Beruflich Dokumente

Kultur Dokumente

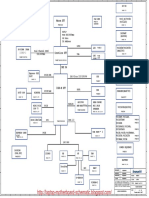

Stepper Motor Interfacing With Microcontroller Tutorial

Hochgeladen von

ChakkaravarthiErOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stepper Motor Interfacing With Microcontroller Tutorial

Hochgeladen von

ChakkaravarthiErCopyright:

Verfügbare Formate

Stepper Motor Tutorial

Home (/) / Rikipedia (/wiki/) / Stepper Motor Tutorial

From Rikipedia Embedded Wiki

Page (/wiki/Stepper_Motor_Tutorial)

Discussion (/mediawiki/index.php?title=Talk:Stepper_Motor_Tutorial&action=edit&redlink=1)

Edit

Nav

Stepper motors can be used in various areas of your microcontroller projects such as making robots,

robotic arm, automatic door lock system etc. This tutorial will explain you construction of stepper motors

(unipolar and bipolar stepper motors ), basic pricipal, di erent controlling types (Half step and Full step),

Interfacing Techniques (using L293D or ULN2003) and programming your microcontroller in C and

assembly to control stepper motor.

Table of Content

Types of Stepper Motors

Unipolar stepper motor

Bipolar stepper motor

Working of Stepper Motor

Step Sequence

Full Step Sequence

Half Step Sequence

Step Angle

Step Sequence for 2-wire control of

Unipolar stepper motor

Step Sequence for Bipolar stepper motor

Stepper Motor Connections

Connecting Unipolar Stepper Motor

2-wire connection for Unipolar Stepper

Motor

Connecting Bipolar Stepper Motor

Stepper Motor Programming

Programming Full step Sequence

Programming Half step Sequence

Programming for 2-wire connection of

Unipolar Stepper Motor

Programming for Bipolar Stepper Motor

Types of Stepper Motors

Types of Stepper Motors

There are basic two types of stepper motors available in market.

Unipolar stepper motor

The unipolar stepper motor has ve or six wires and four coils (actually two coils divided by center

connections on each coil). The center connections of the coils are tied together and used as the power

connection. They are called unipolar steppers because power always comes in on this one pole.

Bipolar stepper motor

The bipolar stepper motor usually has four wires coming out of it. Unlike unipolar steppers, bipolar

steppers have no common center connection. They have two independent sets of coils instead. You can

distinguish them from unipolar steppers by measuring the resistance between the wires. You should nd

two pairs of wires with equal resistance. If you've got the leads of your meter connected to two wires that

are not connected (i.e. not attached to the same coil), you should see in nite resistance (or no continuity).

As already said, we will talk mostly on "Unipolar stepper motors" which is most common type of stepper

motor available in the market.A simple example of 6 lead step motor is given below and in 5 lead step

motor wire 5 and 6 are joined together to make 1 wire as common.

Stepper Motor Coils

Working of Stepper Motor

Now lets discuss the operation pricipal of a stepper motor. When we energize a coil of stepper motor, The

shaft of stepper motor (which is actually a permanent magnet) align itself according to poles of energized

coil. So when motor coils are energized in a particular sequence, motor shaft tend to align itself according

to pole of coils and hence rotates. A small example of energizing operation is given below.

Stepper Motor Coils

You can see in the example, when coil "A" is energized, A north-south polarity is generated at "A+A\" as

shown in the gure above and magnetic shaft automatically align itself according to the poles generated.

When the next coil is energized the shaft again align itself and take a step. Hence the working principal.

Stepper Motor Coils When energized

We have seen that to make the stepper motor work, we need to energize coil in a sequence.

Step Sequence

Stepper motors can be driven in two di erent patterns or sequences. namely, Full Step Sequence

Bulleted list item

Half Step Sequence

Half Step Sequence

we will go through these sequences one by one.

Full Step Sequence

In the full step sequence, two coils are energized at the same time and motor shaft rotates. The order in

which coils has to be energized is given in the table below.

Full Mode Sequence

Step

A\

B\

The working of the full mode sequence is given in the animated gure below.

