Beruflich Dokumente

Kultur Dokumente

Hse-Swms-018-A - Traffic Signal Maintenance - NSW

Hochgeladen von

api-326016071Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hse-Swms-018-A - Traffic Signal Maintenance - NSW

Hochgeladen von

api-326016071Copyright:

Verfügbare Formate

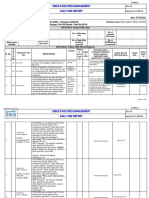

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

Work Activity

Traffic Signal Maintenance

High Risk Activity

YES

NO

Company Information

Company

Safety Officer

Preparation / Review

Name

Position

Date

Integrated Services (ABN 21 008 122 847)

Leah Olszanowski

Prepared By

Leah Olszanowski

Safety Manager

19-04-16

Address

Email

Reviewed By

Martin Olszanowski

Operations Manager

19-04-16

11 Cottonwood Court, Capalaba 4157

info@integrated-services.com.au

Approved By

Martin Olszanowski

General Manager

19-04-16

Phone

Phone

0407 716 436

0407 716 436

Next Due for Review

19-04-17

Signature

Project Information

Client Name

Job Number

(Integrated Services)

Supervisor

Project Review and Revision

Revision

Traffic Technologies

100108

Client Contact

Job Name

Sam Keim

Issue Date

Steve Macann

Street light damages

sam.keim@integratedservices.com.au

Phone

Job Location

0413 334 677

Northern NSW

Phone

0437 824 288

Reason for Revision

Project Approval

Integrated Services

Project Manager

Signature

Date

Client Representative

Signature

Date

Integrated Services

Page 1 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

POTENTIAL HAZARDS / ASPECTS ASSOCIATED WITH THE ACTIVITY / TASK

Identify each of the hazards associated with the activity/task by placing a (x) next to the potential hazard & ensure the hazard is adequately addressed within the SWMS.

Potential site specific hazards shall be addressed at site and recorded within the activity pre-start record.

SWMS to be communicated to all staff and subcontractors during initial toolbox meeting prior to commencement of work.

Work Environment

Energy

Work Process

Chemicals

Plant/Equipment

People

Hazardous/dangerous

Entry/Exit

Gas LP

x Working at heights

x

Elevated work platforms

x Communication

goods

Temp / Extremes /

Gas MP

Falling Objects

x Asbestos /SMF

Cranes

Fatigue

weather

Possible toxic

Confined Space

Gas HP

Sharp materials

Excavator

Stress

substances

Oxygen / Atmospheric

Gas Oxy

High noise levels

Inhalation

Plant movement

x Working alone

Level

Remote site / Difficult

Welder

Ladders

x Contact with:

Explosive tools

Personnel threat

rescue

Trench/hole Collapse

Electrical LV

x Manual Handling

x Dust

Whacker packer

Working at night

Rail / Train movement

Electrical HV

Procedural failure

Bacteria

Winches

Interaction with others

Sharp objects

X Hydraulic Pressure

x Height access

Oils

Hauling equipment

Fitness for work

Poor lighting / visibility

X Kinetic

Spills

Contaminated fluids

Hand tools

x Competency

Trip / slip hazards

X Compressed air

Switching

Fuels

Lockouts / Valves

Vehicle / pedestrians

x Radiation

Room hazards

Drilling muds

Angle grinder

Erosion / flora / fauns

Steam

Drill Rig

Gravity

Permits Required

Working live

HV Access

AR620A - Isolation

AR624D - Work near power lines

Licences / Accreditations Required

Energex WCS 2

Energex WCS 47.2

Electrical Licence

Vehicle licences

Integrated Services

AR

AR624A Authority to Work

Traffic Control Authority

Traffic Management Plan

Energex WCS 6.2

Energex WCS 61

High Risk Work Licence

AR

AR

AR

Dial Before You Dig

AR610A Ground Penetration

AR624C - Hot Works

Energex WCS 34

NSW ASP level 1

Validation of Competency

AR618C - Lift

AR615B - Working at Heights

AR608A - Confined Space

AR624E Work on or near water

x

x

x

AR

Energex WCS 37

Electrical Contractors Licence

Authorised Person

Page 2 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

SWMS References & Activity Controls

Legislation, codes of practices,

standards referenced

Reference drawings, specifications

etc.

