Beruflich Dokumente

Kultur Dokumente

Design Considerations Kalsan II

Hochgeladen von

Engr Amir Jamal QureshiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Considerations Kalsan II

Hochgeladen von

Engr Amir Jamal QureshiCopyright:

Verfügbare Formate

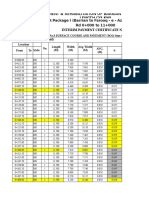

WATSAN

Operational Team

KALSAN-II

Drinking Water Supply Scheme:

U/C SACHAN

STAND POST

(1.5' X 1.5'X 2.25')

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

Breadth

in ft

Depth/Ht

in ft

No of

Units

Pad

4.50

4.50

1.00

1.00

20.25

Cft

stand post

0.75

0.42

1.00

1.00

0.32

Cft

dispose off drain

5.41

1.00

1.00

1.00

5.41

Cft

25.98

Cft

Pad

4.50

4.50

0.33

1.00

6.68

Cft

stand post

0.75

0.42

0.33

1.00

0.10

Cft

dispose off drain

5.41

1.00

0.33

1.00

1.79

Cft

Sand

(cft)

Gravel/

Crush

(cft)

Shingle

Unskilled

Labour

Men-days Men-days

0.57

8.57

Cft

8.57

0.13

P/L PCC (1:4:8)

Pad

4.50

4.50

0.33

1.00

6.68

Cft

stand post

0.75

0.42

0.33

1.00

0.10

Cft

dispose off drain

5.41

1.00

0.33

1.00

1.79

Cft

8.57

Cft

Total

4

Cement

(Bags)

Shingle bed

Total

3

Unit

Excavation (gravelly soil)

Total

2

Quantity

Labour

Skilled

Labour

0.90

4.50

9.00

0.27

0.97

2.60

6.50

13.00

0.39

1.42

0.20

0.40

0.86

3.49

P/L PCC (1:2:4)

Pad

4.00

4.00

0.33

1.00

5.28

Cft

stand post

0.75

0.75

3.42

1.00

1.92

Cft

dispose off drain

6.00

1.00

0.58

1.00

3.48

Cft

pad boundary projection Lond side

4.50

0.25

0.58

2.00

1.31

Cft

Short sides (stand post side)

3.25

0.25

0.48

1.00

0.39

Cft

(Drain side)

3.00

0.25

0.48

1.00

0.36

Cft

1.00

1.00

0.50

1.00

0.50

Cft

13.24

Cft

Seat pad

Total

deduct for drain flow

Net Total

6.00

0.33

0.33

1.00

0.65

Cft

12.59

Cft

GI Pipe 1/2 " dia

10.00

Rft

GI Socket 1/2" dia

No.

GI Elbow 1/2 " dia

No.

Brass tap 1/2"

No.

Quantities for 1 Stand Post

CRS-Mansehra

3.50

24

11.00

22.00

8.57

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Quantities for 6 Stand Posts

CRS-Mansehra

21.00

24

66.00

132.00

51.43

5.14

20.94

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

KALSAN-II

Drinking Water Supply Scheme:

U/C SACHAN

VALVE CHAMBER

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

Breadth

in ft

Depth/Ht

in ft

No of

Units

Quantity

Unit

Excavation (gravelly soil)

4.00

4.00

2.50

1.00

40.00

Cft

P/L PCC (1:4:8) as in Foundation

4.00

4.00

0.25

1.00

4.00

Cft

Stone Masonry in (1:3) CSM

Long Wall

3.50

1.00

2.25

2.00

15.75

Cft

Short Wall

1.50

1.00

2.25

2.00

6.75

Cft

22.50

Cft

30% (1:3) CSM

6.75

Cft

Stone

15.75

Cft

Total

PCC (1:2:4) as coping

5

6

Sand

(cft)

0.50

1.87

2.50

4.00

Cft

Long Wall

3.50

1.00

0.16

2.00

1.12

Cft

Short Wall

1.50

1.00

0.16

2.00

0.48

Cft

1.60

Cft

0.20

1.00

13.50

Sft

0.23

0.84

2.25

Sft

2.79

11.34

1.50

1.50

2.25

4.00

Quantities for 1 Valve Chamber

23

Unskilled

Labour

Men-days Men-days

5.00

0.12

0.45

0.90

2.03

0.05

0.18

0.18

0.27

15.75

1.00

Stone

(cft)

7.00

0.25

1.50

Gravel/

Crush

(cft)

Labour

Skilled

Labour

0.88

4.00

P/L Plaster 3/4" thick in (1:3) CSM

Steel Man hole cover 1.5'x1.5' (16

Guage sheet)

CRS-Mansehra

Cement

(Bags)

4.00

Total

(1.5' X 1.5'X 2.25')

2.00

0.06

7.00

15.75

1.31

3.81

Engr. Amir Jamal Qureshi

WATSAN

Opertaional Team

KALSAN- II

Drinking Water Supply Scheme:

U/C SACHAN

SOURCE TANK

(4' X 4'X 3')

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

Breadth

in ft

Depth/Ht

in ft

No of

Units

Quantity

Unit

Excavation (in hard soil)

