Beruflich Dokumente

Kultur Dokumente

(WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Cutting Sample Paper 2 PDF

Hochgeladen von

Jagannath SahuOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

(WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Cutting Sample Paper 2 PDF

Hochgeladen von

Jagannath SahuCopyright:

Verfügbare Formate

...

T

Q..

Roll No. ......................

"-

Total No. of Questions: 08]

ITotal No. of Pages: 02

Paper ID [PE502]

(Pleasefillthis Paper 10 in OMR Sheet)

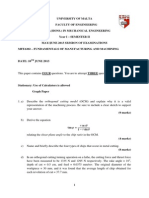

M.Tech. (Sem. - 151)

. t...

..

,,~'( ~~O

METAL CUTTING (PE. .. 502) \

Time: 03 Hours

Instruction

Maximum Marks: 100

to Candidates:

1)

Attempt any Five questions.

2)

All questions carry equal marks.

Ql) (a)

Discuss the 'Tool nomenclatur~' and the effect of different tool angles

on machinability and the tool performance in any machining operation.

(b)

Discuss the 'Merchant force diagram' and its importance in machining.

(c)

Explain different types of-chip fonnation during machining, along with

the mechanisms involved.

Q2) (a) Discuss in detail the force system in oblique cutting. How does it differ

from orthogonal cutting?

(b) Describe the following in relation to orthogonal cutting :(i) Shear strain.

(ii) Rate of strain.

(iii) Total energy ~onsumed per unit volume.

Q3) (a)

Discuss the fundamental factors that affect the tool forces and hence the

tool wear and tool perfonnance in any machining operation.

(b)

Using the concept of dynamometry and theoretical considerations, explain

how the following can be measured during metal cutting :(i)

Force measurement.

(ii) Heat measurement.

(iii) Temperature measurement.

Q4) (a)

Describe any tool life equation. On what basis the tool life criterion is

based?

R-1156 /2058J

R T.O.

(b)

A HSS tool requires regrinding after 2 hours and 45 minutes when

machining steel at a cutting speed of 35m/min: Calc~late the tool Iife if

the speed is increased to 70m/min.

(c)

bt.,

v

How does metallurgy ofthe work material and the cutting tool affect the

machinability in any machining operation?

Q5) (a)

Discuss what different types of wear can take place in cutting tool. Explain

any three of them along with the mechanism involved.

(b)

Taking the optimization variables as 'specific cost' and 'production rate',

describe the procedural steps that are involved in optimizing any machining

operation? Supporfyour answer with a suitable example.

(c)

How brittle fracture is analyzed in tools using the fracture mechanics

approach?

Q6) (a). Discuss the mechanism of grinding in detail. Also describe the cutting

action of the grit and the effeCt of grit force on wheel wear.

I

(b)

How grinding wheels are tested?

(c)

Mention the procedural ~teps required in simulating any grinding process.

What advantages are associated with it?

Q7) (a)

Taking a suitable example discuss how cutting tool wear can be

mathematically modeled using different approaches? What benefits can

be achieved from such modelling?

(b)

Write a note on 't~ollife testing' and the success rate and reliability of

the methods used for the same.

(c)

Discuss the following:

(i)

Wear-Land wear.

(ii) Crater wear,

Q8) Write notes on the following:

(a) Measurement of wear of cutting tools in machining.

(b) Economics

of metal machining. and its importance.

.

(c)

Mechanics of lapping.

(d)

Force system in milling operation.

000

R-1156

"-

Das könnte Ihnen auch gefallen

- (WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Cutting Sample Paper 3 PDFDokument2 Seiten(WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Metal Cutting Sample Paper 3 PDFJagannath SahuNoch keine Bewertungen

- M. Tech. Metal Cutting Subject Code: Pe-502 Paperid: (E0442)Dokument2 SeitenM. Tech. Metal Cutting Subject Code: Pe-502 Paperid: (E0442)amit4u1984Noch keine Bewertungen

- Machine Tools Assignments 1 N 2Dokument3 SeitenMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNoch keine Bewertungen

- Total Workshop QuestionsDokument8 SeitenTotal Workshop QuestionsSanjeet KumarNoch keine Bewertungen

