Beruflich Dokumente

Kultur Dokumente

MBW Report SF6 Gas Analysis PDF

Hochgeladen von

NaveenNavabOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MBW Report SF6 Gas Analysis PDF

Hochgeladen von

NaveenNavabCopyright:

Verfügbare Formate

MBW Report - SF6 Gas Analysis

On-Site SF6 Gas Analysis

The Challenges within the Power Industry and a Unique Measurement Development

By Daniel Mutter, MBW Calibration AG

Abstract

This report reviews some of the current issues relating to the gas analysis of SF 6 gas filled equipment used

throughout the power grid.

Since Kyoto and the introduction of the F-Gas regulations, control of SF6 has become a hot topic worldwide.

The SF6 community is moving toward a closed cycle of SF 6 use, principally as a response to the threat of SF6

being banned and the potential implications to the power industry. Gas quality measurement forms an integral

part of SF6 management, especially with respect to any possible release of gas during or after analysis.

SF6 gas quality must be maintained for its useful properties to remain effective. Routine SF 6 gas testing forms

an integral part of commissioning and maintenance procedures. Commonality of the test procedures varies

between manufacturers, grid companies, countries and continents. Differences include the frequency of tests,

methods of measurement, calibration traceability, units of measurement and the use of data.

SF6 chemistry and the measurement science is associated with routine gas testing are often not well

understood. For such an important test, measurement uncertainty is usually undefined and without the

traceability usually expected within quality systems. The need to improve this situation through effective

training and the adoption of existing best practices from the National and International Metrology structures

is discussed.

Also discussed are the key factors that require industry coordination and integration, including units of

measurement, accuracy or uncertainty, calibration and breakdown gases measured. Current measurement

practices, full gas collection systems and an innovative measurement solution is described together with a

review of the current activity as regards International testing procedures.

Biography

Daniel Mutter, Chairman MBW Calibration AG

Son of the MBW founder, Arthur Mutter, Daniel started working for the company in

1980 on mechanical and product development, and continue the long family tradition

of manufacturing precise solutions to challenging measurement applications. In 1990

he took over as CEO and managed the transition from analogue to digital technology.

Daniel became Chairman of the Board in 2009 and continues to drive the companys

technical focus.

Based in Wettingen Switzerland, MBW has worked closely with BBC, Sprecher &

Schuh, which are today ABB and Alstom, through the development of GIS since the

1970s. MBW specialize in the measurement of water vapor concentration, and

supplied the very first automatic instruments to GIS manufacturers nearby. MBW were

the first manufacturer to include internal SF6 gas collection and remain the only manufacturer of condensation

based SF6 purity measurements.

The MBW principles are of best possible measurement precision, long instrument life and no quibble product

support. Most National Standards Laboratories worldwide use MBW instruments as reference instruments.

www.mbw.ch

MBW Report - SF6 Gas Analysis

On-Site SF6 Gas Analysis

The Challenges within the Power Industry and a Unique Measurement Development

By Daniel Mutter, MBW Calibration AG

A Brief History

The use of SF6 gas insulated switchgear (GIS) expanded rapidly during the 1970s thanks to its reliability,

compact dimensions, durability and safety. GIS failures although rare, were carefully investigated and the

presence of water vapor was clearly identified as a common factor. Manufacturers started to make regular

measurements of humidity in SF6 gas, and even developed their own instruments (see Figure 1) to try to

achieve the precise measurements they needed.

MBW had been manufacturing chilled mirror hygrometers in

the Baden area of Switzerland since 1962, principally as a

supplier for heat treatment applications. The first contact

from the SF6 industry came from the Central Laboratory of

Brown Boveri & CIE (BBC, now ABB), as well as Sprecher &

Schuh (now Alstom), who both approached MBW with the

requirement to measure dew point in SF 6 gas. As a local

supplier, MBW worked closely with the switchgear

development teams based in Switzerland to support their

need to obtain accurate and repeatable measurements, and

over the years, several instruments based on chilled mirror

dew point technology were developed and supplied for SF 6

applications.

The concentration of water vapor (humidity) within SF6 was

identified to be of significance in maintaining gas quality and

Figure 1: BBC Manual Dew Point Instrument

asset reliability. Understanding SF6 properties and specifically

its breakdown components led to requirement for the measurement of contaminants such as SO2 and HF.

These are often performed together with the measurement of humidity during gas analysis procedures.

