Beruflich Dokumente

Kultur Dokumente

Well Identification and Environmental Management

Hochgeladen von

Oghale B. E. OmuaborOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Well Identification and Environmental Management

Hochgeladen von

Oghale B. E. OmuaborCopyright:

Verfügbare Formate

Shell Exploration & Production

Well Identification and

Environmental Management

A lesson in Standards and Data Management

PUG Conference 2008

February 25 Houston, TX

Keith Fraley

Shell Exploration and Production

Shell Exploration & Production

Presentation Overview:

The Problem:

Migrating Critical Data from a Pilot Phase to Production Grade

The Solution:

Leverage Technology, Standards and Interoperability

What To Take away:

Think

agile

Big, even when starting small, but, at all costs, remain

Shell Exploration & Production

Geographic and Resource

Overview:

Piceance Basin Oil Shale

Enormous Resource Potential

Northwest Area of Colorado

Complex Subsurface Hydrological Model

Hydrological Characterization Needed to Formulate Risk

Assessment

Hydrological Drilling and Sampling Program Evolves

Shell Exploration & Production

Geographic and Resource

Overview:

Why is Hydrology Important?

Extremely complex and integrated Aquifer systems

Series of Aquifers are intertwined with Oil Shale Resource

Key to the Financial Risk Assessment of the Project

Key to the Environmental Risk Assessment of the Project

Shell Exploration & Production

Geographic Overview

Shell Exploration & Production

The Problem (Overview):

No mandated standard for storing hydrology Well

header information

No clear method for marking hydrology wells in the

field

No established approach for collection and storage

of hydrology sampling event results

No Field based GIS tools

Shell Exploration & Production

The Problem (In depth):

No mandated standard for storing hydrology well

header information

Hydrology program began as a small R&D effort 20 years ago

Well data was kept in Excel spreadsheets or in peoples heads

No complete record of drilling results

Planned vs Actual drilled

Recompletion info convoluted

Naming conventions non standardized

Survey information not comprehensive

What, where?

Shell Exploration & Production

The Problem (In depth):

No clear method for marking wells in the field

Wells were identified in field in different ways, many not

identified at all

Evolved into a large number of wells (500-600)

Names changed

Initial attempts to mark wells left much to be desired

Location and Survey info was confusing, not complete

Shell Exploration & Production

The Problem (In depth):

No established approach for collection and storage

of hydrology sampling event results

Field Data was logged in a Note Book, no digital entry mechanism

Transcription errors occurred

400,000 analytical results housed in disparate locations

Life cycle for data to end consumers was long and siloed

Critical data was housed with consultants

No common platform for storage and dissemination of hydrology data

Shell Exploration & Production

The Problem (In depth):

No Field based GIS tools

Hard copy maps were ineffective do to dynamic data environment

and amount of data

Needed a digital solution in the field to leverage in house GIS

datasets

Wells, Aerials, Lease and Property Boundaries, Federal Land,

Resource Info

Aerial, Elevation and Topo data critical

GPS Navigation was a value add

Shell Exploration & Production

These Problems resulted in:

Confusion on validity of data

Data Analysis Latency

Over dependency on consultants

Disconnect between back office and field crews

Distrust of data by our end consumers

Shell Exploration & Production

Shell Exploration & Production

The Solution (Overview):

Well Identification Program (WIP) and Environmental

Management Implementation

QA

/ QC all existing wells

Migrate well header info into OpenWorks

Migrate Environmental Sampling Data into EQuIS

Tag wells in the field with standardized methodology

Develop a field GIS platform to disseminate

geographic data

Shell Exploration & Production

The Solution In Depth:

Exhaustive QA / QC process both from office and field

Migrate

well header data out of Excel and into corporate project

well repository (OpenWorks)

Assign internal API numbers for hydrology wells

Spatialize OpenWorks wells for verification against high

resolution aerial photos in ArcGIS

Mandate a standard datum and projection for new wells

Integrate into Petrel via OpenSpirit for use in modeling

Shell Exploration & Production

Shell Exploration & Production

Shell Exploration & Production

The Solution In Depth Cont:

Field verification of every single well

Equip field crews with GIS software / data and corresponding

hard copy maps

Goal: To physically touch and verify every Shell well in basin

Catalog every well with photo, and video of each Pad

Result: Invaluable process that revealed numerous data errors

even after initial QA Step

Residual effect: Creation of road and trail GIS layer via GPS

logging

End Result: Certainty in the data that users were looking for in

order to trust the data we provided

Shell Exploration & Production

The Solution In Depth Cont:

Migrate all Environmental Data to EQuIS:

What?