Personnel Consulted on the

development of SWMS

Work Health and Safety Act

Workplace Health and Safety Regulations

Electrical Safety Act

Electrical Safety Regulation

Environmental Protection Act

Environmental Protection regulation

Plant Code of Practice

Energex Standard Work Procedure Documents

Underground Distribution Construction Manual

Overhead Construction Manual

Distribution Earthing Manual

Queensland Electricity Connection & Metering Manual

Operating Practices Manual

SAHV Procedures (orange book)

Queensland Public Lighting Manual

Integrated Services field staff

Independent Auditor

AS/NZS 3000 Electrical Installations Wiring Rules

AS/NZS 3017 Electrical Installations Testing & Inspection

AS/NZS 3019 Electrical Installation Periodic Verification

AS/NZS 4836 Safe Working on Low Voltage Electrical Systems

AS/NZS 2225 Insulating gloves for electrical

AS/NZS 1742 2010 - MUTCD

AS/NZL 1801 Occupational protective helmets

AS/NZL 1337.1 Personal Eye Protection

AS/NZL 1716 Respiratory Protective Devices

AS/NZL 2210 Safety, protective & occupational footwear

Main Roads Standard Drawings

Main Roads Technical Specifications

Local Government & Council Authority Specification & Drawings

Project Drawings (Issued for Construction)

Project Technical Specification

Integrated Services Senior Mangers

PPE Required

AS/NZL 1801

AS/NZS 1337.1

AS/NZL 1337.1

Hearing

Protection

AS/NZL 1716

AS/NZL 1716

Long sleeve

Cotton Clothing

Hi-Vis

Integrated Services

Min 4121 gloves

Lace-up Ankle

boots

AS/NZL 2210

Fall

Protection

Page 3 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

Integrated Services

Page 4 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

Risk Identification and Risk Matrix

Step 1 Determine the likelihood What is the possibility of the event happening?

Criteria

Description

Almost

Certain

Expected in most situations

Event is a common problem

Likely

Will probable occur in most situations

Event is known to have occurred at

this site or has happened

Possible

Might occur in some situations

Event could occur at the site or Ive

heard of it happening

Unlikely

Could occur in some situations

Event is not likely to occur at the

site or I have not heard of it

happening

Rare

May occur, only in exceptional circumstances

Event is practically impossible

Step 4 Record Risk Score Against the Job Sequence Steps

Score

Action

ACUTE RISK STOP WORK ACT ON THE RISK IMMEDIATELY.

4-A

Will require detailed pre-planning. Safe Work Method Statement

Acute

to be revised, amended and released to work group reflecting

extra control measures implemented

HIGH RISK SENIOR MANAGEMEMENT ATTENTION NEEDED.

3-H

Will require detailed pre-planning. All additional control measures

High

will be recorded on a Safe Work Method Statement

MEDIUME RISK ENSURE ALL SWMS CONTROLS ARE

2-M

IMPLEMENTED PRIOR TO COMENCING WORK

Medium

All additional controls required will be added to the Task Specific

Risk Assessment

LOW RISK CONTINUE WITH WORK ACTIVITY

1-L

Monitor and Review during work activity documenting changing

Low

conditions

Step 2 Determine Consequence What will be the result if it happens?