Since Kyoto, gases with known greenhouse properties have been the subject of increased scrutiny and

regulation. The significance of SF6 in terms of its greenhouse potential is well documented, so in recent years

its use has become increasingly controlled and its release prohibited. Gas analysis was a contributor to

emission of SF6, so innovation was necessary to capture and return measured gas to the compartment as part

of the measurement procedure.

In recent years, focus on improving standards of SF 6 analysis and handling have continued to drive better

understanding of measurement and gas handling. It is however the case that GIS manufacturers, network

operators and SF6 management teams often disagree on various topics; several of which are raised later.

Working groups within organizations such as CIGRE and IEEE continue to debate these issues with the

objective of developing unified standards and best practice guides.

www.mbw.ch

MBW Report - SF6 Gas Analysis

How wet is my SF6?

Arguably the presence of humidity within SF6 is the most significant contribution to poor SF6 quality and

therefore equipment reliability. Without the presence of water vapor the threat of corrosion, arcing and

decomposition would not be so significant. Its measurement has consequentially been an integral part of gas

analysis alongside the development of GIS.

Various types of humidity measurement techniques have

been applied, but in most cases either condensation or

electrical impedance type instruments are used.

Figure 2: Impedance Type Sensor

Impedance or capacitive dew point sensors provide cost effective measurements is gas samples with typical

specifications of 2 C. They are integrated within a gas measurement circuit together with others sensors for

SF6 purity, SO2, HF etc. To meet specification, dew point sensors depend on accurate calibration both during

production, and use. Calibration drift can be significant, so regular calibration is essential to maintain reliable

results.

Chilled mirror hygrometers are based on the physical principal

of condensation formation on a temperature controlled surface.

An optical detection system and closed loop control maintain a

constant frost/dew layer at equilibrium. Such instruments offer

a fundamental measurement principle that is used as a transfer

standard within calibration laboratories up to National Standard

level. Their disadvantage is a high initial cost when compared to

dew point sensors. When used correctly, chilled mirror instruments are highly repeatable and can be considered almost drift

free. Routine calibration adjustment is not required; users can

easily verify performance with a simple mirror clean and ice test

routine that checks measurement stability. This means that

whole life costs are comparable to dew point sensor based

systems. It is however recommended that all instruments have a

calibration check periodically; an interval of two to three years is

typical.

Figure 3: Dew Point Mirror Principle

Frost or Dew?

Whichever measurement technique is used, the correct definition of the actual

measurement value is critical. Below 0 C, the water vapor pressure curve differs

with respect to water or ice. Any instrument should specify whether frost or dew

point is the indicated value so that to correct calculations or comparison of the

humidity values is possible.

Chilled mirror instruments are now equipped with automatic systems that force

the condensate to ice below a specific temperature. Dew point sensors should be

delivered with a calibration certificate that states whether frost or dew point is Figure 4: Frost and Dew Point

the calibration reference. If these are not the case, there is a high possibility that measurements may not be

comparable or repeatable.

www.mbw.ch

MBW Report - SF6 Gas Analysis

ppmV or ppmW?

Humidity measurements are often converted from frost/dew point to ppmv or ppmw. Both are ratios of the

partial humidity content compared to the total gas content. Volumetric ratios are independent of the actual

gas make up; mass ratios depend on the molecular weight of the base gas, so variation of the gas make up has

a direct influence on the result of the calculated value.

Surprisingly, many operational limits are specified in terms of ppmw but without consideration of the SF6

purity. For example, given a fixed amount of water vapor, ppmw in 100% SF6 would not be the same as in 90%

SF6.

Compartment or Atmospheric Pressure?

Dew point is pressure dependent, so derived values such

as ppmv cannot be correct

unless pressure is measured and

included within the calculation.

Whether the displayed value is

at compartment or atmospheric

pressure depends on the procedure used, so this must be

specified and the correct determination confirmed. Possible

differences between instrument

configuration and or product

type must be taken into

consideration in any comparison

of measured data.

Figure 5: Measurement at Atmospheric and GIS Pressure

Breakdown Components

Over time, due to leaks, or as a result of discharge events within GIS, the quality of SF 6 gas diminishes. This

may lead to equipment failure, so in combination with humidity, measurement of SF6 breakdown gases such

as SO2, HF and CO is performed. Which component is significant varies between manufacturers, operators and

countries.

