

504

1.9

2.9E-05

249

7.2E-03

3.46

8.8

0.018

504

8.8

0.018

504

8.8

0.018

249

4.4

8.8

458

6.9

0.015

458

6.9

0.015

458

6.9

0.0075

249

1.9

6.9

0.015

458

6.9

0.015

458

6.9

0.015

458

6.9

0.0075

249

1.9

6.9

0.0098

458

4.5

0.0098

458

4.5

0.0098

458

4.5

0.0075

249

1.9

4.5

0.078

458

35.5

0.14

458

64.2

0.075

458

34.4

0.00059

249

0.15

64.2

24-hr Averages

Sulfur Dioxidej

Nitrogen Oxides

Carbon Monoxide (cold-startup)

0.10

3.0

458

45.8

0.10

183

550.2

6.5

458

45.8

0.10

183

1,192.1

6.5

458

45.8

0.10

249

24.90

45.8

183

1,192.1

0.082

249

20.5

1,192.1

VOC

0.017

458

7.8

0.017

458

7.8

0.017

458

7.8

0.0054

249

1.34

7.8

Lead

9.60E-05

458

0.044

9.60E-05

458

0.044

8.4E-05

458

0.039

4.9E-07

249

1.2E-04

0.044

Mercury

1.38E-05

458

0.0063

1.38E-05

458

0.0063

3.6E-06

458

0.0017

2.5E-07

249

6.3E-05

0.0063

6.0E-04

458

0.28

--

249

--

0.28

Fluorides

Sulfuric Acid Mist g

458

0.28

6.0E-04

458

0.28

6.0E-04

0.0038

458

1.7

0.00686

458

3.1

0.003675

458

1.7

2.9E-05

249

7.2E-03

Ammonia h

0.018

458

3.15

8.0

0.018

458

8.0

0.018

458

8.0

0.018

249

4.4

8.0

30-day Rolling Averages

Sulfur Dioxidej

0.078

458

35.5

0.14

458

64.2

0.075

458

34.4

0.00059

Nitrogen Oxides

0.10

458

45.8

0.10

458

45.8

0.10

458

45.8

0.10

Carbon Monoxide

Ammonia h

0.30

458

137.5

0.30

458

137.5

0.30

458

137.5

0.082

0.018

458

8.0

0.018

458

8.0

0.018

458

8.0

0.018

Notes:

Based on Proposed BACT limits, unless otherwise noted.

a

b

Maximum 1-hour and 3-hour heat input based on 275,000 lb/hr steam; maximum 24-hour and 30-day rolling average heat input based on 250,000 lb/hr steam.

Based on wood residue combustion, Section 1.6, AP-42, September 2003; 65 percent of PM emissions.

Based on AP-42 emission factor for Natural Gas (Section 1.4, July 1998), divided by the heating value for natural gas (1,020 Btu/scf).

e

f

Under cold startup conditions, boiler will be limited to 100,000 lb/hr of steam. Cold startup heat input rate is based on this limited steam rate.

Based on highest stack test results for New Hope Power Company Boilers A, B, and C (1999-2002) excluding 1999 wood test for Unit C.

Based on 4% of the SO2 emissions becomes SO3 from AP-42 for fuel oil burning; then convert to SAM (98/80).

Ammonia emission rate of 30 ppmvd @ 7% O2. Gas flow rate = 101,300 dscfm for 24-hour average. Other fuels based on same emissions factor (0.018 lb/MMBtu).

Based on maximum sorghum fuel content, sorghum fuel analysis September 2009. Maximum values used. Assumed 90% control efficiency for Lead.

j

Uncontrolled emission rates for SO2 are 0.31 for sugarcane bagasse, 0.56 lb/MMBtu for sorghum bagasse, and 0.30 lb/MMBtu for wood.

A control efficiency of 75 percent is applied to all emisison rates, except those due to natural gas combustion.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-2, 2-3, 2-12, 2-13.xlsx

249

0.15

64.2

249

24.9

45.8

249

20.5

137.5

249

4.4

8.0

May 2011

103-87668

Table 2-13: Maximum Annual Emissions for the Biomass Boiler, Highlands EnviroFuels

Regulated

Pollutant

Sugarcane Bagasse

Emission

Activity

Annual

Factor a

Factor

Emissions

(lb/MMBtu)

(1012 Btu/yr)

(TPY)

Sweet Sorghum Bagasse

Emission

Activity

Annual

Factor a

Factor

Emissions

(lb/MMBtu)

(1012 Btu/yr)

(TPY)

Emission

Factor a

(lb/MMBtu)

Wood

Activity

Annual

Factor

Emissions

12

(10 Btu/yr)

(TPY)

Emission

Factor a

Natural Gas

Activity

Annual

Factor

Emissions

12

(lb/MMBtu) (10 Btu/yr)

(TPY)

Total Annual

Emissionsc

(TPY)

Particulate (PM)

Particulate (PM10)

0.015

0.015

1.843

1.843

13.8

13.8

0.015

0.015

1.843

1.843

13.8

13.8

0.015

0.015

0.000

0.000

0.0

0.0

0.0075

0.0075

0.000

0.000

0.0

0.0

27.6

27.6

Particulate (PM2.5)

0.010

1.843

9.0

0.010

1.843

9.0

0.010

0.000

0.0

0.0075

0.000

0.0

18.0

Sulfur dioxide

Nitrogen oxides

Carbon monoxide

VOC

Lead

Mercury

Fluorides

0.078

0.10

0.30

0.017

9.60E-05

1.38E-05

6.0E-04

1.843

1.843

1.843

1.843

1.843

1.843

1.843

71.4

92.2

276.5

15.7

0.088

0.0127

0.55

0.14

0.10

0.30

0.017

9.60E-05

1.38E-05

6.0E-04

1.843

1.843

1.843

1.843

1.843

1.843

1.843

129.0

92.2

276.5

15.7

0.088

0.0127

0.55

0.075

0.10

0.30

0.017

8.4E-05

3.6E-06

6.0E-04

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.0

0.0

0.0

0.0

0.000

0.0000

0.00

0.00059

0.10

0.082

0.0054

4.9E-07

2.5E-07

--

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.0

0.0

0.0

0.0

0.0

0.0

--

200.4

184.3

552.9

31.3

0.18

0.025

1.1

Sulfuric acid mistb

0.00380

1.843

3.50

0.00686

1.843

6.32

0.00368

0.000

0.00

2.9E-05

0.000

0.0

9.8

0.018

1.843

16.2

0.018

1.843

16.2

0.018

0.000

0.0

0.018

0.000

0.0

32.3

Ammonia

Notes:

a

Refer to Table 2-12 for basis of emission factors.

Based on 4% of the SO2 emissions becomes SO3 from AP-42 for fuel oil burning; then convert to SAM (98/80).