Example of Detail Description

Identification

No Injuries

Minor

First aid treatment only; spillage contained at site

Moderate

Medical treatment; spillage contained but with help

Major

Extensive injury; loss of production

Catastrophic

Death; toxic release of chemicals

Risk Controls

Step 3 Determine the Risk Score

Likelihood

Insignificant

Almost Certain

2 Medium

Likely

2 Medium

Possible

1 Low

Unlikely

1 Low

Rare

1 Low

Hierarchy of Control

Integrated Services

Minor

3 High

2 Medium

2 Medium

1 Low

1 Low

Moderate

3 High

3 High

2 Medium

2 Medium

1 Low

Major

4 Acute

3 High

3 High

2 Medium

2 Medium

Catastrophic

4 Acute

4 Acute

3 High

3 High

2 Medium

Where elimination of the risk is not reasonably practicable, the Hierarchy of

Control outlines the order in which the hazards are to be controlled. A

combination of controls is often required to minimise the risk to the lowest

level reasonably practicable if no single measure is sufficient for that purpose.

As Low as Reasonably Practicable (ALARP) via the hierarchy of controls

ELIMINATION

SUBSTITUTION

Increase

Effectiveness &

Sustainability

ADMINISTRATION

BEHAVIOUR

PPE

Increase

Participation &

Supervision Need

Page 5 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

Job Sequence Table

Step

What are the Basic

Steps

Pre

Control(s)

Risk Rating

2M

Manual Handling

2M

Plant Topple/fall from heights

Mobilize Workforce

2M

Potential Hazard(s)

Establishment of site

Site/Work set out

including setting up

Traffic Control where

required

Integrated Services

2M

3H

Traffic Accident

Unsecured loads/Falling objects

Inexperienced personnel

entering site and are unaware of

site conditions and related work

hazards

Persons hit by traffic, Damage to

plant, property

Hazard Control(s)

Use correct lifting techniques (Legs bent/Back straight) or

mechanical aids when loading vehicles/trucks

Competent operator to load and unload plant

Maintain three points of contact when entering or exiting plant

Use correctly rated ramps or loading ramp to load and unload

plant

Load and Unload as per operators manual

All drivers shall hold a current license for the type of vehicle they

are driving.

All plant to be restrained in compliance with QLD Transport load

restraint guidelines.

Prestart checklists shall be completed by drivers prior to driving

vehicles.

All equipment, tools and materials in back of Ute and trucks shall

be properly secured.

All staff to complete PC induction prior to coming to site.

All personnel to actively participate in site specific risk assessment

before commencement of works.

All personnel performing specific work to supply licenses.

All site hazards and rules clearly conveyed to new staff on starting

on site.

Pre-start to be attended by all prior to start of shift

Ensure Traffic Management in place where required

All personnel to wear mandatory PPE (Hard Hats, High Vis clothing,

Safety Footwear, Safety Eyewear)

Ensure a Traffic Management Plan is in place

Where required utilize Traffic Control ensuring all controllers are

competent and licenced

If required ensure there is a safety barrier in place (such as

concrete or water filled), and or a shadow vehicle

Ensure pedestrian access ways are kept clear of obstructions at all

times

Person

Risk Rating

Responsible for

Post

Control(s)

Control(s)

All Staff

1L

Operator

1L

PICW

PICW

1L

Staff/Drivers

PICW

1L

All Staff

PICW

2M

All Staff

Page 6 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

2M

2M

Set up plant on

worksite

2M

4A

Integrated Services

Hand/back injuries

Trips, Slips & falls

Trips, Slips & falls

Plant overturning/ equipment

failure

2M

Manual Handling

4A

General Hazards associated

with site works

Wear safety gloves min class 4121 when manual handling

Use correct lifting techniques

Use 2 man lift, mechanical aids where required

Ensure work zone is clear of obstructions and rubbish

PPE (lace up ankle safety boots)

Park vehicles on flat/level ground

When working at night ensure sufficient artificial light is available

Inspect work zone ensuring area is clear of obstructions and

rubbish

Ensure PPE (lace up ankle safety boots) is worn and in good

serviceable condition

Park plant on flat/level ground

When working at night ensure sufficient artificial light is available

Ensure back of EWP /plant is clear of obstructions and surface is

not slippery

Always face EWP when accessing or exiting and use hand rails

Ensure clear path of travel if carrying a ladder

All operators to have current Verification of Competencies

Review Manufacturers Operating Instructions for plant to be used

Ensure plant outriggers are set on solid platform. Exclusion zone

with all unnecessary personnel /public traffic kept from area.