7.00

7.00

1.50

1.00

73.50

Cft

P/L PCC (1:4:8) as in Foundation

7.00

7.00

0.50

1.00

24.50

Cft

Stone Masonry in (1:3) CSM

Long Wall

7.00

1.50

3.50

2.00

73.50

Cft

Short Wall

2.00

4.00

3.50

2.00

56.00

Cft

129.50

Cft

30% (1:3) CSM

38.85

Cft

Stone

90.65

Cft

1.00

4.00

Cft

Total

P/L PCC (1:2:4) as in Bed

4.00

Vertical Reinforcement in walls

P/L Plaster 3/4" thick in (1:3) CSM

Stone

(cft)

Labour

Steel

#3 bars

(kg)

Binding

wire (kg)

Skilled

Labour

Unskilled

Labour

Men-days Men-days

2.28

2.50

12.50

10.67

40.00

0.50

2.50

25.00

0.76

2.77

5.18

11.66

0.12

0.45

90.65

0.25

20.00

45.50

kg

4.00

3.50

4.00

56.00

Sft

0.93

3.50

0.73

1.12

P/L Pointing 3/4" in (1:2) CSM

7.00

2.25

4.00

63.00

Sft

0.16

0.39

1.13

1.76

P/L RCC (1:2:4) as in Slab

7.56

7.50

0.33

1.00

18.71

Cft

4.00

10.00

0.88

1.78

Decuction for man hole cover

2.00

2.00

0.33

1.00

1.32

Cft

17.39

Cft

7.50

Net Total

8.2

Sand

(cft)

Steel

#4 bars

(kg)

4.00

(#4 @ 12" c/c all around)

8.1

Cement

(Bags)

Gravel/

Crush

(cft)

5.00

50.00

1.37

20.00

0.46

Steel

(#3 @ 6" c/c as main steel)

7.56

15.00

19.30

kg

(#3 @ 9" c/c as temp. steel)

7.50

10.00

12.80

kg

32.10

kg

18.71

Cft

Total

9

Centring and shuttring

7.56

10

Binding wire

2.33

kg

11

GI strainer 2" dia

3.00

12

GI Over flow pipe 1.5" dia

6.00

13

GI wash out pipe 1" dia

5.00

14

GI Plug 1"

1.00

No

15

Steel Man hole cover (2'x2')

4.00

Sft

2.00

7.50

2.00

0.33

1.00

38.00

0.32

0.37

0.19

Rft

0.06

0.12

Rft

0.12

0.24

Rft

0.10

0.20

0.10

Quantities for 1 Source Tank

CRS-Mnasehra

0.32

18.76

20

68.89

50.00

90.65

50.00

38.00

1.69

9.56

23.34

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Drinking Water Supply Scheme:

KALSAN-II

ROOF SLAB DESIGN (1500 Gallon Tank)

fc =

compressive strength of concrete= =

3 ksi

Yield Strength of steel

fy

Max. steel ratio

g pcc =

g Steel=

Specific weight of PCC

Specific weight of steel

Long span = L =

10 ft

Short span =W=

10 ft

Wall thickness=

1.5 ft

50 ksi

max =

U/C SACHAN

0.021

0.15 k/cft

490 lb/cft

Design depth of slab, effective depths and design effective lengths

clear

clear

Perime

span

span

ter P

along along W

(ft)

L (ft)

(ft)

6.5

6.5

40

hmin

(in)

Proposed

h (in)

2.67

Effective

depths

(in)

Design Le

wall

(ft)

(ft)

thickn Clear lengths Le

along L

along W along along

along along ess

L

W

(ft)

L

W

(1)

(2)

(1)

(2)

2.5

3

1.5

8 6.71

8

6.75

8

8

Ultimate Load and ultimate moment

depth h

(ft)

0.33

self wt./ft

(k/ft)

0.0495

Ult. Load Ultimate moments Mu

(k-in)

Wu

(k/ft)

along L

along W

0.0693

4.44

4.44

Design Steel Areas per 1 ft span of slab (b=12")

Asmin =

0.002bh =

Along Short span (main steel)

Asmax =

bd =

max

As

(sq.in)

0.096

a

(in)

0.16

a/2

(in)

0.08

(d-a/2) Design moment Md

(in)

(k-in)

2.92

12.61

Along Long span (transverse steel)

Asmax =

As

(sq.in)

0.096

a

(in)

0.16

max

a/2

(in)

0.08

0.096 sq.in

d=

3 in

0.742 sq.in

d=

W=

Proposed

Remarks

Greater than Mu=4.44 k-in

Proposed

2.5 in

bd =

0.618 sq.in

(d-a/2) Design moment Md

(in)

(k-in)

2.42

10.45

Rebar sizes and spacings

Along Short span (main steel)

Remarks

Greater than Mu=4.44 k-in

10 ft

Bar length

#

length

#

bars

of

As

Area of bar Ab # bars in propo in full bars

(sq.in) Bar No.

