Beruflich Dokumente

Kultur Dokumente

PAC36P: Shimaden Three-Phase Power Regulator

Hochgeladen von

ahmet ozturkOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PAC36P: Shimaden Three-Phase Power Regulator

Hochgeladen von

ahmet ozturkCopyright:

Verfügbare Formate

SHIMADEN THREE-PHASE POWER REGULATOR

SERIES

PAC36P 20~600A

Wide application with variety of functions

Suitable for air conditioning, electric, furnace, dryer,

bio engineering, food industry, chemical industry,

plastic formation and control of heat source applications.

20A

30A, 45A

60A, 90A

135A, 180A

450A, 600A

240A, 300A

FUNCTION

Standard Function

Electronic over current protect function:

Protects thyristor element by shutting off the over current detected by a load

current monitoring CT.

Constant voltage characteristics by means of voltage

Stable output provided by the voltage control function and easy operation achieved

feedback:

by the linear characteristics of control input and output voltage.

Soft start function:

Additional Function (option)

Automatic power adjusting function:

Setting suitable soft start time for the load.

Stable output provided by the voltage control function and easy operation achieved

The suitable power for the control temperature is continuously controlled by a

signal from the programmable controller, computer and adjuster. Applicable for

soft control of the low range.

Constant-current control (Current feedback):

Applicable to controlling the pure metallic heater and the Kanthal Super heater.

Constant-power control (Power feedback):

Applicable to controlling the SiC and the carbon heater, and applicable to high

stability controlling.

Power linear control (Voltage square feedback):

Applicable to precise controlling for Nichrome heater load with power linear

characteristics of the control input / output voltage.

Current limiting funcion:

Applicable to loads with rush current on starting and continuous usage over current

condition such as pure metallic, Tungsten and Molybdenum heaters.

Start up output limiting function:

Applicable to the rush current reduction and load protection on turning on the

Heater break alarm:

Alarm display and output in case of detecting the low power condition of the broken

Rapid fuse:

Perfect protection for the thyristor device and the power line from the over current

power supply.

heater and heater defect.

of the short circuit and the grounding.

Power adjustment function:

Addition of various manual equipment used for adjusting ramp, base (residual

output), manual and high / low.

Monitor and Alarm Output on the Trouble Situation

Over-current protection:

[O.C] monitor lights and alarm output on

Fan stop (for models over 180A):

[FAN] monitor lights and alarm output on

Rapid fuse burnt out:

[FUSE] monitor lights and alarm output on

Heater break alarm:

[H / B] monitor lights and warning output on

SERIES

PAC36P

SPECIFICATION

Control input and Rating

Current input:

Voltage input:

Operating Environment

4~20mA / DC, Receiving impedance:

Ambient temperature

100

range:

-10~50C

1~5V / DC, Input impedance: 200k min.

Ambient humidity:

90% RH max. with no condensation

0~10V / DC, Input impedance: 200k min.

Contact signal:

Non-volatage contact signal

Power terminal and chassis:

Note: Select external power (P) or

Input terminal

(H) in the table of code Selection

Dielectric Strength

Power Supply and Rating

Power terminals

200~220V AC 10% 50 / 60Hz

and chassis:

220~240V AC 10% 50 / 60Hz

400V type:

380~400V AC 10% 50 / 60Hz

400~440V AC 10% 50 / 60Hz

Control Mode:

Adjustable approx. 1~10 sec. (time

Applicable load:

Resistive load, inductive load

Ordinary steel plate / paint coating

Weight:

See external demension drawings.

Terminal Cover:

Installed as standard equipment.

Additional functions

Output voltage control

(option)

0~98% minimum of input voltage

Power adjuster

Connection to

Output stability (95% or

Input fluctuation 2% or less when

voltage / current output type

input fluctuation is 10%.

controller

Control element

configuration:

2500V AC 1 minute

(equivalent to N8.5 Munsell number)

(transformer primary side control)

less of output voltage):

2000V AC 1 minute

380~440V power supply:

External Dimensions and

for reaching 90%)

range:

200~240V power supply:

Material / Finish:

Phase angle control system

Soft start:

500V DC 20M min.

