Beruflich Dokumente

Kultur Dokumente

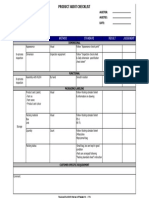

Production Process Audit Checklist

Hochgeladen von

profmlocampo100%(5)100% fanden dieses Dokument nützlich (5 Abstimmungen)

5K Ansichten2 SeitenChecklist used in auditing production processes

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenChecklist used in auditing production processes

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

100%(5)100% fanden dieses Dokument nützlich (5 Abstimmungen)

5K Ansichten2 SeitenProduction Process Audit Checklist

Hochgeladen von

profmlocampoChecklist used in auditing production processes

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Page 1 of 2

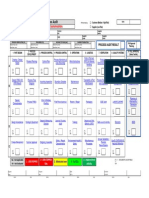

Production Process Audit Checklist

Supplier:

Part #:

Location:

E/C: -

Approval Status:

PGW Supplier Development Engineer:

Ye

s

No

1

2

3

Date:

Part Name:

PRODUCTION APPROVAL REQUIREMENT

COMMENTS

Are part design records (blueprints) available?

Are Part Submission Warrants available for each part number?

Is an acceptable process flow diagram available?

Is an acceptable control plan available and verified by a walk

through?

Is an acceptable DFMEA available?

Is an acceptable PFMEA available?

Is there an acceptable Product Development Plan (Timing Chart)?

Is there an acceptable Tool Progress Report?

Is there an acceptable Inspection Standard?

Is there an acceptable Engineering Change Log?

If needed, has a Launch Plan been developed?

Have PGW APQP checklists been utilized and reviewed?

Has the PGW SNN & SA process been reviewed with the supplier?

Have key personnel involved been designated? (Contact Lists)

Are there key characteristics defined? Has the receiving PGW

plant participated in designating key product characteristics?

Are gauges/fixtures available for measuring key product

characteristics?

Are acceptable measurement system analysis (GRR) study results

available for key characteristics?

Are machine capability study results for each key characteristic

acceptable?

Are Measurement Result Sheets available for all blueprint

dimensions?

Is there an acceptable validation plan available covering material,

performance, and durability tests?

Has an acceptable Run @Rate been scheduled? Conducted?

If applicable, is there an acceptable Appearance Approval Report?

Are physical production approval samples available from each

process/mold/cavity?

Has final product packaging been approved by PGW?

Has the PGW receiving plant notified the supplier of labeling

requirements?

Is there a documented system for lot traceability, including partial

containers and reworked parts? Are unique production lot numbers

used?

Have PPAP sample run parameters been met? Min production run

size, PPAP sample size, capability sample size, variable or attribute

studies,

Have known problems with similar part(s) been reviewed and

addressed?

Is there an acceptable documented corrective action system?

Has past responsiveness to corrective actions been acceptable?

Has the PGW receiving plant communicated incoming receiving

requirements?

Are applicable work instructions and specification sheets available at

the workstations?

Where applicable, is mistake proofing utilized in the process?

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

PGW

Revision 0

QA4.SQM.01.19

4/7/09

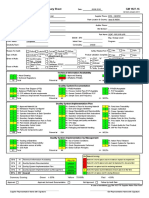

Page 2 of 2

Production Approval Comments & Follow-up Sheet

Supplier:

Part #:

Element

number

PGW

Revision 0

Location:

E/C: -

Issue / Action

Date:

Part Name:

Responsibility

Target

date

QA4.SQM.01.19

4/7/09

Das könnte Ihnen auch gefallen

- QMS Audit Check SheetDokument7 SeitenQMS Audit Check Sheetaboo2uNoch keine Bewertungen

- Apqp PpapDokument50 SeitenApqp PpapEvandro Ribeiro50% (2)

- Supplier Audit ProcedureDokument4 SeitenSupplier Audit Proceduresakshi patil100% (2)

