Beruflich Dokumente

Kultur Dokumente

16.Cpt 9 Construction Management

Hochgeladen von

Ade Y SaputraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

16.Cpt 9 Construction Management

Hochgeladen von

Ade Y SaputraCopyright:

Verfügbare Formate

Study on Rural Energy Supply with Utilization of Renewable Energy

in Rural Areas in the Republic of Indonesia

CHAPTER 9

Manual for Micro-hydro power Development

Chapter 9

CONSTRUCTION MANAGEMENT

9.1 Construction Management for Civil Facilities

9.1.1 Purpose of construction management

Construction management is performed by the contractor himself to satisfy the

standards and to complete the construction works economically and safely within the

construction period. For assuring the quality and functions and for controlling the

progress of work, the contractor makes a construction plan, checks in the middle of

work whether the work is being carried out as scheduled, makes corrections if the work

is delayed, examines whether the predetermined quality and shape are being made and

shows the results on graphs and tables, corrects the items not meeting standards or the

like, and records the progress, quality and shape of the work in comparison to the

specifications and drawings.

Construction management includes progress control, dimension control and quality

control.

9.1.2 Progress control

Progress control is the management of construction process for assuring the execution

of work efficiently and economically within construction period by effectively utilizing

the machines, labour and materials while maintaining sufficient quality and accuracy

instead of merely controlling a series of processes for observing the completion date. In

particular, in countries where a rainy season and a dry season can be clearly recognized,

the construction works are concentrated in dry season and this will impose extra

restrictions on time, and thus progress control must be conducted with extra care. This

is especially important where relying mainly upon manpower in civil works is

unavoidable. On the other hand, hydropower station construction contains works for

generator installation and electric facility construction in addition to civil works, and so

close coordination between the works is required.

When using funds from international financial institutions for importing construction

equipment and materials, various procedures are necessary to obtain approvals from

relevant organs for the import plan, to prepare documents necessary for international

bidding, to make documents for bidding and contracting by export/import agents and to

obtain approvals for export from the government of the country exporting the goods.

When preparing a time schedule for construction, it should be noted that a considerable

- 9-1 -

Study on Rural Energy Supply with Utilization of Renewable Energy

in Rural Areas in the Republic of Indonesia

Manual for Micro-hydro power Development

Chapter 9

period of time is necessary from the start of taking the above procedures to the actual

delivery of goods to the site.

(1) Procedure of progress control

Progress control is made for each of the planning, implementation, reviewing and

handling steps. Progress should be controlled to execute the works as close as possible

to the schedule by carrying out the work in accordance with the construction schedule,

and periodically recording the actual progress on schedule sheets every day, every week

or every month and constantly checking the progress by comparing the planned and

actual progress. If any large deviation is detected between the two, there may be a

problem in the plan or implementation system. Thus, the plan should be reexamined and

corrective measures taken. Then, implementation, reviewing and handling steps should

be implemented on the basis of the revised construction schedule.

(2) Construction schedule chart

Various time schedules should be graphically prepared for progress control and then

used as standard for implementation, review and handling. The following forms are

normally used for the control chart.

(a) Horizontal line type schedule charts (Gantt chart, bar chart)

(b) Curve type schedule charts (graph type)

(c) Network type schedule charts (PERT, CPM)

Bar charts are normally used as schedule charts but the use of network type schedule

charts is more advantageous in power station projects where various types of works

overlap. For knowing the shape (dimensions, quantity, reference height, etc.) of an

object created by the works, the shape is directly measured

9.1.3 Dimension control

It is necessary to ensure that the civil works have been built in conformity with the

contract requirements set forth and intended by the owner. If any items not meeting the

requirements are found, the causes should be pursued and corrective measures taken.

Dimension control can be roughly divided into direct-measurement and photographic

records.

(1) Direct measurement

For knowing the shape (dimensions, quantity, reference height, etc.) of an object created

by the works, the shape is directly measured in accordance with the sequence of

construction works and the measured values are then compared to design values. The

- 9-2 -

Study on Rural Energy Supply with Utilization of Renewable Energy

in Rural Areas in the Republic of Indonesia

Manual for Micro-hydro power Development

Chapter 9

results are recorded, the accuracy of construction checked against standards, and the

degree of construction technology controlled.