Full mode Sequence Animation

Half Step Sequence

In Half mode step sequence, motor step angle reduces to half the angle in full mode. So the angualar

resolution is also increased i.e. it becomes double the angular resolution in full mode. Also in half mode

sequence the number of steps gets doubled as that of full mode. Half mode is usually pre ered over full

mode. Table below shows the pattern of energizing the coils.

Half Mode Sequence

Step

A\

B\

The working of the half mode sequence is given in the animated gure below.

Half mode Sequence Animation

Step Angle

Step angle of the stepper motor is de ned as the angle traversed by the motor in one step. To calculate

step angle,simply divide 360 by number of steps a motor takes to complete one revolution. As we have

seen that in half mode, the number of steps taken by the motor to complete one revolution gets doubled,

so step angle reduces to half.

As in above examples, Stepper Motor rotating in full mode takes 4 steps to complete a revolution, So step

angle can be calculated as...

Step Angle = 360 / 4 = 90

and in case of half mode step angle gets half so 45.

So this way we can calculate step angle for any stepper motor. Usually step angle is given in the spec sheet

of the stepper motor you are using. Knowing stepper motor's step angle helps you calibrate the rotation

of motor also to helps you move the motor to correct angular position.

Step Sequence for 2-wire control of Unipolar stepper motor

Step Sequence for 2-wire control of Unipolar stepper motor

As seen in above explanation, In every step of the sequence, two wires are always set to opposite

polarities. Because of this, it's possible to control steppers with only two wires instead of four, with a

slightly more complex circuit. The stepping sequence is the same as it is for the two coils A and B, and the

opposite polarity value is given to A\ and B\. The sequence is given in the table below:

2-wire Mode Sequence

Step

Step Sequence for Bipolar stepper motor

Bipolar motor has simpler construction. It has two windings with no center taps and a permanent magnet

at the center just like unipolar stepepr motors. Being simpler in contruction, the stepping sequence is a

little complex, as the power for both the coils has to be controlled in such a way that the polarity of the

poles get reversed. This polarity sequence is shown in the table below.

Polarity Sequence

Step

A\

B\

+ve

-ve

-ve

-ve

-ve

-ve

+ve

-ve

-ve

+ve

-ve

-ve

-ve

-ve

-ve

+ve

The above polarity sequence can be interpreted in terms of logic levels for microcontroller by activating

one coil at a time as shown in the table below.

Step Sequence

Step

A\

B\

Stepper Motor Connections

Stepper Motor Connections

Connecting Unipolar Stepper Motor

There are actually many ways you can interface a stepper motor to your controller, out of them the most

used interfaces are:

1. Interface using L293D - H-Bridge Motor Driver

2. Interface using ULN2003/2004 - Darlington Arrays

We will discuss both connection techniques one by one. The above mentioned methods need 4 controller

pins for interface.

Connecting Unipolar stepper using L293D

Unipolar Stepper with L293D

As you see in the circuit above the four pins "Controller pin 1",2,3 and 4 will control the motion and

direction of the stepper motor according to the step sequence programmed in the controller.

Connecting Unipolar stepper using ULN2003/2004

Unipolar Stepper with ULN2003/ULN2004

As already discussed in case of L293D, Here in this circuit too the four pins "Controller pin 1", 2, 3 and 4

will control the motion and direction of the stepper motor according to the step sequence sent by the

controller.

2-wire connection for Unipolar Stepper Motor

We have seen the generally used 4-wire connection method for interfacing unipolar stepper motor, but we

can simplify the design to make controller use less pins with the help of 2-wire connection method. The

circuit for 2-wire connection is shown below.

Unipolar Stepper Motor connection

Connecting Bipolar Stepper Motor

As we have studied that, Bi-polar stepper motors has 2 di erent coils. The step sequence for Bipolar

stepper motor is same as that of unipolar stepper motors. The driving circuit for this require an H-Bridge

as it allows the polarity of the power applied to be controlled independently. This can be done as shown in

the gure below:

Bipolar Stepper Motor connection

Now we have seen the methods for connecting stepper motors with your microcontroller. So keeping

these circuits in mind,we will now look at the programming of microcontroller to control stepper motors.

Stepper Motor Programming

Programming Full step Sequence

C Programming

I am assuming that stepper motor is connected at Port 1.0 to Port 1.3. Adjusting the delay will increase or

decrease the speed of the motor. Here just for demonstration i have taken some delay, you can change it

as you want.