- 1.machine Tool Design Assignment 2017Dokument6 Seiten1.machine Tool Design Assignment 2017Charles OndiekiNoch keine Bewertungen

- Me 2252Dokument3 SeitenMe 2252cbeprabhugmailNoch keine Bewertungen

- Manufacturing Technology - IIDokument2 SeitenManufacturing Technology - IIMANOJ MNoch keine Bewertungen

- Question Paper 2 PDFDokument4 SeitenQuestion Paper 2 PDFfotickNoch keine Bewertungen

- Ain Shams Untversity (' / ') (' (''') / ',L'',-) ' L Faculty of EngineeringDokument2 SeitenAin Shams Untversity (' / ') (' (''') / ',L'',-) ' L Faculty of EngineeringMostafaNoch keine Bewertungen

- Me 5 PT 2021Dokument3 SeitenMe 5 PT 2021SameerNoch keine Bewertungen

- Gujarat Technological UniversityDokument1 SeiteGujarat Technological Universityrajain135Noch keine Bewertungen

- 53131-mt - Precision EngineeringDokument2 Seiten53131-mt - Precision EngineeringSRINIVASA RAO GANTANoch keine Bewertungen

- MCMT Mid-1 P-QusDokument5 SeitenMCMT Mid-1 P-QusN Dhanunjaya Rao BorraNoch keine Bewertungen

- (Question Paper C: 0 Ma KsDokument2 Seiten(Question Paper C: 0 Ma KsvsanthanamNoch keine Bewertungen

- 2013Dokument4 Seiten2013AmyRapaNoch keine Bewertungen

- MEC330Dokument2 SeitenMEC330gowthamNoch keine Bewertungen

- Assignment 3Dokument2 SeitenAssignment 3M Shahrul IzuanNoch keine Bewertungen

- 53112-MT - Theory of Metal Cutting & Tool DesignDokument2 Seiten53112-MT - Theory of Metal Cutting & Tool Designhari0118Noch keine Bewertungen

- Ffiuk: Ain Shams University I - :) Faculty of EngineerngDokument2 SeitenFfiuk: Ain Shams University I - :) Faculty of EngineerngMostafaNoch keine Bewertungen

- 9A03503 Machine ToolsDokument4 Seiten9A03503 Machine ToolssivabharathamurthyNoch keine Bewertungen

- Section: A 1 Attempt All Parts. Write Answer of Each Part in Short. (4 X 2 8)Dokument2 SeitenSection: A 1 Attempt All Parts. Write Answer of Each Part in Short. (4 X 2 8)Tulsi ChouhanNoch keine Bewertungen

- Machine ToolsDokument5 SeitenMachine ToolsSavantNoch keine Bewertungen

- Question Bank For Machining and MetrologyDokument7 SeitenQuestion Bank For Machining and MetrologyAbhisheak DineshNoch keine Bewertungen

- 3-1 MT (Nov 2009 Regular)Dokument5 Seiten3-1 MT (Nov 2009 Regular)micmechNoch keine Bewertungen

- Machine Tools - 1st MID - 3rd B.tech (2009)Dokument2 SeitenMachine Tools - 1st MID - 3rd B.tech (2009)micmechNoch keine Bewertungen

- MP-1 Tut SheetDokument11 SeitenMP-1 Tut SheetAnkur ChelseafcNoch keine Bewertungen

- Model Test Paper: ABES Institute of Technology, GhaziabadDokument2 SeitenModel Test Paper: ABES Institute of Technology, GhaziabadYogesh Kumar GaurNoch keine Bewertungen

- QBMCMFDokument11 SeitenQBMCMFDr.B.S.AjaykumarNoch keine Bewertungen

- R07 Set No. 2Dokument4 SeitenR07 Set No. 2Muhammad Asif Ali0% (1)

- Mantech Tie 6122 Assignment Bouquet Oct 2019 PDFDokument4 SeitenMantech Tie 6122 Assignment Bouquet Oct 2019 PDFNativity MabasaNoch keine Bewertungen

- 29-05 Manufacturing Technology (MT)Dokument1 Seite29-05 Manufacturing Technology (MT)a11972003Noch keine Bewertungen

- Assignment Booklet: BTME ProgrammeDokument20 SeitenAssignment Booklet: BTME ProgrammeSarvanKumarNoch keine Bewertungen