As an example of breakdown diagnostic purpose, incremental changes in SO 2 concentration may allow the

operator to predict or pre plan when gas maintenance may be necessary. Another example could be that

increased concentration of HF may be an indication of a recent partial discharge event.

www.mbw.ch

MBW Report - SF6 Gas Analysis

Gas Collection and Pump Back

To meet the industry requirement for complete capture of SF6 during gas analysis, MBW pioneered an

integrated gas recovery system within the 973-SF6 Analyzer. This fully automated system includes pressure

measurement, regulation and a compressor for pressure control and pump back to the gas compartment at

pressures up to 1000 kPa (10 bar).

For gas analysis on-site, integrated gas recovery means that the engineer simply connects the Analyzer to the

compartment, initiates the measurement and when finished, the system pumps back the measured SF 6.

SF6 Purity Measurement A Unique Approach

Together with humidity, the measurement of SF 6 purity forms an essential part of commissioning and gas

quality tests. SF6 purity is typically measured using conductivity or speed of sound measurement techniques.

During development of the 973-SF6 Analyzer, a Eureka moment occurred. SF6 compartments are maintained

at variable pressures; to achieve repeatable results, the 973-SF6 Analyzer regulates its internal pressure to

250 kPa (2.5 bar) using an internal regulator and compressor. The triple point of pure SF6 is approximately

-49,5 C at 226 kPa (2.26 bar). So when measuring humidity in terms of frost/dew point in the typical SF6 range

(-30-60 C) using a chilled mirror hygrometer, there is clearly a risk that an optically detected condensate

layer could be SF6. From a humidity perspective this adds a potentially significant measurement uncertainty,

but as an analysis option for SF6 purity, there was potential for a highly useful and precise measurement

solution.Using the integrated automation software of the 973-SF6 Analyzer, the MBW development team was

able to develop an automated and reliable dual measurement solution for humidity and SF 6 purity. When

connected to the SF6 compartment or cylinder, the Analyzer extracts a gas sample at regulated flow and

pressures and stabilizes a frost/dew layer for the determination of water vapor concentration. Once analysis is

complete, the humidity value is stored and the Analyzer automatically changes mode and starts to search for

the SF6 condensation point. Measuring the temperature when the condensate forms defines the dew point

and hence the SF6 purity.

As with the condensation method of humidity measurement, this approach for SF 6 purity provides a

fundamental, temperature based measurement method that remains stable over long periods and provides

excellent repeatability. Traceable calibration of the mirror temperature measurement can be performed as

part of a dew point calibration at any accredited laboratory. SF6 purity calibration can also be verified using

reference gases.

Figure 6: 973-SF6 Analyzer

www.mbw.ch

MBW Report - SF6 Gas Analysis

Calibration Traceability, Uncertainty and Responsibility

Most businesses run quality systems such as ISO9001.

Measurements performed within manufacturing or test

procedures are usually specified to be performed using calibrated

instruments. Surprisingly there seems to be no requirement of

traceability within the power industry for measurements

performed during gas analysis. This would not be accepted in

other critical humidity applications such as climatic testing of

products or pharmaceutical production.

Figure 7: MBW 17025 Accreditation

The issue becomes more significant when different measurement systems disagree. When comparing two

measurements, it should be expected that they should agree within the combined uncertainties as defined on

the respective calibration certificates. Calibration uncertainty is the standardized form for defining the

precision of a measurement. During a calibration, an instrument is compared with a reference instrument

that has itself been calibrated by a higher standard, typically an accredited laboratory. Accredited laboratories

are bodies assessed within a National Accreditation scheme to provide calibration services that are

trustworthy and traceable to National Standards. In most regulated organizations (e.g. ISO9000), calibration

traceability must be demonstrated by approved procedures and the availability of reference equipment

calibrated by an accredited laboratory. Such structures reduce the risk of incorrect measurements, minimize

the likelihood of disagreement, and comply with the requirements of Quality Management Systems.

Responsibility for the correct maintenance of equipment rests with some part of the power industry. In the

event of a breakdown due to an incorrect measurement, would an inspector first check that the test

equipment used was fit for purpose? Can measurement equipment without a credible calibration be

considered as such?

CIGRE and IEEE Working Groups

MBW are active within the International Power Community in the development of best practice guides and

standards. In both cases, involvement has been by invitation to support the working groups technical

preparation of documents supporting good humidity/moisture measurement in SF 6 and the calibration of

instrumentation.

CIGRE SCB3.25 - SF6 Analysis

- Working towards a publication that will guide asset managers towards better understanding of analysis and

improved testing procedures.

IEEE Working Group K8 C37.122.5 (P1125) Guide for Moisture Measurement and Control in SF 6

- Drafting of a revised standard.

