Beruflich Dokumente

Kultur Dokumente

Instrument Data Form

Hochgeladen von

SofiaProtopsaltiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Instrument Data Form

Hochgeladen von

SofiaProtopsaltiCopyright:

Verfügbare Formate

Good Stuff Pharmaceuticals

Instrument Data Form

Part A To Be Completed By Originator

If there are questions, please contact the Calibration or Metrology Group for assistance.

Section 1: Reason for Request (Check all that apply):

ADDITION

New

Re-commissioned

MODIFICATION

Exact Replacement

Approved Functional Equivalent

DELETION

Change of Parameter

Relocated/Transferred

Decommissioned

Cannot Locate

Section 2: Instrument Identification (If a replacement or change, original identification #: _________________________________)

1.

2.

3.

4.

5.

6.

7.

8

9

Instrument Type: (Indicator, Recorder, Transmitter, pH, HPLC, etc.)

Equipment/System & Parameter Instrument is monitoring:

Portable Instrument:

YES

NO

Manufacturer:

Model:

Serial Number:

Manufacturers Documentation Provided:

YES

NO

Laboratory Analytical Instrument:

YES

NO

If YES, Qualification Required:

YES

NO

Instrument Location

10.

Department:

(Items below are for general information for portable instruments):

11.

12.

13.

Building:

Floor & Area:

Specific Location/Room:

Section 3: Operations Technical Data

14. Approximate use point or range of use (units):

15. Input (Device) Range of Instrument as configured: ______________________ Units of Measure:

16. Requested Calibration Test Point(s):

Three calibration points are normally specified in the program (approximately 0-10% of range, 45-55% of range and 90-100% of range).

Provide this information ONLY if an additional or fewer test points other than those listed above are requested. Provide explanation for request in Section 4.

And

Or

calibration test points:

%FS

%Reading

Total Test Points

17. Output Signal Range (as applicable): Range: ______________________ Units of Measure: _____________

Units

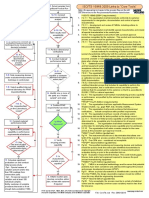

18. Characterization (Check One): GMP

Non-GMP

19. Classification (Check One - only if characterized as GMP):

GMP Critical

GMP Non-critical

GMP Utility

20. Calibration Frequency: (Use only if a schedule other than procedure stipulated intervals of 6 months for GMP Critical or 12 months for GMP

Non-critical instruments or for GMP Utility Instrument is requested.)

Monthly

Schedule:

Quarterly

Semi-annual

Annual

Feb

Mar

Aug

Sep

Jan

Jul

Specify the month(s) calibrations are to be performed if

particular months are requested for operational

purposes:

21. Process Calibration Tolerance:

Apr

Oct

May

Nov

Jun

Dec

(%FS, %Reading, or Units)

(For Instruments classified as GMP Critical, the limit of calibration error allowed before quality is potentially compromised. Not applicable for

devices to be calibrated as a loop or test/laboratory instruments used for different functions.)

22. Source/Reference for Process Calibration Tolerance:

23. Is device part of a loop?

YES

NO

If YES, identify loop components:

Component: A

this device:

Component B:

Component C:

(Use Section 4 if required)

Component D:

Component E:

Component F:

Attach Instrument Data Forms for all components and Loop Data Form for Loop Calibrations

Section 4:

Comments and Characteristics: (Identify any special characteristics, e.g. non-linearity, special hysteresis or temperature

concerns or special uses.)