Dunnage under Stabilizers

Level plant/EWP according to manufacturers specifications

Ensure ladders are set up on level stable ground and the head of

the ladder is tied to pole prior to completing any works

Ensure Plant Prestart Checklists completed

Operator to perform function test and complete log prior to using

EWP

Use correct lifting techniques (Legs bent/Back straight)

Use 2 man lift when carrying pole ladder

Job specific pre start must be completed prior to any high risk

work activity

All work crews on site must be inducted

All workers must attend and be signed on to pre - start

All workers are required to be actively involved in hazard, risk

identification & implementing control measures through the Task

Specific Risk Assessment process

PICW

1L

All Staff

PICW

1L

All Staff

PICW

1L

All Staff

PICW

2M

Operator

All Staff

1L

All Staff

2M

Page 7 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

Working Onsite

3H

2M

Operate EWP / Work

off ladder

Integrated Services

2M

Falling Objects

Trips, Slips & falls

Falling from Height

2M

Contact with other structures

4A

Contact with Live Conductors

Traffic Control must be in place where applicable and clear work

zones must be established

All PPE required on this SWMS or Task Specific Risk Assessment

must be used and in be good condition

Work zones & Drop / Exclusion zones to be delineated

Work zones & Drop / Exclusion zones to be delineated

Safety observer to maintain exclusion zone

Work within the confines or directly over the top of the EWP

bucket

Use lanyards on tools when unable to work over the EWP bucket

All personnel to wear mandatory PPE (Hard Hats)

Inspect work zone ensuring area is clear of obstructions and

rubbish

Ensure PPE (lace up ankle safety boots) is worn and in good

serviceable condition

Park plant on flat/level ground

When working at night ensure sufficient artificial light is available

Ensure back of EWP /plant is clear of obstructions and surface is

not slippery

Always face EWP when accessing or Egressing and use hand rails

Ensure clear path of travel if carrying a ladder

EWP to be used by Licenced / Competent Operator

EWP to be set up as per manufactures operators manual

Approved Harness in test to be worn and attached to approved

attachment point in EWP

Ladder to be attached to pole prior to work being completed

3 points of contact to be maintained at all times while working

from a ladder

Safety observer to be competent rescuer

EWP to be set up as per manufactures Specifications

Spotter / Safety observer to be vigilant and ensure plant exclusion

zones/swing radiuss are maintained

Do NOT set up plant directly underneath Over Head power lines

Qualified / Competent Operator

Electrical safety observers in place to stop activity and reassess if

likelihood of encroaching exclusion zones in relation to people,

property or plant

PICW

2M

Operator

PICW

1L

All Staff

PICW

1L

Operator

PICW

Operator

Safety Observer

PICW

Operator

1L

3H

Safety Observer

Page 8 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

DO NOT breach exclusion zones

Use non-conductive hauling line and mechanical aids where

possible

3H

Plant Failure

3H

Falling Objects

4A

Maintenance to

damaged field

equipment

Integrated Services

Contact with Live Parts

2M

Manual Handling

3H

Falling Objects

Review Manufacturers Operating Instructions for plant to be used

Ensure plant is set as per Manufactures Specifications

Ensure ladders are inspected prior to completing any works

Ensure Plant Prestart Checklists completed

Ensure the EWP has regular inspections and scheduled

maintenance carried out

Operator to perform function test and complete log prior to using

EWP

DO NOT operate plant above the maximum wind velocity stated by

the manufacturer

Work zones & Drop / Exclusion zones to be delineated

Rotate Outreach so maintenance is not completed over live

vehicle/pedestrian traffic

Safety observer to maintain exclusion zone

Work within the confines or directly over the top of the EWP

bucket

Use lanyards on tools when unable to work over the EWP bucket

Mandatory PPE to be worn (Hard Hats)

