Beruflich Dokumente

Kultur Dokumente

Insulation Details For Cold Piping PDF

Hochgeladen von

zampacaanasOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Insulation Details For Cold Piping PDF

Hochgeladen von

zampacaanasCopyright:

Verfügbare Formate

INSULATION

VAPOR BARRIERS

& GLASS CLOTH

FINISH

DRAWING NUMBER

GLASS CLOTH

STAINLESS STEEL

. ..

. . ..

. .

. .

. .

. .

30

STRAPS

SHT. NO.

REV. NO.

BORE COAT

SINGLE LAYER JOINT

MINERAL WOOL

(TYP) 150

FINISH

PIPE

NOTE:

MINERAL WOOL

LOOSE FILL

32-194 SERIES

1. THE MATERIALS SPECIFIED FOR INSULATION, WEATHERPROOFING, AND ACCESSORIES ARE MANDATORY. ALL

ALTERNATIVE MATERIALS MUST MEET THE

GENERIC

DESCRIPTIONS SPECIFIED IN THE SAUDI ARAMCO

MATERIAL STOCK (SAMS) SYSTEM.

2. THE SAUDI ARAMCO PAINTS & COATINGS STANDARDS

(SAPCS) SPECIFIED ARE MANDATORY.

32-196 SERIES

32-208 SERIES

STAINLESS STEEL; STRAP 12mm x 0.4mm

< 36" NPS

08-898 SERIES

A167 TYPE 304

>36" NPS

08-900 SERIES

20mm x 0.5mm

USE ONLY WHERE

S.S NOT ACCEPTABLE

16 BWG

BORE COAT

ANTI- ABRASIVE 2A

OR HYDROCAL B-11

SEALANT

PITTSEAL 444

5. INSULATION THICKNESSES ARE TO BE IN

ACCORDANCE WITH SAES-N-001.

VAPOR BARRIER COATING ACRYLIC LATEX

VAPOR BARRIER

GLASS CLOTH

REINFORCEMENT

WEATHERPROOFING (METAL JACKET)

09-611-982

0.5 THK.

0.6 THK.

ALLOY 3003-14; SHEET

0.8 THK.

12-123 SERIES

09-275-043

WEATHERPROOFING (NON METALLIC)

INSULATION

12mm

ALUMINUM TOPCOAT

NON-METALLIC SHEET

PITTWRAP CW

1. REFER TO SAES-N-001 FOR SPECIFIC SYSTEM

REQUIREMENT FOR CELLULAR GLASS INSULATION.

2. STAINLESS STEEL SHALL NOT BE USED IN COASTAL

AND MARINE APPLICATIONS. USE ALUMINUM STRAPS.

3. VAPOR BARRIER SHALL HAVE A MINIMUM DRY FILM

THICKNESS OF 0.8mm WHEN USED WITH CELLULAR

GLASS INSULATION.

4. ALL INSULATION JOINTS SHALL BE SEALED WITH

SEALANT.

CLAMP

5. ALL JOINTS IN WEATHERPROOFING JACKETS SHALL

BE OVERLAPPED 50mm, ARRANGED TO SHED WATER,

AND SEALED WITH SEALANT.

SEALANT

1/4 " THK. x 2-2" LG C.S. INSULATION

6. ALUMINUM TOPCOAT IS TO REPLACE METAL

JACKETING IN AREAS WHERE JACKETING COULD NOT

BE INSTALLED (I.E. ELBOWS, ETC.) APPLY AT LEAST

TWO COATS; USE CONTRASTING COLOR FOR FIRST

COAT.

APPLY FIRST COATS THREE DAYS AFTER

VAPOR BARRIER IS APPLIED.

PROTECTION SHIELD

PIPE

LOW TEMP.

PIPE

. .. .

. ... .. .. .

. ... . .. .

. . ..

. .. .. . .

. . . . ..

.

.

. .. . .

. . ..

.

... .. . .

.. .. . .

.

..

...

. .

.. .. . .

.

.

... . .. .

SEALANT

FLASHING ANGLE

SEALANT

VAPOR BARRIERS

& GLASS CLOTH

METAL JACKETING

SPECIFIC NOTES

09-611-750

INSULATION

T/2

INSULATION

3. THE INSTALLATION DETAILS SHOWN ARE TYPICAL.

ALTERNATIVE INSTALLATION DETAILS ARE ACCEPTABLE

PROVIDED THEY COMPLY WITH THE SPECIFIC NOTES.

