Beruflich Dokumente

Kultur Dokumente

Irjet V2i627 PDF

Hochgeladen von

Prasad RaikarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Irjet V2i627 PDF

Hochgeladen von

Prasad RaikarCopyright:

Verfügbare Formate

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 02 Issue: 06 | Sep-2015

p-ISSN: 2395-0072

www.irjet.net

Design and Fabrication of fixture for support flywheel housing

Devendra.Gani1, Prasad U. Raikar2

Lecturer, Mechanical Engineering Department, R N Shetty college, Karnataka, India

Assistant Professor, Product Design & Manufacturing Department, VTU, Belagavi, Karnataka, India

1

---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract - Support fly wheel housing is the name of

the component and is used for diesel generators. The

necessity

of

carrying

this

project

is,

after

manufacturing of the component,the sprue,runner and

gate will be attached to the component. These sprue,

runner and gate are unwanted and waste parts. At the

time of manufacturing of the component,it is very

difficult to remove the sprue,runner and gate. Using

trial and error methods may cause accidents and some

times

component

may

break.

For

holding

the

component fixtures are necessary. Because component

is heavy and having some weight. So the component is

not flat and having some intricate profiles. Such kind of

components must and should requires some holding

equipments. With the help of holding arrangements we

part is removed with the help of wedge breaker. We

cannot remove by hammering also. It requires lot of

energy and consumes more energy. But safety will not be

there. Sometimes component may get damage. So to avoid

all these things, designing of fixture is very much essential.

The fixture is holding the component firmly. After fixing

the component in fixture, component will not vibrate. So

that easily we can remove the waste part from the

component. It saves the operators time and it reduces the

cost of production. It is increasing the rate of production

and maintaining the quality.

2. MATERIALS AND METHODS

For fixture design we can use any type material. But it

depends on nature of work, work piece etc. Some fixtures

are designed from wood material, some fixtures are from

metal, some are from plastic materials, and some are from

composite materials etc.

According to support fly wheel housing component, it is

selected mild steel material, for designing of fixture. Mild

steel material is very much use full for designing of a

fixture.

can easily remove the waste parts from the component.

For this reason designing of a fixture is very much

essential. The fixture is very much essential for support

fly wheel housing. The designed fixture will hold the

component firmly without any shake or vibration. With

the help of this fixture we can easily remove the

unwanted parts from the component.

Key Words: Diesel generator, wedge feed breaker,

Fixture, intricate profile

1. INTRODUCTION

For this component designing of a fixture is very much

essential. Why because, the component is heavy. Large in

size and is more weight. This is not possible to carry by

hand. After producing the component the sprue, runner

and gate will be attached to the component. Removing of

these unwanted part is not that much easy. This waste

2015, IRJET

Figure 1:support flywheel housing

ISO 9001:2008 Certified Journal

Page 147

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 02 Issue: 06 | Sep-2015

p-ISSN: 2395-0072

www.irjet.net

Support fly wheel housing is made up of gray cast iron

material. It consists of 4 to 5% of carbon. This is

manufactured in foundry with the help of core and cavity.

The gray cast iron molten metal is having around 600

degree centigrade. The material will be under the furnace,

and is directly poured into the mould. After 3 to 4 hours

the component will become dry. After dry, the component

is allowed to atmospheric air for cooling purpose. After

cooling, the component is removed from the mould, the

component consists of sprue, runner and gate, and these

are attached to the component. Such parts are unwanted.

We have to remove unwanted parts with the help of

removers.

These components are bit large in size and

the weight of the component is around 3kgs.

3. RESULTS AND DISCUSSIONS

Table 1:Before production[without fixture]

Time period

Number of

components

(Hours)

1

09

13

20

27

43

55

63

72

Figure 2:Fixture Assembly

2015, IRJET

ISO 9001:2008 Certified Journal

Page 148

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 02 Issue: 06 | Sep-2015

p-ISSN: 2395-0072

www.irjet.net

Table 2:After production[Using fixture]

Time period

REFERENCES

Number of

components

[1]

Shailesh S.Pachbhai, Laukik P.Raut A Review on

Design of Fixtures, International Journal of Engineering

Research and General Science Volume 2, Issue 2, Feb-Mar

2014 ISSN 2091-2730

(Hours)

1

18

27

38

51

64

77

89

103

[2] C.RadhaMadhavi, B.Ramu, K.Srinivasulu DESIGN OF

MACHINING FIXTURE FOR TURBINE ROTOR BLADE

IJRET: International Journal of Research in Engineering

and Technology eISSN: 2319-1163 | pISSN: 2321-7308

[3] K. Nanthakumar, V. Prabakaran, Design and

Fabrication Testing of Combined Multipurpose Jig a IOSR

Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 11, Issue 4

Ver. VII (Jul- Aug. 2014), PP 86-91

[4] Anil A Jadhav, Prof .Vilas Shinde ELIMINATION OF

DEFECT IN CAPACITOR BY IMPLEMENTING FIXTURES,

International Journal of Technical Research and

Applications e-ISSN: 2320-8163, www.ijtra.com Volume 3,

Issue 1 (Jan-Feb 2015), PP. 132-134,

[5] N. P. Maniar, D. P. Vakharia, Design & Development of

Fixture for CNC Reviews, Practices & Future Directions.