Conclusions

There has been a dramatic increase in the discussion relating to SF 6 management and gas analysis during the

past two years. There is a clear need for improved understanding of the fundamental science and its

application in the management of SF6 equipment. As MBWs experience with both the SF 6 and humidity

standards communities is longstanding, we are trying to make sure that the key technical issues are correctly

considered so that future developments are technically correct and unbiased. We welcome open discussions

with all sections of the SF6 community in this respect.

www.mbw.ch

Das könnte Ihnen auch gefallen

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringVon EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNoch keine Bewertungen

- SF6 Partial DischargeDokument4 SeitenSF6 Partial DischargeCesar VenturoNoch keine Bewertungen

- Knowledge is "Real Power": Introduction to Power QualityVon EverandKnowledge is "Real Power": Introduction to Power QualityNoch keine Bewertungen

- SF - An Excellent Insulating and Quenching Gas: Substantial Properties at A GlanceDokument16 SeitenSF - An Excellent Insulating and Quenching Gas: Substantial Properties at A GlancedennyyusufNoch keine Bewertungen

- Real-Time Simulation Technology for Modern Power ElectronicsVon EverandReal-Time Simulation Technology for Modern Power ElectronicsNoch keine Bewertungen

- Power Quality and EMC in Smart GridDokument6 SeitenPower Quality and EMC in Smart GridMohammed MansoorNoch keine Bewertungen

- Power-system protection A Complete GuideVon EverandPower-system protection A Complete GuideBewertung: 1 von 5 Sternen1/5 (1)

- Voltage GradientDokument7 SeitenVoltage GradientAndré Luiz100% (1)

- 0 - A High-Voltage Fuse Tutorial and Application GuideDokument35 Seiten0 - A High-Voltage Fuse Tutorial and Application GuideFerran MunyósNoch keine Bewertungen

- Ziomek Paper 025 Cigre-Iec 2016 - DC Transformer Bushing Replacement Program in MH HVDC Converter StationsDokument8 SeitenZiomek Paper 025 Cigre-Iec 2016 - DC Transformer Bushing Replacement Program in MH HVDC Converter StationsWaldemar ZiomekNoch keine Bewertungen

- ILIS EnglDokument5 SeitenILIS EnglEk TanNoch keine Bewertungen

- Transformer Health Index Assessment Rev DDokument17 SeitenTransformer Health Index Assessment Rev DTemitope OmoniyiNoch keine Bewertungen

- TDSdescriptionDokument236 SeitenTDSdescriptionapi-26946645100% (1)

- 7.21 Outdoor Bus StructuresDokument191 Seiten7.21 Outdoor Bus StructuresEdyta MarzecNoch keine Bewertungen

- 13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledDokument5 Seiten13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledRomany AllamNoch keine Bewertungen

- Analysis of The Root Causes of Transformer Bushing Failures: June 2013Dokument7 SeitenAnalysis of The Root Causes of Transformer Bushing Failures: June 2013singowongsoNoch keine Bewertungen

- Descriptive Bulletin 242-32Dokument25 SeitenDescriptive Bulletin 242-32mashan98Noch keine Bewertungen

- 2008CoxPaper - The Benefits of Online DGA Tap Changer MonitoringDokument6 Seiten2008CoxPaper - The Benefits of Online DGA Tap Changer Monitoringlbk50Noch keine Bewertungen

- Murray Loop Test To Locate Ground FaultDokument2 SeitenMurray Loop Test To Locate Ground FaultAnonymous HyOfbJ6Noch keine Bewertungen

- Manual LDM5 U enDokument3 SeitenManual LDM5 U enLuizAugustoMedeirosNoch keine Bewertungen

- Article Ultrasonic or TevDokument2 SeitenArticle Ultrasonic or Tevanchak99Noch keine Bewertungen

- Analysis of The Root Causes of Transformer Bushing Failures PDFDokument6 SeitenAnalysis of The Root Causes of Transformer Bushing Failures PDFElsonMilanNoch keine Bewertungen

- BreakerDokument92 SeitenBreakerphanindraNoch keine Bewertungen

- Eee-Vii-high Voltage Engineering NotesDokument177 SeitenEee-Vii-high Voltage Engineering NotesACE PROFILESNoch keine Bewertungen