Electrical safety observer shall be in place to stop activity and

reassess if likelihood of encroaching exclusion zones in relation to

people, property or plant

Isolate Traffic Signal Controller at Main Circuit Breaker / Main Fuse

use and prove de-energised

Use appropriate PPE Type O Gloves when proving field circuit is

de energised

Use a 2 man lift to remove any damaged posts/parts off site

Do not over reach when ontop of ladder to relocate/re-allign field

equipment

Work zones & Drop / Exclusion zones to be delineated

Ensure work area is established and there is no one else present in

the work area if removing traffic signal equipment

Safety observer to maintain exclusion zone

2M

PICW

2M

Operator

PICW

Operator

3H

Safety Observer

All Staff

1L

PICW

2M

Operator

Page 9 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

Work within the confines or directly over the top of the EWP

bucket

Use lanyards on tools when unable to work over the EWP bucket

All personnel to wear mandatory PPE (Hard Hats)

4A

Maintenance of Traffic

Signal Cabinet

equipment

Clean up

site/Demobilization

10

Clean up

site/Demobilization

Integrated Services

Contact with Live Parts

2M

Traffic Incident

2M

Ant or Spider Bites

2M

Manual Handling

2M

Traffic Accident

Unsecured loads/Falling objects

Electrical safety observer shall be in place as competent assistant

to oversee works within cabinet

Where required implement SWMS for working live

Use appropriate PPE Gloves when working in lower half of cabinet

and communicate with assistant about what is being done

Ensure Traffic Control is in place and all vehicles have flashing lights

to notify public that there are works in progress

If already onsite co ordinate with Police when switching Traffic

Signal on and Off to minimise risk of incident

Establish clear lines of communication with Traffic Control and or

Police Control when turning intersection back on

Using competent assistant, turn traffic signals back on when traffic

has stopped or is travelling in the same direction

Check work area for spider or Ants

Spray the area with insect spray if ants or spider are found

Ensure long sleeves and long pants are always worn

Use correct lifting techniques (Legs bent/Back straight)or

mechanical aids when loading vehicles/trucks

Use 2 person lift where required

All drivers shall hold a current license for the type of vehicle they

are driving

All plant to be restrained in compliance with QLD Transport load

restraint guidelines

Prestart checklists shall be completed by drivers prior to driving

vehicles

All equipment, tools and materials in back of Ute and trucks shall

be properly secured

PICW

Operator

3H

Safety Observer

All Staff

1L

PICW

1L

Operator

All Staff

1L

Onsite

Supervisor

1L

Staff/Drivers

Page 10 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

EWP basket to be stowed and secured

All ladders to be loaded onto racks and secured / Restrained by

approved straps

Always notify the BTMC that works have been completed

Sign off and Acceptance

By Signing the below you confirm that you have:

Agree to implement control measures as directed

Name

Signature

Date

Integrated Services

Been Provided Opportunity to have input into this

SWMS

Work in a manner which is safe for you and others

Name

Signature

Date

Read and agree with the content of this SWMS

Will stop work immediately if you cant work to this

SWMS Name

Signature

Date

Page 11 of 12

SWMS Traffic Signal Maintenance

HSE-SWMS-018-A

Integrated Services

Page 12 of 12

Das könnte Ihnen auch gefallen

- Company Task Renew Main Mast Equipment: a) Navigation LightDokument17 SeitenCompany Task Renew Main Mast Equipment: a) Navigation LightAbid MujtabaNoch keine Bewertungen

- Risk Assess - 98-Installation Fuel Oil ConditioniDokument4 SeitenRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriNoch keine Bewertungen