Environmental Quality Information System (EQuIS)

EarthSoft Corp (http://www.earthsoft.com)

Why?

Highly Refined Data Model

Front End Clients for Data Analysis

Field Data Collection Tools

Scope

Migrated 400,000 analytical results

Train Lab and field crews

Shell Exploration & Production

The Solution In Depth Cont:

2D barcode stickers for all Hydrology Wells

2D Barcode encoded with relevant well header info (Lat, Lon, API, Well

Name, Permit Name, Sec Town Range, Drill Date, Elevation, Well

Purpose)

Well

headed info encoded as an XML Stream

Barcode based on published DataMatrix standard

Provided a platform for existing and future field based applications

Well headed info pulled directly out of OpenWorks and encoded into

Barcode Tiff Image

Software Development Kit from Lead Technologies

Shell Exploration & Production

2D barcode stickers cont

Vinyl Sticker from DuraLabel placed on well

Low cost, easy to implement and replace

Field tested for 1 year prior to implementation

3.0 mil vinyl material

Weather and sun resistant

Used on military equipment and drillings rigs the

world over

Shell Exploration & Production

Shell Exploration & Production

Shell Exploration & Production

The Solution In Depth Cont:

Field Crew Equipped Hardware

Panasonic Toughbook 30

MIL-STD-810F Tested

Intrinsically safe device (for use in explosion-prone areas)

GPS

Bluetooth

Wide Area Wireless Enabled

Rugged Bluetooth Barcode Readers

2D Datamatrix compatible

Shell Exploration & Production

The Solution In Depth Cont:

Software Field Crews (Approach):

Geographic Based

Aerial Imagery Foundation

GPS Integration Capable

In Line with Shell Global GIS Initiatives

3D Capable

Open

Cost Effective

Lean and Mean

Shell Exploration & Production

The Solution In Depth Cont:

Software (Choice):

ArcGIS Explorer (AGX) for field GIS Platform

Data Delived as a cached bundle, leveraging both ESRI ArcGIS Online Services and

internal Shell ArcGIS Services

Easy to use, and straight forward for our Field Crews

GPS Navigation

NEMA feeds from Toughbook Integrated GPS Chip

EarthBridge integrated into AGX as Custom Task

EarthBridge ports NEMA feeds into KML (originally designed for Google Earth)

Enables field crews to see their location real-time in AGX

EQuIS IDEF (Intelligent Data Entry Form)

IDEF Integration into AGX as Custom Task

Stream Lined Data Collection

Custom Shell Barcode integration

Eliminate Date Entry errors

Shell Exploration & Production

The Solution In Depth Cont:

Additional Factors for Choosing AGX

Lean yet powerful SDK and OpenGL Support

Platform for Subsurface Data Integration

HTML Capable Notes

Easily Integrate Well Photo and Video Logs

Existing Powerful Tools

Go to location

Import File

Measure

Identify

ESRI Data Support

File Geodatabases

Shapefiles

Rasters

Shell Exploration & Production

AGX: Offline Delivery

Cached AGS Service Bundles

ESRI ArcGIS Online

1 meter Aerial Photos

USGS Topo 1:24k

US Street Map

3d Elevation Model

Shell AGS Services

1 foot Aerial Photos

Property Boundaries

Lease Location

Hydrology Pads

Resource

File Geodatabase

Vector Data

Wells

Deviation Surveys

KML

Real-time GPS

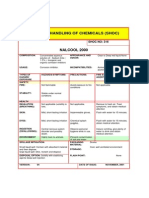

Well Identification Program

Objective: To have a system that will help with well and subsequent

data identification, and reduce in over-all project costs.

Ruggedized Field Laptop

Shell Exploration & Production

GPS / GIS Integration

Field Interface for

EQuIS Sampling

GIS / GPS

Navigation

OpenWorks Well DB

Current Well ID Program: Not clearly defined and confusing; not cost

effective.