- Guest Editorial - Understanding Dissolved Gas Analysis (DGA) Techniques and InterpretationsDokument10 SeitenGuest Editorial - Understanding Dissolved Gas Analysis (DGA) Techniques and InterpretationsAlpesh PatelNoch keine Bewertungen

- PD-Diagnosis Physical Basic Practical Experience With OWTS: April 2006Dokument41 SeitenPD-Diagnosis Physical Basic Practical Experience With OWTS: April 2006dio39saiNoch keine Bewertungen

- On - Line Partial Discharge TestingDokument61 SeitenOn - Line Partial Discharge TestingNirmalKumarSelvarajNoch keine Bewertungen

- ST2451Dokument37 SeitenST2451Abhishek PrakashNoch keine Bewertungen

- AbbDokument12 SeitenAbbAH IMRANNoch keine Bewertungen

- Partial Discharge Detection Using RFI MeasurementsDokument6 SeitenPartial Discharge Detection Using RFI Measurementsmiamor$44Noch keine Bewertungen

- Understanding Power System Harmonics Grady April 2012Dokument181 SeitenUnderstanding Power System Harmonics Grady April 2012Pablo FloresNoch keine Bewertungen

- 13 Ed Gulski PraesentationDokument45 Seiten13 Ed Gulski Praesentationcarlos vidalNoch keine Bewertungen

- Unit IVDokument75 SeitenUnit IVJanapareddy Veerendra KumarNoch keine Bewertungen

- 3 PH Transformer and Generator ModelsDokument11 Seiten3 PH Transformer and Generator ModelsMansa ManuNoch keine Bewertungen

- Use of Data From Cigre High Voltage Equipment Reliability SurveyDokument6 SeitenUse of Data From Cigre High Voltage Equipment Reliability SurveyZakaria BelloulaNoch keine Bewertungen

- Summary Paper For For C37 243 IEEE Guide For Application of Digital Line Current Differential Relays PSRC Sept 2016 v5Dokument20 SeitenSummary Paper For For C37 243 IEEE Guide For Application of Digital Line Current Differential Relays PSRC Sept 2016 v5Debayan BhattacharyaNoch keine Bewertungen

- Amted310010en WebDokument120 SeitenAmted310010en WebMemo TipNoch keine Bewertungen

- Modeling and Simulation in XENDEE: IEEE 34 Node Test FeederDokument12 SeitenModeling and Simulation in XENDEE: IEEE 34 Node Test Feedercarlos cervantesNoch keine Bewertungen

- Analysis of Excessive Hydrogen Generation in Transformers in ServiceDokument8 SeitenAnalysis of Excessive Hydrogen Generation in Transformers in ServiceandikaubhNoch keine Bewertungen

- Energy Audit of A 400-220 KV Substation - A Case Study PDFDokument8 SeitenEnergy Audit of A 400-220 KV Substation - A Case Study PDFRajuNoch keine Bewertungen

- GCB Application GuideDokument61 SeitenGCB Application GuideAnonymous fbeCwgBFYNoch keine Bewertungen

- Power Quality ManagementDokument13 SeitenPower Quality ManagementAniruddh NagaNoch keine Bewertungen

- Paper - Comparison Study of Partial Discharge Detection Methods For SwitchgearsDokument5 SeitenPaper - Comparison Study of Partial Discharge Detection Methods For SwitchgearsNguyen Vu Nhat HaNoch keine Bewertungen

- Partial Discharge TestingDokument6 SeitenPartial Discharge TestinggvamovicNoch keine Bewertungen

- E1 M1 C1 Presentation - enDokument1 SeiteE1 M1 C1 Presentation - enmaniking1Noch keine Bewertungen

- Applied Voltage Test System For TransformersDokument3 SeitenApplied Voltage Test System For Transformerschaima haddoudiNoch keine Bewertungen

- Joe Mooney Presentation For MC C37-114 PSRC May 2016 1 12 16Dokument19 SeitenJoe Mooney Presentation For MC C37-114 PSRC May 2016 1 12 16apofview100% (1)

- 12 KentDokument140 Seiten12 KentTrường ArsenalNoch keine Bewertungen

- ## Etap Earth Sample PDFDokument5 Seiten## Etap Earth Sample PDFdcf67myNoch keine Bewertungen

- HVDC LCC Modelling: Digsilent PowerfactoryDokument3 SeitenHVDC LCC Modelling: Digsilent Powerfactorybeimar heredia saiguaNoch keine Bewertungen

- Power Cables Cable Accessories Cable Monitoring & Maintenance SystemsDokument58 SeitenPower Cables Cable Accessories Cable Monitoring & Maintenance Systemsfigv1975Noch keine Bewertungen