- MCMT Unit-1 PPQDokument2 SeitenMCMT Unit-1 PPQN Dhanunjaya Rao BorraNoch keine Bewertungen

- Estelar: Faculty of EngineeringDokument1 SeiteEstelar: Faculty of EngineeringPrasad Apv100% (1)

- R7210301 Production TechnologyDokument1 SeiteR7210301 Production TechnologysivabharathamurthyNoch keine Bewertungen

- Code - No: 07A6EC04Dokument4 SeitenCode - No: 07A6EC04ideepujNoch keine Bewertungen

- ME3201Dokument1 SeiteME3201Md. Tariqul Islam MunnaNoch keine Bewertungen

- MT R07, Sup, AprilMay - 2012Dokument34 SeitenMT R07, Sup, AprilMay - 2012N Dhanunjaya Rao BorraNoch keine Bewertungen

- Production Technology SyllabusDokument9 SeitenProduction Technology SyllabusPankaj SharmaNoch keine Bewertungen

- Manufacturing Technology Question Papers of JntuaDokument15 SeitenManufacturing Technology Question Papers of JntuaHimadhar SaduNoch keine Bewertungen

- Jntuworld: R09 Set No. 2Dokument6 SeitenJntuworld: R09 Set No. 2Dr-Asit Kumar ParidaNoch keine Bewertungen

- Question Paper For MeDokument4 SeitenQuestion Paper For MeVishal JhaNoch keine Bewertungen

- CAT I - EMMU 7241 - Machine Tool Vibrations and Cutting DynamicsDokument2 SeitenCAT I - EMMU 7241 - Machine Tool Vibrations and Cutting DynamicsCharles OndiekiNoch keine Bewertungen

- Sathyabama Question PaperDokument3 SeitenSathyabama Question PaperamiestudentNoch keine Bewertungen

- Time: 3 Hours Answer All Questions Maximum: 100 MarksDokument3 SeitenTime: 3 Hours Answer All Questions Maximum: 100 MarksAnonymous ZB6qyhD6Noch keine Bewertungen

- The Following QuestionsDokument1 SeiteThe Following QuestionsKiRoBahaaNoch keine Bewertungen

- ADVANCED MANUFACTURING PROCESSES April 2018 PDFDokument2 SeitenADVANCED MANUFACTURING PROCESSES April 2018 PDFshardul jagdaleNoch keine Bewertungen

- Manufacturing Process 1Dokument1 SeiteManufacturing Process 1sameer_m_daniNoch keine Bewertungen

- Question Bank BTMEC601 Manufacturing Processes IIDokument14 SeitenQuestion Bank BTMEC601 Manufacturing Processes IINeel PawarNoch keine Bewertungen

- Metal FormingDokument6 SeitenMetal FormingHarish Kumar SNoch keine Bewertungen

- (WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Non Conventional Machining Processes Sample Paper 1 PDFDokument2 Seiten(WWW - Entrance-Exam - Net) - PTU M.Tech in Production Engineering Non Conventional Machining Processes Sample Paper 1 PDFAbdur RahmanNoch keine Bewertungen

- PRODUCTIONTECHNOLOGYDokument4 SeitenPRODUCTIONTECHNOLOGYSamiullah MohammedNoch keine Bewertungen

- BTME 2nd Year AssignmentDokument15 SeitenBTME 2nd Year AssignmentshishunalNoch keine Bewertungen

- Mech3002y 3 2007 2 PDFDokument6 SeitenMech3002y 3 2007 2 PDFKeshav GopaulNoch keine Bewertungen

- Answer Any Five Questions From Section-BDokument1 SeiteAnswer Any Five Questions From Section-BCharyNoch keine Bewertungen

- MP 20Dokument2 SeitenMP 20hkumarchauhan392Noch keine Bewertungen

- 18ME35A-MCF Vtu QuestionsDokument5 Seiten18ME35A-MCF Vtu QuestionsRakshith M100% (7)

- PUT Paper of Manufacturing Science II (2019-20)Dokument3 SeitenPUT Paper of Manufacturing Science II (2019-20)Tulsi ChouhanNoch keine Bewertungen

- Code No: 35033Dokument5 SeitenCode No: 35033SRINIVASA RAO GANTANoch keine Bewertungen