Originator (Signature):

Name (printed):

Date:

Page 1 of 2

Good Stuff Pharmaceuticals

Instrument Data Form

Part B To be competed by Calibration/Metrology Group

24. Instrument Manufacturers Stated Accuracy (%FS,

%Reading, or units):

25. Device Calibration SOP Identification (if SOP is to be used) :

26. Instrument Calibration Limits:

27. New Calibration Sheet required:

YES

NO

If YES, attach new Calibration Sheet for routing and approval

28. P&ID Drawing Number (if any)

29. P&ID Tag Number (if any):

Note: Instruments classified as GMP Utility may not require a calibration SOP or Calibration Sheet. If the instrument is classified as

GMP Utility, a Preventive Maintenance Task may used to check the instrument if it is not to be calibrated. Verify that a Preventive

Maintenance Task has been developed for the GMP Utility functionally checked instrument within the CCMS or CMMS.

30. Preventive Maintenance Task established for GMP Utility instrument:

YES

NO

If NO, explain the reason in Section 32, Explanations and General Comments, below.

31. Identify any exceptions to calibration program requirements: (Examples: Less than full range calibration, Non-standard calibration

frequency, lack of repeatability challenges, etc.)

Minimum Three Point

Calibration?

Full Range Calibration?

YES

NO

YES

NO

32. Explanations and General Comments:

Part B Prepared By (Signature):

Procedure Specified Calibration

Frequency?

YES

NO

Process Calibration Tolerance s set?

(GMP Critical only)

YES

Repeatability challenges developed?

(Mechanical devices or Identified

Electromechanical devices only)

NO

YES

Name (printed):

Date:

Name (printed):

Date:

Name (printed):

Date:

NO

Part C Return to Originator

33. Request returned to Originator (reasons):

By (Calibration/Metrology Signature):

Part D Review And Approvals

Calibration/Metrology Group Supervision (Signature):

Only Calibration/Metrology Group approval is required for Exact Replacements and increasing the frequency of calibration.

End User Department (Signature):

Name (printed):

Date:

Quality Control (Signature):

Name (printed):

Date:

Part E CMMS Entry Verification

Entered By (Signature):

Name (printed):

Date Entered:

Entry Reviewed By (Signature):

Name (printed):

Date Entered:

Page 2 of 2

Das könnte Ihnen auch gefallen

- Lab Equipment CalibrationDokument3 SeitenLab Equipment Calibrationjohn100% (1)

- Eaton PpapDokument7 SeitenEaton PpapcalinfnNoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Control PlanDokument6 SeitenControl PlanFahmy Khoerul HudaNoch keine Bewertungen

- Bosch KE-Jetronic System DescriptionDokument3 SeitenBosch KE-Jetronic System DescriptionJack Tang50% (2)

- Customer Information: BRKT Assy Center HingeDokument1 SeiteCustomer Information: BRKT Assy Center HingepodraoNoch keine Bewertungen

- Condensed Handbook of Measurement and Control, 3rd EditionVon EverandCondensed Handbook of Measurement and Control, 3rd EditionBewertung: 4 von 5 Sternen4/5 (6)

- Ib Psychology - Perfect Saq Examination Answers PDFDokument2 SeitenIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- Metrology MCQDokument8 SeitenMetrology MCQVijay Kumar Nattey83% (6)

- Ppap, R&R, MsaDokument8 SeitenPpap, R&R, MsaArun SaigalNoch keine Bewertungen

- Measuring Equipment in A LaboratoryDokument8 SeitenMeasuring Equipment in A Laboratorypulas6289Noch keine Bewertungen

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Dokument12 SeitenChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalNoch keine Bewertungen

- GLP Ipa Equipment Qualification - Final4Dokument35 SeitenGLP Ipa Equipment Qualification - Final4agus kurniawanNoch keine Bewertungen

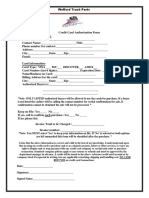

- Credit Card Authorization Form WoffordDokument1 SeiteCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNoch keine Bewertungen

- PPAP Process-Guide ExampleDokument5 SeitenPPAP Process-Guide ExampleN.B.P0% (1)

- Automated Software Testing Interview Questions You'll Most Likely Be Asked: Job Interview Questions SeriesVon EverandAutomated Software Testing Interview Questions You'll Most Likely Be Asked: Job Interview Questions SeriesNoch keine Bewertungen