500V DC 20M min.

and power terminal:

Item 7, (Output Adjusting Function)

200V type:

Insulation Resistance

Mixed antiparallel configuration of

Internal Power (standard):

0~100%

SCRs and diodes

External Power:

0~100%

Over-current Protection

Manual Power:

0~100%

System

Base Power:

0~100%

Electronic type (gate signal

External power + Manual

breaking system) standard:

approx. 130% of rated current

power:

Rapid fuse type (optional):

130~150% of rated current

External power + Base

Electronic type:

Turn power OFF and reapply

power:

Connection to contact

Rapid fuse:

Replace fuse.

output type controller

Reset

0~100%

0~100%

Current Capacity and

External Power:

0~100%

Cooling System

High-low power:

0~100%

20A,30A,45A,60A,90A,135A:

Self-cooling system

180A,240A,300A,450A,600A:

Forced air cooling system

Constant-current control

(current feedback)

Alarm Monitors and Rating

Applicable loads:

Over-current:

[O.C] monitor lights. / AL1-AL2

Fan stop:

[FAN] monitor lights. / AL1-AL2

conducting

(power feedback)

Applicable loads:

conducting

Fuse burnt out:

[FUSE] monitor lights./AL1-AL2

Applicable loads:

[H / B] monitor lights. / HB1-HB2

Current limit:

240V AC 1A / Resistive load

Power Lamp

Correct Phase sequence:

Open / opposite phase:

sequence:

Nichrome heater

Output limiting function:

conducting

Output contact rating:

SiC, carbon heaters

Power linear control (voltage feedback)

conducting

Heater break:

Pure metallic heaters, super Kathal, etc.

Constant-power control

Green LED lights.

50~100% of rated current

Start up output limiting:

0~60% output for 1~60sec.

Rapid fuse:

With alarm output function

Heater break alarm:

Setting at 0~100% of rated current

Automatic power adjusting

Red LED lights.

function:

50~100%

INTERNAL HEAT GENERATED

Internal heat generated by series PAC36P at maximum current operation is as follows.The heat decreases is proportional to the current

decrease. Ventilation should be considered for the system.

Rating current (A)

20

Internal heat generated (W)

82

30

45

60

90

135

180

240

300

450

600

121

151

196

274

442

620

731 1040 1567 2000

Approx. 10% more heat is generated in case of using rapid fuse.

SHIMADEN THREE-PHASE POWER REGULATOR

ORDERING INFORMATION

ITEMS

CODE

SPECIFICATIONS

SERIES PAC36P

CONTROL INPUT

Phase Angle Control 3-Phase Power Regulator

3

1~5V DC, Input Impedance: 200k / contact signal

4~20mA DC, Receiving Impedance: 100 / contact signal

0~10V DC, Input Impedance: 200k / contact signal

Others (Please consult before ordering.)

15-

POWER SUPPLY

200~220V

16-

220~240V

17-

380~400V

18-

400~440V

200~240V

380~440V

CODE

CURRENT CAPACITY

CODE

021

20A

022

20A

031

30A

032

30A

041

45A

042

45A

061

60A

062

60A

091

90A

092

90A

131

135A

132

135A

181

180A

182

180A

241

240A

242

240A

301

300A

302

300A

451

450A

452

450A

600A

602

600A

601

FEEDBACK FUNCTION

Constant voltage (standard feature)

Constant current

Constant power

Voltage Square-root

OUTPUT CONTROL FUNCTIONS

None

Startup time output control limiting (0~60%, 1~60sec.)

Current limiting

Startup time output control + Current limiting

WHEN USED

WITH VOLTAGE

AND CURRENT

EXTERNAL POWER

ADJUSTER

OUTPUT

CONTROLLER

None (Internal installation as standard)

External power adjuster

Manual power adjuster

Base power adjuster

External power + Manual power

External power + Base power

WHEN USED WITH

External power adjuster

CONTACT OUTPUT

HEATER BREAK ALARM

High-Low power adjuster

0

Without

1

RAPID FUSE

With (0~100% setting of rated current)

0

Without

AUTO POWER ADJUSTMENT FUNCTIONS

REMARKS

With (See rapid fuse table.)

0

Without

4~20mA DC, Receiving Impedance: 100

0~10V DC, Input Impedance: 200k

0

Without

With (Please consult before ordering.)

SERIES

PAC36P

Rapid Fuse Option

CURRENT CAPACITY FUSE CAPACITY

PARTS NO.