4. CONVENTIONAL UNITS OF MEASUREMENTS MAY BE

USED IN LIEU OF THE METRIC MEASUREMENTS SHOWN.

1.5 LB DENSITY

KILN DRIED

FIG. 3

STRAP

VAPOR BARRIER

& GLASS CLOTH

TEMP LOWER LIMIT

-268^C

SAMS

STOCK

NUMBER

HORIZONTAL CONTRACTION JOINT

FIG. 2

METAL JACKETING

216mm

MULTI-LAYER JOINT

FLANGE COVER

FIG. 1

12mm

SEE INSULATION PROCEDURE

MULTI-LAYER PIPE INSULATION

FOAM GLASS

ALUMINUM ASTM B209

SEALANT AT JOINTS

(KEEP JOINTS STAGGERED)

INSULATION

BORE COAT

INSULATION

1 OR 2 LAYERS

AS REQUIRED

1 1/2 T

min.

CELLULAR GLASS

WOOD BLOCKS

SEALANT 12mm INTO SPACE

METAL STRAP ONE SIDE ONLY

SEALANT

DESIGN

LIMITATIONS

ALUMINUM ASTM;

ALLOY; STRAP

LINER; GALV. STEEL

GLASS WOOL

VAPOR BARRIER

SEALANT, 12mm INTO SPACE

METAL STRAP ONE SIDE ONLY

LOW TEMP.

PIPE

. . .

.

. ..

. .. . .

. .

. ..

.

.

.

.

.

. .

. .

. . . . . . . .. . .. . . . .

A

25

.

.. . .

.

..

.

. . . . . . .. ..

.

.

.. . . . .

.

. .

. ..

. .

. . .

.. .

. .

.

.

TYPE

ACCESSORIES

METAL JACKETING

INDEX

PLANT NO.

AA-036913 1OF 2 06

METAL JACKETING

MATERIAL

BORE COAT

990

STRAP

GENERAL NOTES

12mm

BOLT LENGTH + 25mm

STAINLESS STEEL BANDS

STAGGERED JOINTS

ARRANGEMENT

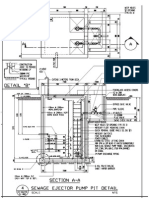

SECTION A-A

INSULATION MATERIALS

3T OR

150mm

WOODEN BLOCKS AT 4 EQUALLY SPACED

KILN DRIED BEECH

WOOD BLOCKS

TO EXTEND

BEYOND CLAMPS

AND 1 ON THE 6 OCLOCK POSITION

7. BURRIED PIPING DOES NOT REQUIRE METAL WEATHERPROOF JACKETING. USE NON-METALLIC SHEETS.

SEALANT

STRAPS

HARDWOOD

1. ADD WOOD BLOCKS AFTER BORE

COATING AND CONTINUE WITH

THE PROCEDURE.

MINERAL WOOL

VAPOR BARRIER

& GLASS CLOTH

2. APPLY BORE COAT IF REQUIRED PER SAES-N-001.

NOTE:

COAT C.S. PARTS PER APCS-22.

3. TWO SETS OF CLAMPS REQUIRED PER

SUPPORT. CLAMP MAY BE 2 OR 3 PIECES.

CENTER HANGER ASSY

AT MIDPOINT OF WOOD BLOCKS

PEDESTAL SUPPORT

3. INSTALL PREFORMED CELLULAR GLASS WHILE THE

BORE COATING IS STILL WET.

4. USE SEALANT TO JOIN INSULATION SECTIONS.

5. SECURE INSULATION PIECES AROUND PIPE USING

METAL STRAPS.

HANGER TYPE SUPPORTS FOR PIPE SIZES OVER 4"

PIPERACK SUPPORT DETAIL

FIG. 5

1. PREPARE AND COAT (SAPCS) PIPING IN ACCORDANCE

WITH SAES-H-101.

METAL JACKETING

2. SEE INSULATION PROCEDURE.

FIG. 4

INSTALLATION PROCEDURE:

PIPE SUPPORT

NOTES:

6. APPLY VAPOR BARRIER LAYER.

FIG. 6

7. APPLY ONE LAYER OF GLASS CLOTH.

NOTE:

SECURE INSULATION WITH

STAINLESS STEEL STRAPS.

METAL JACKETING SHOULD BE EASY TO INSTALL

AND REMOVE WITHOUT BEING DAMAGED.

WEATHER PROOFING TO OVERLAP 50mm

AT JOINT. APPLY SEALANT TO

ALL MATING SURFACES.

1000

.

.

.

.

.

.

. .. .