- PRODUCT AUDIT CHECKLIST PCB TemplateDokument15 SeitenPRODUCT AUDIT CHECKLIST PCB TemplateMekong Tom100% (4)

- Supplier Audit Checklist - ZftvsDokument3 SeitenSupplier Audit Checklist - Zftvsaboo2uNoch keine Bewertungen

- Process AuditDokument15 SeitenProcess Auditdesurkarb100% (2)

- Turtle DiagramDokument22 SeitenTurtle DiagramVikas0% (1)

- Product & Manufacturing Process Audit Checklist: Part NumberDokument6 SeitenProduct & Manufacturing Process Audit Checklist: Part NumberDuy Le100% (4)

- Manufacturing Process Audit ChecklistDokument4 SeitenManufacturing Process Audit Checklistgksp100% (4)

- Guidelines For Control PlanDokument4 SeitenGuidelines For Control PlanArjun Rathore100% (1)

- APQPDokument2 SeitenAPQPRenata Codruta100% (1)

- Internal Audit Checklist - Quality Assurance & Quality ControlDokument3 SeitenInternal Audit Checklist - Quality Assurance & Quality ControlSachin Ramdurg100% (2)

- Internal Audit Checklist - QualityDokument3 SeitenInternal Audit Checklist - QualitySachin Ramdurg100% (1)

- Audit Checklist in Production AreaDokument5 SeitenAudit Checklist in Production AreaPrince Moni100% (2)

- Process Audit ChecklistDokument15 SeitenProcess Audit Checklistmulachu100% (1)

- QMP-18 Initial Production ControlDokument5 SeitenQMP-18 Initial Production Controlom cncNoch keine Bewertungen

- Internal Audit Checklist - Top ManagementDokument1 SeiteInternal Audit Checklist - Top ManagementSachin Ramdurg100% (4)

- Internal Audit Checklist - ProductionDokument3 SeitenInternal Audit Checklist - ProductionSachin Ramdurg100% (3)

- Procedure For NPD HandoverDokument1 SeiteProcedure For NPD HandoverTushar Wagh100% (1)

- Internal Audit Checklist - PurchaseDokument2 SeitenInternal Audit Checklist - PurchaseSachin Ramdurg89% (9)

- IMDSDokument13 SeitenIMDSJohn OoNoch keine Bewertungen

- Process & Product Audit Check SheetDokument6 SeitenProcess & Product Audit Check SheetPrakashRai100% (7)

- 4th Edition PPAPDokument83 Seiten4th Edition PPAPTerri Paleno Lebow100% (1)

- Competence For Internal AuditorsDokument2 SeitenCompetence For Internal AuditorsSachin Ramdurg100% (1)

- Turtle DiagramDokument2 SeitenTurtle DiagramBhuwan Chopra100% (4)

- Iso Iatf Quality System Manual PDFDokument53 SeitenIso Iatf Quality System Manual PDFKrishnamoorthyNoch keine Bewertungen

- GM 1927-16 PCPA ChecksheetDokument4 SeitenGM 1927-16 PCPA Checksheetrahul100% (1)

- Product Audit ReportDokument2 SeitenProduct Audit ReportManoharar R100% (2)

- Appendix 25 VDA 6 3 Process AuditDokument12 SeitenAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- Production Audit ChecklistDokument1 SeiteProduction Audit ChecklistAnton MymrikovNoch keine Bewertungen

- Product Audit FormatDokument2 SeitenProduct Audit FormatSUBODHH50% (2)

- Process Check Item Method Standard Result Judgement: Index: Auditor: Product Code: Auditee: Lot No: Date: CustomerDokument1 SeiteProcess Check Item Method Standard Result Judgement: Index: Auditor: Product Code: Auditee: Lot No: Date: CustomerDuy LeNoch keine Bewertungen

- 21-Product Safety ProcedureDokument1 Seite21-Product Safety ProcedurealijadoonNoch keine Bewertungen

