Beruflich Dokumente

Kultur Dokumente

CHE Facts - Industrial Gas Burners - July 2016

Hochgeladen von

John Urdaneta0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

72 Ansichten1 SeiteIndustrial Gas Burners - July 2016

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenIndustrial Gas Burners - July 2016

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

72 Ansichten1 SeiteCHE Facts - Industrial Gas Burners - July 2016

Hochgeladen von

John UrdanetaIndustrial Gas Burners - July 2016

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Facts At Your Fingertips

Industrial Gas Burners

Department Editor: Scott Jenkins

ombustion in industrial burners is a critical operation in the

chemical process industries

(CPI) for supplying thermal energy

for heat transfer, fluid heating, steam

generation, distillation, endothermic

chemical reactions, metal melting and

others. Burners are mechanical devices utilized for mixing proper quantities

of fuel and air, and also for maintaining

a stable flame inside fired equipment.

Included here are brief descriptions of

key aspects of industrial burner components and operation.

Fuel-air mix

Industrial process burners can be

classified in several ways, including

the type of fuel-air mixing involved

(diffusion or premixing).

Raw-gas burners are used for

most applications. In these burners,

the fuel gas passes through orifices

in the gas tip and is injected directly

into the combustion zone, where it

mixes with air. A stabilizer cone is located just below the gas to improve

combustion stability. These burners

are suitable for mounting in plenum

chambers (the area where air enters

the burner), and can be used with

preheated combustion air.

Pre-mix burners are those in which

fuel and air are mixed prior to combustion. Pre-mix burners are sometimes used in specialized applications. In these burners, the kinetic

energy made available by the expansion of the fuel gas through the

fuel-gas orifice introduces about half

of the combustion air (called primary

air) into the Venturi mixer. This mixture then exits through a large burner

tip, where it is mixed with the balance

of the combustion air (secondary air).

This secondary airflow enters the

burner through the outer, secondary

air register. Premix burners require

less furnace draft than raw-gas burners. Premix burners can produce a

wide range of flame shapes.

Reducing NOx

Combustion operations frequently

create nitrogen oxides (NOx), specifically NO and NO2, which must

32

Fuel

Secondary

combustion

zone

fluegas recirculation to help reduce

NOx formation. The best results are

obtained where internal fluegas recirculation is used to dilute the fuel

gas in a staged fuel burner, creating

a gas with a low calorific value.

Primary

combustion

zone

Flame size

Air

Fuel

be highly controlled, as they can be

harmful pollutants. Currently, three

burner configuration methods exist

for reducing nitrogen oxides in burners: staged air, staged fuel and internal fluegas recirculation combined

with staged air or staged fuel.

Staged air burners. These types of

burners work by introducing 100% of

the fuel into the burner and only part

of the combustion air (primary air),

thus creating a sub-stoichiometric

flame. This flame has a reduced temperature and therefore inhibits NOx

formation. The flame is completed

with the addition of the secondary

air to complete the combustion process. This process allows for greater

control at lower burner loads and

also accommodates a wider range

of fuels.

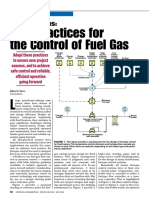

Staged fuel burners. This burner

method introduces 100% of the

combustion air into the burner and

splits the fuel supply into primary and

secondary volumes (Figure). The primary fuel mixes with the combustion

air to create a flame. As with staged

air burners, the peak flame temperature is lower, and NOx formation is

reduced. Secondary fuel is added to

complete the combustion process.

Staged fuel burners provide greater

NOx reduction, as the fuel supply

has a larger effect on NOx formation. This method is more commonly

used when a consistent fuel supply

is available.

Internal fluegas recirculation burners. This method combines either

staged air or staged fuel with internal

Chemical Engineering

The size of the burner flame is an important parameter in controlling the

heat transfer to tubes in the furnace.

The flame size and shape should be

such that the tubes impingement of

the flame upon the tubes they are

heating is avoided.