.. .

. .. .

.

.

. ..

. .

.

.

. . .

.

.

. . . . ..

.

... . .. .. .... ..

.. .... . .

.

. . . .. ...

. . . .. .... .

... .. . . ..

.. . . .

... .. .. .

.

.

. . . ..

.. .... .... .

.

... . .

.

.

.

.

.

.. .. ...

.

. . .

.

. .

.

.

. .

. .. . .

.

.

. .

. . . ..

200

50 100

SEALANT

VALVE

...

.. ..

. .. ..

.

. ..

.

.. . .

PACKED GLASS WOOL

1 1/2 LB. DENSITY

SEALANT

INSULATION

BOTTOM COLLAR

SEE DETAIL 4

HEAVY FILLET OF SEALANT

IF BEVELED CORNER

NOT FURNISHED.

SECTION AL ELEVATION

VAPOR BARRIER

& GLASS CLOTH

1. FOLLOW THE SAME INSULATION DETAILS

FOR PIPE SIZES 6" AND ABOVE AND THEIR

RELATED SUPPORT DESIGN.

DOUBLE FINISH OVER JOINT

SEALANT

FIG. 8

WRAP WITH GLASS WOOL

HOLD IN PLACE

WITH TWINE.

INSULATION

SEALANT

VERTICAL CONTRACTION JOINT

(FOR PIPE SIZES 30" & ABOVE)

FIG. 10B

FIG. 9

VAPOR BARRIER

& GLASS CLOTH

INSULATION

VAPOR BARRIER

& GLASS CLOTH

VAPOR BARRIER

& GLASS CLOTH

OVERLAP JOINT AS SHOWN

VAPOR BARRIER

& GLASS CLOTH

CLAMP

INSULATION

DRAWING RESPONSIBILITY :

VESSEL STANDARDS COMMITTEE

SEALANT IN ALL

JOINTS

GLASS FIBER

LOW TEMP. PIPE

STEEL CRADLE

SEALANT

PIPE SADDLE

FIG. 14

VAPOR BARRIER

& GLASS CLOTH.

COUNTER-FLASHED

AS SHOWN.

INSULATION

SEALANT IN

ALL JOINTS

SUPPORT WELDED TO PIPE.

PEDESTAL SUPPORT AT ELBOW

FIG. 13

HEAVY FILLET OF

SEALANT

INSULATION

SEALANT

HEAVY FILLET

OF SEALANT

FIG. 11B

LOW TEMP. PIPE

NOTCH OR CHAFF

INSULATION TO

THICKNESS OF

ANCHOR AS SHOWN.

CARRY INSULATION DOWN

TO BOTTOM PLATE

METAL JACKETING

SINGLE LAYER

STEEL ANCHOR

INSULATION

STAGGERED JOINTS

STANDARD WELD ELBOW

INSULATION

SHEET METAL LINER

(TWO HALVES)

SEALANT

SECURE INSULATION

WITH STAINLESS

STEEL STRAPS

STANDARD WELD TEE

SINGLE LAYER

PREFORMED FITTING

INSULATION. INCREASE DIA.

OF ELBOW INSULATION

1/4 "

BY REAMING.

SEALANT IN ALL JOINTS

VAPOR BARRIER

& GLASS CLOTH

SEALANT

VALVE INSULATION COVER

FIELD FABRICATED TEE

PREFORMED

INSULATION

INSULATION

BOX IN TWO HALVES

ABOUT VERTICAL

VAPOR BARRIER

& GLASS CLOTH

SECURE INSULATION

WITH STAINLESS

STEEL STRAPS

SECURE INSULATION WITH

STAINLESS STEEL

STRAPS.

NOTE:

BOLT LENGTH +25

LOW TEMP. PIPE

DOUBLE LAYER

FIG. 11A

SECURE INSULATION

WITH STAINLESS

STEEL STRAPS.

INSULATION

STANDARD WELD ELBOW

DOUBLE LAYER

FIG. 10A

(min.)

VAPOR BARRIER

& GLASS CLOTH

VAPOR BARRIER

& GLASS CLOTH

C

SECTION C-C

ALUMINUM TOP COAT OR

PREFORMED METAL JACKET

SEALANT

STANDARD WELD TEE

(min.)

HEAVY FILLET

OF SEALANT

SLEEPER

SADDLE & SLEEPER SUPPORT

FIG. 12

LOW TEMP. PIPE

SEALANT

SADDLE

INSULATION

FIG. 7

INSULATION SECTION

KEYED TO SUPPORT

RING SUPPORT

WELDED TO PIPE

KILN DRIED

BEECH WOOD

... ... .. .