20A

30A

CR6L-

30S

30A

40A

50SHA 40S

45A

60A

50SHA 60S

60A

100A

50SHB 100S

90A

120A

50SHB 120S

135A

200A

CS5F

200

180A

250A

CS5F

250

240A

350A

CS5F

350

300A

450A

CS5F

450

450A

600A

CS5F

600

600A

800A

CS5F

800

DRAWING OF ADDITIONAL FUNCTION CHARACTERISTIC

Automatic Power Adjusting Function

Constant Current Characteristics (Current Feedback)

Power Linear Characteristics (Voltage Feedback)

Constant Power Characteristics (Power Feedback)

Power characteristic

control signal

Current Limiting Characteristics

Start up Output Limiting Characteristics

SHIMADEN THREE-PHASE POWER REGULATOR

Base (Residual) Power Characteristics

Output Power

Base&power

adjustment

Heater Break Alarm Circuit

High / Low Power Characteristics

HEATER CHARACTERISTICS

Heater elements are characterized as listed in the following table. Start up time output control limiting circuit is necessarily used for infrared

lamp load. Addition of current limiting function is required for the loads with large heat capacity such as Platinum, Molybdenum, Tungsten

and Kanthal Super.

Rated

Resistance

Heater

Maximum

Temperature

Group

Load Type

Alloy

Nichrome

Iron Chrome

Graphite

Kanthal A

1100C (in air)

1200C (in air)

Tungsten

Molybdenum

Platinum

Kanthal Super

2400C (in vacuum)

1800C (in vacuum)

1400C (in vacuum)

1700C (in air)

Pure Metallic

Variable

Resistance

Heater

Carbonized

Silicon

Techorandom

Silliconit

Elema

Resistance-Temperature

characteristics

Additional Function

General characteristics.

Covered by standard specification.

1330C (in air)

1600C (in air)

1600C (in air)

1600C (in air)

Infrared lamp (Tungsten):

Start up time output control limiting

circuit.

Rush current should be reduced to

the rating range by current limiting

function.

Covered by standard specification

by selecting twice current capacity.

Covered by load capacity by

adding current limiting function.

(Care has to be taken in the

configuration without transformer.)

Adjust voltage to the terminal

voltage of the load by using transformer.

SERIES

PAC36P

EXAMPLE OF THE AUTOMATIC POWER FUNCTION

The automatic power function is a power adjusting function that provides suitable control output to the thyristor by external equipment

(programmable controller, computer or controller) and improves controlling ability continuously providing suitable power to the SV(Set Value)

Contstant Value Control

Output with automatic power

control function and result of control

Output without automatic power control

function and result of control

Output

Output

Maximum output

Maximum output

Control without hunting

Temperature

Temperature

Hunting

Time

Time

Power changes along with the SV value to prevent

overshooting and allow optimum control.

The power gets excessive in low range, resulting in

overshooting and hunting.

Program Control

Output with automatic power control

function and result of control

Output with automatic power control function

and result of control

Maximum output

Maximum output

Output

Output

Smooth control

Temperature

Temperature

Time

Overshooting

Time

Soft control of the program is possible without

transient characteristic (overshooting) at the start time

Power gets excessive at the start time,

resulting in overshooting. In some cases control

characteristics deteriorate in a low range.

Procedure for Automatic Power Ajusting Function

By setting output optimum to the low range set value on the

[AUTO-POWER] adjuster, the output characteristic is

designated to the line connecting automatic power adjusting

value and the output at the maximum temperature. In case of

adjusting maximum output, adjusters for internal power and

external power are employed.

Output

Temperature

Soft Control by Automatic Power Adjusting Function

In case of achieving small temperature stress such as bio industry and fine ceramic manufacturing, the automatic power adjustment is

effective for precision control. The temperature control range expands for the same PID value in the PID control condition.

Combination with Type SR253 or SR25 Adjuster

TIC

SR253

or

SR25

When the SV analog output (4~20mA or 0~10V) of

the SR253 (SR25) controller is input to the auto power

terminals (AP1 and AP2) of the PAC36, maximum

power cramping, is set automatically by

controller setting (SV) and the efficiency of control is

improved. The combination plays another role; it

effectively saves a total load when several thyristors

are turned on simultaneously.

AP1-AP2.

SHIMADEN THREE-PHASE POWER REGULATOR

PANEL INFORMATION AND CONTROL TERMINALS

Code

Lower terminal

Upper terminal

Terminal No.