Proposed Well ID Program: Physical tagging of wells with a 2D Bar

Code with relevant information.

Benefits of 2D Bar Code System:

Reduction in human effort, and data recording duplication

Elimination of well ID confusion

Aid in data QC and input of data into main databases

Well ID, location, and sample ID errors eliminated

In-field managers can track progress on each well

Allow independent field personnel to track latest

information at

the well site

History is available at each well for all borehole life-cycle

activities

Minimizes chance of old data being used

Data latency is significantly reduced

Errors can be quickly corrected

New information can be quickly reported in a hard-copy

computer readable format

Barcodes can be quickly replaced if damaged

Bar codes are secure and keep data classified, and are

easily combined with encryption and limited user operation

procedures.

Well Name

API, UWI

Total Depth

Drill Date

Comp Date

LL

Contact

Use/Program

etc

The data capacity of a 2-D bar code is

up to 3 K Bytes of data. This should be

sufficient for the most of the information

required including the elevation,

coordinates, well construction

information including location of the

screen and pump, and any other

information associated with the well.

Integrated

wireless GPS

EQuIS

Sampling

Form

Wireless Bar Code

Reader

Reads Data from well bar

code and reports to field

Laptop

Shell Exploration & Production

Screen Shots:

Evolution not Revolution.

Shell Exploration & Production

Screen Shots:

Evolution not Revolution.

Shell Exploration & Production

A Lesson in Standards and Data Management

Leveraged Standards

XML

Barcodes

Webservices

DataMatrix

Barcode Encoding

NEMA

GPS Integration

KML

Real-time GPS Display

MIL-STD-810F

Intrinsically Safe Devices

Leveraged RDMS

OpenWorks

Shell Exploration & Production

In Summary, lessons learned

Testament to Standards

The wonderful thing about Tiggers, is Tiggers is a wonderful thing

Think big, even when starting small

Starting with a scalable vision is imperative for even the smallest projects

Remain Agile (http://www.agilealliance.org/)

Geography matters

Providing easy to use geographic tools in the field is critical

Leverage, leverage, leverage

Leveraging standards and common, open APIs can provide robust solutions in

a timely manner

Shell Exploration & Production

Thank you

Questions?

Das könnte Ihnen auch gefallen

- Computer Project Design: ConceptsDokument25 SeitenComputer Project Design: Conceptsali100% (1)

- Google Earth Engine WorkshopDokument24 SeitenGoogle Earth Engine WorkshopHarityas WiyogaNoch keine Bewertungen

- MethodologyDokument6 SeitenMethodologygazz1982Noch keine Bewertungen

- My ProjectDokument2 SeitenMy Projectjean efoubaNoch keine Bewertungen

- HajanDokument7 SeitenHajandivyabalan006Noch keine Bewertungen

- Digital Shoreline Analysis System (DSAS) 4.0Dokument30 SeitenDigital Shoreline Analysis System (DSAS) 4.0Wahyu SugionoNoch keine Bewertungen

- Egems Databese SystemDokument22 SeitenEgems Databese SystemHydrologywebsiteNoch keine Bewertungen

- Arc Hydro Groundwater IntroduccionDokument11 SeitenArc Hydro Groundwater IntroduccionFrancoPaúlTafoyaGurtzNoch keine Bewertungen

- Seg DDokument2 SeitenSeg Dpani56Noch keine Bewertungen

- Geocap Brochure 2020Dokument31 SeitenGeocap Brochure 2020Nguyễn Duy LươngNoch keine Bewertungen

- Encom Discover 2011Dokument45 SeitenEncom Discover 2011Erland PrasetyaNoch keine Bewertungen

- Data Sheet: Product OverviewDokument4 SeitenData Sheet: Product OverviewDidi AuliaNoch keine Bewertungen

- Auto OrthorectificationDokument16 SeitenAuto OrthorectificationbardionsonNoch keine Bewertungen

- Products of IGIS ProjectDokument36 SeitenProducts of IGIS Projectpanky111Noch keine Bewertungen

- Automating Archydro For Watershed Delineation: Carol Kraemer and Sudhanshu S PandaDokument6 SeitenAutomating Archydro For Watershed Delineation: Carol Kraemer and Sudhanshu S PandaUtut Rara PutraNoch keine Bewertungen