(2) Photo-graphic records

Photographic records are made as supplementary data for later confirmation of the

progress of the works including conditions before and after the works, the portions that

may not be seen upon completion of the structure, and the results of direct

measurement.

9.1.4 Quality control

Quality control is used to maintain the standards of quantity set forth in the design and

specifications.

(1) Procedure of quality control

For performing quality control, standardization must first of all be carried out.

Standards or criteria should be established for all the phases ranging from material

purchasing to work execution, and the works should be controlled in accordance with

these.

(a) Standards for materials

Quality standards for materials to be used should be clarified and quantitatively defined.

(b) Quality standards

Control characteristics for the required quality should be clarified and quantitatively

defined.

(c) Work standards

Facility handling standards, inspection standards and standards for working methods

should be determined.

(d) Test and inspection methods

Standards for tests and inspections should be established.

As stated above, it is necessary to establish material standards, use the materials of

predetermined quality and perform the work, inspection and test in accordance with the

predetermined methods satisfying quality standards.

(2) Quality characteristics

Examples of quality characteristics and test items for the required quality control are

shown in Table 9-1

- 9-3 -

Study on Rural Energy Supply with Utilization of Renewable Energy

in Rural Areas in the Republic of Indonesia

Kind

Concrete

Earth

Asphalt

Manual for Micro-hydro power Development

Chapter 9

Table 9.1.1 Examples of quality characteristics

Quality characteristics

Tests

Slump

Slump test

Air Content

Air content test

Compressive strength

Compression test

Bending strength

Bending test

Grain size

Grain size analysis

Degree of compactness

Dry density test

Penetration index

Various penetration tests

In-situ CBR value

In-situ CBR test

Density and voids

Marshall test

Temperature at delivery to site

Temperature test at delivery to site

Flatness of pavement surface

Flatness test

(3) Control method

Typical quality control methods are as explained below.

(a) Histogram

For finding the distributing conditions of certain characteristic values of products, the

measured values of required samples should be obtained and bar graphs prepared.

Histograms are convenient for judging whether the quality characteristics satisfy the

standards, whether the product distribution has certain allowance from the standards,

and whether the distribution of the overall quality is appropriate.

(b) Control chart

Control charts have a wide application range, are useful among quality control methods

and are therefore the most frequently utilized. Control charts show pairs of control

limits and, if any plotted points are located outside the limit, this means that there is a

critical quality fluctuation.

Control charts are classified as shown below depending on whether the items being

considered are continuous data such as length, strength and weight or discrete values

such as fraction defective ratio, number of defective portions and number of defects.

Control charts

_

~

for continuous data ......... X control chart, X control chart, X

control chart, R control chart,

process capability chart.

Control charts

for discrete values ......... P control chart, Pn control chart, C

control chart, U control chart

- 9-4 -

Study on Rural Energy Supply with Utilization of Renewable Energy

in Rural Areas in the Republic of Indonesia

Manual for Micro-hydro power Development

Chapter 9

9.2 Construction Management for Turbine, Generator and Associated Equipment

9.2.1 Installation

(1) Heavy machinery

Heavy machinery (suited to the weights to be lifted) of the required number for

transporting materials, parts and equipment on the site should be secured for the

required period of time. The heavy machinery should include machines for loading,

unloading, hauling and handling loads inside power station.

(2) Manpower of direct labourers and technicians

The number of direct labourers and technicians required varies depending on the types,

capacities, sizes and installation method of turbine and generator, equipment

configuration, delivery route, heavy machinery available, working environment and

experience of contractor. The numbers of direct labourers and technicians required

are roughly estimated as follows. The installation period also varies depending on the

above items but approximately 2 to 4 months will be needed normally.