(sq.in)

1ft span

sed span

(ft)

0.096

0.096

3

4

0.11

0.196

0.9

0.5

Along Long span (transverse steel)

2

1

L=

20

10

0.096

0.096

3

4

0.11

0.196

0.9

0.5

2

1

Total steel (#3 bars) required

CRS- Mansehra

20

10

=

34

30

Bar length=

#

length

#

bars

of

As

Area of bar Ab # bars in propo in full bars

(sq.in) Bar No.

(sq.in)

1ft span

sed span

(ft)

10 ft

wt. of

steel

(kg)

200

100

10 ft

wt. of

steel

(kg)

200

100

34

30

= L

Remarks

Proposed

bars @ 6" c/c)

10 ft

(#3

= W

Remarks

Proposed

bars @ 6" c/c)

(#3

68 kg

17

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

SAY

CRS- Mansehra

75 kg

17

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

KALSAN- II

Drinking Water Supply Scheme:

U/C SACHAN

STORAGE TANK:

1500 US GALLONS

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

Excavation (gravelly soil, not

requiring blasting)

Long Wall

Short Wall

Plinth/Apron

shingle bed

10.67

6.67

10.17

6.7

Breadth

in ft

2

2

3

6.1

Depth/Ht

in ft

1

1

0.5

0.5

No of

Units

2

2

1

1

Total

Quantity

Unit

42.68

26.68

15.26

20.44

105.05

Cft

Cft

Cft

Cft

Cft

Cement

(Bags)

Sand

(cft)

Gravel/

Crush

(cft)

Stone

(cft)

Shingle

(cft)

Labour

Steel

#3 Steel

#4

bars (kg) bars (kg)

Binding

Wire

(kg)

Skilled

Labour

Unskilled

Labour

Men-days

Men-days

2.31

Shingle as in Bed

6.67

6.67

0.5

22.24

Cft

P/L PCC (1:4:8) as in Foundation

Long Wall

Short Wall

Plinth/Apron

Bed

Total

10.67

6.67

10.17

7.17

2

2

3

7.17

0.5

0.5

0.5

0.5

2

2

1

1

21.34

13.34

15.26

25.70

75.64

Cft

Cft

Cft

Cft

Cft

7.50

37.50

75.00

2.34

8.55

P/L PCC (1:2:4) as in Bed

7.17

7.17

0.25

12.85

Cft

2.60

6.50

13.00

0.40

1.45

10.17

7.17

1.5

1.5

1

1

2

2

30.51

21.51

52.02

cft

cft

cft

10.40

26.00

52.00

2.44

4.94

60.60

30.60

52.02

kg

kg

Cft

1.04

0.61

0.31

0.52

190.69

134.44

325.13

34.34

290.79

87.24

203.55

Cft

Cft

Cft

Cft

Cft

Cft

Cft

11.63

26.17

36

122.80

kg

2

2

10.07

7.10

17.17

cft

cft

cft

20.60

11.90

kg

kg

5

Ring Beam (18"X12")

5.1 RCC (1:2:4)

Long sides

Short sides

Total

22.24

0.33

5.2 Steel

Main steel (4, #4 bars)

Shear stirrups (#3@ 12" c/c)

5.3 Centring and shuttering

6

CR Stone Masonry in (1:6) CSM

Long Wall

Short Wall

200

4.5

17.34

1.5

40

2

10.17

7.17

1.5

1.5

6.25

6.25

2

2

Total

Deduct for 2 seismic bands

Net Total

30% (1:6) CSM

Stone

7

Vertical Reinforcement in walls

(#4 @ 12" c/c all around)

11.25

8

Seismic Bands

8.1 @ 2' from top of ring beam

8.11 RCC (1:2:4)

Long sides

short sides

10.17

7.17

1.5

1.5

0.33

0.33

Total

70.00

35.00

10.67

0.61

0.31

80.00

203.55

130.00

3.60

9.00

1.23

18.00

1.23

0.81

1.63

8.12 Steel

Main steel (2,#4) bars

Shear stirrups(#3 @ 12"c/c)

CRS-Mansehra

68

1.75

40

27.00

15.00

21/22

0.21

0.12

0.21

0.12

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Detail of Materials

Detail of Quantities

Sub

Head

No

Description

Length

in ft

corner reinforcement (1,#4 bar 2'

ovelap with main steel at each

corner)

8.2 @ 2' from top of 1st seismic band

8.21 RCC (1:2:4)

Long wall

short wall

Total

8.22 Steel

Main steel (2,#4) bars

Shear stirrups(#3 @ 12"c/c)

corner reinforcement (1,#4 bar 2'

ovelap with main steel at each

corner)

Breadth

in ft

Depth/Ht

in ft

5.25

10.17

7.17

1.5

1.5

0.33

0.33

No of

Units

Quantity

Unit

6.40

kg

2

2

10.07

7.10

17.17

cft

cft

cft

68

1.75

40

20.60

11.90

kg

kg

5.25

6.40

kg

Cement

(Bags)

Sand

(cft)

Gravel/

Crush

(cft)

Stone

(cft)

Shingle

(cft)

Labour

Steel

#3 Steel

#4

bars (kg) bars (kg)