- Jonas Eberle, Dr. Christian Hüttich, Prof. Dr. Christiane SchmulliusDokument1 SeiteJonas Eberle, Dr. Christian Hüttich, Prof. Dr. Christiane SchmulliusPas SatNoch keine Bewertungen

- Catalog - Scientific Software GroupDokument32 SeitenCatalog - Scientific Software GrouppetroljoseNoch keine Bewertungen

- gis-ERSC BatzliDokument18 Seitengis-ERSC Batzliashstu88Noch keine Bewertungen

- Whole Plot Quick Start TutorialDokument0 SeitenWhole Plot Quick Start TutorialSheila FabianaNoch keine Bewertungen

- Michael Corsello: Computer Scientist / BiologistDokument13 SeitenMichael Corsello: Computer Scientist / BiologistMichael CorselloNoch keine Bewertungen

- Embedded System & Robotics Quadcopter Android Apps DevelopmentDokument6 SeitenEmbedded System & Robotics Quadcopter Android Apps DevelopmentArchanaSharmaNoch keine Bewertungen

- ArcGIS2 3.0 Lecture1Dokument270 SeitenArcGIS2 3.0 Lecture1rajaanwar100% (1)

- HEC GeoRAS4 UsersManualDokument204 SeitenHEC GeoRAS4 UsersManualHana Siti KusumadewiNoch keine Bewertungen

- Remote Sensing of EnvironmentDokument10 SeitenRemote Sensing of EnvironmentNajoua AziziNoch keine Bewertungen

- PDA Testing-2008 State of The ArtDokument9 SeitenPDA Testing-2008 State of The ArtLivian TeddyNoch keine Bewertungen

- BP Water Resources - ESRI PDFDokument28 SeitenBP Water Resources - ESRI PDFreluNoch keine Bewertungen

- Switching to ArcGIS Pro from ArcMapVon EverandSwitching to ArcGIS Pro from ArcMapBewertung: 4.5 von 5 Sternen4.5/5 (2)

- A Scalable Geospatial Web Service For Near Real-Time, High-Resolution Land Cover MappingDokument10 SeitenA Scalable Geospatial Web Service For Near Real-Time, High-Resolution Land Cover MappingPhani NNoch keine Bewertungen

- Google Earth Engine Planetary-Scale Geospatial AnaDokument10 SeitenGoogle Earth Engine Planetary-Scale Geospatial Anajhunior mayco tan vásquezNoch keine Bewertungen

- Gil Etal SSS10 SpaceSyntaxToolkitDokument20 SeitenGil Etal SSS10 SpaceSyntaxToolkitBeykhan YamanNoch keine Bewertungen

- A Sample Geodatabase Structure For Managing Archaeological DataDokument13 SeitenA Sample Geodatabase Structure For Managing Archaeological DataMarko CekovićNoch keine Bewertungen

- GIS Applications in Hydrology and Hydraulics QuestionnaireDokument2 SeitenGIS Applications in Hydrology and Hydraulics QuestionnaireSachin KhandareNoch keine Bewertungen

- XsenseDokument47 SeitenXsensenanoteraCHNoch keine Bewertungen

- DCEP 1.0 Lecture1Dokument286 SeitenDCEP 1.0 Lecture1Mihaela Vasiliu100% (1)

- Geophysical Data Processing, An Introduction: August 2010Dokument63 SeitenGeophysical Data Processing, An Introduction: August 2010Cholisina Anik PerwitaNoch keine Bewertungen

- An Integrated GIS Application System For Soil Moisture Data AssimilationDokument7 SeitenAn Integrated GIS Application System For Soil Moisture Data AssimilationRaju KoiralaNoch keine Bewertungen

- Customizing Arcgis For Spatial Decision Support - Case Study: Locating Potential Small Water Reservoirs in BeninDokument9 SeitenCustomizing Arcgis For Spatial Decision Support - Case Study: Locating Potential Small Water Reservoirs in Beninkarlman1Noch keine Bewertungen

- Regional Online Training On Geographic Information System For Hydrology - v3Dokument5 SeitenRegional Online Training On Geographic Information System For Hydrology - v3YosephNoch keine Bewertungen

- Big Data in Research and EducationDokument70 SeitenBig Data in Research and EducationShanmugasundaram MuthuswamyNoch keine Bewertungen