Terminal code

C 1 (+)

C 2 (-)

R 1

R 2

R 3

11

13

15

AL 1

17

AL 2

19

AL 3

S 1

S 2

CL 1

CL 2

10

CL 3

12

AP 1

14

AP 2

16

HB 1

18

HB 2

20

Adjusters

Internal power adjuster (standard)

Soft start time adjuster (standard)

Heater break alarm setting device (option)

Automatic power adjuster (option)

Monitor Lamps

P.L.: Power supply

: Green LED turns on at correct phase sequence.

: Red LED turns on at open / opposite phase sequence.

O.C.: Over-current

Fuse: Burning-out of rapid fuse (option)

H / B: Heater break alarm (option)

FAN: Stoppage of cooling fan (standard for 180A or above)

Terminal Codes and Functions

C1-C2: Control input

R1-R2-R3: External power (option)

M: Manual / base adjustment (option)

AL1-AL2-AL3: Alarm output common to over-current, FAN

and FUSE

S1 - S2: External sequence signal for start up time output

control limiting

CL1-CL2-CL3: Current limiting adjuster

AP1-AP2: Automatic Power signal input

HB1-HB2: Heater break alarm output

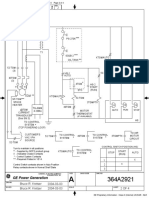

CIRCUIT BLOCK AND WIRING OF CONTROL TERMINAL

Circuit Block

Additional Function (Option) (Lower Terminal)

Terminal)

Additional function terminals are all optional items. No addtion

can be made after delivery. Select the option on ordering.

Start up time output control

limiting function

Output limit adjustment 0 ~ 60%

(approx.20% when shipped)

Time Limit adjustment 1~ 60 sec.

(approx. 1 sec. when shipped)

Connect SI-S2 terminals for function

only for power supply tuned on

instance. (In case of open terminal of

S1-S2, output limit is effective.

Insert a sequence contact between

S1-S2 that operates synchronously

with the switching of load (heater) after

power is supplied.

Current limiting function

Setting 50 ~ 100% of current rating.

Operated when the current exceeds

the preset current by comparing the

load current to the preset current.

Automatic power function

Adjusts the thyristor control

output to the optimum value by the

external signal.

Heater break alarm

240V AC 1A

Resistive For configuration of multipie heaters.

Generates alarm output by detecting

load

low capacity and temperature

distribution error from defect and

break down of heaters.

SERIES

PAC36P

Output Adjusting Function (Upper Terminal)

This function is availalbe by connecting adjuster (rating B 10k 1W), after delivery.

Wiring with contact output controller

External power

High / Low power

To adjust output of

To adjust maximum output

contact ON (Controller

for conducted (on) output

output contact C-L

contact C-L and to maintain

non-conduct (off) (C-H

conducted).

conducted) output.

Conduct ON: 0~100%

High power: With C-L on

0~100%

Low power: With C-H on

High power x Low power

Wiring with voltage / current output controller

External power

Manual power

Internal power adjuster

To adjust power manually

as standard

Short circuit R2 and

R3 when power

adjuster is not used.

(Adjust by internal

power adjuster).

Input of 100%:

0~100%

External power + Manual power (auto / manual)

Base (residual) power

External contact switches

To keep output steady

automatic / manual for power

when the control

adjusting selection of

signal is at 0%.

automatic and manual

The maximum power

is adjusted by internal

operations.

Please prepare the

power adjuster.

automatic / manual switch.

Input of 0%: 0~100%

External power + Bass (residual) power

To adjust maximum

Alarm circuit

Alarm output.

output and to maintain

Conduct between AL1 and

some parts of output of

AL2.

0% control signal.

Non conduct between AL1

and AL3.

Operation

Over-current protection circuit

on operation.

Fuse burnt out.

Cooling fan stopped.

SHIMADEN THREE-PHASE POWER REGULATOR

EXTERNAL DIMENSION, WEIGHT, MOUNTING

20A

30A 45A

Weight: approx. 9kg.

60A 90A

Weight: approx.12kg.

135A 180A 240A 300A

Weight: approx. 16.5kg.

Weight: approx. 36kg.

Mounting diagram

450A 600A

Weight: approx. 55kg.