10.00

3.60

9.00

Binding

Wire

(kg)

Skilled

Labour

Unskilled

Labour

Men-days

Men-days

0.06

18.00

0.06

0.81

1.63

27.00

0.21

0.12

0.21

0.12

10.00

0.06

0.06

15.00

9.1 RCC (1:2:4) as in core wall

Long wall

7.17

0.33

5.5

26.03

cft

Short wall

6.5

0.33

5.5

23.60

cft

49.63

cft

67.40

kg

Total

9.2 Steel

Horizontal(#3 @6"c/c)

Vertical (#3 @6"c/c)

44

52

Total

11

70.80

kg

138.20

kg

Pointing (0.75") in (1:2) CSM

10.17

5.58

226.99

Sft

12.1 P/L RCC (1:2:4) as in Slab

Decuction for manhole cover

10.67

2

10.67

2

0.333

0.333

1

1

37.91

1.33

36.58

68.00

37.91

12

6

1

4.00

Cft

Cft

Cft

kg

Cft

Rft

Rft

No.

Sft

Net Total

Steel (#3 @ 6" c/c) (as per detail)

12.2 Centring and shuttering

13 GI over flow pipe 1.5" dia.

14 GI wash out pipe 1.5" dia

15 GI Plug 1.5 "

16 Steel man hole cover (2'x2')

10.67

10.67

0.333

10.00

50.00

2.33

130.00

0.57

1.42

7.40

18.50

1.38

37.00

75.00

Quantities for 1 Tank

CRS-Mansehra

25.00

56.33

21/22

212.92

263.00

203.55

22.24

270.00

1.38

4.09

6.36

1.72

0.76

0.24

0.12

3.48

0.75

0.38

0.48

0.24

28.73

68.23

0.68

274.00

4.98

4.71

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Hydraulic Statement of DWSS Kalsan 2

S.NO

Length of

Name of Line pipe

in

" ft "

Sector

Zone

Projected

Popolation

(persons)

Design Q in

US GAL

Proposed dia Velocity in

Head

of G.I pipe in

" Loss per

" inches"

ft/sec "

1000 ft

Total

Head

Losss

Hydraulic Grade

U/End

L/End

Ground

Level

Terminal

Pressrure in

ft of water

Supply Main

1

ST1--WST

4200

All

All

257

2.14

0.75

1.51

29.10

122.22

5750

5627.78

5558

69.8

Distribution NetWork

1

WST--1

100

108

1.35

0.75

1.20

19.30

1.93

5558

5556.07

5500

56.1

1--2

20

28

0.35

0.5

0.53

5.82

0.12

5556.1

5556

5500

56.0

1--3

2250

81

1.01

0.5

1.03

21.00

47.25

5556.1 5508.85

5450

58.9

WST--4

20

108

1.35

0.75

0.90

11.30

0.23

5557.77

5550

7.8

4--5

320

14

0.18

0.5

0.53

5.82

1.86

5557.8 5555.94

5535

20.9

4--6

800

95

1.19

0.75

0.90

11.30

9.04

5555.9 5546.86

5425

121.9

6--7

500

20

0.25

0.5

1.05

21.00

10.50

5546.9

5536.4

5450

86.4

6--8

500

81

1.01

0.75

0.90

11.30

5.65

5546.9 5541.25

5420

121.3

ST2--9

400

41

0.51

0.5

0.52

5.80

2.32

5451

91.7

5558

5545

5542.68

Peaking Factor 1.5

CRS-Mansehra

19

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

Remarks

Proposed

Proposed

Proposed

Proposed

Proposed

Proposed

Proposed

Proposed

Proposed

Proposed

CRS-Mansehra

19

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

DRINKING WATER SUPPLY SCHEME

KALSAN-II

U/C SACHAN

DESIGN CRITERIA

DESIGN PERIOD

Design Period

20 years

DESIGN POPULATION

No. of persons/H.H for present population

Design growth rate

=

=

7.5

3%

Design growth rate factor G.R.F

1.8

SECTOR NO. 1

Sr. # Zone Name

# of persons/

H.Hs H.H

1 ZONE 1

Present population

(July 2006)

Persons

G.R.F

7.5

60

0

TOTAL

1.8

60

Design

population

(July 2026)

Persons

108

0

108

SECTOR NO. 2

Sr. # Zone Name

1 ZONE 2

# of persons/

H.Hs H.H

8

7.5

Present population

(July 2006)

Persons

G.R.F

60

1.8

TOTAL

60

Design

population

(July 2026)

Persons

108

108

SECTOR NO. 3

Sr. # Zone Name

1 ZONE 3

TOTAL

# of persons/

H.Hs H.H

3

7.5

TOTAL DESIGN POPULATION =

Present population

(July 2006)

G.R.F

Persons

23

1.8

257

Design

population

(July 2026)

Persons

41

41

Persons

DESIGN WATER DEMAND

Water requirement of design population @ 10 gpcd =

2570 GPD (Imp)

2.14 GPM (US)

Additional water requirement

1 Schools

NO.

# students in 2006

1

20

# students in

2026

36

taking half as

outsiders

18

TOTAL

1 Mosques

NO.