Maximum flame diameter can be

calculated using Equation (1).

(1)

where:

Df max = Maximum flame dia., ft

Lf = Flame length, ft

SVflame = Specific volume of flame,

ft3/lb

SVfuel + air = Specific volume of fuel

and air mixture, ft3/lb

Vf = Flame propagation velocity, ft/s

Maximum burner length can be

calculated from Equation (2)

(2)

where:

Db = Burner diameter, ft

Vb = Burner exit velocity, ft/s

The diameter of the burner flame

should be evaluated at maximum

burner-flame length.

Burner spacing

Burner spacing is normally 2 to 5 ft, or

sufficient to provide reasonable burner-to-burner clearance, as based on

the maximum burner-flame diameter.

Burner-to-tube clearance must also

be such that minimum clearance is

based on a reasonable distance between burner outside-flame diameter

and outside diameter of the tubular

heating surfaces.

n

Editor's note: The content presented in this column was

adapted from the following articles: Cross, Alan, Fired-Heater

Burner Performance, Chem. Eng., April 2008, pp. 4447

and Al-Hajji, M.H., Burner Inspection and Maintenance,

Chem. Eng., November 2014, pp. 4045.

www.chemengonline.com

July 2016

Das könnte Ihnen auch gefallen

- PPE Problem Set 1Dokument128 SeitenPPE Problem Set 1Gracee86% (14)

- Damping of Process TowersDokument4 SeitenDamping of Process TowersJerry DsouzaNoch keine Bewertungen

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationVon EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNoch keine Bewertungen

- Chemical Engineering - June 1997 - Pipe Design For Robust SystemsDokument9 SeitenChemical Engineering - June 1997 - Pipe Design For Robust Systemshtaboada2008100% (1)

- Successful Start Up of The Worlds Newest FCCDokument14 SeitenSuccessful Start Up of The Worlds Newest FCCEQP1210100% (1)

- Supercritical PlantDokument71 SeitenSupercritical PlantNitish KumarNoch keine Bewertungen

- Physical Science Overview-1Dokument5 SeitenPhysical Science Overview-1api-315431582Noch keine Bewertungen

- Burn Selection MatrixDokument1 SeiteBurn Selection MatrixsahasidNoch keine Bewertungen

- Compressor Station Optimization Using Simulation-Based OptimizationDokument10 SeitenCompressor Station Optimization Using Simulation-Based OptimizationAmbrish SinghNoch keine Bewertungen

- Haldor Topse SpecDokument13 SeitenHaldor Topse SpecRafiNoch keine Bewertungen

- Application of Lean Premix BurnersDokument29 SeitenApplication of Lean Premix BurnersAJan RayongNoch keine Bewertungen

- Test3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Dokument18 SeitenTest3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Anas SaadNoch keine Bewertungen

- Zeeco Burner Division DB SeriesDokument6 SeitenZeeco Burner Division DB Series1mmahoneyNoch keine Bewertungen

- REFORMER Upgrades To Convection Section & Radiant Section at TRINGEN 1 Ammonia Plant, Trinidad X 0Dokument8 SeitenREFORMER Upgrades To Convection Section & Radiant Section at TRINGEN 1 Ammonia Plant, Trinidad X 0David PierreNoch keine Bewertungen

- Thermal Oxidation For VOC Control: 13.1 Combustion BasicsDokument17 SeitenThermal Oxidation For VOC Control: 13.1 Combustion Basicsdardocapo100% (1)

- Adiabatic PrerefDokument47 SeitenAdiabatic Prerefleonard chokNoch keine Bewertungen

- Sulfur Tail Gas Thermal Oxidizer Systems Pickard Callidus Technologies SRU League City 2010Dokument6 SeitenSulfur Tail Gas Thermal Oxidizer Systems Pickard Callidus Technologies SRU League City 2010Navneet KumarNoch keine Bewertungen

- Ganapathy PDFDokument90 SeitenGanapathy PDFpinenamuNoch keine Bewertungen

- Field Guide To SpectrosDokument126 SeitenField Guide To SpectrosernestoNoch keine Bewertungen