- High-Power-Rectifier-Systems-CATALOGO TECNICODokument16 SeitenHigh-Power-Rectifier-Systems-CATALOGO TECNICOEdgardo Kat ReyesNoch keine Bewertungen

- Distributed Power Flow Controler (DPFC)Dokument44 SeitenDistributed Power Flow Controler (DPFC)rajesh_d84Noch keine Bewertungen

- Simplified Control Model For HVDC ClassicDokument54 SeitenSimplified Control Model For HVDC ClassicBhaskar SenNoch keine Bewertungen

- GITDokument29 SeitenGITsknayak6Noch keine Bewertungen

- Pantograph Isolator Hot Spot EliminationDokument40 SeitenPantograph Isolator Hot Spot Eliminationjilu_siluNoch keine Bewertungen

- Harmonic Filter DesignDokument4 SeitenHarmonic Filter DesignMarcos C I S100% (1)

- Practical Application of Tan Delta Diagnostic Testing in CablesDokument7 SeitenPractical Application of Tan Delta Diagnostic Testing in CablesNouman AsgharNoch keine Bewertungen

- PD Knowledge Rules For Insulation Condition Assessment of Power Cables Version 23-07-01Dokument9 SeitenPD Knowledge Rules For Insulation Condition Assessment of Power Cables Version 23-07-01SISWANTONoch keine Bewertungen

- Transformer Life Extension Pdmsa Southafrica 2010Dokument17 SeitenTransformer Life Extension Pdmsa Southafrica 2010Eddy Fernando Queca CadizNoch keine Bewertungen

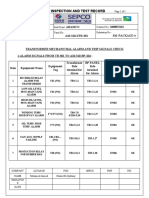

- Site Inspection and Test Record:: A10-310-XFR-801Dokument4 SeitenSite Inspection and Test Record:: A10-310-XFR-801NaveenNavabNoch keine Bewertungen

- Site Inspection and Test Record:: A10-310-XFR-801Dokument4 SeitenSite Inspection and Test Record:: A10-310-XFR-801NaveenNavabNoch keine Bewertungen

- Site Inspection and Test Record:: A10-310-XFR-802Dokument4 SeitenSite Inspection and Test Record:: A10-310-XFR-802NaveenNavabNoch keine Bewertungen

- Site Inspection and Test Record:: A10-310-XFR-301Dokument2 SeitenSite Inspection and Test Record:: A10-310-XFR-301NaveenNavabNoch keine Bewertungen

- Interface RP104 To SG 301-1aDokument1 SeiteInterface RP104 To SG 301-1aNaveenNavabNoch keine Bewertungen

- Site Inspection and Test Record:: A10-310-XFR-301Dokument2 SeitenSite Inspection and Test Record:: A10-310-XFR-301NaveenNavabNoch keine Bewertungen

- Interface RP104 To SG 301-1aDokument1 SeiteInterface RP104 To SG 301-1aNaveenNavabNoch keine Bewertungen

- Metal Enclosed Breaker SwitchgearDokument8 SeitenMetal Enclosed Breaker SwitchgearNaveenNavabNoch keine Bewertungen

- Site Testing Pre Commissioning PDFDokument2 SeitenSite Testing Pre Commissioning PDFadi nugrohoNoch keine Bewertungen

- CL-NG-6460-0002-020 Checklist For Surge Arrester Rev00Dokument3 SeitenCL-NG-6460-0002-020 Checklist For Surge Arrester Rev00NaveenNavabNoch keine Bewertungen

- Wire and Cable (600V and Below)Dokument3 SeitenWire and Cable (600V and Below)NaveenNavabNoch keine Bewertungen

- Metal Enclosed Breaker SwitchgearDokument8 SeitenMetal Enclosed Breaker SwitchgearNaveenNavabNoch keine Bewertungen

- WI-NG-6460-002-022 Work Instruction-NER Rev00Dokument5 SeitenWI-NG-6460-002-022 Work Instruction-NER Rev00NaveenNavabNoch keine Bewertungen

- National Grid: Check List of Neutral Earthing Resistor (NER) CommissioningDokument2 SeitenNational Grid: Check List of Neutral Earthing Resistor (NER) CommissioningNaveenNavabNoch keine Bewertungen

- Medium Voltage CableDokument5 SeitenMedium Voltage CableNaveenNavabNoch keine Bewertungen