1

CRS-Mansehra

Population in 2026

257

# attending

mosques (10%)

25.7

15/16

Daily req. @ 2.5

gpcd GPD (Imp)

45

45

Daily req. @ 3

gpcd GPD (Imp)

77.1

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

TOTAL

2 Animals

Large animals

Small animals

No.

No.

# in 2006

9

# in 2006

2

Total additional water requirements =

# in

2026

14

daily

requirement @

12 GPD (Imp)

168

# in

2026

3

daily

requirement @ 6

GPD (Imp)

18

231

GPD (Imp)

0.19

GPM (US)

Design Water Demand of community =

FLOWS AND CONSUMPTIONS

Safe Yield of source(s)

=

Design water consumption =

2.33

3.17

GPM (US)

2.33

GPM (US)

MAIN STORAGE TANK CAPACITY

Design water consumption of community =

2.33

77.1

GPM (US)

OK

GPM (US)

Total water storage per day =

3355

GPD (US)

3355 GALLONS (US)

Taking half day storage,

Design capacity of tank =

1678 GALLONS (US)

PROPOSED

CRS-Mansehra

MAIN STORAGE TANK

1500 GALLONS (US) CAPACITY

15/16

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

DRINKING WATER SUPPLY SCHEME

KALSAN-II

U/C

SACHAN

TRANSPORTATION COST

TRANSPORTATION COST UP TO NEAREST ROAD SITE

Total

quantity Unit Transp. Rate (PKR)

Sr.#

Item Description

1 Cement

99

Bags

75

per bag

2 Sand

359

cft

0

per cft

3 Gravel

452

cft

25

per cft

4 Shingle

74

cft

25

per cft

5 Steel & Binding wire

642

kg

5

per kg

6 Stone

310

cft

25

per cft

7 Pipe materials

1

LS

5500

per job

8 Steel manhole cover

3

No.

150

per No.

TOTAL

7 % of Total Cost

Amount

Amount

(PKR)

(USD)

7425

123.8

0

0

11300

188.3

1850

30.8

3210

53.5

7750

129.2

5500

91.7

450

7.5

37485

0 % of Total Cost

Amount

Amount

(PKR)

(USD)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

TRANSPORTATION COST OF DONKEY CARRIAGE

Total

Sr.#

Item Description

quantity Unit Transp. Rate (PKR)

1 Cement

99

Bags

per bag

2 Sand

359

cft

per cft

3 Gravel

452

cft

per cft

4 Shingle

74

cft

per kg

5 Steel & Binding wire

642

kg

per cft

6 Stone

310

cft

per cft

7 Pipe materials

1

LS

per job

8 Steel manhole cover

3

No.

per No.

TOTAL

0 % of Total Cost

Amount

Amount

(PKR)

(USD)

0

0

0

0

0

0

0

0

0

0

0

0

TRANSPORTATION COST OF MANUAL CARRIAGE

Total

Sr.#

Item Description

quantity Unit Transp. Rate (PKR)

1 Cement

99

Bags

50

per bag

2 Sand

359

cft

50

per cft

3 Gravel

452

cft

50

per cft

4 Shingle

74

cft

50

per cft

5 Steel & Binding wire

642

kg

5

per kg

6 Stone

310

cft

50

per cft

14 % of Total Cost

Amount

Amount

(PKR)

(USD)

4950

82.5

17950

299.2

22600

376.7

3700

61.7

3210

53.5

15500

258.3

7 Pipe materials

8 Steel manhole cover

1

3

LS

No.

5000

80

per job

per No.

TOTAL

TOTAL TRANSPORTATION COST OF DWSS KALSAN-I

CRS-Mansehra

14

will be arranged locally

from Ichrian by trolly

from Ichrian by trolly

from Sachan by trolly

624.75

TRANSPORTATION COST OF JEEPABLE CARRIAGE

Total

quantity Unit Transp. Rate (PKR)

Sr.#

Item Description

1 Cement

99

Bags

per bag

2 Sand

359

cft

per cft

3 Gravel

452

cft

per cft

4 Shingle

74

cft

per kg

5 Steel & Binding wire

642

kg

per cft

6 Stone

310

cft

per cft

7 Pipe materials

1

LS

per job

8 Steel manhole cover

3

No.

per No.

TOTAL

0

0

Remarks

Remarks

Remarks

0

0

5000

240

83.3

4

73150

1219.1667

110,635.00

1,843.92

Remarks

5 trips per day each 1cft

5 trips per day each 1cft

5 trips per day each 1cft

5 trips per day each 1cft

5 trips per day each 1cft

21

% of Total Cost

Amir Jamal Qureshi

WATSAN

Operational Team

KALSAN-II U/C

FITTINGS AND FIXTURES' DETAIL

SACHAN

DRINKING WATER SUPLLY SCHEME

NEW INSTALLATION

Sr

#

Item Description

1 Sockets 3/4"

Sockets1.5"

2 (wash out main tank)

3 Unions 3/4"

4 Ball valve 3/4"

5 GI Elbows 3/4" ( 90 deg)

6 GI Elbows 1.5" ( 90 deg)

7 GI T 2"-3/4"(source tank)

1

2

3

4

5

6

Sr

#

Sockets 3/4"

Unions 3/4"

Sockets 1/2"

Unions 1/2"

GI T's (3/4"-1/2")

Ball valve 3/4"(out let)

Item Description

1 GI pipe 1/2" dia

2 GI Elbows 0.5"(90 deg)

3 Sockets 1/2"

4 Brass Taps 1/2"

Total length

(RFt)

Total

Qty

(No.)