. . .

.. .. .

.

.

. . ..

. .

.

. ..

.

.

. .

.

.

. . . ..

. .. .

. . .

PIPE

GLASS WOOL FOR CONTRACTION.

INCREASE INSIDE DIA. OF ELBOW

INSULATION 1/4 " BY REAMING

C

L

. .

.. . . . . ..... .

. .. . .

. . . . . ..

. .

..

. .

.. . .. . ...

.. . . .

. .. ..

.. .

.. . . ..

. . .. . .

. .. . . .. . .

. .

.

. . .. .... .

.

. .. . . .

..

. . . ..

.. . .

..

9. INSTALL WEATHERPROOFING.

PREFORMED INSULATION

C

L

PIPE

SEALANT

EXTEND DRAIN PIPE

OUTSIDE COVER

WITH PLUG

METAL JACKETING

VAPOR BARRIER

& GLASS CLOTH

VAPOR BARRIERS

& GLASS CLOTH

T

.

. .

............. ... . . ... . .

. .

.

. ...... .... .. ... ..

. . . .. . .. ..

.

. .... .... .

. .. .

. .

. ... .

... . .

.. . . .

..... ... ... .

... . ....

.. . .

50

8. APPLY ANOTHER TWO VAPOR BARRIER LAYERS.

LOW TEMP.

76

1 1/2 T

200

INSULATION

SEALANT

LOW TEMP. PIPE

76

STRAP

MINERAL

WOOL

100 50

EXTEND VENT/RV PIPE

OUTSIDE INSULATION

SECURE INSULATION

WITH STAINLESS

STEEL STRAPS AND SEALS.

HEAVY FILLET OF SEALANT

IF BEVELED CORNER

NOT FURNISHED.

750

METAL JACKETING

DOUBLE FINISH

OVER JOINT

RING CLAMP

METAL STRAP

ANCHOR

OUTSIDE INSULATION

BLIND FLANGE

06

MAR96

REV.

NO.

DATE

ESSD

BY

DATABASE & COMPLETELY REVISED.

CHECKED BY

DRAWN BY

VAPOR BARRIER

& GLASS CLOTH

INSULATION

VAPOR BARRIER

& GLASS CLOTH

INSULATION

LOW TEMP. PIPE

ONE LAYER OF

SECTIONAL INSULATION

JOINT ADHESIVE

OUTER LAYER ONLY

CUT FROM 2" THICK

INSULATION BLOCK

ELEVATION

FIG. 16

ANCHOR AT PUMPS AND GUIDES

CERT.

APPD.

NONE

SCALE:

ENG. DEPT.

OPRG. DEPT.

APPD. FOR CONST.

CERTIFIED

CONSTRUCTION OR FOR ORDERING

PROTECTIVE COATING (SPRAY

GRADE) APPLIED TO OUTSIDE

SURFACE OF INSULATION

CUT FROM 2" THICK

CELLULAR GLASS

BLOCK SECURE

WITH STRAPS.

MATERIAL UNTIL CERTIFIED AND DATED

BURIED CHILLED WATER LINES

SECTION E-E

DATE

END JOINTS VERTICAL ON

SECTIONAL INSULATION

EXPOSED CHILLED WATER LINES

FIG. 17

BY

INSULATION DETAILS

FOR COLD PIPING

SECURE INSULATION

WITH STAINLESS STEEL

STRAPS.

HEAVY FILLET OF

SEALANT

SECTION D-D

REINFORCING GLASS CLOTH

75mm MINIMUM OVERLAP

THIS DRAWING IS NOT TO BE USED FOR

JOINT ADHESIVE

SEALANT

HEAVY FILLET OF

SEALANT

ALL JOINTS TO

BE BUTTERED WITH

A 1.5mm MIN.

LAYER

OF SEALANT

CHKD.

DATE COMPLETED

DATE STARTED

VAPOR BARRIER

DESCRIPTION

JO/EWO

SAUDI ARABIAN OIL COMPANY

FIG. 15

SUPPORTS FOR PIPE SIZES 4" AND SMALLER

DRAWING DIGITIZED INTO CADD

RLO

DETAILS OF CHILLED WATER LINES

STD. DWG.

PLANT NO.

INDEX

990

METRIC

DRAWING NUMBER

SHT. NO.

REV. NO.

AA-036913 1OF 2 06

Saudi Aramco 2615 ENG. (3/91)

CopyrightSaudi Aramco 2009. All rights reserved.