[Tip: Do testing... ]

1. #include<REG2051.H>

2. #definestepperP1

3.

4. voiddelay()

5. {

6.

unsignedchari,j,k;

7.

for(i=0;i<6;i++){

8.

for(j=0;j<255;j++)

8.

for(j=0;j<255;j++)

9.

10.

for(k=0;k<255;k++);

11. }

12.

13. voidmain()

14. {

15.

while(1){

16.

stepper=0x0C;

17.

delay();

18.

stepper=0x06;

19.

delay();

20.

stepper=0x03;

21.

delay();

22.

stepper=0x09;

23.

delay();

24.

25. }

Assembly Programming

1.

org0H

2.

3.

stepperequP1

4.

5. main:

6.

movstepper,#0CH

7.

acalldelay

8.

movstepper,#06H

9.

acalldelay

9.

acalldelay

10.

movstepper,#03H

11.

acalldelay

12.

movstepper,#09H

13.

acalldelay

14.

sjmpmain

15.

16. delay:

17.

movr7,#4

18. wait2:

19.

movr6,#0FFH

20. wait1:

21.

movr5,#0FFH

22. wait:

23.

djnzr5,wait

24.

djnzr6,wait1

25.

djnzr7,wait2

26.

ret

27.

end

The working of the above code can be seen in the demo animation below.

Full Step Sequence Simulation

Programming Half step Sequence

C Programming

Just the main routine changes rest everything remains same, i mean same delay routine.

1. voidmain()

2. {

3.

while(1){

4.

stepper=0x08;

5.

delay();

5.

delay();

6.

stepper=0x0C;

7.

delay();

8.

stepper=0x04;

9.

delay();

10.

stepper=0x06;

11.

delay();

12.

stepper=0x02;

13.

delay();

14.

stepper=0x03;

15.

delay();

16.

stepper=0x01;

17.

delay();

18.

stepper=0x09;

19.

delay();

20.

21. }

Assembly Programming

Here also the main routine changes rest everything remains same.

1. main:

2.

movstepper,#08H

3.

acalldelay

4.

movstepper,#0CH

5.

acalldelay

6.

movstepper,#04H

7.

acalldelay

8.

movstepper,#06H

9.

acalldelay

10.

movstepper,#02H

11.

acalldelay

11.

acalldelay

12.

movstepper,#03H

13.

acalldelay

14.

movstepper,#01H

15.

acalldelay

16.

movstepper,#09H

17.

acalldelay

18.

sjmpmain

The working of the above code can be seen in the demo animation below.

Half Step Sequence Simulation

Programming for 2-wire connection of Unipolar Stepper Motor

C Programming

1. voidmain()

2. {

3.

while(1){

4.

stepper=0x03;

5.

delay();

6.

stepper=0x01;

7.

delay();

8.

stepper=0x00;

9.

delay();

10.

stepper=0x02;

11.

delay();

12.

12.

13. }

Assembly Programming

1. main:

2.

movstepper,#03H

3.

acalldelay

4.

movstepper,#01H

5.

acalldelay

6.

movstepper,#00H

7.

acalldelay

8.

movstepper,#02H

9.

acalldelay

10.

sjmpmain

The working of the above code can be seen in the demo animation below.

2-wire connection of Unipolar Stepper Motor simulation

Programming for Bipolar Stepper Motor

C Programming

1. voidmain()

2. {

3.

while(1){

4.

stepper=0x08;

5.

delay();

6.

stepper=0x02;

7.

delay();

8.

stepper=0x04;

9.

delay();

10.

stepper=0x01;

11.

delay();

12.