Unit : mm

SERIES

PAC36P

APPLICATION EXAMPLES

Application Connecting a Conventional Heater

Application with Transformer

Noise absorbing capacitor

C Oil capacitor

0.1~0.5 F / 1500V

The aim of transformer

Isolates primary / secondary circuits.

Adjust to the terminal voltage of the load.

Note for transformer design

Generally, margin is set for magnetic flux density in

application of switching controlling. The value of the

magnetic flux density should be less than 8000 Gauss.

Avoid unbalance of load and rush current from magnetic

saturation.

EXTERNAL POWER ADJUSTER

External dimension and mounting

Lead: Vinyl lead wire 1 meter

Panel / Knob: 1 ea

Rating

Type: RV30YN20S

Characteristics / Resistance: B 10k 1W

2.5

M9P0.75

55

6

40

30

Names and scale

External power / 0~100%

Manual power / the same as above

Base power / the same as above

High / Low power / the same as above

Current Limitrer / 50~100%

30

50

60

70

9.5

1.6

20

10

20

37

80

10

90

0

100

t1.0

Panel Cutout

3

9.5

12

1.5

17

Unit: mm

Series

PAC36P

Warning

This product is designed for controlling the power of a heater or similar equipment used in a general industrial

facilities. (It is not to be used for any purpose which regulates the prevention of serious effects on human life or safety.)

Caution

If the possibility of loss or damage to your system or property as a result of failure of any part of the process exists, proper

safety measures must be made before the instrument is put into use so as to prevent the occurrence of trouble.

ISO 9001

(The contents of this brochure are subject to change without notice.)

Temperature and Humidity Control Specialists

Head Office: 2-30-10 Kitamachi, Nerima-Ku, Tokyo 179-0081 Japan

Phone: +81-3-3931-7891 Fax: +81-3-3931-3089

E-MAIL: exp-dept@shimaden.co.jp URL: http://www.shimaden.co.jp

Das könnte Ihnen auch gefallen

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Gen ProtectionDokument92 SeitenGen ProtectionjovenlouNoch keine Bewertungen

- Iec TR 61597-2021Dokument34 SeitenIec TR 61597-2021ahmet ozturk100% (2)

- HVAC Engineer Resume SummaryDokument12 SeitenHVAC Engineer Resume SummarySri Hari50% (2)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetVon EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNoch keine Bewertungen

- Dsb19 0003. 30rb Xa XW Exv Board ChangesDokument4 SeitenDsb19 0003. 30rb Xa XW Exv Board Changesชัยณรงค์ เทียนบุตรNoch keine Bewertungen

- Battles Map by Map (UK Edition) by DKDokument288 SeitenBattles Map by Map (UK Edition) by DKahmet ozturk100% (3)

- Analog Circuit Design Volume Three: Design Note CollectionVon EverandAnalog Circuit Design Volume Three: Design Note CollectionBewertung: 3 von 5 Sternen3/5 (2)

- Paul A. Longley, Michael F. Goodchild, David J. Maguire, David W. Rhind-Geographic Information Systems and Science-Wiley (2005)Dokument605 SeitenPaul A. Longley, Michael F. Goodchild, David J. Maguire, David W. Rhind-Geographic Information Systems and Science-Wiley (2005)KamilaNoch keine Bewertungen

- Turning Gear MotorDokument7 SeitenTurning Gear Motorahmet ozturkNoch keine Bewertungen

- STARFINDER SOCIETY ROLEPLAYING GUILD SHIPSDokument10 SeitenSTARFINDER SOCIETY ROLEPLAYING GUILD SHIPSJackNoch keine Bewertungen

- EN - PDW3000 Gutor UpsDokument4 SeitenEN - PDW3000 Gutor Upsperumal1312Noch keine Bewertungen

- Variador User HandyDokument6 SeitenVariador User HandyDavid S. Valenzuela Portillo100% (2)

- Modular 1800W rectifier for telecom and datacomDokument3 SeitenModular 1800W rectifier for telecom and datacomCarlos AngaritaNoch keine Bewertungen

- TP4860C Outdoor Power System Brochure 05 - (20130416)Dokument2 SeitenTP4860C Outdoor Power System Brochure 05 - (20130416)José Esteban Casalino Guerrero100% (1)

- The ISO27k Standards: # Standard Published Title NotesDokument8 SeitenThe ISO27k Standards: # Standard Published Title NotesGiselle GirondinNoch keine Bewertungen