SAY

(No.)

Unit cost

(PKR)

Total Cost

(PKR)

193

17

3284

45

90

42

2

2

2

1

DISTRIBUTION SYSTEM

1420

4

57

1420

1

14

1500

4

60

1500

1

15

4

48

3

3

3

2

56

204

21

62

122

2705

612

63

186

244

65

16

69

17

7

1

17

56

13

45

26

204

1110

914

897

776

182

204

4200

Qty/100

Rft (No.)

SUPPLY MAIN

4

168

4200

TAP STANDS

Qty/tap

Total

Total Tap

SAY Unit cost

stand

Qty

stands

(NO.)

(PKR)

(No.)

(No.)

6

10

60

80

32.75

6

2

12

15

13

6

1

6

8

13

6

1

6

8

85

TOTAL COST FOR FITTINGS AND FIXTURES

Total Cost

(PKR)

2620

195

104

680

14,867

ACCESSORIES' DETAIL

Location

Quantity

1 GI strainer 2" dia

source tank

RFt

Unit

cost

(PKR)

132.65

2 GI Over flow pipe 1.5" dia

source tank

RFt

93.9

563

3 GI wash out pipe 1" dia

source tank

RFt

62.35

312

No.

30

30

12

RFt

93.9

1127

main tank

wash out main

tank

Source tank,

main tank

RFt

93.9

563

No.

45

45

No.

600

1200

Valve chamber

No.

350

350

Sr

#

Item Description

GI Plug 1"

4 GI Over flow pipe 1.5" dia

5 GI wash out pipe 1.5" dia

6 GI Plug 1.5"

Steel Man hole cover

7 (2'x2')

Steel Man hole cover

8 (1.5'x1.5')

9 Barbed wire

CRS-Mansehra

wash out

source tank

main tank

unit

source tank

100

Ft

3.35

TOTAL COST FOR ACCESSORIES

25

Total Cost (PKR)

398

335

4,923

Engr. Amir Jamal Qureshi

WATSAN

Operational Team

KALSAN-II

DRINKING WATER SUPPLY SCHEME

U/C

SACHAN

SUMMARY OF OVER ALL PROJECT COST

MATERIAL COST

Sr.#

A

1

2

3

4

5

6

7

8

Item Description

Quantity

CIVIL WORKS

Cement

99

Sand

359

Gravel

452

Shingle

74

Stone

310

Steel (#4 bars)

324

Steel (#3 bars)

308

Steel Binding wire

7

SUB TOTAL - A

Unit

Unit

Amount Amount

Rate

(PKR)

(USD)

(PKR)

Bags

cft

cft

cft

cft

kg

kg

kg

370

36630

0

0

0

0

15552

14784

336

67,302

610.5

0

0

0

0

259.2

246.4

5.6

1,122

3900

Rft

42.9

167310

2789

1420

Rft

42.9

60918

1015

32.75

25873

431

14867

11288

14,867

4,923

273,892

341,194

248

82

4,565

5,687

48

48

48

Remarks

PIPE WORKS

1 Supply main

3/4" dia

2 Distribution mains

3/4" dia

1/2" dia

790

Rft

Fitting & fixtures

3 (as per detail)

1

L.S.

4 Accessories (as per detail)

1

L.S.

SUB TOTAL- B

SUB TOTAL MATERIAL COST

300 Rft is already installed

(excluding this)

2700 Rft is already installed

(excluding this)

TRANSPORTATION COST

Sr.#

1

2

3

4

5

6

7

8

Item Description

Cement

Sand

Gravel

Shingle

Steel & Binding wire

Stone

Pipe materials etc

steel manhole covers

Donkey Manual

up to nearest road

Jeepable

carriage carriage

site (PKR)

carriage (PKR) (PKR)

(PKR)

7425

0

0

4950

0

0

0

17950

11300

0

0

22600

1850

0

0

3700

3210

0

0

3210

7750

0

0

15500

5500

0

0

5000

450

0

0

240

SUB TOTAL TRANSPORTATION COST

Total

Amount

(PKR)

12375

17950

33900

5550

6420

23250

10500

690

Amount

(USD)

206

299

565

93

107

388

175

12

110,635

1,845

LABOR COST

Sr.#

Category

Quantity

unit

1 Unskilled Labor

118

man-days

2 Skilled Labour

46

man-days

3 Plumber

68

man-days

SUB TOTAL LABOR COST

Rate Amount Amount

(PKR) (PKR)

(USD)