- Thermal Oxidizer WP (Ver A)Dokument35 SeitenThermal Oxidizer WP (Ver A)felamendoNoch keine Bewertungen

- Troubleshooting Liquid Carryover in Gas Compression Systems MySep White PaperDokument11 SeitenTroubleshooting Liquid Carryover in Gas Compression Systems MySep White Paperthlim19078656Noch keine Bewertungen

- Case Story DK - Green Methanol - Web 1Dokument4 SeitenCase Story DK - Green Methanol - Web 1Pao M. MorenoNoch keine Bewertungen

- Process Heaters Furnaces and Fired Heaters PDFDokument12 SeitenProcess Heaters Furnaces and Fired Heaters PDFHaris Nu'man Aulia100% (1)

- Energy Efficiency in Steam Systems - CHE - Facts - 0409Dokument1 SeiteEnergy Efficiency in Steam Systems - CHE - Facts - 0409John UrdanetaNoch keine Bewertungen

- Cdi6 Fire Technology and Arson Investigation Revised by Reyes FDokument185 SeitenCdi6 Fire Technology and Arson Investigation Revised by Reyes FHanna Sobreviñas AmanteNoch keine Bewertungen

- Electric Heaters For Safe Startup ofDokument9 SeitenElectric Heaters For Safe Startup ofSteve WanNoch keine Bewertungen

- Heurtey Petrochem: Coker Furnace Run LengthDokument24 SeitenHeurtey Petrochem: Coker Furnace Run LengthFayaz MohammedNoch keine Bewertungen

- Methanol DistillationDokument6 SeitenMethanol DistillationNaseeb AliNoch keine Bewertungen

- CHE BP - Best Practices For The Control of Fuel Gas - May 2014Dokument4 SeitenCHE BP - Best Practices For The Control of Fuel Gas - May 2014John UrdanetaNoch keine Bewertungen

- CHE BP - Best Practices For The Control of Fuel Gas - May 2014Dokument4 SeitenCHE BP - Best Practices For The Control of Fuel Gas - May 2014John UrdanetaNoch keine Bewertungen

- 6 MarchDokument51 Seiten6 MarchmaritsyaditaaNoch keine Bewertungen

- BBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFDokument2 SeitenBBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFAdianto RahmanNoch keine Bewertungen

- Revista PetroleoDokument115 SeitenRevista PetroleojesslpezNoch keine Bewertungen

- Revista PetroleoDokument115 SeitenRevista PetroleojesslpezNoch keine Bewertungen

- Simulation of Ammonia Production From Synthesis GaDokument12 SeitenSimulation of Ammonia Production From Synthesis Gasagar dasguptaNoch keine Bewertungen

- Heat Recovery From Chilled Water Systems: Applications For Heat Reclaim ChillersDokument20 SeitenHeat Recovery From Chilled Water Systems: Applications For Heat Reclaim ChillersvineethNoch keine Bewertungen

- Correcting Improper Performance of Direct Fired Heaters - May 2013Dokument8 SeitenCorrecting Improper Performance of Direct Fired Heaters - May 2013John UrdanetaNoch keine Bewertungen

- CHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015Dokument11 SeitenCHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015John UrdanetaNoch keine Bewertungen

- Ammonia Converter FailureDokument15 SeitenAmmonia Converter FailureAnonymous UoHUagNoch keine Bewertungen

- HP May 2014Dokument115 SeitenHP May 2014John UrdanetaNoch keine Bewertungen

- Ammonia Process For FutureDokument5 SeitenAmmonia Process For FutureSARFRAZ ALINoch keine Bewertungen

- NASH VectraXL enDokument4 SeitenNASH VectraXL enJohn UrdanetaNoch keine Bewertungen

- PHA Pro User Guide 8.3.4Dokument523 SeitenPHA Pro User Guide 8.3.4Yenny Orozco Jaramillo88% (8)