(Skilled labourers)

(Unskilled labourers)

Foreman:

Mechanics:

Welders:

Pipe fitters:

Rigger:

1

3 to 4

1 to 2

1 to 2

1

Crane & heavy

machinery operators:

Electricians:

1 to 2

2 to 3

Odd-jobbers:

5 to 6

(3) Temporary facilities

The following temporary facilities should be considered:

(a) Distribution board for temporary power source

(b) Lodging facilities

(c) Warehouse

(d) Site construction office

(4) General tools and consumables

- 9-5 -

Study on Rural Energy Supply with Utilization of Renewable Energy

in Rural Areas in the Republic of Indonesia

Manual for Micro-hydro power Development

Chapter 9

(5) Classification of installation work

(a) Inspection of dimensions and level of concrete foundation

(b) Transport of materials, parts and equipment from warehouse to power station

(e) Unpacking

(d) Preparing scaffolds

(e) Assembly and installation

(f) Welding and gas cutting

(g) Wiring

(h) Piping work and flushing

(i) Hydraulic pressure test

(j) Non-destructive test

(k) Centering, leveling

(1) Shaft runout test

(m) Painting

(6) Inspection during installation

(a) Centering & leveling

(b) Shaft runout measurement

(c) Measurement of caps of rotating parts

(d) Confirmation of dimensions of each portion

(e) Dye penetration test or ultrasonic crack examination for field welds of stress

carrying parts

(f) Relation between guide vane opening and servomotor stroke

(g) Insulation resistance measurement

9.2.2 Adjustment at trim operation

(1) Instruments, tools and materials

Prior to commencement of the tests, provision should be made for dummy load by water

rheostat or the like if an actual load for the tests can not be expected.

(2) Manpower schedule

Occupation

Test engineers (mechanical):

Test engineers (electrical):

Testing personnel:

Number of Personnel

1 to 2

1 to 2

10 to 12

Test period

- 9-6 -

Study on Rural Energy Supply with Utilization of Renewable Energy

in Rural Areas in the Republic of Indonesia

Manual for Micro-hydro power Development

Chapter 9

This varies depending on the types of turbine and generator, equipment configuration,

and experience of testers, but is normally 1 to 2 months.

(3) Test items

(a) Appearance inspection

(b) Insulation resistance measurement

(c) Withstand voltage test

(d) Tests for turbine ancillary equipment

- Performance test for governor

- Tests for oil pressure supply and lubricating systems

- Tests for water supply and drainage systems

(e) Exciter combination tests

(f) No-water overall tests

(g) Water filling tests

(h) Initial running tests

(i) Automatic start and stop tests

(j) Synchronizing tests

(k) Load rejection tests

Safe stopping after rejection of loads during operation should be confirmed mainly

for the pressure change in the penstock, machine speed change and voltage change

of generator.

(1) Output and opening tests

It should be confirmed that there are no abnormal phenomena within operating load

range, and that the discharge and output satisfy the specifications.

(m) Vibration measurement

To be performed during output and opening tests.

(n) Load tests

Continuous operation should be made under full load until the temperature of the

coils and bearings of the generator stabilizes.

- 9-7 -

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

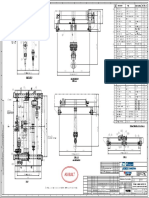

- 3147 Hoist r3Dokument1 Seite3147 Hoist r3Ade Y SaputraNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- SEMA MH Hook Block Assly. Sheet 1 3Dokument1 SeiteSEMA MH Hook Block Assly. Sheet 1 3Ade Y SaputraNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Section:A-A': Typical Power JointDokument1 SeiteSection:A-A': Typical Power JointAde Y SaputraNoch keine Bewertungen

- Cable Sizing and Schedule-R - 02 - (As BUILT)Dokument6 SeitenCable Sizing and Schedule-R - 02 - (As BUILT)Ade Y SaputraNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 2MLD09-0100-01664365 B: ClientDokument1 Seite2MLD09-0100-01664365 B: ClientAde Y SaputraNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- SEMA AH Hook Block Assly. Sheet 2 3Dokument1 SeiteSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Jual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaDokument5 SeitenJual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaAde Y SaputraNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- SAP PM T - CodesDokument4 SeitenSAP PM T - CodesBujjibabu Katta0% (1)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Paper Title (Use Style - Paper Title)Dokument6 SeitenPaper Title (Use Style - Paper Title)Ade Y SaputraNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Besi U PDFDokument1 SeiteBesi U PDFAde Y SaputraNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Jual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaDokument5 SeitenJual Besi Pipa Galvanis Medium - Harga Distributor - TokoBesiBajaAde Y SaputraNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- MHPPDokument8 SeitenMHPPAde Y Saputra100% (1)

- Fuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Dokument18 SeitenFuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Ade Y SaputraNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Star - DeltaDokument4 SeitenStar - DeltaAde Y SaputraNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- ACSR BS215 Part 2Dokument1 SeiteACSR BS215 Part 2Ade Y SaputraNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Harga ArresterDokument2 SeitenHarga ArresterAde Y SaputraNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- NA2XSEBY KabelDokument5 SeitenNA2XSEBY KabelSemar AngNoch keine Bewertungen

- Acsr SPLN 41-7 PDFDokument2 SeitenAcsr SPLN 41-7 PDFAde Y Saputra100% (1)

- Acsr SPLN 41-7 PDFDokument2 SeitenAcsr SPLN 41-7 PDFAde Y Saputra100% (1)

- 50 AMP WELDER ReceptacleDokument2 Seiten50 AMP WELDER ReceptacleAde Y SaputraNoch keine Bewertungen

- Acsr - Astm b232Dokument3 SeitenAcsr - Astm b232Ade Y SaputraNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Variable Frequency DriveDokument40 SeitenVariable Frequency DriveAde Y Saputra100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Tipe NGRDokument4 SeitenTipe NGRAde Y SaputraNoch keine Bewertungen

- 100W Son-T High OutputDokument2 Seiten100W Son-T High OutputAde Y SaputraNoch keine Bewertungen

- Acsr Din en 50182Dokument1 SeiteAcsr Din en 50182Ade Y SaputraNoch keine Bewertungen

- Engineering Note: PT - Indah Kiat Pulp & Paper TBKDokument8 SeitenEngineering Note: PT - Indah Kiat Pulp & Paper TBKAde Y SaputraNoch keine Bewertungen

- NGR GarutRev1Dokument1 SeiteNGR GarutRev1Ade Y SaputraNoch keine Bewertungen

- LBKP Feed PumpDokument1 SeiteLBKP Feed PumpAde Y SaputraNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Engineering Note: PT - Indah Kiat Pulp & Paper TBKDokument8 SeitenEngineering Note: PT - Indah Kiat Pulp & Paper TBKAde Y SaputraNoch keine Bewertungen

- Piping Instalation (11aug09)Dokument10 SeitenPiping Instalation (11aug09)Ade Y SaputraNoch keine Bewertungen

- Percentage Wall Reduction Is The Most FrequentlyDokument4 SeitenPercentage Wall Reduction Is The Most Frequentlysanketpavi21Noch keine Bewertungen

- Is 5484 1997Dokument9 SeitenIs 5484 1997Cristian Walker100% (2)

- A 1Dokument4 SeitenA 1Izreen FaraNoch keine Bewertungen

- Drilling Attachment: CPA Range OverviewDokument3 SeitenDrilling Attachment: CPA Range OverviewPablo NarváezNoch keine Bewertungen

- Syllabus - Lean and Agile ManufacturingDokument2 SeitenSyllabus - Lean and Agile ManufacturingjvanandhNoch keine Bewertungen

- Structural Foam Molding Is A LowDokument2 SeitenStructural Foam Molding Is A LowRaqib RahmanNoch keine Bewertungen

- L-5 Recent Trends in Production and Operations ManagementDokument34 SeitenL-5 Recent Trends in Production and Operations ManagementKrystle DseuzaNoch keine Bewertungen

- TQM PPT On Toyota (24!12!07)Dokument13 SeitenTQM PPT On Toyota (24!12!07)priyapatel497Noch keine Bewertungen

- N7MYS1Dokument9 SeitenN7MYS1jaskaran singhNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Recruitment Shipping and Logistics ManagerDokument2 SeitenRecruitment Shipping and Logistics Managercedric NchoNoch keine Bewertungen

- MudMaster HPHT Pistons Mud PumpDokument2 SeitenMudMaster HPHT Pistons Mud PumpifebrianNoch keine Bewertungen

- Karakterisasi Material PDFDokument40 SeitenKarakterisasi Material PDFmiftakhurNoch keine Bewertungen