- Medium Voltage CableDokument5 SeitenMedium Voltage CableNaveenNavabNoch keine Bewertungen

- Wire and Cable (600V and Below)Dokument3 SeitenWire and Cable (600V and Below)NaveenNavabNoch keine Bewertungen

- 9 Igbt-Hgtg30n120d2 PDFDokument6 Seiten9 Igbt-Hgtg30n120d2 PDFNaveenNavabNoch keine Bewertungen

- ABB MCP Installation and Maintenance 3BSY200425-GVC - A1bDokument96 SeitenABB MCP Installation and Maintenance 3BSY200425-GVC - A1bNaveenNavabNoch keine Bewertungen

- Active Internal Arc Protection For Switchgear - Ultra-Fast Earthing Switch UFES - Arc Fault Protection (Apparatus) ABB PDFDokument5 SeitenActive Internal Arc Protection For Switchgear - Ultra-Fast Earthing Switch UFES - Arc Fault Protection (Apparatus) ABB PDFNaveenNavabNoch keine Bewertungen

- 2 - Didoe-RHRG30120CC Fast Rectifer DiodeDokument3 Seiten2 - Didoe-RHRG30120CC Fast Rectifer DiodeSai Bhargav VeerabathiniNoch keine Bewertungen

- 7 - IGBT With Antiparallel Diode-Q67040-A4420-A2 PDFDokument9 Seiten7 - IGBT With Antiparallel Diode-Q67040-A4420-A2 PDFNaveenNavabNoch keine Bewertungen

- BM (Eng) PDFDokument8 SeitenBM (Eng) PDFNaveenNavabNoch keine Bewertungen

- What Is The Importance of Reactive Power in Transmission Lines - Quora PDFDokument7 SeitenWhat Is The Importance of Reactive Power in Transmission Lines - Quora PDFNaveenNavabNoch keine Bewertungen

- Not 0092016 1902016Dokument5 SeitenNot 0092016 1902016ubyisismayilNoch keine Bewertungen

- A Review About Vector Group Connections in TransformersDokument7 SeitenA Review About Vector Group Connections in TransformersMohamed Wahid100% (1)

- Design Best PracDokument24 SeitenDesign Best PracBhanu PratapNoch keine Bewertungen

- What Is Actually Reactive Power - ResearchGateDokument3 SeitenWhat Is Actually Reactive Power - ResearchGateNaveenNavabNoch keine Bewertungen

- Consumer Protection ActDokument34 SeitenConsumer Protection ActshikhroxNoch keine Bewertungen

- 02 CT311 Site WorksDokument26 Seiten02 CT311 Site Worksshaweeeng 101Noch keine Bewertungen

- Sharat Babu Digumarti Vs State, Govt. of NCT of Delhi (Bazee - Com Case, Appeal) - Information Technology ActDokument17 SeitenSharat Babu Digumarti Vs State, Govt. of NCT of Delhi (Bazee - Com Case, Appeal) - Information Technology ActRavish Rana100% (1)

- Chemical & Ionic Equilibrium Question PaperDokument7 SeitenChemical & Ionic Equilibrium Question PapermisostudyNoch keine Bewertungen

- VRARAIDokument12 SeitenVRARAIraquel mallannnaoNoch keine Bewertungen

- Leather PuppetryDokument8 SeitenLeather PuppetryAnushree BhattacharyaNoch keine Bewertungen

- Acute Suppurative Otitis MediaDokument41 SeitenAcute Suppurative Otitis Mediarani suwadjiNoch keine Bewertungen

- FINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Dokument45 SeitenFINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Edmar Cielo SarmientoNoch keine Bewertungen

- Initial Police Report: Calamba City Police Station Brgy Real, Calamba City, Laguna E-Mail: 545-1694/545-6789 Loc 8071Dokument1 SeiteInitial Police Report: Calamba City Police Station Brgy Real, Calamba City, Laguna E-Mail: 545-1694/545-6789 Loc 8071Jurish BunggoNoch keine Bewertungen

- OsciloscopioDokument103 SeitenOsciloscopioFredy Alberto Gómez AlcázarNoch keine Bewertungen

- Linux ProgramDokument131 SeitenLinux ProgramsivashaNoch keine Bewertungen

- Physiol Toric Calculator: With Abulafia-Koch Regression FormulaDokument1 SeitePhysiol Toric Calculator: With Abulafia-Koch Regression FormuladeliNoch keine Bewertungen