- Improve Vacuum Heater Reliability: Hydrocarbon ProcessingDokument4 SeitenImprove Vacuum Heater Reliability: Hydrocarbon Processingros56Noch keine Bewertungen

- Chap 34 PDFDokument16 SeitenChap 34 PDFnelson escuderoNoch keine Bewertungen

- Pushing The Limits - Breakthrough in Pre-Reformer Design: Ingo Hanke and Norbert RingerDokument6 SeitenPushing The Limits - Breakthrough in Pre-Reformer Design: Ingo Hanke and Norbert Ringervaratharajan g rNoch keine Bewertungen

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDokument1 SeiteFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263Noch keine Bewertungen

- FUELSDokument15 SeitenFUELSJohn Archie MendozaNoch keine Bewertungen

- Trimming Nox From Furnaces - Rev3Dokument6 SeitenTrimming Nox From Furnaces - Rev3Deepika UmlaniNoch keine Bewertungen

- 8q1pQq PDFDokument100 Seiten8q1pQq PDFJonathan Riveros RojasNoch keine Bewertungen

- SCR Reactor Performance Profiling and Results Analysis PDFDokument7 SeitenSCR Reactor Performance Profiling and Results Analysis PDFkangsungjinNoch keine Bewertungen

- A Guide To Assist in Evaluating Liquid Fuel FlamesDokument16 SeitenA Guide To Assist in Evaluating Liquid Fuel FlamestinuvalsapaulNoch keine Bewertungen

- Study of Dry Ice Formation During Blowdown of CO - CH From CryogenicDokument9 SeitenStudy of Dry Ice Formation During Blowdown of CO - CH From CryogenicAbul HassanNoch keine Bewertungen

- XP Flare Article ReprintDokument5 SeitenXP Flare Article ReprintAnonymous cuOIjrLINoch keine Bewertungen

- TraysDokument23 SeitenTraysAmgadNoch keine Bewertungen

- Instrumentation For Fired Heaters IP 15-1-1: ScopeDokument14 SeitenInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezNoch keine Bewertungen

- TP Hicap UltlonoxDokument18 SeitenTP Hicap Ultlonoxhoangviet20006Noch keine Bewertungen

- Catschool 1: Prereforming CatalystsDokument32 SeitenCatschool 1: Prereforming CatalystsAbubakar SiddiqNoch keine Bewertungen

- 17 - Residue Upgradation 1Dokument22 Seiten17 - Residue Upgradation 1SHREENoch keine Bewertungen

- The Star Process by Uhde: Industrial SolutionsDokument24 SeitenThe Star Process by Uhde: Industrial SolutionsAjaykumarNoch keine Bewertungen

- Aspen Plus® Process Simulation of Calcium Looping With Different Indirect Calciner Heat Transfer Concepts - ScienceDirectDokument10 SeitenAspen Plus® Process Simulation of Calcium Looping With Different Indirect Calciner Heat Transfer Concepts - ScienceDirectZhofran BintangNoch keine Bewertungen

- Guide Line To Vendor Regarding Tube Layout PreparationDokument4 SeitenGuide Line To Vendor Regarding Tube Layout PreparationSalman AkramNoch keine Bewertungen

- Carbon CaptureDokument13 SeitenCarbon CaptureShubhalaxmi SwainNoch keine Bewertungen

- Relative Rates of Coke Formation From Hydrocarbons in Steam CrackingDokument6 SeitenRelative Rates of Coke Formation From Hydrocarbons in Steam CrackingTaylorNoch keine Bewertungen

- Example of Incinerator CostestimationDokument2 SeitenExample of Incinerator CostestimationCalcetinNoch keine Bewertungen

- FULLTEXT01Dokument210 SeitenFULLTEXT01Mohamed TarekNoch keine Bewertungen

- 11 8783 WP Column Analysis PDFDokument22 Seiten11 8783 WP Column Analysis PDFHassanNoch keine Bewertungen