- Tas6xx Rev 05 Install Man 600-00282-000Dokument132 SeitenTas6xx Rev 05 Install Man 600-00282-000Angel FrancoNoch keine Bewertungen

- SPD39T 39B6X Service Manual-01-0226 PDFDokument63 SeitenSPD39T 39B6X Service Manual-01-0226 PDFAlejandroVCMXNoch keine Bewertungen

- GE Gas Turbine Training Manual PDFDokument290 SeitenGE Gas Turbine Training Manual PDFmehrzad rahdar100% (11)

- 29TC679FDokument29 Seiten29TC679FGustavo ChavezNoch keine Bewertungen

- MFA350 :: ROAL Living EnergyDokument6 SeitenMFA350 :: ROAL Living EnergyroalscribdNoch keine Bewertungen

- SM1800 50 33Dokument4 SeitenSM1800 50 33sam100% (1)

- 2006 SM600Dokument2 Seiten2006 SM600Ioryogi KunNoch keine Bewertungen

- DPU-3P-Digital Power ControllerDokument8 SeitenDPU-3P-Digital Power ControllerLechien LeNoch keine Bewertungen

- Digital Controller R35Dokument12 SeitenDigital Controller R35Takagi PhạmNoch keine Bewertungen

- GUTOR PDW DataDokument4 SeitenGUTOR PDW Dataeng_iqbalNoch keine Bewertungen

- Temperature ControllerDokument8 SeitenTemperature ControllerWai Ee YapNoch keine Bewertungen

- Catalogo MtsDokument57 SeitenCatalogo MtsLuis Miguel Martinez100% (1)

- sm1600 GBDokument4 Seitensm1600 GBTran Hong HiepNoch keine Bewertungen

- Gradateur CI-Tronic Analogue Power Controller Type ACI 30-1 and ACI 50-1Dokument8 SeitenGradateur CI-Tronic Analogue Power Controller Type ACI 30-1 and ACI 50-1marocainissamNoch keine Bewertungen

- UPS Nghean PDFDokument2 SeitenUPS Nghean PDFNguyễn Công CườngNoch keine Bewertungen

- Control Ad or Temperatura Shimaden - SR73Dokument8 SeitenControl Ad or Temperatura Shimaden - SR73Alexis Daniel Rosas MachadoNoch keine Bewertungen

- Compact Switch Mode Rectifier Provides 700W Constant Power Output for Telecom ApplicationsDokument4 SeitenCompact Switch Mode Rectifier Provides 700W Constant Power Output for Telecom ApplicationsrobertwebberNoch keine Bewertungen

- Compact switch mode rectifier with overvoltage protectionDokument2 SeitenCompact switch mode rectifier with overvoltage protectionNguyen Minh TuNoch keine Bewertungen

- MKC - PKCDokument12 SeitenMKC - PKCTymbark MaspexNoch keine Bewertungen

- E5ar-T Ds CSMKJJDokument12 SeitenE5ar-T Ds CSMKJJSteven TjiputraNoch keine Bewertungen

- Controlreg 200/200P: Control ElectronicsDokument4 SeitenControlreg 200/200P: Control ElectronicsMuhammad Rizwan SiddiquiNoch keine Bewertungen

- 3000W Single Output Power Supply Spec SheetDokument6 Seiten3000W Single Output Power Supply Spec SheetGrigoriu CodrutaNoch keine Bewertungen

- Powersupply 4A12-P4Dokument4 SeitenPowersupply 4A12-P4FightingEntropyNoch keine Bewertungen

- SI 3010KM DatasheetDokument9 SeitenSI 3010KM DatasheetAndres GuioNoch keine Bewertungen

- Thyristor Control Heater Panel GuideDokument63 SeitenThyristor Control Heater Panel Guidevaithy1990Noch keine Bewertungen

- Power Sentinel Charger: SCR Automatic Battery ChargerDokument4 SeitenPower Sentinel Charger: SCR Automatic Battery ChargerarfineiraNoch keine Bewertungen

- GutorDokument4 SeitenGutorFakhr-e-Alam100% (1)

- 3000W Single Output Power Supply: SeriesDokument7 Seiten3000W Single Output Power Supply: SeriesAlexander PekarovskiyNoch keine Bewertungen

- Large White PV Display That’s Easier to ReadDokument4 SeitenLarge White PV Display That’s Easier to ReadVijaya KumarNoch keine Bewertungen