- Materials Science and Technology of Optical FabricationVon EverandMaterials Science and Technology of Optical FabricationNoch keine Bewertungen

- NAAMM Metal Bar Grating Manual 531 - Part17Dokument2 SeitenNAAMM Metal Bar Grating Manual 531 - Part17Jagannath SahuNoch keine Bewertungen

- SSPC PA1 2016 - Part10Dokument1 SeiteSSPC PA1 2016 - Part10Jagannath SahuNoch keine Bewertungen

- MGB 532-XX First Ballot 02122019 Part2Dokument1 SeiteMGB 532-XX First Ballot 02122019 Part2Jagannath SahuNoch keine Bewertungen

- MGB 532-XX First Ballot 02122019 Part7Dokument1 SeiteMGB 532-XX First Ballot 02122019 Part7Jagannath SahuNoch keine Bewertungen

- NAAMM Metal Bar Grating Manual 531 - Part2Dokument2 SeitenNAAMM Metal Bar Grating Manual 531 - Part2Jagannath SahuNoch keine Bewertungen

- 10 Price Action Candlestick Patterns You Must Know - Part10Dokument2 Seiten10 Price Action Candlestick Patterns You Must Know - Part10Jagannath SahuNoch keine Bewertungen

- Iso 10721-1-1997Dokument119 SeitenIso 10721-1-1997Jagannath SahuNoch keine Bewertungen

- Tiginox 385: Classification: en Iso 14343-ADokument1 SeiteTiginox 385: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- SSPC PA1 2016 - Part1Dokument1 SeiteSSPC PA1 2016 - Part1Jagannath SahuNoch keine Bewertungen

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part6Dokument2 Seiten10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part6Jagannath SahuNoch keine Bewertungen

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part5Dokument2 Seiten10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part5Jagannath SahuNoch keine Bewertungen

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part3Dokument2 Seiten10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part3Jagannath SahuNoch keine Bewertungen

- 10 Price Action Candlestick Patterns You Must Know - Part4Dokument2 Seiten10 Price Action Candlestick Patterns You Must Know - Part4Jagannath SahuNoch keine Bewertungen

- Interpreting SNT TC 1A PDF 2Dokument1 SeiteInterpreting SNT TC 1A PDF 2Jagannath SahuNoch keine Bewertungen

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part2Dokument2 Seiten10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part2Jagannath SahuNoch keine Bewertungen

- Name:-Pratik NayakDokument16 SeitenName:-Pratik NayakJagannath SahuNoch keine Bewertungen

- Interpreting SNT TC 1A PDF 1Dokument1 SeiteInterpreting SNT TC 1A PDF 1Jagannath SahuNoch keine Bewertungen

- Miginox 347 / Tiginox 347: Classification: ApprovalsDokument1 SeiteMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNoch keine Bewertungen

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADokument1 SeiteMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- Miginox 347si: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 347si: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDokument1 SeiteAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNoch keine Bewertungen

- Miginox 307: Classification: en Iso 14343-ADokument1 SeiteMiginox 307: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADokument1 SeiteMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNoch keine Bewertungen

- CWC-BookletF1 36 PDFDokument1 SeiteCWC-BookletF1 36 PDFJagannath SahuNoch keine Bewertungen

- Automig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Dokument1 SeiteAutomig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Jagannath SahuNoch keine Bewertungen

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Dokument1 SeiteAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuNoch keine Bewertungen

- CWC-BookletF1 24Dokument1 SeiteCWC-BookletF1 24Jagannath SahuNoch keine Bewertungen

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Dokument1 SeiteAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNoch keine Bewertungen

- CWC-BookletF1 29 PDFDokument1 SeiteCWC-BookletF1 29 PDFJagannath SahuNoch keine Bewertungen

- Jungbluth Main Catalogue-LanacDokument60 SeitenJungbluth Main Catalogue-LanacMilenkoBogdanovicNoch keine Bewertungen

- Final ExamDokument2 SeitenFinal ExamblacmsNoch keine Bewertungen

- Contents of HvacDokument2 SeitenContents of Hvaclijo johnNoch keine Bewertungen