Denotes maximum for any fuel combination.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-2, 2-3, 2-12, 2-13.xlsx

May 2011

103-87668

Table 2-14: Short-Term Emissions of Hazardous Air Pollutants from the Biomass Boiler

Emission

Factor

HAP

Biomass Boiler

Sugarcane Bagasse

Activity

Control

Hourly

Ref

Factor

Efficiency Emissions

(lb/MMBtu)

(MMBtu/hr)

(lb/MMBtu)

459

UD

UD

459

ND

ND

459

UD

ND

UD

ND

459

90

9.40E-04

2.05E-05

459

2.29

5.00E-03

459

90

1.77E-03

3.85E-05

459

UD

Acetophenone

ND

Acrolein

UD

ND

2.05E-05

459

5.00E-03

459

3.85E-05

459

Antimony

Arsenic

Benzene

Beryllium

bis(2ethylhexyl)phthalate

6.71E-04

459

Cadmiuma

3.33E-05

ND

459

Carbon Disulfide

Carbon Tetrachloride

Chlorine

ND

0.00040

Chlorobenzene

Chloroform

Chromiuma

Chromium+6

ND

ND

2.05E-03

1.37E-04

459

90

6.30E-03

ND

Ethylbenzene

ND

Formaldehyde

1.50E-03

ND

Hexane

Hydrogen Chlorideb

9.90E-03

459

Hydrogen Fluoride

6.00E-04

459

Lead-Totala

9.60E-05

459

2.31E-03

459

90

Mercury

1.38E-05

Methanol

UD

ND

Methyl Isobutyl Ketone

Methylene Chloride

ND

Phosphorus

Propionaldehyde

Seleniuma

Styrene

Dioxin/Furan (2, 3, 7, 8Tetrachlorodibenzo-p-dioxin)

Toluene

1, 1, 2-Trichloroethane

Trichloroethylene

Vinyl Chloride

m- & p-Xylene

o-Xylene

459

ND

0.24

ND

7.90E-06

459

0.0036

ND

0.24

ND

3.62E-03

Antimony

90

9.40E-04

1.13E-04

459

90

0.24

90

459

0.24

4.88E-06

5.13E-04

5.18E-03

2.29

Arsenic

0.0042

2.00E-04

0.0021

2.29

0.0052

1.93

90

1.77E-03

5.09E-07

459

90

2.33E-05

0.24

90

2.93E-07

ND

1.77E-03

0.31

Beryllium

2.15E-05

1.20E-05

ND

bis(2ethylhexyl)phthalate

1.88E-04

0.0011

90

1.53E-03

Cadmiuma

ND

0.021

ND

0.24

2.69E-05

ND

ND

0.24

ND

Carbon Tetrachloride

0.31

4.70E-08

4.10E-06

459

459

1.53E-03

ND

459

ND

4.50E-05

459

459

1.47

3.10E-03

459

1.42

ND

0.24

ND

2.06E-02

1.47

459

ND

ND

3.3E-05

459

0.015

ND

0.24

ND

1.51E-02

Chlorobenzene

2.8E-05

459

0.013

ND

0.24

ND

1.28E-02

Chloroform

459

0.0014

9.40E-02

Chromiuma

8.40E-05

ND

90

90

459

ND

459

90

9.40E-02

5.22E-05

90

459

90

6.30E-03

ND

3.50E-06

459

2.39E-03

0.0016

6.50E-06

459

0.0030

0.24

0.24

90

ND

Carbon Disulfide

Chlorine

0.24

0.24

3.42E-05

ND

6.30E-03

Chromium+6

0.24

2.05E-05

2.98E-03

Cobalt

0.24

ND

ND

m&p-Cresol

0.24

0.24

ND

ND

Cumene

Dibenzofurans

0.24

ND

ND

ND

ND

Dibutylphthalate

0.24

2.93E-04

2.93E-04

1,4-Dichlorobenzene(p)

0.24

ND

Ethylbenzene

ND

459

ND

ND

ND

ND

ND

459

ND

459

459

459

ND

1.78E-09

ND

ND

ND

459

459

459

459

ND

ND

459

ND

ND

459

0.0012

459

ND

ND

459

ND

3.1E-05

459

ND

0.014

459

0.69

ND

1.50E-03

ND

459

0.69

ND

0.0044

459

2.02

0.075

0.24

1.83E-02

1.42E-02

2.02

459

ND

1.8

0.24

4.39E-01

0.44

Hexane

4.54

0.08

10

459

36.68

0.097

459

44.47

ND

95

ND

44.47

Hydrogen Chlorideb

0.275

6.00E-04

459

0.275

6.0E-04

459

0.275

ND

ND

2.75E-01

Hydrogen Fluoride

90

4.40E-03

9.60E-05

459

90

4.40E-03

8.4E-05

459

90

3.85E-03

5.00E-04

0.24

90

1.22E-05

Lead-Totala

0.11

2.31E-03

459

90

0.11

0.0016

459

90

3.80E-04

0.24

90

459

6.33E-03

1.38E-05

459

6.33E-03

3.6E-06

459

7.34E-02

0.0017

0.24

6.33E-03

Mercurya

459

UD

ND

459

459

ND

0.24

ND

ND

Methanol

459

UD

ND

ND

459

UD

ND

2.60E-04

ND

9.28E-06

6.35E-05

4.40E-03

0.11

ND

459

ND

ND

0.24

ND

ND

Methyl Isobutyl Ketone

459

ND

ND

459

ND

ND

459

ND

ND

0.24

ND

ND

Methylene Chloride

5.04E-02

1.10E-03

5.04E-02

3.30E-05

1.51E-03

0.0021

5.04E-02

Nickela

459

90

ND

459

ND

459

459

0.0142

ND

3.10E-05

ND

459

ND

ND

2.94E-04

6.41E-06

459

90

459

459

90

ND

ND

90

ND

ND

ND

0.24

0.24

Manganesea

459

5.04E-05

ND

0.24

5.13E-05

ND

5.04E-05

4-Nitrophenol

ND

0.24

ND

2.34E-05

Pentachlorophenol (PCP)

ND

0.24

ND

2.34E-02

Phenols

0.24

90

Formaldehyde

ND

459

ND

1.10E-07

459

ND

459

ND

5.10E-08

459

459

5.10E-05

459

459

0.0142

ND

2.34E-05

0.023

2.70E-05

459

0.012

ND

0.24

ND

1.24E-02

Phosphorus

459

ND

6.10E-05

459

0.028

ND

0.24

ND

2.80E-02

Propionaldehyde

2.94E-04

2.80E-06

459

2.40E-05

ND

5.86E-07

ND

2.94E-04

0.87

Seleniuma

459

1.28E-04

0.87

ND

3.94E-09

8.30E-04

ND

ND

ND

ND

ND

0.42

ND

ND

8.25E-03

ND

1.15E-02

459

90

90

ND

459

ND

ND

459

ND

0.0019

ND

459

ND

ND

459

ND

8.60E-12

459

3.94E-09

ND

459

459

459

459

459

459

0.046

ND

ND

ND

ND

ND

1.00E-04

ND

ND

ND

ND

ND

459

459

459

459

459

459

0.046

ND

ND

ND

ND

ND

9.20E-04

ND

ND

1.80E-05

ND

2.50E-05

459

459

459

459

459

459

0.42

ND

ND

0.0083

ND

0.011

0.0034

ND

ND

ND

ND

ND

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-14, 2-15 Appx B HAPs.xlsx

ND

4

4

Benzene

ND

ND

ND

ND

ND

1.00E-04

ND

ND

ND

ND

ND

459

459

8

Acrolein

ND

ND

ND

ND

ND

4.0E-03

ND

459

459

6.41E-06

UD

459

ND

459

ND

459

2.05E-03

1.37E-04

9.40E-02

Acetophenone

ND

ND

ND

3.10E-05

ND

Acetaldehyde

1.47E-06

1.83

0.0032

1,4-Dichlorobenzene(p)