250

29500

492

450

20700

345

450

30600

510

80,800

1,347

6

4

6

15

Remarks

% of Total Cost

% of Total Cost

% of Total Cost

% of Total Cost

TOTAL COST

PKR

532,629

USD

8,877

CONTINGENCIES CHARGES @2.5% OF TOTAL COST

PKR

13,316

USD

222

GRAND TOTAL

PKR

545,945

USD

9,099

CRS-Mansehra

13

Engr. Amir Jamal Qureshi

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Letter To Consultants For Mobilization at SiteDokument2 SeitenLetter To Consultants For Mobilization at SiteEngr Amir Jamal Qureshi57% (7)

- Oil Tanker Construction RulesDokument84 SeitenOil Tanker Construction Rulessasikumarmarine100% (4)

- Plan and Profile STA. 04+550 TO STA. 04+900Dokument1 SeitePlan and Profile STA. 04+550 TO STA. 04+900Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 04+200 TO STA. 04+550Dokument1 SeitePlan and Profile STA. 04+200 TO STA. 04+550Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 03+150 TO STA. 03+500Dokument1 SeitePlan and Profile STA. 03+150 TO STA. 03+500Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 03+850 TO STA. 04+200Dokument1 SeitePlan and Profile STA. 03+850 TO STA. 04+200Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 03+150 TO STA. 03+500Dokument1 SeitePlan and Profile STA. 03+150 TO STA. 03+500Engr Amir Jamal QureshiNoch keine Bewertungen

- ABOpp 13b PDFDokument1 SeiteABOpp 13b PDFEngr Amir Jamal QureshiNoch keine Bewertungen

- BR-,3a.dwg A3Dokument1 SeiteBR-,3a.dwg A3Engr Amir Jamal QureshiNoch keine Bewertungen

- Abopp 9Dokument1 SeiteAbopp 9Engr Amir Jamal QureshiNoch keine Bewertungen

- Slab, Diaphragm and Exp JT D PDFDokument1 SeiteSlab, Diaphragm and Exp JT D PDFEngr Amir Jamal QureshiNoch keine Bewertungen

- BR-R 000.Dwg Layout1Dokument1 SeiteBR-R 000.Dwg Layout1Engr Amir Jamal QureshiNoch keine Bewertungen

- Plan and Profile STA. 04+450 TO STA. 04+800Dokument1 SeitePlan and Profile STA. 04+450 TO STA. 04+800Engr Amir Jamal QureshiNoch keine Bewertungen

- General Arragement - DWG LayoDokument1 SeiteGeneral Arragement - DWG LayoEngr Amir Jamal QureshiNoch keine Bewertungen

- Summary of The Chief Minister KPK DraftDokument2 SeitenSummary of The Chief Minister KPK DraftEngr Amir Jamal Qureshi100% (1)

- Typical Cross Section For Cut and Fill Area: Annex 2 - 2Dokument3 SeitenTypical Cross Section For Cut and Fill Area: Annex 2 - 2Engr Amir Jamal QureshiNoch keine Bewertungen

- Asphaltic Wearing Course Calculation Sheet PK-1Dokument52 SeitenAsphaltic Wearing Course Calculation Sheet PK-1Engr Amir Jamal QureshiNoch keine Bewertungen

- HARI PUR BYPASS Alignment With DetailsDokument1 SeiteHARI PUR BYPASS Alignment With DetailsEngr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 3Dokument1 SeiteLocation Map Thanidani Nathiagali 3Engr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 2Dokument1 SeiteLocation Map Thanidani Nathiagali 2Engr Amir Jamal QureshiNoch keine Bewertungen

- Bridges Progress-May 2016Dokument3 SeitenBridges Progress-May 2016Engr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 1Dokument1 SeiteLocation Map Thanidani Nathiagali 1Engr Amir Jamal QureshiNoch keine Bewertungen

- SING BOARDS List SpecimensDokument25 SeitenSING BOARDS List SpecimensEngr Amir Jamal QureshiNoch keine Bewertungen

- Draft MOM - DD 25-7-16Dokument4 SeitenDraft MOM - DD 25-7-16Engr Amir Jamal QureshiNoch keine Bewertungen

- Location Map Thanidani Nathiagali 2Dokument1 SeiteLocation Map Thanidani Nathiagali 2Engr Amir Jamal QureshiNoch keine Bewertungen

- Draft MOM - DD 25-7-16Dokument4 SeitenDraft MOM - DD 25-7-16Engr Amir Jamal QureshiNoch keine Bewertungen

- NWFP Public Propert (Removal of Encroachment) Act 1977Dokument6 SeitenNWFP Public Propert (Removal of Encroachment) Act 1977Engr Amir Jamal QureshiNoch keine Bewertungen

- Government of Khyber Pakhtunkhwa11Dokument1 SeiteGovernment of Khyber Pakhtunkhwa11Engr Amir Jamal QureshiNoch keine Bewertungen

- Progress Report-April 2016Dokument4 SeitenProgress Report-April 2016Engr Amir Jamal QureshiNoch keine Bewertungen

- PLOT Sizes For Fuel and CNGDokument1 SeitePLOT Sizes For Fuel and CNGEngr Amir Jamal QureshiNoch keine Bewertungen