- Effect of Minor and Trace Elements in Cast IronDokument2 SeitenEffect of Minor and Trace Elements in Cast IronsachinguptachdNoch keine Bewertungen

- Sterile Medical Device Package DevelopmentDokument34 SeitenSterile Medical Device Package DevelopmentSofiaProtopsalti100% (2)

- Cooper Industries PPAP Forms KitDokument25 SeitenCooper Industries PPAP Forms KitAshutosh SinghNoch keine Bewertungen

- RCFA Report Template For Mechanical EquipmentDokument11 SeitenRCFA Report Template For Mechanical EquipmentFaisal Tariq100% (1)

- Cal ChecklistDokument9 SeitenCal ChecklistImad AghilaNoch keine Bewertungen

- Pre - Functional Checklist Documentation 9Dokument5 SeitenPre - Functional Checklist Documentation 9renjithv_4Noch keine Bewertungen

- Mechanical Equipment TestingDokument12 SeitenMechanical Equipment TestingChemi YeNoch keine Bewertungen

- Sap Calibration ProcessDokument20 SeitenSap Calibration Processsachin100% (2)

- SQD-025 PPAP ChecklistDokument7 SeitenSQD-025 PPAP ChecklistMadhan RajNoch keine Bewertungen

- Analytical Equipment QualificationDokument35 SeitenAnalytical Equipment Qualificationexs1905880% (5)

- Test Method Validation GuidanceDokument2 SeitenTest Method Validation GuidanceSofiaProtopsalti100% (1)

- Control Plan Audit FormDokument2 SeitenControl Plan Audit Formdpcastilla50% (2)

- Practical Approaches to Method Validation and Essential Instrument QualificationVon EverandPractical Approaches to Method Validation and Essential Instrument QualificationNoch keine Bewertungen

- Ac7114-5 - Rev - 0 Audit Criteria For Nondestructive Testing Facility Eddy Current SurveyDokument15 SeitenAc7114-5 - Rev - 0 Audit Criteria For Nondestructive Testing Facility Eddy Current SurveyskluxNoch keine Bewertungen

- Core Tools PDFDokument1 SeiteCore Tools PDFsentrakerjaan100% (3)

- A Practical Guide to Maintenance EngineeringVon EverandA Practical Guide to Maintenance EngineeringBewertung: 4 von 5 Sternen4/5 (6)

- Manage Test Equipment Calibration Processes With SAP Plant Maintenance and Quality ManagementDokument42 SeitenManage Test Equipment Calibration Processes With SAP Plant Maintenance and Quality Managementgkraoatl100% (2)

- Romaco Aseptic Liquid Filling-EnDokument28 SeitenRomaco Aseptic Liquid Filling-EnSofiaProtopsaltiNoch keine Bewertungen

- Introduction to N.C.M., a Non Contact Measurement ToolVon EverandIntroduction to N.C.M., a Non Contact Measurement ToolNoch keine Bewertungen

- CGMP Equipment, Instruments, and CalibrationDokument5 SeitenCGMP Equipment, Instruments, and CalibrationMina Maher Mikhail100% (1)

- Mba633 Road To Hell Case AnalysisDokument3 SeitenMba633 Road To Hell Case AnalysisAditi VarshneyNoch keine Bewertungen

- Template Seat Heat Peeland Stick Heater Control PlanpostedDokument6 SeitenTemplate Seat Heat Peeland Stick Heater Control PlanpostedvfuntanillaNoch keine Bewertungen

- Manage Test Equipment Calibration Processes With SAP Plant Maintenance and Quality ManagementDokument6 SeitenManage Test Equipment Calibration Processes With SAP Plant Maintenance and Quality ManagementRajendra G100% (1)