- Pressure Transmitter Cerabar T PMP 131Dokument8 SeitenPressure Transmitter Cerabar T PMP 131James GilNoch keine Bewertungen

- Ari PremioDokument0 SeitenAri PremioCandiano PopescuNoch keine Bewertungen

- CI CW DatasheetDokument6 SeitenCI CW DatasheetRam ReddyNoch keine Bewertungen

- SCR w5 enDokument10 SeitenSCR w5 enAji Beni LastomoNoch keine Bewertungen

- T3000Dokument12 SeitenT3000Hamdi HosniNoch keine Bewertungen

- KAM CatalogDokument34 SeitenKAM Catalog08Dhanushka100% (1)

- PT-76 Series Temperature Controller Operation Manual - B0Dokument2 SeitenPT-76 Series Temperature Controller Operation Manual - B0jowegNoch keine Bewertungen

- Manual MaxthermoDokument8 SeitenManual Maxthermolfrago6Noch keine Bewertungen

- ZVF300 Frequency Converter Specs General TypeDokument3 SeitenZVF300 Frequency Converter Specs General Typesk91222Noch keine Bewertungen

- Integrative DC Power Series - 48VDC Up To 17.4kW: FeaturesDokument2 SeitenIntegrative DC Power Series - 48VDC Up To 17.4kW: FeaturesKarrar Hussain100% (1)

- RM2048XP v1.6Dokument2 SeitenRM2048XP v1.6Hoa LuongNoch keine Bewertungen

- Inverter WelderDokument6 SeitenInverter WelderkokiskoNoch keine Bewertungen

- K8Ab-As: Model Number StructureDokument10 SeitenK8Ab-As: Model Number Structureedwin_tilungNoch keine Bewertungen

- ML7000 Product OverviewDokument2 SeitenML7000 Product OverviewbandihootNoch keine Bewertungen

- SLI50 Inverter DatasheetDokument2 SeitenSLI50 Inverter DatasheetLarry RichardsonNoch keine Bewertungen

- C324G Low Power Quad OpAmpDokument12 SeitenC324G Low Power Quad OpAmpwhynot05Noch keine Bewertungen

- 5kva Solar InverterDokument2 Seiten5kva Solar InverterEng-Fadi Hafez KhNoch keine Bewertungen

- Shimaden Digital Controller: Shimaden, Temperature and Humidity Control SpecialistsDokument8 SeitenShimaden Digital Controller: Shimaden, Temperature and Humidity Control SpecialistsGeta IvanNoch keine Bewertungen

- 7225 AcDokument12 Seiten7225 AcEdson AyalaNoch keine Bewertungen

- RW748U 700W 48V DC Wall Mount RectifierDokument2 SeitenRW748U 700W 48V DC Wall Mount RectifierGuillermo OvelarNoch keine Bewertungen

- RISH Master 3430: Digital Multifunction InstrumentDokument5 SeitenRISH Master 3430: Digital Multifunction InstrumentJAY PARIKHNoch keine Bewertungen

- Hauser Endress: Pressure Transducer Cerabar T PMP 131Dokument8 SeitenHauser Endress: Pressure Transducer Cerabar T PMP 131CardonettiNoch keine Bewertungen

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesDokument19 SeitenCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesRicardo Teixeira de AbreuNoch keine Bewertungen

- Milli Piyango: Biletlerin Listesi (Çekiliş No:13)Dokument3 SeitenMilli Piyango: Biletlerin Listesi (Çekiliş No:13)ahmet ozturkNoch keine Bewertungen

- Iec 61937-1-2021Dokument52 SeitenIec 61937-1-2021ahmet ozturkNoch keine Bewertungen

- Energy Storage Technologies Battery Storage For Grid StabilizationDokument39 SeitenEnergy Storage Technologies Battery Storage For Grid Stabilizationahmet ozturkNoch keine Bewertungen

- Basic Protection Theory 2013 BWDokument68 SeitenBasic Protection Theory 2013 BWGigi KentNoch keine Bewertungen

- dgpt2 2011 English Rev1 PDFDokument18 Seitendgpt2 2011 English Rev1 PDFAdil AbdoNoch keine Bewertungen

- Basic Protection Theory 2013 BWDokument68 SeitenBasic Protection Theory 2013 BWGigi KentNoch keine Bewertungen