Phenols

0.38

ND

ND

ND

Dibutylphthalate

Pentachlorophenol (PCP)

ND

0.24

0.18

459

459

459

4-Nitrophenol

0.24

ND

459

90

ND

1.47E-06

1.83

459

459

1.10E-03

0.38

459

ND

ND

ND

ND

ND

Nickela

459

ND

m&p-Cresol

459

459

HAP

3.2E-09

459

(lb/hr)

8.3E-04

459

459

(lb/hr)

ND

(lb/hr)

Maximum

Emissions for

All Fuels

UD

(%)

Hourly

Emissions

459

3.33E-05

ND

(MMBtu/hr)

Natural Gas

Emission

Activity

Control

Factor

Ref

Factor

Efficiency

6

(lb/10 scf)

(MMscf/hr)

(%)

459

6.71E-04

Ref

Wood

Activity

Control

Hourly

Factor

Efficiency Emissions

(lb/MMBtu)

0.31

459

Manganese

(%)

Emission

Factor

(lb/hr)

1.53E-03

ND

90

ND

(MMBtu/hr)

459

Cobalt

Cumene

Dibenzofurans

Sorghum Bagasse

Activity

Control

Hourly

Ref

Factor

Efficiency Emissions

(lb/hr)

Acetaldehyde

(%)

Emission

Factor

4

4

0.24

0.24

0.24

0.24

0.24

0.24

0.24

0.24

0.24

90

Styrene

Dioxin/Furan (2, 3, 7, 8Tetrachlorodibenzo-p-dioxin)

Toluene

1, 1, 2-Trichloroethane

Trichloroethylene

Vinyl Chloride

m- & p-Xylene

o-Xylene

May 2011

103-87668

Table 2-14: Short-Term Emissions of Hazardous Air Pollutants from the Biomass Boiler

Emission

Factor

HAP

Sugarcane Bagasse

Activity

Control

Hourly

Ref

Factor

Efficiency Emissions

(lb/MMBtu)

(MMBtu/hr)

ND

459

459

Acenaphthylene

ND

1.00E-06

459

Anthracene

4.56E-07

459

Benzo (a) anthracene

Benzo(a)pyrene

3.00E-06

1.00E-06

Benzo(b)fluoranthene

Benzo(e)pyrene

Benzo(g,h,i)perylene

Benzo(j,k)fluoranthene

1.97E-06

Chrysene

3.00E-06

(%)

(lb/hr)

Emission

Factor

Sorghum Bagasse

Activity

Control

Hourly

Ref

Factor

Efficiency Emissions

(lb/MMBtu)

(MMBtu/hr)

ND

ND

459

ND

459

4.59E-04

ND

1.00E-06

459

2.09E-04

4.56E-07

459

459

1.38E-03

3.00E-06

459

4.59E-04

1.00E-06

3.00E-06

459

1.38E-03

1.00E-06

459

4.59E-04

459

ND

ND

459

9.03E-04

1.97E-06

459

1.38E-03

3.00E-06

(%)

(lb/hr)

Emission

Factor

Ref

Wood

Activity

Control

Hourly

Factor

Efficiency Emissions

(%)

(lb/hr)

Natural Gas

Emission

Activity

Control

Factor

Ref

Factor

Efficiency

6

(lb/10 scf)

(MMscf/hr)

(%)

Hourly

Emissions

Maximum

Emissions for

All Fuels

(lb/hr)

(lb/hr)

4.39E-07

3-Methylcholanthrene

(MMBtu/hr)

ND

ND

459

ND

1.80E-06

0.24

4.39E-07

ND

4

4

459

4.39E-07

4.17E-04

1.80E-06

7

7

0.24

459

4.17E-04

0.0023

1.80E-06

4.59E-04

9.1E-07

5.0E-06

0.24

4.39E-07

2.29E-03

Acenaphthene

Acenaphthylene

2.09E-04

3.0E-06

459

0.0014

5.86E-07

1.38E-03

Anthracene

1.38E-03

6.5E-08

459

0.24

4.39E-07

1.38E-03

459

4.59E-04

2.6E-06

459

2.98E-05

0.0012

7

7

0.24

459

2.40E-06

1.80E-06

2.93E-07

1.19E-03

Benzo (a) anthracene

Benzo(a)pyrene

459

1.38E-03

1.0E-07

459

4.59E-05

7

7

0.24

3.00E-06

1.20E-06

1.80E-06

0.24

4.39E-07

1.38E-03

Benzo(b)fluoranthene

1.00E-06

459

4.59E-04

2.6E-09

459

1.19E-06

ND

0.24

ND

4.59E-04

459

ND

9.3E-08

459

4.26E-05

0.24

2.93E-07

4.26E-05

Benzo(e)pyrene

Benzo(g,h,i)perylene

459

9.03E-04

1.6E-07

459

7.34E-05

1.20E-06

1.80E-06

ND

9.03E-04

Benzo(j,k)fluoranthene

459

1.38E-03

3.8E-08

459

1.74E-05

1.80E-06

7

7

0.24

0.24

4.39E-07

1.38E-03

Chrysene

4.17E-06

ND

1.20E-06

ND

0.24

2.93E-07

4.17E-06

Dibenzo(a,h)anthracene

0.24

ND

7.34E-04

0.0016

3.00E-06

0.24

7.32E-07

ND

5.50E-03

Fluoranthene

2.80E-06

0.24

6.84E-07

1.56E-03

Fluorene

3.99E-05

indeno(1,2,3-cd)pyrene

Naphthalene

POMs

3-Methylcholanthrene

Acenaphthene

POMs

ND

Dibenzo(a,h)anthracene

ND

459

ND

ND

459

ND

9.1E-09

459

Dimethylbenz(a)anthracene

ND

459

ND

ND

459

ND

ND

459

459

0.0055

1.20E-05

459

0.0055

1.6E-06

459

ND

459

ND

ND

459

ND

3.4E-06

459

ND

459

ND

ND

459

ND

8.7E-08

459

459

0.0105

2.30E-05

459

0.0105

9.7E-05

459

Fluoranthene

Fluorene

HAP

(lb/MMBtu)

1.20E-05

1.80E-06

0.24

4.39E-07

6.10E-04

ND

0.24

1.49E-04

4.45E-02

0.24

ND

2.38E-07

1.70E-05

0.24

4.15E-06

3.21E-03

Perylene

Phenanthrene

0.0017

5.00E-06

0.24

1.22E-06

4.59E-03

Pyrene

0.057

6.58E-04

0.24

1.61E-04

0.06

Total POMs**

indeno(1,2,3-cd)pyrene

Naphthalene

2.30E-05

Perylene

Phenanthrene

459

ND

ND

459

ND

5.2E-10

459

5.00E-06

459

0.0023

5.00E-06

459

0.0023

7.0E-06

459

2.38E-07

0.0032

Pyrene

1.00E-05

459

0.0046

1.00E-05

459

0.0046

3.7E-06

459

Total POMs**

6.44E-05

459

0.030

6.44E-05

459

0.030

0.00012

459

ND

Dimethylbenz(a)anthracene

3.99E-05

0.044

MAXIMUM SINGLE HAP

4.54

36.68

44.47

0.439

44.47

MAXIMUM SINGLE HAP

TOTAL

8.65

42.07

53.92

0.460

55.27

TOTAL

UD = Undetected

ND = No Data available

a

Assumed 90% control efficiency for all metals, except mercury for which zero control was assumed.

b

For HCl a control efficiency of 95 percent was applied.