- Safe Hoisting and Rigging ProceduresDokument3 SeitenSafe Hoisting and Rigging ProceduresAditya Raj MishraNoch keine Bewertungen

- Pha ExcavationDokument13 SeitenPha ExcavationirshadNoch keine Bewertungen

- Daily HSE ReportDokument5 SeitenDaily HSE ReportSayeed MalikNoch keine Bewertungen

- Skylift ChecklistDokument1 SeiteSkylift ChecklistSUKHVINDERNoch keine Bewertungen

- 6 RA - Template - BROGAN r2Dokument9 Seiten6 RA - Template - BROGAN r2Daniel100% (1)

- How Chin Engineering: Job Safety AnalysisDokument6 SeitenHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Unsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentDokument5 SeitenUnsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentTayyab Hasnain Saadat JanjuaNoch keine Bewertungen

- F-Sp-Hse06-01 Rev 03 Hira NewDokument14 SeitenF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNoch keine Bewertungen

- Permanent Facilities Storage ProtectionDokument2 SeitenPermanent Facilities Storage ProtectionMOHAMMED RIYAN TNoch keine Bewertungen

- H&S Meeting Minutes - TemplateDokument5 SeitenH&S Meeting Minutes - TemplategrantNoch keine Bewertungen

- Machine Guarding Checklist: Questions Requirements For All SafeguardsDokument2 SeitenMachine Guarding Checklist: Questions Requirements For All SafeguardsAVENON MardocheeNoch keine Bewertungen

- Safety Checklist for Hot Work ProcedureDokument1 SeiteSafety Checklist for Hot Work Proceduresafety86Noch keine Bewertungen

- Backfilling and Compaction MVLDokument3 SeitenBackfilling and Compaction MVLLawrence adeleke OmisakinNoch keine Bewertungen

- 12 Ways To Boost Workplace SafetyDokument6 Seiten12 Ways To Boost Workplace Safetymuhammadarifh4486Noch keine Bewertungen

- Job HazardDokument2 SeitenJob HazardBre WirabumiNoch keine Bewertungen

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDokument5 Seiten(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiNoch keine Bewertungen

- Contact NoDokument3 SeitenContact NovictorNoch keine Bewertungen

- PPE Hazard Assessment FormDokument3 SeitenPPE Hazard Assessment FormeastNoch keine Bewertungen

- SWP 003 Pouring ConcreteDokument1 SeiteSWP 003 Pouring ConcreteJICKNoch keine Bewertungen

- 09.00AM to11.00PM Clear: TCE EffwaDokument3 Seiten09.00AM to11.00PM Clear: TCE EffwaAjayNoch keine Bewertungen

- Demoltion Work Risk AssesmentDokument2 SeitenDemoltion Work Risk AssesmentBijin BalakrishnanNoch keine Bewertungen

- Final Risk AssessmentDokument8 SeitenFinal Risk Assessmentapi-514194726Noch keine Bewertungen

- JSA NO 2 Piling WorkDokument6 SeitenJSA NO 2 Piling WorkfadliNoch keine Bewertungen

- Risk Assessment of Trees MaintenanceDokument9 SeitenRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Dokument6 SeitenThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNoch keine Bewertungen

- Safety AlertDokument1 SeiteSafety Alertindrak1978Noch keine Bewertungen

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDokument1 SeiteJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNoch keine Bewertungen

- Behavior Based Safety (BBS) : Emco QatarDokument29 SeitenBehavior Based Safety (BBS) : Emco QatarparthaNoch keine Bewertungen

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Dokument6 SeitenCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDokument168 SeitenAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNoch keine Bewertungen

- JHA Maintenance Tech HVACDokument2 SeitenJHA Maintenance Tech HVACMdavaNoch keine Bewertungen

- Safety Arabtec FormsDokument49 SeitenSafety Arabtec FormsEtibar AliyevNoch keine Bewertungen