- Turtle Diagram (Calibration)Dokument1 SeiteTurtle Diagram (Calibration)semaphore689% (9)

- QMP-13 Production ControlDokument9 SeitenQMP-13 Production Controlom cncNoch keine Bewertungen

- Production Audit ChecklistDokument2 SeitenProduction Audit Checklistandruta197833% (3)

- Manufacturing Audit ChecklistDokument8 SeitenManufacturing Audit Checklistgksp100% (1)

- Internal Audit Checklist - Tool ManufacturingDokument1 SeiteInternal Audit Checklist - Tool ManufacturingSachin Ramdurg100% (2)

- PRODUCT AUDIT CHECKLIST (WO Schedule)Dokument7 SeitenPRODUCT AUDIT CHECKLIST (WO Schedule)Ranjeet Dongre100% (1)

- PPAP Process-Guide ExampleDokument5 SeitenPPAP Process-Guide ExampleN.B.P0% (1)

- Internal Audit Checklist - Packing & DispatchDokument2 SeitenInternal Audit Checklist - Packing & DispatchSachin Ramdurg100% (6)

- 1n GM 1927 16 Process Control Plan Audit April 2005Dokument12 Seiten1n GM 1927 16 Process Control Plan Audit April 2005kunjan2165100% (2)

- Product Audit ChecklistDokument1 SeiteProduct Audit ChecklistRoy PhanNoch keine Bewertungen

- Internal Audit Checklist New Product Dev.Dokument10 SeitenInternal Audit Checklist New Product Dev.dhir.ankur100% (3)

- C32 Electronic Unit Injector - Adjust PDFDokument4 SeitenC32 Electronic Unit Injector - Adjust PDFmanu luvunga100% (2)

- QAF12 Process Audit Rev 09Dokument4 SeitenQAF12 Process Audit Rev 09ukavathekarNoch keine Bewertungen

- State of Patriot MissilesDokument13 SeitenState of Patriot MissilesTaira Mai100% (1)

- Layered Process Audit FormDokument3 SeitenLayered Process Audit FormPawan Sehrawat100% (7)

- Control PlanDokument1 SeiteControl PlanAmit PatelNoch keine Bewertungen

- Procedure: Measurement System Analysis ExecutionDokument1 SeiteProcedure: Measurement System Analysis Executionaslam100% (1)

- Audit Checklist in Production AreaDokument5 SeitenAudit Checklist in Production AreaPrince Moni100% (2)

- Internal Audit Checklist PurchaseDokument4 SeitenInternal Audit Checklist Purchasedhir.ankur100% (2)

- Internal Audit Checklist - MaintenanceDokument2 SeitenInternal Audit Checklist - MaintenanceSachin Ramdurg92% (12)

- New Process Qualification Check ListDokument7 SeitenNew Process Qualification Check Listccocos7182Noch keine Bewertungen

- 02-Engine Mechanical System PDFDokument129 Seiten02-Engine Mechanical System PDFSigit Indrawan100% (1)

- Control Plan Audit FormDokument2 SeitenControl Plan Audit Formdpcastilla50% (2)

- Manufacturing Process Audit Checklist: Reference DocumentsDokument4 SeitenManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- Advance Concrete PDFDokument33 SeitenAdvance Concrete PDFUdom RithNoch keine Bewertungen

- Process Audit Check ListDokument47 SeitenProcess Audit Check ListAnas NazriNoch keine Bewertungen

- IATF Implementation Plan and Co-Ordinator RolesDokument3 SeitenIATF Implementation Plan and Co-Ordinator RolesKumaravel50% (2)

- MsaDokument7 SeitenMsaGobi PSNoch keine Bewertungen

- Layered Process Audits TemplateDokument3 SeitenLayered Process Audits TemplatemajidrashidNoch keine Bewertungen

- 462116-01 AA - 1510 Excel ESI Command Codes Addendum - 10 Feb 2009Dokument103 Seiten462116-01 AA - 1510 Excel ESI Command Codes Addendum - 10 Feb 2009quyenducqdc100% (1)