References

1. Based on highest stack test results for New Hope Power Company Boilers A, B, and C (1999-2002) excluding 1999 wood test for Unit C.

2. Based on HAP Emissions for U.S. Sugar-Clewiston Boiler 7 - Highest of three runs January 31, 2000.

3. Based on average of three stack testing runs of Boiler No. 7. (December, 2002)

4. Based on AP-42 emission factors for wood combustion (Section 1.6).

5. Based on the maximum of stack test result for boilers firing wood or a combination of wood and bagasse, 2004-2007. See Appendix B, Table B-4.

6. Based on AP-42 emission factors for natural gas combustion (Section 1.4).

7. Based on HAP testing of bagasse fired boilers. Maximum of 18 runs for HCl. Emissions for Cl 2 based on AP-42 for wood firing and Appendix B, Table B-4, which shows 4% of HCl is emitted as Cl 2.

8. Based on the maximum of fuel analysis results for SRF sweet sorghum analysis conducted Sept. 2009.

9. Based on the ratio of wood emission factor for Chromium VI to Chromium.

10. Based on maximum chlorine content of sorghum (0.24% Cl or 0.32 lb/MMBtu as HCl) and assuming 75% inherent removal in ash. Chlorine emissions are 4% of HCl, based on AP-42 for wood firing and Appendix B, Table B-4.

**Sum of all POMs, unless emission factors are only listed for Total POMs, not individuals, and will be noted.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-14, 2-15 Appx B HAPs.xlsx

May 2011

103-87668

Table 2-15: Summary of Annual Emissions of Hazardous Air Pollutants from the Biomass Boiler

Fuel Scenario

Maximum Single HAP

(TPY)

Total HAPs

(TPY)

Bagasse Only

6.91

15.84

90% Bagasse/10% Wood

6.85

18.26

70% Bagasse/30% Natural Gas

4.56

11.40

Worst-Case HAPs Total

6.91

18.26

See Appendix B, Tables B-5, B-6, and B-7.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-14, 2-15 Appx B HAPs.xlsx

May 2011

103-87668

Table 2-16. Maximum Annual Fugitive Dust Emissions for Highlands EnviroFuels, LLC

M

SOURCE

TYPE OF

OPERATION

MOISTURE

WIND

CONTENT a SPEED b

(%)

(MPH)

UNCONTROLLED

UNCONTROLLED

UNCONTROLLED

PM EMISSION

PM10 EMISSION

PM2.5 EMISSION

CONTROL

CONTROL

TYPE

EFFICIENCY

FACTOR

(%)

(LB/TON)

FACTOR

FACTOR

FACTOR

(LB/TON) c

(LB/TON) c

(LB/TON) c

CONTROLLED

CONTROLLED

CONTROLLED

PM EMISSION

PM10 EMISSION

PM2.5 EMISSION

ACTIVITY

MAXIMUM ANNUAL EMISSIONS

FACTOR

FACTOR

FACTOR

(LB/TON)

(LB/TON)

PM (TSP)

PM10

PM2.5

(TONS/YR)

(TONS/YR)

(TONS/YR)