International Journal of Scientific & Engineering Research

Volume 4, Issue 2, February-2013 ISSN 2229-5518.

4. CONCLUSIONS

BBBBBBB

Such kind of components requires fixture for holding

purpose. It is very difficult to hold the component by hand

at the time of machining. Because this component is large

in size and is more weight. It needs suitable holding

arrangements. Designing of fixture is very much important

and it is necessary. After designing of the fixture,

production rate is increased. It avoids maximum accidents.

Life of the tool will be more and can be use for longer

period of time. It is only one time tool manufacturing

investment. It saves the operators time and produces

good quality products.

ACKNOWLEDGEMENT

We thank PG Coordinator, Dr. A. V Shivapur, Department

of PG Studies, VTU, Belagavi and Dr. R.R Malagi, HOD

Department of PDM, VTU, Belagavi for their co-operation,

constant encouragement and valuable suggestions

throughout this research work.

2015, IRJET

ISO 9001:2008 Certified Journal

Page 149

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDokument9 SeitenSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosPrasad RaikarNoch keine Bewertungen

- Determination of Extinction, Absorption and Scattering Coefficients of Gold NanoparticlesDokument2 SeitenDetermination of Extinction, Absorption and Scattering Coefficients of Gold NanoparticlesPrasad RaikarNoch keine Bewertungen

- Sensors and Actuators B: Chemical: CD Concentration Sensor Based On Fiber Grating TechnologyDokument6 SeitenSensors and Actuators B: Chemical: CD Concentration Sensor Based On Fiber Grating TechnologyPrasad RaikarNoch keine Bewertungen

- HTTP WWW - Google.co - in Url Q HTTP Nptel - Iitm.ac - in Courses IIT-MADRAS Machine Design II PDF 2 7Dokument15 SeitenHTTP WWW - Google.co - in Url Q HTTP Nptel - Iitm.ac - in Courses IIT-MADRAS Machine Design II PDF 2 7fiemsabyasachiNoch keine Bewertungen

- Irjet V2i412 PDFDokument9 SeitenIrjet V2i412 PDFPrasad RaikarNoch keine Bewertungen

- 110 - Gears&Gear Lubrication PDFDokument4 Seiten110 - Gears&Gear Lubrication PDFPrasad RaikarNoch keine Bewertungen

- Irjet V2i4135 PDFDokument6 SeitenIrjet V2i4135 PDFPrasad RaikarNoch keine Bewertungen

- P 839 PDFDokument17 SeitenP 839 PDFPrasad RaikarNoch keine Bewertungen

- Akki2011 PDFDokument6 SeitenAkki2011 PDFPrasad RaikarNoch keine Bewertungen

- Irjet V2i4147 PDFDokument5 SeitenIrjet V2i4147 PDFPrasad RaikarNoch keine Bewertungen

- MechDokument35 SeitenMechkumarNoch keine Bewertungen

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDokument9 SeitenSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosPrasad RaikarNoch keine Bewertungen

- Sliding Wear and Friction Behaviour of Al-18% Si-0.5% MG Alloy PDFDokument6 SeitenSliding Wear and Friction Behaviour of Al-18% Si-0.5% MG Alloy PDFPrasad RaikarNoch keine Bewertungen

- Pinondisk PDFDokument5 SeitenPinondisk PDFPrasad RaikarNoch keine Bewertungen

- Contact Stress On The Surface of Gear Teeth With Different Profile PDFDokument8 SeitenContact Stress On The Surface of Gear Teeth With Different Profile PDFPrasad RaikarNoch keine Bewertungen

- A Study of Churning Losses in Dip-Lubricated Spur Gears PDFDokument11 SeitenA Study of Churning Losses in Dip-Lubricated Spur Gears PDFPrasad RaikarNoch keine Bewertungen

- Investigation Load-Independent Power Losses Gear SystemsDokument189 SeitenInvestigation Load-Independent Power Losses Gear SystemsPrasad RaikarNoch keine Bewertungen

- Vehicle Body Engineering Guide to Painting & Rust PreventionDokument28 SeitenVehicle Body Engineering Guide to Painting & Rust PreventionPrasad RaikarNoch keine Bewertungen

- Steel PDFDokument31 SeitenSteel PDFPrasad RaikarNoch keine Bewertungen

- Aerodynamics Basics PDFDokument39 SeitenAerodynamics Basics PDFPrasad RaikarNoch keine Bewertungen

- AluminiumDokument20 SeitenAluminiumPrasad RaikarNoch keine Bewertungen

- Vehicle AerodynamicsDokument15 SeitenVehicle AerodynamicsPrasad RaikarNoch keine Bewertungen