- Fonthill Cemetery Project Phase 1: Progress Report PresentationDokument23 SeitenFonthill Cemetery Project Phase 1: Progress Report PresentationNobuhle MatangaNoch keine Bewertungen

- Oil IT Journal - WWW - Oilit.com - May 2008Dokument18 SeitenOil IT Journal - WWW - Oilit.com - May 2008newmetroNoch keine Bewertungen

- AaronschroederresumeDokument2 SeitenAaronschroederresumeapi-285001679Noch keine Bewertungen

- GCDKit Paper Janousek 2006Dokument5 SeitenGCDKit Paper Janousek 2006HERNAN FELIPE HUERTA AVILEZNoch keine Bewertungen

- SubTelForum Issue32 May2007Dokument3 SeitenSubTelForum Issue32 May2007nautapronautaNoch keine Bewertungen

- Cavbase-Visualization and Database For Cavern Construction, Solution Mining Process, Brine Production and Product StorageDokument7 SeitenCavbase-Visualization and Database For Cavern Construction, Solution Mining Process, Brine Production and Product StoragepbldzcmsNoch keine Bewertungen

- Increasing Drilling Efficiencies Through Analysis of Real-Time and Historic Drilling DataDokument3 SeitenIncreasing Drilling Efficiencies Through Analysis of Real-Time and Historic Drilling DataAnonymous VNu3ODGavNoch keine Bewertungen

- Autodesk Geotechnical Module HelpDokument23 SeitenAutodesk Geotechnical Module HelpPreso UL100% (1)

- Autodesk Geotechnical Module HelpDokument23 SeitenAutodesk Geotechnical Module HelpHumberto Chumbiauca100% (1)

- NRSC Bhuvan - Data - Content - and - Map - Standards PDFDokument50 SeitenNRSC Bhuvan - Data - Content - and - Map - Standards PDFAshoka VanjareNoch keine Bewertungen

- Global Observations and Alerts From Lagrange-Point, Pole-Sitter, and Geosynchronous Orbits (GOAL&GO)Dokument36 SeitenGlobal Observations and Alerts From Lagrange-Point, Pole-Sitter, and Geosynchronous Orbits (GOAL&GO)Clifford StoneNoch keine Bewertungen

- A System For Cleaning High Volume Bathymetry: International Hydrographic ReviewDokument18 SeitenA System For Cleaning High Volume Bathymetry: International Hydrographic ReviewAbbie JenkinsNoch keine Bewertungen

- Water: Ipeat Calibration Tool of SWATDokument17 SeitenWater: Ipeat Calibration Tool of SWATCristhian HuilcapazNoch keine Bewertungen

- CS AIML 3A IceSightDokument8 SeitenCS AIML 3A IceSight2101641530003Noch keine Bewertungen

- Configuring and Managing The Multiuser GeodatabaseDokument7 SeitenConfiguring and Managing The Multiuser GeodatabaseJordán López0% (1)

- Petrosys EP WorkflowsDokument5 SeitenPetrosys EP WorkflowsAz HassanNoch keine Bewertungen

- 1-2c RBD - PpsDokument11 Seiten1-2c RBD - PpsOghale B. E. OmuaborNoch keine Bewertungen

- Letter To Employers On CFI and RSA RegistrationDokument2 SeitenLetter To Employers On CFI and RSA RegistrationOghale B. E. OmuaborNoch keine Bewertungen

- 2-2b Other Monitoring TechniquesDokument24 Seiten2-2b Other Monitoring TechniquesOghale B. E. OmuaborNoch keine Bewertungen

- Tank 09 - Alexandria Governorate (Tank Roof Structure) : Exxon MobilDokument46 SeitenTank 09 - Alexandria Governorate (Tank Roof Structure) : Exxon MobilOghale B. E. OmuaborNoch keine Bewertungen

- Determination of API Gravity of Crude OilDokument9 SeitenDetermination of API Gravity of Crude OilOghale B. E. OmuaborNoch keine Bewertungen

- Exxonmobil Alex. Tank #9 Api-650 Calculation SheetDokument19 SeitenExxonmobil Alex. Tank #9 Api-650 Calculation SheetOghale B. E. OmuaborNoch keine Bewertungen