BIOMASS DELIVERIES

SUGARCANE TRUCK TRAFFIC ON PAVED ROADSi

VEHICULAR TRAFFIC

--

--

0.11 lb/VMT

0.022 lb/VMT

0.0054 lb/VMT

WATER/SWEEP

50

0.055 lb/VMT

0.011 lb/VMT

0.0027 lb/VMT

25,500 VMT

0.70

0.14

SORGHUM TRUCK TRAFFIC ON PAVED ROADSi

VEHICULAR TRAFFIC

--

--

0.11 lb/VMT

0.022 lb/VMT

0.0054 lb/VMT

WATER/SWEEP

50

0.055 lb/VMT

0.011 lb/VMT

0.0027 lb/VMT

25,500 VMT

0.70

0.14

0.035

WOOD TRUCK TRAFFIC ON PAVED ROADSi

VEHICULAR TRAFFIC

--

--

0.11 lb/VMT

0.022 lb/VMT

0.0054 lb/VMT

WATER/SWEEP

50

0.055 lb/VMT

0.011 lb/VMT

0.0027 lb/VMT

1,475 VMT

0.041

0.0081

0.0020

BAGASSE FROM DRYING SYSTEM-TO-TRANSFER CONVEYOR

CONTINUOUS DROP

50

6.9

0.000040

0.000019

0.0000028

ENCLOSURE

0.000040

0.000019

0.0000028

467,874 TPY

0.0093

0.0044

0.00067

TRANSFER CONVEYOR-TO-HOPPER

CONTINUOUS DROP

50

6.9

0.000040

0.000019

0.0000028

ENCLOSURE

0.000040

0.000019

0.0000028

467,874 TPY

0.0093

0.0044

0.00067

467,874 TPY

0.0093

0.0044

0.00067

467,874 TPY

0.0093

0.0044

0.00067

46,787 TPY

0.00093

0.00044

0.000067

0.035

BAGASSE HANDLING

HOPPER-TO-BAGASSE DISTRIBUTION CONVEYOR

CONTINUOUS DROP

BAGASSE DISTRIBUTION CONVEYOR-TO-METER BINS

CONTINUOUS DROP

BAG. DIS. CONV. OVERFLOW-TO-SURPLUS BAGASSE CONVEYOR

SURPLUS BAGASSE CONVEYOR-TO-BAGASSE STORAGE PILE

FRONT END LOADER (RECLAIM)-TO-RECLAIM CONVEYOR

RECLAIM CONVEYOR-TO-RETURN CONVEYOR

CONTINUOUS DROP

BAGASSE STORAGE PILE

FRONT END LOADER BAGASSE STORAGE PILE MAINTENANCE

BULLDOZER BAGASSE STORAGE PILE MAINTENANCE

6.9

0.000040

0.000040

0.000019

0.000019

0.000019

0.0000028

0.0000028

0.0000028

ENCLOSURE

ENCLOSURE

ENCLOSURE

0

0

0

0.000040

0.000040

0.000040

0.000019

0.000019

0.000019

0.0000028

0.0000028

0.0000028

50

6.9

0.000040

0.000019

0.0000028

ENCLOSURE

0.000040

0.000019

0.0000028

46,787 TPY

0.00093

0.00044

0.000067

BATCH DROP

50

6.9

0.000040

0.000019

0.0000028

NONE

0.000040

0.000019

0.0000028

46,787 TPY

0.00093

0.00044

0.000067

46,787 TPY

0.00093

0.00044

0.000067

46,787 TPY

0.00093

0.00044

0.000067

46,787 TPY

0.00093

0.00044

0.000067

46,787 TPY

0.00093

0.00044

0.000067

--

0.015

0.0076

0.0076

10,950 VMT

0.37

0.044

0.0044

2,190 hr/yr

0.008

0.0005

0.00018

CONTINUOUS DROP

HOPPER-TO-BAGASSE DISTRIBUTION CONVEYOR

50

6.9

0.000040

CONTINUOUS DROP

CONTINUOUS DROP

BAGASSE TRANSFER CONVEYOR-TO-HOPPER

50

6.9

CONTINUOUS DROP

RETURN CONVEYOR-TO-BAGASSE TRANSFER CONVEYOR

50

50

50

50

6.9

6.9

6.9

CONTINUOUS DROP

50

6.9

WIND EROSION

--

--

VEHICULAR TRAFFIC

--

--

VEHICULAR TRAFFIC

--

--

0.000040

0.000040

0.000040

0.000040

-0.27 lb/VMT

0.031 lb/hr

0.000019

0.000019

0.000019

0.000019

0.0000028

0.0000028

0.0000028

0.0000028

-0.032 lb/VMT

0.0018 lb/hr

-0.0032 lb/VMT

0.00067 lb/hr

ENCLOSURE

ENCLOSURE

ENCLOSURE

0

0

0

ENCLOSURE

WATERING

50

PARTIAL ENCLOSURE/WATERING

75

PARTIAL ENCLOSURE/WATERING

75

0.000040

0.000040

0.000040

0.000040

-0.07 lb/VMT

0.008 lb/hr

0.000019

0.000019

0.000019

0.000019

-0.008 lb/VMT

0.00046 lb/hr

0.0000028

0.0000028

0.0000028

0.0000028

-0.0008 lb/VMT

0.00017 lb/hr

WOOD HANDLING

TRUCK DUMP-TO-WOOD STORAGE PILE

UNLOADING CONVEYOR-TO-HOGGER

HOGGER

HOGGER-TO-STORAGE CONVEYOR

BATCH DROP

40

6.9

0.000054

0.000026

0.0000039

NONE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

CONTINUOUS DROP

40

6.9

0.000054

0.000026

0.0000039

ENCLOSURE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

CRUSHING

--

--

0.020

0.0095

0.0014

ENCLOSED

95

0.0010

0.00047

0.000072

47,705 TPY

0.024

0.011

0.0017

BATCH DROP

40

6.9

0.000054

0.000026

0.0000039

ENCLOSURE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

SCREEN-TO-STORAGE CONVEYOR

CONTINUOUS DROP

40

6.9

0.000054

0.000026

0.0000039

ENCLOSURE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

STORAGE CONVEYOR-TO-WOOD STORAGE PILE

CONTINUOUS DROP

40

6.9

0.000054

0.000026

0.0000039

ENCLOSURE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

BATCH DROP

40

6.9

0.000054

0.000026

0.0000039

NONE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

RECLAIM CONVEYOR-TO-RETURN CONVEYOR

CONTINUOUS DROP

40

6.9

0.000054

0.000026

0.0000039

ENCLOSURE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

RETURN CONVEYOR-TO-HOPPER

CONTINUOUS DROP

40

6.9

0.000054

0.000026

0.0000039

ENCLOSURE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

HOPPER-TO-HORIZONTAL DISCHARGE CONVEYOR

WOOD STORAGE PILEf

CONTINUOUS DROP

40

6.9

0.000054

0.000026

0.0000039

ENCLOSURE

0.000054

0.000026

0.0000039

47,705 TPY

0.0013

0.00061

0.000093

WIND EROSION

--

--

WATERING

50

VEHICULAR TRAFFIC

--

--

3.52 lb/VMT

0.86 lb/VMT

0.086 lb/VMT

PARTIAL ENCLOSURE/WATERING

75

0.88 lb/VMT

0.21 lb/VMT

VEHICULAR TRAFFIC

--

--

3.32 lb/hr

0.61 lb/hr

0.073 lb/hr

PARTIAL ENCLOSURE/WATERING

75

0.83 lb/hr

0.15 lb/hr

ASH DROP TO DRAG CONVEYOR 1

CONTINUOUS DROP

10

6.9

0.000378

0.000179

0.0000271

ENCLOSURE

0.000378

0.000179

0.0000271

21,634 TPY

DRAG CONVEYOR 1 TO DRAG CONVEYOR 2

CONTINUOUS DROP

10

6.9

0.000378

0.000179

0.0000271

ENCLOSURE

0.000378

0.000179

0.0000271

21,634 TPY

DRAG CONVEYOR 2 TO DRAG CONVEYOR 3

CONTINUOUS DROP

10

6.9

0.000378

0.000179

0.0000271

ENCLOSURE

0.000378

0.000179

0.0000271

DRAG CONVEYOR 3 TO ASH SILO

CONTINUOUS DROP

10

6.9

0.000378

0.000179

0.0000271

ENCLOSURE

0.000378

0.000179

0.0000271

FRONT END LOADER (RECLAIM)-TO-RECLAIM CONVEYOR

FRONTEND LOADER WOOD STORAGE PILE MAINTENANCE

BULLDOZER WOOD STORAGE PILE MAINTENANCE

--

--

--

--

--

-0.021 lb/VMT

0.018 lb/hr

--

0.20

0.10

10,950 VMT

4.81

1.18

0.10

0.12

2,190 hr/yr

0.91

0.17

0.020

0.0041

0.0019

0.00029

0.0041

0.0019

0.00029

21,634 TPY

0.0041

0.0019

0.00029

21,634 TPY

0.0041

0.0019

0.00029

21,634 TPY

0.0041

0.0019

0.00029

ASH HANDLING

ASH SILO TO TRUCK

ASH TRUCK TRAFFIC ON PAVED ROADSj

CONTINUOUS DROP

10

6.9

0.000378

0.000179

VEHICULAR TRAFFIC

--

--

0.11 lb/VMT

0.022 lb/VMT

PRODUCT LOAD OUT

ETHANOL TRUCK TRAFFIC ON PAVED ROADSi

VEHICULAR TRAFFIC

--

--

0.13 lb/VMT

DENATURANT/GASOLINE TRUCK TRAFFIC ON PAVED ROADSi

VEHICULAR TRAFFIC

--

--

LIME DELIVERIES

LIME TRUCK TRAFFIC ON PAVED ROADSi

VEHICULAR TRAFFIC

--

--

0.0000271

ENCLOSURE

0.000378

0.000179

0.0000271

0.0054 lb/VMT

WATER/SWEEP

50

0.06 lb/VMT

0.011 lb/VMT

0.0027 lb/VMT

735 VMT

0.020

0.0041

0.0010

0.027 lb/VMT

0.0065 lb/VMT

WATER/SWEEP

50

0.066 lb/VMT

0.013 lb/VMT

0.0033 lb/VMT

1,640 VMT

0.055

0.011

0.0027

0.13 lb/VMT

0.027 lb/VMT

0.0065 lb/VMT

WATER/SWEEP

50

0.066 lb/VMT

0.013 lb/VMT

0.0033 lb/VMT

74 VMT

0.0025

0.00049

0.00012

0.11 lb/VMT

0.022 lb/VMT

0.0054 lb/VMT

WATER/SWEEP

50

0.055 lb/VMT

0.011 lb/VMT

0.0027 lb/VMT

47 VMT

0.00129

0.00026

0.000064

DENATURANT/GASOLINE DELIVERIES

TOTAL

Notes:

Bagasse will be dried to 50% moisture after it is sent through the drying system. Wood moisture content based on sample testing conducted March 2008, New Hope Power Company, LLC.

a

b

Based on the average of hourly windspeed data from Fort Myers International Airport for 2001-2005.