CADD-02

Das könnte Ihnen auch gefallen

- Bougainvillea GlabraDokument1 SeiteBougainvillea GlabrazampacaanasNoch keine Bewertungen

- A036697001v03 PDFDokument1 SeiteA036697001v03 PDFzampacaanasNoch keine Bewertungen

- Inspection Test Plan For ElectricalDokument38 SeitenInspection Test Plan For Electricalzampacaanas76% (29)

- Brochure Green FilterDokument2 SeitenBrochure Green FilterzampacaanasNoch keine Bewertungen

- Glowing GodzillaDokument1 SeiteGlowing GodzillazampacaanasNoch keine Bewertungen

- Standard Water Height Level, Setting From Supplier (OASIS)Dokument2 SeitenStandard Water Height Level, Setting From Supplier (OASIS)zampacaanasNoch keine Bewertungen

- Fireproofing STD - ARAMCODokument1 SeiteFireproofing STD - ARAMCOzampacaanasNoch keine Bewertungen

- GabbDokument1 SeiteGabbzampacaanasNoch keine Bewertungen

- AA-036911-001 Insulation Details For Hot Piping PDFDokument1 SeiteAA-036911-001 Insulation Details For Hot Piping PDFzampacaanas100% (2)

- S 00 Taa A 29 001 001Dokument1 SeiteS 00 Taa A 29 001 001zampacaanasNoch keine Bewertungen

- Manhole QuotationDokument6 SeitenManhole QuotationzampacaanasNoch keine Bewertungen

- Project Quality Plan RevDokument81 SeitenProject Quality Plan Revzampacaanas89% (9)

- Xk-0092 - Gsoc SowDokument31 SeitenXk-0092 - Gsoc SowzampacaanasNoch keine Bewertungen

- H359219001V00Dokument1 SeiteH359219001V00zampacaanasNoch keine Bewertungen

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Dokument16 Seiten3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasNoch keine Bewertungen

- Submersible Pump Detail DrawingDokument1 SeiteSubmersible Pump Detail DrawingzampacaanasNoch keine Bewertungen

- 3-Way Plug ValveDokument12 Seiten3-Way Plug ValvezampacaanasNoch keine Bewertungen

- H359217001V00Dokument1 SeiteH359217001V00zampacaanasNoch keine Bewertungen

- Eco-Friendly Domestic Water Filtration Solution: Clean, Healthy and Tasty WaterDokument2 SeitenEco-Friendly Domestic Water Filtration Solution: Clean, Healthy and Tasty WaterzampacaanasNoch keine Bewertungen

- Alf - Ms For PaintingDokument3 SeitenAlf - Ms For PaintingzampacaanasNoch keine Bewertungen

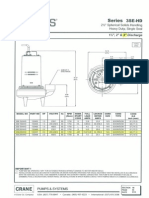

- 3SE2094HDDokument1 Seite3SE2094HDzampacaanasNoch keine Bewertungen

- Quality Requirements For MFCDokument8 SeitenQuality Requirements For MFCzampacaanasNoch keine Bewertungen

- 28 SABG SchoolDokument4 Seiten28 SABG SchoolzampacaanasNoch keine Bewertungen

- PHE Method StatementDokument3 SeitenPHE Method Statementzampacaanas0% (1)

- 2-Square Ceiling DiffuserDokument21 Seiten2-Square Ceiling DiffuserzampacaanasNoch keine Bewertungen

- Vibration PadDokument2 SeitenVibration PadzampacaanasNoch keine Bewertungen

- C10!20!4Catalog Heating CalculationDokument64 SeitenC10!20!4Catalog Heating CalculationhoathinhdonNoch keine Bewertungen

- LSQ092H-3 Service ManualDokument75 SeitenLSQ092H-3 Service ManualzampacaanasNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Service Manual. YANGFAN 2058 BOW 1Dokument239 SeitenService Manual. YANGFAN 2058 BOW 1Oleksandr RakshaNoch keine Bewertungen

- DeZURIK BHP HIGH PERFORMANCE BUTTERFLY VALVESDokument22 SeitenDeZURIK BHP HIGH PERFORMANCE BUTTERFLY VALVESLuis Daniel ContrerasNoch keine Bewertungen

- Valves PDFDokument12 SeitenValves PDFAnonymous HFIQgANMQNoch keine Bewertungen

- F 1789 - 17Dokument15 SeitenF 1789 - 17Acilasac 2018Noch keine Bewertungen

- Portland Bolt Strength Requirements by Grade ChartDokument3 SeitenPortland Bolt Strength Requirements by Grade Chartanta520Noch keine Bewertungen