- VT 01 07 DRDokument17 SeitenVT 01 07 DROghale B. E. OmuaborNoch keine Bewertungen

- Gtmax Sole Propiertorship FormsDokument12 SeitenGtmax Sole Propiertorship FormsOghale B. E. OmuaborNoch keine Bewertungen

- Wireline NotesDokument46 SeitenWireline NotesDavide Boreaneze100% (15)

- Fidel Castro Talks With Intellectuals: "OUR DUTY IS TO STRUGGLE"Dokument208 SeitenFidel Castro Talks With Intellectuals: "OUR DUTY IS TO STRUGGLE"cubadebate100% (1)

- FHN Oml26 Release 211010Dokument3 SeitenFHN Oml26 Release 211010Oghale B. E. OmuaborNoch keine Bewertungen

- Wpse GuideDokument74 SeitenWpse GuideOghale B. E. Omuabor100% (1)

- GSG Diffuser Style Barrel Pump - E00612Dokument12 SeitenGSG Diffuser Style Barrel Pump - E00612siva242245Noch keine Bewertungen

- Novo Health Benefit TableDokument6 SeitenNovo Health Benefit TableOghale B. E. OmuaborNoch keine Bewertungen

- Biology of Bananas and Plantains-Bz Jul07Dokument19 SeitenBiology of Bananas and Plantains-Bz Jul07Arslanian HovnanianNoch keine Bewertungen

- Operations Management, Compelte Slides, Supply Chain ManagementDokument919 SeitenOperations Management, Compelte Slides, Supply Chain ManagementSadiq Sagheer100% (12)

- CVS 4150 & 4160 Pressure Controller July 2012 PDFDokument12 SeitenCVS 4150 & 4160 Pressure Controller July 2012 PDFOghale B. E. OmuaborNoch keine Bewertungen

- Dider-1 Well Test Program, DraftDokument30 SeitenDider-1 Well Test Program, DraftOghale B. E. Omuabor0% (1)

- Tubingperformancerelationtpr 140607023150 Phpapp02Dokument17 SeitenTubingperformancerelationtpr 140607023150 Phpapp02Oghale B. E. Omuabor0% (1)

- Urhobo DictionaryDokument53 SeitenUrhobo Dictionarymartha_russell_3Noch keine Bewertungen

- Perkins Catalog Diesel Generating SetDokument2 SeitenPerkins Catalog Diesel Generating Setngemplex100% (1)

- 10 Driving Offences in LagosDokument2 Seiten10 Driving Offences in LagosOghale B. E. OmuaborNoch keine Bewertungen

- Shoc Card For Nalcool 2000Dokument1 SeiteShoc Card For Nalcool 2000Oghale B. E. OmuaborNoch keine Bewertungen

- P Psia T ºF T ºF B RB/MCFDokument27 SeitenP Psia T ºF T ºF B RB/MCFOghale B. E. OmuaborNoch keine Bewertungen

- GasoholDokument21 SeitenGasoholOghale B. E. OmuaborNoch keine Bewertungen

- The New Atlantis by Frances BaconDokument50 SeitenThe New Atlantis by Frances BaconOghale B. E. OmuaborNoch keine Bewertungen

- Gasm BexDokument27 SeitenGasm BexOghale B. E. OmuaborNoch keine Bewertungen

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Dokument4 SeitenCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Oghale B. E. OmuaborNoch keine Bewertungen

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Dokument4 SeitenCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Oghale B. E. OmuaborNoch keine Bewertungen

- Google Earth As A (Not Just) Geography Education ToolDokument9 SeitenGoogle Earth As A (Not Just) Geography Education ToolHellen CristanchoNoch keine Bewertungen

- Literature Review of Marketing PlanDokument6 SeitenLiterature Review of Marketing Planc5nc3whz100% (1)

- 20230107232119tangazo La Kazi Taasisi MbalimbaliDokument13 Seiten20230107232119tangazo La Kazi Taasisi MbalimbaliDaniel EudesNoch keine Bewertungen

- Bhutan-NationalGIS Technical Proposal DraftDokument61 SeitenBhutan-NationalGIS Technical Proposal DraftshankarNoch keine Bewertungen