Batch Drop and Continuous Drop Emission Factors are computed from AP-42 (USEPA, 2006) Section 13.2.4: E= k x 0.0032 x (U/5)^1.3 / (M/2)^1.4 lb/ton, where k = 0.74 for PM, 0.35 for PM10, and .053 for PM2.5.

Refer to Table 2-2 for biomass usage, worst-case fugitive is for the 10% wood scenario. Usage rates for bagasse (425,340 TPY) and wood (43,368 TPY), and an additional 10% was added to account for year-to-year variations.

Assuming 10% of biomass is overfeed.

Refer to Table C-1, Appendix C for calculation.

Refer to C-2 in Appendix C.

Refer to Table C-3 in Appendix C.

Refer Table C-4 in Appendix C.

Refer to Table C-4, Appendix C, for emissions calculation. Table 2-25 shows ash generation based on sugarcane bagasse at 1.5% ash, sorghum bagasse at 2.7% ash, wood at 9% ash.

Emission factor reference: AP-42 (USEPA, 2004) Section 11.19.2. PM 2.5 assumed to be equal to PM10.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-16 C1-C5.xlsx

7.9

1.8

0.33

May 2011

103-87668

Table 2-17: Physical, Performance, and Emissions Data for the Cooling Tower

Parameter

Physical Data

Number of Cells

Deck Dimensions (ft)

Length

Width

Height

Stack Dimensions

Height (ft)

Stack Top Effective Inner Diameter per cell (ft)

Effective Diameter, all cells (ft)

Performance Data

Circulating Water Flow Rate (CWFR) (gal/min)

Design Wet Bulb Temperature (F)

Design Cold Water Temperature (F)

Heat Rejected (MMBtu/hr)

Design Air Flow Rate per cell (acfm)

Hours of Operation

Typical Valuesa

Basis

CAD Drawing

80

40

30

CAD Drawing

CAD Drawing

Estimated

35

33

33.0

Estimated

Estimated

Estimated

34,000

77

Fagen

272.22

211,860

8,760

Fagen

Emission Data

Drift Rateb (DR) (percent)

0.0010

Fagen

Total Dissolved Solids (TDS) Concentration, maximum (ppm)c

500

Estimated

Solution Driftd (SD) (lb/hr)

170

Calculated

PM Drifte (lb/hr)

(TPY)

0.0851

0.373

PM10 Drift

PM10 Portion (percent) of PM Drift

PM10 Emissions (lb/hr)

(TPY)

50

Estimated

0.0425

0.186

PM2.5 Drift

PM2.5 Portion (percent) of PM Drift

PM2.5 Emissions (lb/hr)

(TPY)

50

Estimated

0.0425

0.186

Footnotes:

a

Typical cooling tower design for indicated conditions.

Drift rate is the percent of circulating water.

TDS estimated based on typical TDS value for freshwater in the vicinity of the proposed project.

Includes water and based on circulating water flow rate and drift rate (CWFR x DR x 8.34 lb/gal x 60 min/hr).

PM calculated based on total dissolved solids and solution drift (TDS x SD).

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-17 Cooling Tower.xlsx

May 2011

103-87668

Table 2-18: Physical, Performance, and Emissions Data for the Truck/Rail Loading Rack Flare

Parameter

Values

Basis

30

1

Estimated

Estimated

Physical Data

Dimensions (ft)

Stack Height

Stack Diameter

Performance Data

3

Hourly Ethanol/Blends Throughput (10 gallons/hr)

3

Annual Ethanol/Blends Throughput (10 gallons/yr)

Flare Pilot Heat Rate (MMBtu/hr)

Flare Control Efficiency (%)

Flare Pilot Hours of Operation (hr/yr)

Flare Hours of Operation (hr/yr)

VOC Loading Emission Factor Calculation

Saturation Factor (unitless)

Molecular Weight of Vapors (lb/lb-mol)

Product Temperature (R)

True Vapor Pressure (psia)

3

VOC Loading Loss - Total (lb/10 gal)

36

600 gpm, truck or railcar filling

37,620,000

0.184

98.0

8,760

3,120

Highlands Envirofuels, LLC

based on 3 scfm natural gas

Estimated

Maximum

Maximum

1

64

534.3

AP-42 Table 5.2-1

TANKS 4.0.9d

TANKS 4.0.9d

8.63

TANKS 4.0.9d (Based on

gasoline RVP of 12)

12.9

Flare Heat Input Calculation

Gasoline Heat Content (Btu/gal)

Gasoline Density (lb/gal)

Gasoline Heat Content (Btu/lb)

130,000

6.17

21,070

AP-42 Appendix A

AP-42 Appendix A

displaced truck gasoline vapors

9.8

Calculated

Flare Heat Input Rate (MMBtu/hr)b

VOC Loading Emission Calculation

Uncontrolled VOCs

Controlled VOCs

lb/hr

463.66

9.27

TPY

242.3

4.85

Flare Combustion Emission Factors

SO2 (lb/MMBtu)c

0.00059

AP-42 Table 1.4-2

NOx (lb/MMBtu)d

0.068

AP-42 Table 13.5-1

CO (lb/MMBtu)d

0.37

0.0034

AP-42 Table 13.5-1

AP-42 Table 13.5-1

0.14

AP-42 Table 13.5-1

PM/PM10/PM2.5 (lb/MMBtu)d

VOCs - Total Hydrocarbons (lb/MMBtu)e

Emissions Calculations

SO2 (lb/MMBtu)

NOx (lb/MMBtu)

CO (lb/MMBtu)

PM/PM10/PM2.5 (lb/MMBtu)

VOCs - Total Hydrocarbons (lb/MMBtu)

Loading and Combustion Total VOCs

a

Activity Factor

(MMBtu/hr)

9.8

9.8

9.8

(lb/hr)

0.0057

0.66

3.61

Emissions

9.8

9.8

0.034

1.37

0.052

2.13

--

10.64

6.98

(TPY)

0.0090

1.04

5.64

The emission factor for VOCs is based on the following equation for loading loss:

VOC Loading Loss (lb/10 3 gal) = 12.46 x Saturation Factor x Vapor Pressure (psia) x Molecular Weight (lb/lb-mol)

/ Temperature (R)

The flare heat input rate is calculated based on the following equation:

Flare Heat Rate (MMBtu/hr) = Hourly Ethanol Throughput (10 3 gallons/hr) x VOC Loading Loss (lb/10 3 gal)

x Gasoline Heat Content (Btu/lb)/10 6

Based on AP-42 Table 1.4-2, 0.6 lb/106 scf for Natural Gas, and 1,020 Btu/scf for natural gas.