- .013-00-Checking AidsDokument3 Seiten.013-00-Checking Aidsdaniel_sasikumarNoch keine Bewertungen

- Check Sheet Model SCCDokument39 SeitenCheck Sheet Model SCCN.PalaniappanNoch keine Bewertungen

- ARO Pump ManualDokument8 SeitenARO Pump Manualrazaq athabNoch keine Bewertungen

- MMTI Literature ReviewDokument39 SeitenMMTI Literature ReviewGargee GhoshNoch keine Bewertungen

- First-Man-Up User ManualDokument24 SeitenFirst-Man-Up User ManualJoshuaNoch keine Bewertungen

- SY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical ReferenceDokument88 SeitenSY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical Referencealopezcuervo82190% (1)

- Mole Reactions and Stoichiometry MultipleDokument25 SeitenMole Reactions and Stoichiometry MultiplelinaNoch keine Bewertungen

- LG Wd1873rds Manual de UsuarioDokument76 SeitenLG Wd1873rds Manual de UsuarioJosè Otoniel Osorio BarreraNoch keine Bewertungen

- Pavement Evaluation and Overlay Des - DR MSA - LatestDokument103 SeitenPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruNoch keine Bewertungen

- Catalogo Towel RailsDokument1 SeiteCatalogo Towel RailsrodijammoulNoch keine Bewertungen

- Sensores AvDokument12 SeitenSensores Avhb CorpNoch keine Bewertungen

- EWF2703 TV EmersonDokument57 SeitenEWF2703 TV EmersonEriksson Miguel Tapia SolisNoch keine Bewertungen

- Manual Kls MartinDokument27 SeitenManual Kls MartinChris AliNoch keine Bewertungen

- Hazard-Identification Dec 2015Dokument22 SeitenHazard-Identification Dec 2015Dumitru EninNoch keine Bewertungen

- 592-A2GA DesbloqueadoDokument27 Seiten592-A2GA DesbloqueadoVicktor GranadosNoch keine Bewertungen

- Griet DSP ProgramsDokument14 SeitenGriet DSP ProgramsJaipaul CheernamNoch keine Bewertungen

- Pile Foundations in Engineering Practice by S - by Civildatas - Blogspot.inDokument784 SeitenPile Foundations in Engineering Practice by S - by Civildatas - Blogspot.inTatiana RodríguezNoch keine Bewertungen

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDokument4 SeitenInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDNoch keine Bewertungen

- Scarifier 9 Piecies Tooth TypeDokument2 SeitenScarifier 9 Piecies Tooth Typeangga setyawanNoch keine Bewertungen

- Standard Terms & Conditions of Sale Pre-Engineered BuildingsDokument18 SeitenStandard Terms & Conditions of Sale Pre-Engineered BuildingsHongducBuiNoch keine Bewertungen

- Business Dynamics in The 21st CenturyDokument270 SeitenBusiness Dynamics in The 21st CenturyskilmagNoch keine Bewertungen

- Ncomputing VSpace Server Management Console User ManualDokument34 SeitenNcomputing VSpace Server Management Console User ManualJeff IvanNoch keine Bewertungen

- SYNC2000 - 4.00.022014 Protocol ConverterDokument2 SeitenSYNC2000 - 4.00.022014 Protocol ConverterAnasSalemNoch keine Bewertungen

- Fracture in Concrete and Reinforced ConcreteDokument23 SeitenFracture in Concrete and Reinforced ConcreteNilay GandhiNoch keine Bewertungen

- RDSL 993K Z4D - Z4ZDokument11 SeitenRDSL 993K Z4D - Z4ZDAnielNoch keine Bewertungen

- EST 2011B v1.0 Configuration 10/28/2018 7:43 AMDokument2 SeitenEST 2011B v1.0 Configuration 10/28/2018 7:43 AMbagusNoch keine Bewertungen