- BR 00305001 eDokument13 SeitenBR 00305001 eHasrat NawazNoch keine Bewertungen

- File 356 LS2100 Static Starter PDFDokument28 SeitenFile 356 LS2100 Static Starter PDFahmet ozturkNoch keine Bewertungen

- PQ PDFDokument6 SeitenPQ PDFGiri Tharan RockNoch keine Bewertungen

- Harmonic and Loss Analysis of Space-Vector Modulated ConvertersDokument6 SeitenHarmonic and Loss Analysis of Space-Vector Modulated Convertersahmet ozturkNoch keine Bewertungen

- ZXWN EIR Technical SpecificationDokument35 SeitenZXWN EIR Technical SpecificationCoachArun MishraNoch keine Bewertungen

- Digitalization in HealthcareDokument2 SeitenDigitalization in HealthcareAlamNoch keine Bewertungen

- HBL Tower Mechanical Floor EssayDokument3 SeitenHBL Tower Mechanical Floor EssayHammadNoch keine Bewertungen

- MS Agreement Product SheetDokument2 SeitenMS Agreement Product SheetAbdeldjalil AchourNoch keine Bewertungen

- New GD&TDokument3 SeitenNew GD&TvasantNoch keine Bewertungen

- Spanning Tree Protocol: CCNA3-1 Chapter 5-2Dokument34 SeitenSpanning Tree Protocol: CCNA3-1 Chapter 5-2mohammad ramdhanNoch keine Bewertungen

- Replication Avamar DatadomainDokument94 SeitenReplication Avamar DatadomainAsif ZahoorNoch keine Bewertungen

- Huawei HCNA-VC Certification TrainingDokument3 SeitenHuawei HCNA-VC Certification TrainingArvind JainNoch keine Bewertungen

- Fixed Displacement Radial Piston Pump: Replaces: 03.95Dokument16 SeitenFixed Displacement Radial Piston Pump: Replaces: 03.95kamalNoch keine Bewertungen

- Tally Erp 9.0 Material Control Centre in Tally Erp 9.0Dokument27 SeitenTally Erp 9.0 Material Control Centre in Tally Erp 9.0Raghavendra yadav KMNoch keine Bewertungen

- Test Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeDokument6 SeitenTest Logic Insertion For Optimization of Testing Parameters On Lower Technology NodeshaguftaNoch keine Bewertungen

- Introduction To ComputersDokument120 SeitenIntroduction To ComputersJimmy ReeceNoch keine Bewertungen

- PDF Service Manual Ge Healthcare Dash 2500 DLDokument71 SeitenPDF Service Manual Ge Healthcare Dash 2500 DLWidassNoch keine Bewertungen

- Hydrogen Application Step by Step GuideDokument13 SeitenHydrogen Application Step by Step Guidewindreader1Noch keine Bewertungen

- Seminar-Machining Centers and Machine Tool StructuresDokument20 SeitenSeminar-Machining Centers and Machine Tool StructuresniteshwanNoch keine Bewertungen

- Gige Camera and Lighting For Pc-Based Machine VisionDokument24 SeitenGige Camera and Lighting For Pc-Based Machine VisionCarlos MolinaNoch keine Bewertungen

- Service and Support training-HP LaserJet Pro M501, HP LaserJet Enterprise M507, M506, MFP M528, M527, Managed E50145, E50045, MFP E52645, E52545Dokument39 SeitenService and Support training-HP LaserJet Pro M501, HP LaserJet Enterprise M507, M506, MFP M528, M527, Managed E50145, E50045, MFP E52645, E52545Alves CarvalhoNoch keine Bewertungen

- BCAS Cicular - In-Line X-Ray - 11-2017Dokument26 SeitenBCAS Cicular - In-Line X-Ray - 11-2017agarwalabhay3_991072Noch keine Bewertungen

- Engine Driven Welders PDFDokument13 SeitenEngine Driven Welders PDFLazzarus Az GunawanNoch keine Bewertungen

- WLC D1Dokument2 SeitenWLC D1jvtamilanbanNoch keine Bewertungen

- GCC Jaguariv UserguideDokument120 SeitenGCC Jaguariv UserguideDiana ArghirNoch keine Bewertungen

- Release Notes Sap 2000 V 2331Dokument8 SeitenRelease Notes Sap 2000 V 2331sami touatiNoch keine Bewertungen