- Technical Document Review: Gamp Good Practice Guide: Calibration ManagementDokument6 SeitenTechnical Document Review: Gamp Good Practice Guide: Calibration ManagementHassan HoudoudNoch keine Bewertungen

- SD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore FacilitiesDokument33 SeitenSD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore Facilitiestho03103261100% (1)

- Room - Air - Conditioner - v1.6Dokument110 SeitenRoom - Air - Conditioner - v1.6cobalt boronNoch keine Bewertungen

- Purpose: 2. Inclusions in This Document:: Master Inspection Characteristics (MIC)Dokument20 SeitenPurpose: 2. Inclusions in This Document:: Master Inspection Characteristics (MIC)nikku115Noch keine Bewertungen

- GP 09-04-01Dokument31 SeitenGP 09-04-01Anbarasan Perumal100% (1)

- CNC Milling ReportDokument15 SeitenCNC Milling ReportStarscream Aisyah78% (37)

- SAP Calibiration ProcesDokument20 SeitenSAP Calibiration ProcesTarun ShakyaNoch keine Bewertungen

- Ipc TM 650Dokument2 SeitenIpc TM 650Eduardo Velazquez MoraNoch keine Bewertungen

- Machine Capability For Process AuditsDokument4 SeitenMachine Capability For Process AuditsBrian Pringle0% (2)

- Air Performance Test FormDokument3 SeitenAir Performance Test FormMelvin DapitanonNoch keine Bewertungen

- Vi. - Mechanical Integrity Program: Nevada Division of Environmental Protection Chemical Accident Prevention ProgramDokument6 SeitenVi. - Mechanical Integrity Program: Nevada Division of Environmental Protection Chemical Accident Prevention Programcoolguy12345Noch keine Bewertungen

- DI-SESS-81315A (1) Failure Analysis and Corrective Action ReportDokument3 SeitenDI-SESS-81315A (1) Failure Analysis and Corrective Action ReportJayjean KwakNoch keine Bewertungen

- GLP Ipa Equipment Qualification - Final4Dokument35 SeitenGLP Ipa Equipment Qualification - Final4عبدالعزيز بدرNoch keine Bewertungen

- CH 1 - Intro J5800Dokument54 SeitenCH 1 - Intro J5800mohd_mizanNoch keine Bewertungen

- FM 695Dokument3 SeitenFM 695Valentin Le TirantNoch keine Bewertungen

- PPAP ChecklistDokument3 SeitenPPAP ChecklistJetesh DevgunNoch keine Bewertungen

- Domestic Water Booster Test ProcedureDokument6 SeitenDomestic Water Booster Test ProcedureEduardo ChvaNoch keine Bewertungen

- Nabl 122-08 Push Pull Gauge WebDokument16 SeitenNabl 122-08 Push Pull Gauge Webprasadjoshi781429Noch keine Bewertungen

- Test Case TemplateDokument25 SeitenTest Case TemplaterajadevnathNoch keine Bewertungen

- Part Submission WarrantDokument4 SeitenPart Submission WarrantSam AnuNoch keine Bewertungen

- ImteDokument8 SeitenImteShahid HussainNoch keine Bewertungen

- Inspected Equipment Detail: Inspection Certificate of NDTDokument1 SeiteInspected Equipment Detail: Inspection Certificate of NDTSpectex dubaiNoch keine Bewertungen

- Essential Requirements of PPAPDokument4 SeitenEssential Requirements of PPAPeditor_ijtelNoch keine Bewertungen

- Installation / Operational Qualification Protocol For The PHSC 338 Validation Project Protocol Number: IOQ0001.00Dokument30 SeitenInstallation / Operational Qualification Protocol For The PHSC 338 Validation Project Protocol Number: IOQ0001.00iftikhar4498929Noch keine Bewertungen

- 701P37410 Synergix Scanner Service ManualDokument218 Seiten701P37410 Synergix Scanner Service Manualjovan5510% (1)