- Handling Uncertainty Under Spatial Feature Extraction Through Probabilistic Shape Model (PSM)Dokument6 SeitenHandling Uncertainty Under Spatial Feature Extraction Through Probabilistic Shape Model (PSM)Ijsrnet EditorialNoch keine Bewertungen

- GIS Applications in AgricultureDokument19 SeitenGIS Applications in AgricultureAsqa KhanNoch keine Bewertungen

- Q GisDokument108 SeitenQ GismarkourusNoch keine Bewertungen

- thesisWvanDeursen PDFDokument126 SeitenthesisWvanDeursen PDFAndreea SavuNoch keine Bewertungen

- Guide: Getting StartedDokument59 SeitenGuide: Getting StartedDeluxeNoch keine Bewertungen

- Burrough Peter A y McDonnell Rachael A (1998) Principles of Geographical Information Systems PDFDokument19 SeitenBurrough Peter A y McDonnell Rachael A (1998) Principles of Geographical Information Systems PDFSantiago Sora100% (1)

- Topic 1 Introduction To Land Surveying LDokument70 SeitenTopic 1 Introduction To Land Surveying Lsmit patel100% (1)

- GathaDokument2 SeitenGathaFerdianNoch keine Bewertungen

- Strengths of Cube: in Transport ModellingDokument25 SeitenStrengths of Cube: in Transport ModellingSyǝd KhairiNoch keine Bewertungen

- Leapfrog Geo - User's GuideDokument97 SeitenLeapfrog Geo - User's GuideCarlos MamaniNoch keine Bewertungen

- CVL 203 PhotogrammetryDokument28 SeitenCVL 203 PhotogrammetryMajd KlNoch keine Bewertungen

- Coordinate Reference Systems: (Best Practices For Assignment, Manipulation and Conversion in GIS Systems)Dokument45 SeitenCoordinate Reference Systems: (Best Practices For Assignment, Manipulation and Conversion in GIS Systems)Kaoru AmaneNoch keine Bewertungen

- Gocad Tutorial OldDokument34 SeitenGocad Tutorial OldcranmaniaNoch keine Bewertungen

- Location Intelligence For Dummies EbookDokument27 SeitenLocation Intelligence For Dummies Ebookwaltfred123Noch keine Bewertungen

- Prof. Anil Kumar: P & Ifm, Upes, DDNDokument60 SeitenProf. Anil Kumar: P & Ifm, Upes, DDNAyyappan SubramanianNoch keine Bewertungen

- A Business Case For SAP GIS IntegrationDokument7 SeitenA Business Case For SAP GIS IntegrationCharles AshmanNoch keine Bewertungen

- Category Analyst Interview Questions and Answers Guide.: Global GuidelineDokument11 SeitenCategory Analyst Interview Questions and Answers Guide.: Global Guidelinemuhammad hamzaNoch keine Bewertungen

- Predictive ModelingDokument1 SeitePredictive ModelingMiklos MaricsyNoch keine Bewertungen

- Case Study PanajiDokument28 SeitenCase Study PanajiIsmail IchuNoch keine Bewertungen

- An Integrated GIS-based Analysis System For Land-Use Management of Lake Areas in Urban Fringe PDFDokument14 SeitenAn Integrated GIS-based Analysis System For Land-Use Management of Lake Areas in Urban Fringe PDFMaicol Camargo HernandezNoch keine Bewertungen

- 100 People Curriculum-Global IssuesDokument62 Seiten100 People Curriculum-Global Issuesapi-369394202Noch keine Bewertungen

- 8 - 2019 - Global Mapping of Eco-Environmental Vulnerability From Human and Nature Disturbances PDFDokument10 Seiten8 - 2019 - Global Mapping of Eco-Environmental Vulnerability From Human and Nature Disturbances PDFAndres DelgadoNoch keine Bewertungen

- Pengenalan Mineral OptikDokument10 SeitenPengenalan Mineral OptikPaulo da CostaNoch keine Bewertungen

- GEMS UserManualDokument534 SeitenGEMS UserManualJitendraHatwarNoch keine Bewertungen

- Web Application TORDokument3 SeitenWeb Application TORFaxikko FazyNoch keine Bewertungen

- TEMS Discovery 21.0.2 Release NoteDokument22 SeitenTEMS Discovery 21.0.2 Release NoteDanilo Benitez100% (1)