- Carpentry Work PDFDokument2 SeitenCarpentry Work PDFcityofdarwingisNoch keine Bewertungen

- Hand-Operated Power Tool SafetyDokument2 SeitenHand-Operated Power Tool SafetySanthoshKumarNoch keine Bewertungen

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDokument4 SeitenJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNoch keine Bewertungen

- Toolbox Training Session - Harness and LanyardDokument3 SeitenToolbox Training Session - Harness and LanyardSarah AjodhaNoch keine Bewertungen

- RA of Chlorination & Disinfection of Domestic Water Supply SystemDokument12 SeitenRA of Chlorination & Disinfection of Domestic Water Supply SystemAhmad Omar50% (2)

- CIVE3707 Risk Assessment Steel Beam LiftingDokument1 SeiteCIVE3707 Risk Assessment Steel Beam LiftingJosh Booth100% (2)

- Lifting Operation BNQDokument2 SeitenLifting Operation BNQsathiamurti100% (1)

- JSA ScaffoldingDokument2 SeitenJSA Scaffoldingmyco samNoch keine Bewertungen

- Construction Job Hazards Analysis: This Is A TEMPLATEDokument1 SeiteConstruction Job Hazards Analysis: This Is A TEMPLATETamNoch keine Bewertungen

- KBR It It Sti InstructionsDokument2 SeitenKBR It It Sti InstructionsbotahraNoch keine Bewertungen

- RA082-C Grinding - ThornliebankDokument2 SeitenRA082-C Grinding - Thornliebankloveson709Noch keine Bewertungen

- Risk Assessment for Office AreasDokument9 SeitenRisk Assessment for Office AreaszulmaulNoch keine Bewertungen

- Warehouse Job Hazard AssessmentDokument2 SeitenWarehouse Job Hazard AssessmentAnonymous cuHV7lTNoch keine Bewertungen

- FINAL Shivani Confined Space PermitDokument1 SeiteFINAL Shivani Confined Space PermitVimal SinghNoch keine Bewertungen

- 003 SWMS - ExcavationDokument11 Seiten003 SWMS - Excavationsasi kumar50% (2)

- Using Hand Drill (WS)Dokument2 SeitenUsing Hand Drill (WS)John KalvinNoch keine Bewertungen

- Office EHS Audit ChecksheetDokument3 SeitenOffice EHS Audit ChecksheetPanbarasan GanapathyNoch keine Bewertungen

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDokument13 SeitenJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNoch keine Bewertungen

- SWMS Bored PilingDokument17 SeitenSWMS Bored PilingnaraNoch keine Bewertungen

- Jacks and Vehicle Stands PDFDokument1 SeiteJacks and Vehicle Stands PDFcityofdarwingisNoch keine Bewertungen

- 023 Ladder UseDokument3 Seiten023 Ladder Useraathi_cdiNoch keine Bewertungen

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDokument1 SeiteScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNoch keine Bewertungen

- Building De-Dusting JSADokument3 SeitenBuilding De-Dusting JSAJayesh J PillaiNoch keine Bewertungen

- Hse-Swms-013-A - Streetlighting Maintenance and Installation DM LightingDokument12 SeitenHse-Swms-013-A - Streetlighting Maintenance and Installation DM Lightingapi-326016071100% (1)

- Collision Avoidance at Sea - Practice and ProblemsDokument10 SeitenCollision Avoidance at Sea - Practice and ProblemsfaumijkNoch keine Bewertungen

- Research Proposal of BRTSDokument8 SeitenResearch Proposal of BRTSAbhilasha SolankiNoch keine Bewertungen

- Metro Bus IslamabadDokument7 SeitenMetro Bus IslamabadMustafeez KhanNoch keine Bewertungen

- Front Office ImportantDokument11 SeitenFront Office ImportantSumit PratapNoch keine Bewertungen