- Payment of Wages 1936Dokument4 SeitenPayment of Wages 1936Anand ReddyNoch keine Bewertungen

- An Enhanced Radio Network Planning Methodology For GSM-R CommunicationsDokument4 SeitenAn Enhanced Radio Network Planning Methodology For GSM-R CommunicationsNuno CotaNoch keine Bewertungen

- CBSE 10th ResultsDokument1 SeiteCBSE 10th ResultsAkshit SinghNoch keine Bewertungen

- MegaMacho Drums BT READ MEDokument14 SeitenMegaMacho Drums BT READ MEMirkoSashaGoggoNoch keine Bewertungen

- Ships Near A Rocky Coast With Awaiting Landing PartyDokument2 SeitenShips Near A Rocky Coast With Awaiting Landing PartyFouaAj1 FouaAj1Noch keine Bewertungen

- An Analysis of Students' Error in Using Possesive Adjective in Their Online Writing TasksDokument19 SeitenAn Analysis of Students' Error in Using Possesive Adjective in Their Online Writing TasksKartika Dwi NurandaniNoch keine Bewertungen

- Bichelle HarrisonDokument2 SeitenBichelle HarrisonShahbaz KhanNoch keine Bewertungen

- DBM Uv W ChartDokument2 SeitenDBM Uv W ChartEddie FastNoch keine Bewertungen

- MSCM Dormitory Housing WEB UpdateDokument12 SeitenMSCM Dormitory Housing WEB Updatemax05XIIINoch keine Bewertungen

- API RP 7C-11F Installation, Maintenance and Operation of Internal Combustion Engines.Dokument3 SeitenAPI RP 7C-11F Installation, Maintenance and Operation of Internal Combustion Engines.Rashid Ghani100% (1)

- Communication Skill - Time ManagementDokument18 SeitenCommunication Skill - Time ManagementChấn NguyễnNoch keine Bewertungen

- Affidavit of Co OwnershipDokument2 SeitenAffidavit of Co OwnershipEmer MartinNoch keine Bewertungen

- Libya AIP Part1Dokument145 SeitenLibya AIP Part1Hitham Ghwiel100% (1)

- Sociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadDokument44 SeitenSociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadJohn Blackburn100% (20)

- UG ENGLISH Honours PDFDokument59 SeitenUG ENGLISH Honours PDFMR.Shantanu SharmaNoch keine Bewertungen

- Unit 1 Bearer PlantsDokument2 SeitenUnit 1 Bearer PlantsEmzNoch keine Bewertungen

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDokument7 SeitenSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0Noch keine Bewertungen

- E-CRM Analytics The Role of Data Integra PDFDokument310 SeitenE-CRM Analytics The Role of Data Integra PDFJohn JiménezNoch keine Bewertungen

- Practical Reservoir Engineering and CharacterizationVon EverandPractical Reservoir Engineering and CharacterizationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Well Integrity for Workovers and RecompletionsVon EverandWell Integrity for Workovers and RecompletionsBewertung: 5 von 5 Sternen5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesVon EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesBewertung: 4 von 5 Sternen4/5 (2)

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Abrasive Water Jet Perforation and Multi-Stage FracturingVon EverandAbrasive Water Jet Perforation and Multi-Stage FracturingNoch keine Bewertungen

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsVon EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsBewertung: 4 von 5 Sternen4/5 (4)

- Casing and Liners for Drilling and Completion: Design and ApplicationVon EverandCasing and Liners for Drilling and Completion: Design and ApplicationBewertung: 5 von 5 Sternen5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesVon EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNoch keine Bewertungen

- Guide to the Practical Use of Chemicals in Refineries and PipelinesVon EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsVon EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsVon EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsBewertung: 4 von 5 Sternen4/5 (6)

- Petroleum Production Engineering, A Computer-Assisted ApproachVon EverandPetroleum Production Engineering, A Computer-Assisted ApproachBewertung: 4.5 von 5 Sternen4.5/5 (11)

- Advanced Production Decline Analysis and ApplicationVon EverandAdvanced Production Decline Analysis and ApplicationBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityVon EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityBewertung: 3 von 5 Sternen3/5 (2)

- Gas and Oil Reliability Engineering: Modeling and AnalysisVon EverandGas and Oil Reliability Engineering: Modeling and AnalysisBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Heavy and Extra-heavy Oil Upgrading TechnologiesVon EverandHeavy and Extra-heavy Oil Upgrading TechnologiesBewertung: 4 von 5 Sternen4/5 (2)