- Revised LabDokument18 SeitenRevised LabAbu AyemanNoch keine Bewertungen

- Topic 4 Statistic II (Form 3)Dokument2 SeitenTopic 4 Statistic II (Form 3)Ct KursiahNoch keine Bewertungen

- 12.3 What Is The Nomenclature System For CFCS/HCFCS/HFCS? (Chemistry)Dokument3 Seiten12.3 What Is The Nomenclature System For CFCS/HCFCS/HFCS? (Chemistry)Riska IndriyaniNoch keine Bewertungen

- GENTLENESSDokument4 SeitenGENTLENESSAprylleCourtneyMayeMauyaoNoch keine Bewertungen

- TPT 510 Topic 3 - Warehouse in Relief OperationDokument41 SeitenTPT 510 Topic 3 - Warehouse in Relief OperationDR ABDUL KHABIR RAHMATNoch keine Bewertungen

- Week 1 Macro (DDR)Dokument49 SeitenWeek 1 Macro (DDR)Stevie Sean100% (1)

- Recruitment Process Outsourcing PDFDokument4 SeitenRecruitment Process Outsourcing PDFDevesh NamdeoNoch keine Bewertungen

- Veerasaiva Pantha in 12th Century MaharashtraDokument2 SeitenVeerasaiva Pantha in 12th Century MaharashtrarathkiraniNoch keine Bewertungen

- (Official) AVTC5 - Unit 1 - Before ClassDokument11 Seiten(Official) AVTC5 - Unit 1 - Before ClassNhân NguyễnNoch keine Bewertungen

- RG-RAP6260 (G) Hardware InstallationDokument26 SeitenRG-RAP6260 (G) Hardware InstallationrazuetNoch keine Bewertungen

- Bo Sanchez-Turtle Always Wins Bo SanchezDokument31 SeitenBo Sanchez-Turtle Always Wins Bo SanchezCristy Louela Pagapular88% (8)

- Liquid Process Piping - Part 1 General Piping Design PDFDokument33 SeitenLiquid Process Piping - Part 1 General Piping Design PDFnitin guptaNoch keine Bewertungen

- Climate Declaration: For White Corex PlasterboardDokument1 SeiteClimate Declaration: For White Corex PlasterboardAbdullah BeckerNoch keine Bewertungen

- Ericsson Private 5G Solution BriefDokument5 SeitenEricsson Private 5G Solution BriefTanesan WyotNoch keine Bewertungen

- Ageing World ReportDokument4 SeitenAgeing World Reporttheresia anggitaNoch keine Bewertungen

- Directorate of Technical Education, Maharashtra StateDokument47 SeitenDirectorate of Technical Education, Maharashtra StatePandurang GunjalNoch keine Bewertungen

- The English We SpeakDokument2 SeitenThe English We Speakcaeronmustai100% (1)

- LEARNING ACTIVITY SHEET in Oral CommDokument4 SeitenLEARNING ACTIVITY SHEET in Oral CommTinTin100% (1)

- Application Tracking System: Mentor - Yamini Ma'AmDokument10 SeitenApplication Tracking System: Mentor - Yamini Ma'AmBHuwanNoch keine Bewertungen

- Introduction of Woman Role in SocietyDokument12 SeitenIntroduction of Woman Role in SocietyApple DogNoch keine Bewertungen

- Pediatric Infectious DiseasesDokument3 SeitenPediatric Infectious DiseasesAiri FirdausiaNoch keine Bewertungen

- Ashfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)Dokument36 SeitenAshfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)surajnayak77Noch keine Bewertungen

- 56257375851Dokument3 Seiten56257375851Anneliese FernandesNoch keine Bewertungen

- 2012 Karshaniya YavaguDokument4 Seiten2012 Karshaniya YavaguRANJEET SAWANTNoch keine Bewertungen

- The FlyDokument8 SeitenThe FlyDrei Tiam Lacadin100% (1)

- Module 2 - Part III - UpdatedDokument38 SeitenModule 2 - Part III - UpdatedDhriti NayyarNoch keine Bewertungen

- Data Abstraction and Problem Solving With C Walls and Mirrors 6th Edition Carrano Solutions ManualDokument36 SeitenData Abstraction and Problem Solving With C Walls and Mirrors 6th Edition Carrano Solutions Manualallocaturnonylgvtt100% (12)