AP-42 Table 13.5-1 (Industrial Flares), soot for lightly smoking flares (40 g/L).

Assuming all PM is converted to PM10 and PM2.5.

Assumed all hydrocarbons are VOCs for conservative estimate.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-18, 2-19 Truck Loading Rack Flare.xlsx

May 2011

103-87668

Table 2-19: Truck/Rail Loading Rack Flare HAP Emission Estimates

Total VOC Emissions

Maximum Hourly (lb/hr)

Total Losses (TPY)

Speciated Constituents of

Gasoline VOCsa

10.64

6.98

VOC Emissions

(lb/hr)

(TPY)

CAS Number

% of Total Vapor

Released

71-43-2

106-97-8

590-18-1

624-64-6

627-20-3

110-82-7

287-92-3

75-83-2

108-08-7

74-84-0

1.41

28.53

0.83

1.02

0.67

0.43

0.61

1.04

0.43

0.07

0.150

3.04

0.0883

0.109

0.0713

0.0458

0.0649

0.111

0.0458

0.00745

0.098

1.99

0.058

0.071

0.047

0.030

0.043

0.073

0.030

0.0049

Ethylbenzeneb

Heptane, n-

100-41-4

142-82-5

0.06

0.40

0.00638

0.0426

0.0042

0.028

Hexane, n-b

Isobutane

Isopropyl Benzene

Methylcyclohexane

Methylcyclopentane

Methylheptane, 3Methylhexane, 3Methylpentane, 3Octane, nPentane, nPentene, 1Propane

110-54-3

75-28-5

98-82-8

108-87-2

96-37-7

589-81-1

589-34-4

96-14-0

111-65-9

109-66-0

109-67-1

74-98-6

3.75

8.34

0.01

0.12

1.41

0.06

0.42

1.99

0.03

7.25

0.86

1.06

0.399

0.887

0.00106

0.0128

0.150

0.00638

0.0447

0.212

0.00319

0.771

0.0915

0.113

0.26

0.58

0.00070

0.0084

0.098

0.0042

0.029

0.139

0.0021

0.51

0.060

0.074

Tolueneb

Trans-2-Pentene

Trimethylbenzene, 1,2,4Trimethylbenzene, 1,3,5-

108-88-3

646-04-8

95-63-6

108-67-8

1.25

1.37

0.05

0.02

0.133

0.146

0.00532

0.00213

0.087

0.096

0.0035

0.00140

Trimethylpentane, 2,2,4-b

Trimethylpentane, 2,3,4-

540-84-1

565-75-3

0.42

0.07

0.0447

0.00745

0.029

0.0049

Xylene, o-b

Unidentified VOC

95-47-6

NA

0.04

35.98

0.00426

3.83

10.64

0.34

0.0028

2.51

6.98

0.22

Benzeneb

Butane, nButene, cis-2Butene, trans-2Pentene, cis-2Cyclohexane

Cyclopentane

Dimethylbutane, 2,2Dimethylpentane, 2,4Ethane

Total VOC

Total HAPs

Speciation is based on EPAs SPECIATE 3.2 program for profile No. 2490.

Hazardous Air Pollutant (HAP).

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-18, 2-19 Truck Loading Rack Flare.xlsx

May 2011

103-87668

Table 2-20: Physical, Performance, and Emissions Data for the Emergency Generator

Parameter

Values

Basis

Performance Data

Capacity (hp)

(ekW)

2,682

2,000

Caterpillar

Caterpillar

Fuel: No. 2 Fuel Oil or Natural Gas

Maximum Sulfur Content (%)

Average Heat Input Rate (MMBtu/hr)

(gal/hr)

Hours of Operation (hr/yr)

0.0015

19.45

138.9

500

On-road diesel fuel

Estimated

Calculated

Maximum

Emission Factors

SO2 (lb/MMBtu)

0.00059

for Natural Gas firing

NOx (g/hp-hr)

5.39

CAT

CO (g/hp-hr)a

0.29

0.026

CAT

0.11

CAT

PM/PM10/PM2.5 (g/hp-hr)a

a

VOC (g/hp-hr)

CAT

Emissions Calculations

SO2

NOx

CO

PM/PM10/PM2.5

VOC

a

Activity Factor

19.45 MMBtu/hr

2,682 hp

2,682 hp

2,682 hp

2,682 hp

(lb/hr)

0.011

31.80

1.71

0.15

0.65

Emissionsb

(TPY)

0.0029

7.95

0.43

0.038

0.16

Subpart IIII emission factors are based on a weighted cycle. Manufacturer data, based on 100% load, for

Caterpillar diesel engine (CAT 3516C TA) is considered more representative. Therefore, the manufacturer

emission factors were used.

Example Calculation:

0.29 g/hp-hr CO x 2,682 hp/generator x lb/454.6 g = 1.71 lb/hr CO

1.71 lb/hr CO x 500 hr/yr x 1 ton/2,000 lb = 0.43 TPY CO

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-20 to 2-23 Emergency Equip.xlsx

May 2011

103-87668

Table 2-21: HAPs Emission Estimates for the Emergency Generator

Pollutant

Activity Factor

Emission Factor

(lb/MMBtu) a

(MMBtu/hr)

2.52E-05

7.88E-06

7.76E-04

7.89E-05

2.79E-03

1.30E-04

2.81E-04

1.93E-04

19.45

19.45

19.45

19.45

19.45

19.45

19.45

19.45

Acetaldehyde

Acrolein

Benzene

Formaldehyde

Propylene

Naphthalene

Toluene

Xylene

(MMBtu/yr)

9,725

9,725

9,725

9,725

9,725

9,725

9,725

9,725

TOTAL HAP

Based on information provided in EPA's AP-42, Tables 3.4-3 and 3.4-4.

Based on 500 hr/yr.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-20 to 2-23 Emergency Equip.xlsx

Total Emissions

(lb/hr)

(TPY)

4.90E-04

1.53E-04

1.51E-02

1.53E-03

5.43E-02

2.53E-03

5.47E-03

3.75E-03

0.083

1.23E-04

3.83E-05

3.77E-03

3.84E-04

1.36E-02

6.32E-04

1.37E-03

9.38E-04

0.021

May 2011

103-87668

Table 2-22: Physical, Performance, and Emissions Data for the Emergency Fire Pump Engine

Parameter

Performance Data

Capacity (hp)

(eKw)

Fuel: No. 2 Fuel Oil or Natural Gas

Maximum Sulfur Content (%)

Average Heat Input Rate (MMBtu/hr)

Hours of Operation (hr/yr)

Emission Factors

SO2 (lb/MMBtu)

Values

Basis

600

448

Caterpillar

Caterpillar

0.0015

On-road diesel fuel

4.3

500

Calculated

Maximum

0.00059

for Natural Gas firing

NOx (g/Kw-hr)

CO (g/Kw-hr)

PM/PM10/PM2.5 (g/Kw-hr)

3.60

3.50

0.20

Subpart IIII, Table 4

Subpart IIII, Table 4

VOC (g/Kw-hr)b

0.40

Subpart IIII, Table 4

Subpart IIII, Table 4

Emissions Calculations

SO2

NOx

CO

PM/PM10/PM2.5

VOC

Activity Factor

4.3 MMBtu/hr

448 kW

448 kW

448 kW

448 kW

(lb/hr)

0.0025

3.55

3.45

0.20

0.39

Emissionsc

(TPY)

0.0006

0.89

0.86

0.049

0.10

Based on 31.4 gal/hr diesel and 136,000 Btu/gal.