- Glass PDFDokument17 SeitenGlass PDFPrasad RaikarNoch keine Bewertungen

- Wind Tunnels1 PDFDokument56 SeitenWind Tunnels1 PDFPrasad RaikarNoch keine Bewertungen

- Unit7 8 GSP PDFDokument51 SeitenUnit7 8 GSP PDFPrasad RaikarNoch keine Bewertungen

- Plastics & Composte Materials PDFDokument27 SeitenPlastics & Composte Materials PDFPrasad RaikarNoch keine Bewertungen

- Unit7 8 GSP PDFDokument51 SeitenUnit7 8 GSP PDFPrasad RaikarNoch keine Bewertungen

- Visvesvaraya Technological University: Dr. K. E. Prakash - RegistrarDokument2 SeitenVisvesvaraya Technological University: Dr. K. E. Prakash - RegistrarPrasad RaikarNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ESAB Welding HandbookDokument31 SeitenESAB Welding Handbookhooky1100% (4)

- 1999 System Wiring Diagrams. Chevrolet - SuburbanDokument1 Seite1999 System Wiring Diagrams. Chevrolet - SuburbanJimmy Perera BurgosNoch keine Bewertungen

- Technical Specifications: 12 V 18ah AGM 5 YearsDokument2 SeitenTechnical Specifications: 12 V 18ah AGM 5 YearsDaniel EspinozaNoch keine Bewertungen

- 3 Phase Induction Motors Objective Questions With AnswersDokument3 Seiten3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)

- Zener DataDokument2 SeitenZener Dataapi-27149887Noch keine Bewertungen

- 2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesDokument6 Seiten2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesPavithraRamNoch keine Bewertungen

- Catálogo King LaiDokument144 SeitenCatálogo King LaiJason Salas FloresNoch keine Bewertungen

- Wacker Neuson-Dpu - 25 KNDokument3 SeitenWacker Neuson-Dpu - 25 KNMilutin BožovićNoch keine Bewertungen

- Brochure 45 AntasariDokument11 SeitenBrochure 45 AntasariFisio Terapi100% (1)

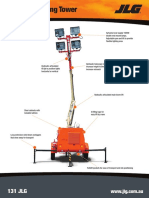

- JLG Lighting Tower 6308AN Series II 20150907Dokument2 SeitenJLG Lighting Tower 6308AN Series II 20150907DwiSulistyo09Noch keine Bewertungen

- Microsoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbaDokument14 SeitenMicrosoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbashubhamformeNoch keine Bewertungen

- NDI Manual 2013 - v10Dokument13 SeitenNDI Manual 2013 - v10Yudha Bhakti NugrahaNoch keine Bewertungen

- Bottom Ash HopperDokument8 SeitenBottom Ash HopperBhargav ChaudhariNoch keine Bewertungen

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDokument7 SeitenPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4Noch keine Bewertungen

- An Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDokument8 SeitenAn Algorithm For Minimax Solution of Overdetennined Systems of Non-Linear EquationsDewi FitriyaniNoch keine Bewertungen

- Micron Ezeprox Access Control KeypadDokument4 SeitenMicron Ezeprox Access Control KeypadThuy VuNoch keine Bewertungen

- Advantages & Disadvantages CITWDokument5 SeitenAdvantages & Disadvantages CITWSreePrakashNoch keine Bewertungen

- XHLE Long Coupled Centrifugal Pump EnglishDokument8 SeitenXHLE Long Coupled Centrifugal Pump Englishgagi1994brahimNoch keine Bewertungen

- Concrete: Concrete Is A Composite Material Composed of Fine and CoarseDokument36 SeitenConcrete: Concrete Is A Composite Material Composed of Fine and CoarseclubmailusNoch keine Bewertungen

- Final ReportDokument33 SeitenFinal ReporttsutsenNoch keine Bewertungen

- The Shand CCS Feasibility Study Public ReportDokument124 SeitenThe Shand CCS Feasibility Study Public ReportSai RuthvikNoch keine Bewertungen

- VisiLogic Software Manual-LadderDokument158 SeitenVisiLogic Software Manual-LadderEduardo Vasquez CastroNoch keine Bewertungen

- January2016page1to36 Layout 1Dokument36 SeitenJanuary2016page1to36 Layout 1c737Noch keine Bewertungen

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDokument1 SeiteBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalNoch keine Bewertungen

- Niveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DDokument1 SeiteNiveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DAWOUNANGNoch keine Bewertungen

- Technical Presentation - Arik Ethan Kinajil (25231)Dokument5 SeitenTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanNoch keine Bewertungen

- Method StatementDokument2 SeitenMethod StatementKumar Jbs100% (1)

- Schneider LV Switchboard Inspection GuideDokument59 SeitenSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- Failure Analysis of Syngas Bypass Line Rupture inDokument11 SeitenFailure Analysis of Syngas Bypass Line Rupture inshahgardezNoch keine Bewertungen

- Power and Simplicity: Pace ScientificDokument16 SeitenPower and Simplicity: Pace ScientificAnonymous mNQq7ojNoch keine Bewertungen