- Sop 1 Recommended Standard Operating Procedures For Preparation of Test/Calibration ReportsDokument8 SeitenSop 1 Recommended Standard Operating Procedures For Preparation of Test/Calibration ReportsGiuseppe GoriNoch keine Bewertungen

- Calibration Service Assessment Form FDokument8 SeitenCalibration Service Assessment Form FMohini Marathe0% (1)

- SAP PP Work CentreDokument15 SeitenSAP PP Work CentrebethojiNoch keine Bewertungen

- Application Form For Laboratory Accreditation.Dokument5 SeitenApplication Form For Laboratory Accreditation.AnkurNoch keine Bewertungen

- IEA Wind Recommended Practice for the Implementation of Renewable Energy Forecasting SolutionsVon EverandIEA Wind Recommended Practice for the Implementation of Renewable Energy Forecasting SolutionsNoch keine Bewertungen

- Process Monitoring and Improvement HandbookVon EverandProcess Monitoring and Improvement HandbookNoch keine Bewertungen

- Worried About Cleanroom Costs?: Adding These Energy-Saving, Maintenance-Reducing Features Can Save A Bundle!Dokument3 SeitenWorried About Cleanroom Costs?: Adding These Energy-Saving, Maintenance-Reducing Features Can Save A Bundle!SofiaProtopsaltiNoch keine Bewertungen

- Public Summary: Summary For ARTG Entry: ARTG Entry For Sponsor Postal AddressDokument1 SeitePublic Summary: Summary For ARTG Entry: ARTG Entry For Sponsor Postal AddressSofiaProtopsaltiNoch keine Bewertungen

- ASTM D3578 Rubber GloveDokument5 SeitenASTM D3578 Rubber GloveSofiaProtopsalti100% (3)

- Still Transpaleta Electrica Operare Mare Inaltime Egv SDokument13 SeitenStill Transpaleta Electrica Operare Mare Inaltime Egv SSofiaProtopsaltiNoch keine Bewertungen

- New DPM Laboratory Format 1Dokument1 SeiteNew DPM Laboratory Format 1SofiaProtopsaltiNoch keine Bewertungen

- 20 Overview of A Gamma ValidationDokument2 Seiten20 Overview of A Gamma ValidationSofiaProtopsaltiNoch keine Bewertungen

- 2013 PDA Europe 131031Dokument27 Seiten2013 PDA Europe 131031SofiaProtopsaltiNoch keine Bewertungen

- PD CamFFU Integrated Solution is-EC 120427 enDokument1 SeitePD CamFFU Integrated Solution is-EC 120427 enSofiaProtopsaltiNoch keine Bewertungen

- Brochure Algeness GB ScreenDokument5 SeitenBrochure Algeness GB ScreenSofiaProtopsaltiNoch keine Bewertungen

- Aesculus 01 PDFDokument11 SeitenAesculus 01 PDFSofiaProtopsaltiNoch keine Bewertungen

- Appendix 1 UoL Risk Assessment Form v4 February 2016Dokument10 SeitenAppendix 1 UoL Risk Assessment Form v4 February 2016SofiaProtopsaltiNoch keine Bewertungen

- 2016 Martin ArcheryDokument16 Seiten2016 Martin ArcherySofiaProtopsaltiNoch keine Bewertungen

- 2046 - Absorbance SpectrophotometryDokument12 Seiten2046 - Absorbance SpectrophotometrySofiaProtopsaltiNoch keine Bewertungen

- MHRA Borderlines With Medical Devices 2016Dokument12 SeitenMHRA Borderlines With Medical Devices 2016SofiaProtopsaltiNoch keine Bewertungen

- 087 CE-Marking of Biological and Chemical IndicatorsDokument2 Seiten087 CE-Marking of Biological and Chemical IndicatorsSofiaProtopsaltiNoch keine Bewertungen

- Consolidated ARGMD Part IIDokument122 SeitenConsolidated ARGMD Part IISofiaProtopsaltiNoch keine Bewertungen