- A Superior Alternative To Carbon or Low Alloy Steels: Sandvik 3R12/4L7Dokument4 SeitenA Superior Alternative To Carbon or Low Alloy Steels: Sandvik 3R12/4L7Saravanan MariNoch keine Bewertungen

- Testing Solutions For The Food IndustryDokument12 SeitenTesting Solutions For The Food IndustryWilliam Rolando Miranda ZamoraNoch keine Bewertungen

- Tech Guide To Filling MachinesDokument12 SeitenTech Guide To Filling MachinesLatifani Ayu ChaerunnisaNoch keine Bewertungen

- Brochure Presssysteme Int NetDokument28 SeitenBrochure Presssysteme Int NetgkpNoch keine Bewertungen

- Ugiweb 52289Dokument117 SeitenUgiweb 52289muratcanNoch keine Bewertungen

- Seal Material and Arrangement GuideDokument48 SeitenSeal Material and Arrangement Guideleo100% (2)

- S 13 CRDokument6 SeitenS 13 CRBardan RahmatanNoch keine Bewertungen

- FibersparDokument2 SeitenFibersparippon_osotoNoch keine Bewertungen

- TR0038 - 3 Valve ActuatorsDokument49 SeitenTR0038 - 3 Valve ActuatorsAliNaqvi100% (2)

- Check Valves Specification RequirementsDokument9 SeitenCheck Valves Specification RequirementsFlorante NoblezaNoch keine Bewertungen

- TankerDokument60 SeitenTankerlopezdestructionNoch keine Bewertungen

- Safety Valve SUS304 - SL40F-DDokument1 SeiteSafety Valve SUS304 - SL40F-DhungNoch keine Bewertungen

- Recommended Practices For Storage and Transport of Edible Oils and FatsDokument13 SeitenRecommended Practices For Storage and Transport of Edible Oils and FatsM Alim Ur RahmanNoch keine Bewertungen

- The World Nickel Factbook 2018 PDFDokument52 SeitenThe World Nickel Factbook 2018 PDFMuhammad Agung RiyadiNoch keine Bewertungen

- Design and Fabrication of Distillation Tower PlatesDokument16 SeitenDesign and Fabrication of Distillation Tower PlatesMiguel Martinez GuerreroNoch keine Bewertungen

- Cutting Wheel En12413Dokument48 SeitenCutting Wheel En12413JomyJoseNoch keine Bewertungen

- Unisteri®: Medium-Sized Steam Sterilizer For Health Care Efficient, Intelligent, ExceptionalDokument9 SeitenUnisteri®: Medium-Sized Steam Sterilizer For Health Care Efficient, Intelligent, ExceptionalSaleh HamadanyNoch keine Bewertungen

- Thermal Analysys of LNG TankDokument9 SeitenThermal Analysys of LNG Tanksameh tawfeekNoch keine Bewertungen

- Chemical Composition (In Weight %) : Specification SheetDokument6 SeitenChemical Composition (In Weight %) : Specification SheetGusti CahyonoNoch keine Bewertungen

- Selected Formulary Book On Petroleum, Lubricants, Fats, Polishes, Glass, Ceramics, Nitrogenous Fertilizers, Emulsions, Leather and InsecticidesDokument27 SeitenSelected Formulary Book On Petroleum, Lubricants, Fats, Polishes, Glass, Ceramics, Nitrogenous Fertilizers, Emulsions, Leather and InsecticidesNatalieNoch keine Bewertungen

- Penguard Universal: Technical Data SheetDokument5 SeitenPenguard Universal: Technical Data Sheetkanogkand kasrirakuptNoch keine Bewertungen

- Conveyor Pizza Oven Composition With 1 Baking Deck: External ConstructionDokument2 SeitenConveyor Pizza Oven Composition With 1 Baking Deck: External Constructioncris bunagNoch keine Bewertungen

- Protection Tubes and Thermowells: Thermowell Materials Selection GuideDokument3 SeitenProtection Tubes and Thermowells: Thermowell Materials Selection GuideJp NairNoch keine Bewertungen

- JIS G3448 AngDokument10 SeitenJIS G3448 AngNastyNoch keine Bewertungen

- Heat-Flex HI-TEMP 1200: Protective & Marine CoatingsDokument4 SeitenHeat-Flex HI-TEMP 1200: Protective & Marine CoatingsAna CabreraNoch keine Bewertungen