- AREMA MRE 2013 TOC-Vol3 Comm-Trans-HSR PDFDokument2 SeitenAREMA MRE 2013 TOC-Vol3 Comm-Trans-HSR PDFalaajabbarNoch keine Bewertungen

- Delhi Traffic PoliceDokument2 SeitenDelhi Traffic Policeakshgill86Noch keine Bewertungen

- Air Freedom RightsDokument3 SeitenAir Freedom RightsDefit Archila KotoNoch keine Bewertungen

- Website Part 2 Tourist Camp 1Dokument5 SeitenWebsite Part 2 Tourist Camp 1api-142879776Noch keine Bewertungen

- Checks For First Timers AirBus A320Dokument5 SeitenChecks For First Timers AirBus A320Khurram NaseemNoch keine Bewertungen

- Urban Transit Systems and Technology. Vukan R. VuchicDokument29 SeitenUrban Transit Systems and Technology. Vukan R. VuchicGANESHANoch keine Bewertungen

- 2017 Fdot July Ebook PDFDokument1.226 Seiten2017 Fdot July Ebook PDFDamen JohnsonNoch keine Bewertungen

- Fs Flying School ManualDokument78 SeitenFs Flying School ManualJonathan TooleNoch keine Bewertungen

- Historical Roads Preservation GuideDokument86 SeitenHistorical Roads Preservation GuideCAP History LibraryNoch keine Bewertungen

- Faa Ac 150/5300-13aDokument290 SeitenFaa Ac 150/5300-13apirula12345Noch keine Bewertungen

- Oman Driving LicenseDokument16 SeitenOman Driving LicenseswelitshhNoch keine Bewertungen

- CEHWRD330: Transportation Engineering FundamentalsDokument48 SeitenCEHWRD330: Transportation Engineering FundamentalsMikealla DavidNoch keine Bewertungen

- Major Causes of Road Accidents and Remedial MeasuresDokument4 SeitenMajor Causes of Road Accidents and Remedial Measurespuivgi2012Noch keine Bewertungen

- Overview Selected Proposals - FINALDokument11 SeitenOverview Selected Proposals - FINALStefano Bbc RossiNoch keine Bewertungen

- 1090 Interference Study Final Report v26Dokument82 Seiten1090 Interference Study Final Report v26standapNoch keine Bewertungen

- 6 Traffic Analysis TechniquesDokument77 Seiten6 Traffic Analysis TechniquesRenalyn AndradeNoch keine Bewertungen

- PHAK - Chapter 14Dokument10 SeitenPHAK - Chapter 14mvwe1947Noch keine Bewertungen

- From Atob: Sample PagesDokument10 SeitenFrom Atob: Sample PagesFaqət MaqsudovaNoch keine Bewertungen

- Valley Line West LRT - March 13, 2018Dokument11 SeitenValley Line West LRT - March 13, 2018Anonymous TdomnV9OD4Noch keine Bewertungen

- MoHUA NMTGuidanceFINAL PDFDokument190 SeitenMoHUA NMTGuidanceFINAL PDFchharingNoch keine Bewertungen

- Review of Progress of NHAI Works in Gujarat State byDokument67 SeitenReview of Progress of NHAI Works in Gujarat State byavishek1527Noch keine Bewertungen

- Aerodrome ManualDokument128 SeitenAerodrome ManualNanda Win Lwin100% (2)

- TIA Taman Melawati Final 05122011Dokument50 SeitenTIA Taman Melawati Final 05122011Fatin AminzalNoch keine Bewertungen

- APTA 2022 Public Transportation Fact BookDokument52 SeitenAPTA 2022 Public Transportation Fact BookFernando ZinglerNoch keine Bewertungen

- Types of Road Intersection and InterchangeDokument5 SeitenTypes of Road Intersection and InterchangehungrynomadphNoch keine Bewertungen

- C 2-Traffic StudiesDokument82 SeitenC 2-Traffic StudiesPraz AarashNoch keine Bewertungen