- Dehydration Plant Twenty Years PaperDokument5 SeitenDehydration Plant Twenty Years Papersejerson07Noch keine Bewertungen

- Gas Spec Cs 2010Dokument4 SeitenGas Spec Cs 2010MauricioNoch keine Bewertungen

- Distillation Column ReboilerDokument13 SeitenDistillation Column ReboilerLouie GresulaNoch keine Bewertungen

- Progress of Modern Pyrolysis Furnace TechnologyDokument4 SeitenProgress of Modern Pyrolysis Furnace TechnologyDavid Rodrigues100% (1)

- Books: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsDokument1 SeiteBooks: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsRaul tejadaNoch keine Bewertungen

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988Von EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNoch keine Bewertungen

- Immersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006Dokument5 SeitenImmersion Heaters-Selection & Implementation-Article From Chemical Engineering January-2006John UrdanetaNoch keine Bewertungen

- CHE - Superheater Problems in Steam Generators - Feb 2016Dokument10 SeitenCHE - Superheater Problems in Steam Generators - Feb 2016John Urdaneta100% (1)

- CHE EP - Field Troubleshoot 101 and How To Get The Job Done - June 2016Dokument7 SeitenCHE EP - Field Troubleshoot 101 and How To Get The Job Done - June 2016John UrdanetaNoch keine Bewertungen

- Optimizing Pump Systems - Apr.2009Dokument4 SeitenOptimizing Pump Systems - Apr.2009John UrdanetaNoch keine Bewertungen

- CHE EP - Field Troubleshoot 101 and How To Get The Job Done - June 2016Dokument7 SeitenCHE EP - Field Troubleshoot 101 and How To Get The Job Done - June 2016John UrdanetaNoch keine Bewertungen

- Che Apr 2009 - GsoDokument7 SeitenChe Apr 2009 - GsoJohnUrdanetaNoch keine Bewertungen

- Optimizing Pump Systems - Apr.2009Dokument4 SeitenOptimizing Pump Systems - Apr.2009John UrdanetaNoch keine Bewertungen

- Che Apr 2009 - GsoDokument7 SeitenChe Apr 2009 - GsoJohnUrdanetaNoch keine Bewertungen

- Vizio User Manual - M321iA2Dokument80 SeitenVizio User Manual - M321iA2John UrdanetaNoch keine Bewertungen

- Vizio User Manual - M321iA2Dokument80 SeitenVizio User Manual - M321iA2John UrdanetaNoch keine Bewertungen

- NDIA Standard For Earned Value Management SystemsDokument89 SeitenNDIA Standard For Earned Value Management SystemsJohn UrdanetaNoch keine Bewertungen

- Vizio User Manual UM - M321iA2Dokument80 SeitenVizio User Manual UM - M321iA2John UrdanetaNoch keine Bewertungen

- UM M321iA2 PDFDokument80 SeitenUM M321iA2 PDFJohn UrdanetaNoch keine Bewertungen

- NDIA Standard For Earned Value Management SystemsDokument89 SeitenNDIA Standard For Earned Value Management SystemsJohn UrdanetaNoch keine Bewertungen

- Smith Ab 01023Dokument24 SeitenSmith Ab 01023John UrdanetaNoch keine Bewertungen

- Troubleshooting GuideDokument1 SeiteTroubleshooting GuideJohn UrdanetaNoch keine Bewertungen

- Smith MN 01011Dokument8 SeitenSmith MN 01011John UrdanetaNoch keine Bewertungen

- Varec IOM102 2557Dokument34 SeitenVarec IOM102 2557ybwangNoch keine Bewertungen

- PSLL p18 1, Neo Dyn 100p5Dokument2 SeitenPSLL p18 1, Neo Dyn 100p5John UrdanetaNoch keine Bewertungen

- 01 AssignmentDokument24 Seiten01 AssignmentsasthiNoch keine Bewertungen

- Molecular Control of Bioactivity in Sol-Gel GlassesDokument6 SeitenMolecular Control of Bioactivity in Sol-Gel GlassesLcdaora TererelNoch keine Bewertungen