- NOC Fuel Station PannianDokument1 SeiteNOC Fuel Station PannianEngr Amir Jamal QureshiNoch keine Bewertungen

- Motor Installation and Maintenance ManualDokument23 SeitenMotor Installation and Maintenance ManualVenkat CherukuriNoch keine Bewertungen

- Swimming PoolsDokument19 SeitenSwimming PoolsRoshni George100% (2)

- SPCC Inspection Form TransformersDokument4 SeitenSPCC Inspection Form TransformersAkhmad ZainudinNoch keine Bewertungen

- MSDS SodiumchloroasetatDokument10 SeitenMSDS Sodiumchloroasetatanastasia natalisaNoch keine Bewertungen

- Metabolismo de Nitrógeno y Fósforo Inorgánicos Disueltos en La Columna de AguaDokument15 SeitenMetabolismo de Nitrógeno y Fósforo Inorgánicos Disueltos en La Columna de Aguamoises hernandezNoch keine Bewertungen

- Steam Condensate Drainage OptionsDokument6 SeitenSteam Condensate Drainage Optionssatishchemeng100% (2)

- Quantity of Water (Water Supply Engineering)Dokument7 SeitenQuantity of Water (Water Supply Engineering)Shuvanjan Dahal100% (7)

- Net Case StudyDokument3 SeitenNet Case StudySarthak DalviNoch keine Bewertungen

- Sample Spec For AWWA HDPE Pipe Fittings 6.02revDokument6 SeitenSample Spec For AWWA HDPE Pipe Fittings 6.02revmg4myNoch keine Bewertungen

- Aniqa Saleem-Sustainable DesignDokument13 SeitenAniqa Saleem-Sustainable DesignaniqaNoch keine Bewertungen

- Grade 4 WKST - Air, Water&WeatherDokument3 SeitenGrade 4 WKST - Air, Water&WeatherMOHAMMED ASIFALINoch keine Bewertungen

- ETYS 2016 Appendix A - 3Dokument1 SeiteETYS 2016 Appendix A - 3ChairimanNoch keine Bewertungen

- Mekelle University: Ethiopian Institute of Technology (EIT-M)Dokument37 SeitenMekelle University: Ethiopian Institute of Technology (EIT-M)michaeljesusNoch keine Bewertungen

- Segreen Business Park in San Felice SegrateDokument25 SeitenSegreen Business Park in San Felice SegrateSaber ElkassasNoch keine Bewertungen

- Julita P1Dokument1 SeiteJulita P1Lhyenmar HipolNoch keine Bewertungen

- Pavement in Japan: Kazuyuki KuboDokument11 SeitenPavement in Japan: Kazuyuki KuboJin XiaoqingNoch keine Bewertungen

- 8-The Chemistry of The Environment PDFDokument52 Seiten8-The Chemistry of The Environment PDFJewel LimNoch keine Bewertungen

- 355GF Data Sheet US - MetricDokument2 Seiten355GF Data Sheet US - Metricminov minovitchNoch keine Bewertungen

- CV BadruzDokument2 SeitenCV BadruzBadruz ZamanNoch keine Bewertungen

- Chapter 10: Environmental Management Plan (Emp)Dokument23 SeitenChapter 10: Environmental Management Plan (Emp)Tan Kang YaoNoch keine Bewertungen

- What Is The Purpose of Coagulation and FlocculationDokument5 SeitenWhat Is The Purpose of Coagulation and FlocculationMpumeleloNoch keine Bewertungen

- Huy Minh - Homework - 854b85e7-5506-42ca-820e-0d0705 - 231202 - 110650Dokument2 SeitenHuy Minh - Homework - 854b85e7-5506-42ca-820e-0d0705 - 231202 - 110650Minh PhuongNoch keine Bewertungen

- DENR Administrative Order 35Dokument15 SeitenDENR Administrative Order 35Gabrielo BarrinuevoNoch keine Bewertungen

- 0173-527-EN SAB 128 Og SAB 163Dokument213 Seiten0173-527-EN SAB 128 Og SAB 163John Søndergaard Hansen100% (2)

- WWW Durhamtech Edu Faculty Safety Safety 20data 20sheets 20 SDS Northern 20durham Acetic 20acid HTM PDFDokument5 SeitenWWW Durhamtech Edu Faculty Safety Safety 20data 20sheets 20 SDS Northern 20durham Acetic 20acid HTM PDFPetrescu MihaiNoch keine Bewertungen

- River City Strategy Volume 01 Report Part2 PDFDokument8 SeitenRiver City Strategy Volume 01 Report Part2 PDFTjokde DalemNoch keine Bewertungen

- Activated Sludge Process and Its Design, Operation and ControlDokument148 SeitenActivated Sludge Process and Its Design, Operation and ControlDr. Akepati Sivarami Reddy92% (26)

- 4 Yr PDFDokument98 Seiten4 Yr PDFAbinash MandalNoch keine Bewertungen

- Audit Report Template 37Dokument52 SeitenAudit Report Template 37Ahmed Hosney100% (1)