- 52 1057 01 Silicone Adhesives in Healthcare ApplicationsDokument6 Seiten52 1057 01 Silicone Adhesives in Healthcare ApplicationsSofiaProtopsaltiNoch keine Bewertungen

- Scientific Injection Molding: A Tool For Lean Manufacturing: by Frank Staples and Alpesh PatelDokument4 SeitenScientific Injection Molding: A Tool For Lean Manufacturing: by Frank Staples and Alpesh PatelSofiaProtopsaltiNoch keine Bewertungen

- Gamma Plastic ResistanceDokument5 SeitenGamma Plastic ResistanceSofiaProtopsaltiNoch keine Bewertungen

- Freeform Blister MachineryDokument6 SeitenFreeform Blister MachinerySofiaProtopsaltiNoch keine Bewertungen

- Research Project Presentation of Jobairul Karim ArmanDokument17 SeitenResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanNoch keine Bewertungen

- CUIT 201 Assignment3 March2023Dokument2 SeitenCUIT 201 Assignment3 March2023crybert zinyamaNoch keine Bewertungen

- Summative Test in Foundation of Social StudiesDokument2 SeitenSummative Test in Foundation of Social StudiesJane FajelNoch keine Bewertungen

- Sop GC6890 MS5973Dokument11 SeitenSop GC6890 MS5973Felipe AndrinoNoch keine Bewertungen

- تأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFDokument36 Seitenتأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFSofiane DouifiNoch keine Bewertungen

- Sociology of Crimes and Ethics Suggested Answer "A"Dokument34 SeitenSociology of Crimes and Ethics Suggested Answer "A"Bernabe Fuentes Jr.Noch keine Bewertungen

- Hemax-530 PDFDokument2 SeitenHemax-530 PDFNice BennyNoch keine Bewertungen

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDokument8 SeitenPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoNoch keine Bewertungen

- CE-23113-SP-902-R01-00 Asset SpecificationDokument14 SeitenCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберNoch keine Bewertungen

- Car Parking DesignDokument6 SeitenCar Parking Designcharler kinyuajNoch keine Bewertungen

- Mathematics4 q4 Week4 v4Dokument11 SeitenMathematics4 q4 Week4 v4Morales JinxNoch keine Bewertungen

- With You: Full-Line CatalogDokument68 SeitenWith You: Full-Line CatalogCOMINoch keine Bewertungen

- Reviewer in PE&H 1st Quarter 18-19Dokument7 SeitenReviewer in PE&H 1st Quarter 18-19rhex minasNoch keine Bewertungen

- Chomsky's Universal GrammarDokument4 SeitenChomsky's Universal GrammarFina Felisa L. AlcudiaNoch keine Bewertungen

- Scan WV1DB12H4B8018760 20210927 1800Dokument6 SeitenScan WV1DB12H4B8018760 20210927 1800Sergio AlvarezNoch keine Bewertungen

- Slide 7 PV NewDokument74 SeitenSlide 7 PV NewPriyanshu AgrawalNoch keine Bewertungen

- Concrete Casting - Pump Station ADokument13 SeitenConcrete Casting - Pump Station ABright MuzaNoch keine Bewertungen

- Types of ComputersDokument7 SeitenTypes of ComputersSyed Badshah YousafzaiNoch keine Bewertungen

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Dokument6 SeitenSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonNoch keine Bewertungen

- CKRE Lab (CHC 304) Manual - 16 May 22Dokument66 SeitenCKRE Lab (CHC 304) Manual - 16 May 22Varun pandeyNoch keine Bewertungen

- Slup 230Dokument24 SeitenSlup 230Jelena TodorovicNoch keine Bewertungen

- Filling The Propylene Gap On Purpose TechnologiesDokument12 SeitenFilling The Propylene Gap On Purpose Technologiesvajidqc100% (1)