- Paint Slip Coefficient PDFDokument28 SeitenPaint Slip Coefficient PDFRk Sabarinathan100% (1)

- Lean Principles Value Stream Mapping EbookDokument144 SeitenLean Principles Value Stream Mapping EbookSyed Shiraz SabriNoch keine Bewertungen

- Hot Rolled SteelDokument2 SeitenHot Rolled SteelabhishekNoch keine Bewertungen

- SikaDur 53Dokument2 SeitenSikaDur 53pnNoch keine Bewertungen

- USE of DWC Giga Pipes in Highway ConstructionDokument16 SeitenUSE of DWC Giga Pipes in Highway ConstructionSuresh TripathiNoch keine Bewertungen

- Lecture 2Dokument30 SeitenLecture 2hayelomNoch keine Bewertungen

- Consumption of Formalin in Industries of PakistanDokument2 SeitenConsumption of Formalin in Industries of PakistanAzfer HayatNoch keine Bewertungen

- Aeg Lavamat l64850l - Manual 071013Dokument36 SeitenAeg Lavamat l64850l - Manual 071013Sakthipriya JeganathanNoch keine Bewertungen

- 055 - Guidelines For NDT of GRP Pipe Systems and Tanks 8Dokument1 Seite055 - Guidelines For NDT of GRP Pipe Systems and Tanks 8bharathaninNoch keine Bewertungen

- TEM List 2Dokument42 SeitenTEM List 2aminNoch keine Bewertungen

- 01-SAMSS-034 RTR (Fiberglass) Pressure Pipe and Fittings 19-MAR-2013Dokument19 Seiten01-SAMSS-034 RTR (Fiberglass) Pressure Pipe and Fittings 19-MAR-2013asiqnaNoch keine Bewertungen

- Complete Book ListDokument3 SeitenComplete Book ListsigmasundarNoch keine Bewertungen

- JitDokument15 SeitenJitYashovardhan MaheshwariNoch keine Bewertungen

- Laboratory Manual MEC224 Mechanical Engineering WorkshopDokument30 SeitenLaboratory Manual MEC224 Mechanical Engineering WorkshopSunil SharmaNoch keine Bewertungen

- Kaizen Lean Management Service Sector2Dokument22 SeitenKaizen Lean Management Service Sector2Mahathir FansuriNoch keine Bewertungen

- JntuK CAD/CAM Question PaperDokument4 SeitenJntuK CAD/CAM Question PaperANILKUMAR KONDANoch keine Bewertungen

- Aircraft Hardware - Continuous Assessment Test (CAT) Course: Ame 08 April 2017Dokument4 SeitenAircraft Hardware - Continuous Assessment Test (CAT) Course: Ame 08 April 2017JowiNoch keine Bewertungen

- 04 Bab 2 Deskripsi Kegiatan-Revisi 6Dokument1 Seite04 Bab 2 Deskripsi Kegiatan-Revisi 6Blank KusumaNoch keine Bewertungen

- Spark: How to Lead Yourself and Others to Greater SuccessVon EverandSpark: How to Lead Yourself and Others to Greater SuccessBewertung: 4.5 von 5 Sternen4.5/5 (132)

- Summary of Noah Kagan's Million Dollar WeekendVon EverandSummary of Noah Kagan's Million Dollar WeekendBewertung: 5 von 5 Sternen5/5 (1)

- The First Minute: How to start conversations that get resultsVon EverandThe First Minute: How to start conversations that get resultsBewertung: 4.5 von 5 Sternen4.5/5 (57)

- The Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverVon EverandThe Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverBewertung: 4.5 von 5 Sternen4.5/5 (186)

- Scaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0Von EverandScaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0Bewertung: 5 von 5 Sternen5/5 (1)

- Coach the Person, Not the Problem: A Guide to Using Reflective InquiryVon EverandCoach the Person, Not the Problem: A Guide to Using Reflective InquiryBewertung: 5 von 5 Sternen5/5 (64)

- The 7 Habits of Highly Effective PeopleVon EverandThe 7 Habits of Highly Effective PeopleBewertung: 4 von 5 Sternen4/5 (2565)

- How to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobVon EverandHow to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobBewertung: 4.5 von 5 Sternen4.5/5 (36)