Based on Subpart IIII emission limit for NOx + NMHC of 4.0 g/Kw-hr. Assuming 90% is NOx, and 10% is VOCs.

Example Calculation:

3.5 g/Kw-hr CO x 448 Kw x lb/454.6 g = 3.45 lb/hr CO

3.45 lb/hr CO x 500 hr/yr x 1 ton/2,000 lb = 0.86 TPY CO

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-20 to 2-23 Emergency Equip.xlsx

May 2011

103-87668

Table 2-23: Fire Pump HAPs Emission Estimates

Pollutant

Acetaldehyde

Acenaphthylene

Acrolein

Anthracene

Benzene

Benzo(a)anthracene

Benzo(a)pyrene

1,3-Butadiene

Chrysene

Fluoranthene

Formaldehyde

Indeno(1,2,3-cd)pyrene

Phenanthrene

Propylene

Naphthalene

Toluene

Xylene

Emission

Factor

(lb/MMBtu) a

(MMBtu/hr)

7.67E-04

1.42E-06

9.25E-05

1.87E-06

9.33E-04

1.68E-06

1.88E-07

3.91E-05

3.53E-07

7.61E-06

1.18E-03

3.75E-07

2.94E-05

2.58E-03

8.48E-05

4.09E-04

2.85E-04

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

Activity Factor

Based on information provided in EPA's AP-42, Table 3.3-2.

Based on 500 hr/yr.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-20 to 2-23 Emergency Equip.xlsx

(MMBtu/yr)b

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

2,135

TOTAL HAP

Emissions

(lb/hr)

(TPY)

3.28E-03

6.06E-06

3.95E-04

7.99E-06

3.98E-03

7.17E-06

8.03E-07

1.67E-04

1.51E-06

3.25E-05

5.04E-03

1.60E-06

1.26E-04

1.10E-02

3.62E-04

1.75E-03

1.22E-03

0.027

8.19E-04

1.52E-06

9.88E-05

2.00E-06

9.96E-04

1.79E-06

2.01E-07

4.17E-05

3.77E-07

8.12E-06

1.26E-03

4.00E-07

3.14E-05

2.75E-03

9.05E-05

4.37E-04

3.04E-04

0.0068

May 2011

103-87668

Table 2-24. Summary of Particulate Emissions from Silo Bagfilters

Emission Source

Loading Rate

(TPH)

(TPY)

Ash Silo

--

--

Lime Silo (Wastewater Treatment)

25

500

Lime Silo (Dry Sorbent Injection)

219

880

Bin Vent Filter

Gas Flow

Rate

Emission Rate

8,040

2,458 scfm

0.01 gr/dscf

0.21

0.847

20

2,458 scfm

0.01 gr/dscf

0.21

0.002

4.0

2,458 scfm

0.01 gr/dscf

0.21

0.00042

0.63

0.849

Loading Time

(hr/yr)

a

Total Particulate Emissions =

a

Based on 52 lb/hr of lime to the boiler and 8,040 hr/yr for boiler operation.

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-24 Material Silos.xlsx

PM/PM10/PM2.5

Hourly

Annual

Emissions

Emissions

(lb/hr)

(TPY)

May 2011

103-87668

Table 2-25. Estimation of Truck Traffic

Maximum Heat Input

from Biomass a

(MMBtu/yr)

Fuel

Sugarcane Bagasse

Sorghum Bagasse

Wood

TRUCK TRAFFIC

1,843,140

1,843,140

368,628

Activity Factor

Trucks/yearb

Sugarcane

Annual Sugarcane Harvested

750,000 TPY

30,000

750,000 TPY

30,000

Wood

Annual Wood Deliveries

43,368 TPY

1,735

Ashc

Annual Ash Generation

13,828 TPY

553

36,000,000 Gallons/yr

4,000

1,620,000 Gallons/yr

180

1,380 TPY

55

Sorghuma

Annual Sorghum Harvested

a

Ethanol

Annual Final Product

Denaturant/Gasoline Deliveries

Annual Denaturant/Gasoline

Limed

Annual Lime Deliveries

a

Refer to Table 2-2.

Based on 25 tons per truck load capacity or 9,000 gallons per truck.

Total future ash is based on 9% ash in wood, 1.5% ash in sugarcane bagasse, and 2.7% ash

in sorghum bagasse. Worst case is therefore burning 30% wood with remainder bagasse.

d

Total includes dry sorbent injection reagent and wastewater treatment lime (see Table 2-24).

Y:\Projects\2010\103-87668 Highlands\PSD\Final\Tables\2\Table 2-25 Truck traffic.xlsx

May 2011

103-87668

Table 2-26: VOC Emission Estimates for Fugitive Equipment Leaks, HEF Ethanol Process

Uncontrolled Emissionsd

Control

Efficiency

Controlled Emissionsd

Emission Factors

Weighted Average

(kg/hr/source)a

VOC Content (%)b

(lb/hr)

(TPY)

(%)c

(lb/hr)

(TPY)

Component Type

Service

Component

Count

Valves

Gas/Vapor

25

0.00597

100

0.33

1.44

87

0.043

0.187

Valves

Light Liquid

200

0.00403

96

1.70

7.46

84

0.272

1.193

Valves

Heavy Liquid

100

0.00023

0.0025

0.0111

0.0025

0.0111

Sealless Valves

Light Liquid

200

4.90E-07

96

0.00021

0.00091

84

0.00003

0.00015

Sealless Valves

Heavy Liquid

100

Pump Seals

Light Liquid

0.0199

96

69

Pump Seals

Heavy Liquid

0.00862

Pump Seals, Dual Mech.

Light Liquid

50

0.0199

96

2.101

9.204

69

0.651

2.853

Pump Seals, Dual Mech.

Heavy Liquid

10

0.00862

Agitator Seals

Light Liquid

10

0.0199

96

0.42

1.84

69

0.13

0.57

Agitator Seals

Heavy Liquid

10

0.00862

0.0095

0.0415

0.009

0.042

Compressor Seals

Gas/Vapor

0.228

100

Pressure Relief Valves

Gas/Vapor

0.104

100

Connectors

All

1250

0.00183

30

1.51

6.61

93

0.11

0.46

Open-Ended Lines

All

60

0.0017

30

0.067

0.295

0.067

0.295

Sampling Connections

All

20

0.015

30

0.20

0.87

0.198

0.867

6.35

27.81

Total VOCs

1.49

6.52

Total HAPse

0.074

0.33

Emission factors are based on Protocol for Equipment Leak Emission Estimates , EPA-453/R-95-017, November 1995. Table 2-1 for SOCMI Average Emission

Factors, or Table 2-11 for Default-Zero Values.

For components in heavy liquid service, weighted average VOC content estimated at 5 perecent.