- Roadmap JEE 2024Dokument27 SeitenRoadmap JEE 2024Pratham KatariaNoch keine Bewertungen

- ACH150X Course Study Notes (Precipitation Titrations) 2020Dokument8 SeitenACH150X Course Study Notes (Precipitation Titrations) 2020Kgaugelo TraciaNoch keine Bewertungen

- 4.hvac b5-Ct04Dokument55 Seiten4.hvac b5-Ct04Tuấn NguyễnNoch keine Bewertungen

- Chapter 9 ChemistryDokument1 SeiteChapter 9 ChemistryMuhammad Hammad MaahiNoch keine Bewertungen

- Design and Development of Micro-Channel Using PDMS For Biomedical ApplicationsDokument6 SeitenDesign and Development of Micro-Channel Using PDMS For Biomedical ApplicationsgpaivNoch keine Bewertungen

- PH Impact On The Sol Gel Preparation of Calcium Hydroxyapatite Ca10 Po4 6 Oh 2 Using A Novel Complexing Agent Dcta PDFDokument8 SeitenPH Impact On The Sol Gel Preparation of Calcium Hydroxyapatite Ca10 Po4 6 Oh 2 Using A Novel Complexing Agent Dcta PDFfishvalNoch keine Bewertungen

- Liquid-Liquid ExtractionDokument5 SeitenLiquid-Liquid ExtractionFahad ShakeelNoch keine Bewertungen

- Speciality PolymersDokument63 SeitenSpeciality PolymersChini ChineeNoch keine Bewertungen

- Problems in UVDokument6 SeitenProblems in UVCaleb JalmascoNoch keine Bewertungen

- Design, Fabrication and Performance Analysis of Vapor Absorption Refrigeration System Powered by Solar Using NanofluidDokument5 SeitenDesign, Fabrication and Performance Analysis of Vapor Absorption Refrigeration System Powered by Solar Using NanofluidchilakaprakashNoch keine Bewertungen

- 3 - Classification of ElementsDokument10 Seiten3 - Classification of ElementsV̶a̶i̶s̶h̶n̶a̶v̶Noch keine Bewertungen

- InTech-Direct Dissolution of Cellulose Background Means and ApplicationsDokument36 SeitenInTech-Direct Dissolution of Cellulose Background Means and ApplicationsMichael PearsonNoch keine Bewertungen

- Alkyl Halide-Jeemain - Guru PDFDokument37 SeitenAlkyl Halide-Jeemain - Guru PDFUma JadounNoch keine Bewertungen

- Final05 PDFDokument7 SeitenFinal05 PDFRam chandraNoch keine Bewertungen

- KTG (Objective HCV V-2) 04.01.22Dokument2 SeitenKTG (Objective HCV V-2) 04.01.22Quark classes kanpurNoch keine Bewertungen

- BS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctDokument60 SeitenBS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctRamiAl-fuqahaNoch keine Bewertungen

- Lecture 6 STMDokument29 SeitenLecture 6 STMROHITM RA1811002040067Noch keine Bewertungen

- Selective Oxidation of Aldehydes To Carboxylic Acids With Sodium Chlorite-Hydrogen PeroxideDokument3 SeitenSelective Oxidation of Aldehydes To Carboxylic Acids With Sodium Chlorite-Hydrogen PeroxidejavasoloNoch keine Bewertungen

- PPT-Introduction To MELCOR and The RN PackageDokument42 SeitenPPT-Introduction To MELCOR and The RN PackagejackleesjNoch keine Bewertungen

- Lab Sheet Air Conditioning (Perfect Gas)Dokument8 SeitenLab Sheet Air Conditioning (Perfect Gas)JIJENDERKUMAR A/L VIJAYAN MoeNoch keine Bewertungen

- Chapter 5-Design For Multiple ReactionsDokument8 SeitenChapter 5-Design For Multiple ReactionsSang HoàngNoch keine Bewertungen