13. }

Assembly Programming

1. main:

2.

movstepper,#08H

3.

acalldelay

4.

movstepper,#02H

5.

acalldelay

6.

movstepper,#04H

7.

acalldelay

8.

movstepper,#01H

9.

acalldelay

10.

sjmpmain

Das könnte Ihnen auch gefallen

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsVon EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNoch keine Bewertungen

- Stepper MotorDokument3 SeitenStepper Motormpkkbtech100% (1)

- Stepper Motor InterfacingDokument5 SeitenStepper Motor InterfacingShobanraj Letchumanan100% (1)

- USB To RS232 Using Atmel ATtiny2313 or ATmega8Dokument4 SeitenUSB To RS232 Using Atmel ATtiny2313 or ATmega8Nugraha Indrawan100% (2)

- Generating PWM With PIC Microcontroller - MikroC ProDokument3 SeitenGenerating PWM With PIC Microcontroller - MikroC Proemilfrancu100% (1)

- PWM Using Ic555Dokument1 SeitePWM Using Ic555Sachin Arora100% (1)

- Voltage StabilizerDokument5 SeitenVoltage Stabilizersqh_uetNoch keine Bewertungen

- Eeeb371 Pic Exp6newDokument7 SeitenEeeb371 Pic Exp6newSalemAbaad100% (2)

- 8051 Project LCD InterfacingDokument7 Seiten8051 Project LCD InterfacingShailesh Sankdasariya100% (5)

- Full Control of A PWM DCAC Converter For AC Voltage RegulationDokument9 SeitenFull Control of A PWM DCAC Converter For AC Voltage RegulationAndrés Felipe CelisNoch keine Bewertungen

- The Seven Segment DisplayDokument5 SeitenThe Seven Segment DisplayTewodros Kassahun100% (2)

- AC Drives and Soft Starter Application Guide - AllenBradleyCoDokument5 SeitenAC Drives and Soft Starter Application Guide - AllenBradleyCojoyama100% (1)

- Controlling LED Matrices With The MBI5026 DriverDokument9 SeitenControlling LED Matrices With The MBI5026 DriverLaurentiu Iacob100% (1)

- Zero CrossingDokument16 SeitenZero CrossingAryan KapsNoch keine Bewertungen

- Project Status Review Semester: 7 EE (Group No: 2) Project I (2170001)Dokument51 SeitenProject Status Review Semester: 7 EE (Group No: 2) Project I (2170001)UmangNoch keine Bewertungen

- Implementing A Bootloader For The PIC16F87X: OperationDokument24 SeitenImplementing A Bootloader For The PIC16F87X: Operationboslim1580100% (1)

- Isolated Power Supply 30wDokument43 SeitenIsolated Power Supply 30wchinnadurai20006034100% (1)

- Chapter 5 - DC - Ac Converter (Part A)Dokument29 SeitenChapter 5 - DC - Ac Converter (Part A)andersonNoch keine Bewertungen

- 19v From A Car BatteryDokument4 Seiten19v From A Car Batterysafet100% (1)

- Oscillators Module 02Dokument20 SeitenOscillators Module 02ervaishu5342100% (1)

- I2C Adapter For 1602 and 2004 LCD Displays - ENDokument27 SeitenI2C Adapter For 1602 and 2004 LCD Displays - ENharm ?100% (1)

- Driver Circuits - PowerGuru - Power Electronics Information PortalDokument5 SeitenDriver Circuits - PowerGuru - Power Electronics Information PortaldevchandarNoch keine Bewertungen

- Motor StepperDokument4 SeitenMotor Stepperfavour ukpai100% (1)

- Basics of The Communication ProtocolDokument19 SeitenBasics of The Communication ProtocolNEETHU PRAKASH100% (1)

- Zero Voltage Switching Resonant Power Devices by Bill AndrecakDokument28 SeitenZero Voltage Switching Resonant Power Devices by Bill AndrecakRekhamtrNoch keine Bewertungen

- Contents: Diac Triac Other Types of ThyristorDokument24 SeitenContents: Diac Triac Other Types of ThyristorKharol A. Bautista100% (1)

- 1.2 Block Diagram With Explanation:: Chapter-1Dokument27 Seiten1.2 Block Diagram With Explanation:: Chapter-1SAMEULNoch keine Bewertungen

- Develop Ineo-250 Error C2557Dokument2 SeitenDevelop Ineo-250 Error C2557Tariq MajeedNoch keine Bewertungen

- Activity 3 in Industrial ElectronicsDokument15 SeitenActivity 3 in Industrial ElectronicsFrancis Valdez Lopez100% (1)

- AVR Hardware Design ConsiderationsDokument14 SeitenAVR Hardware Design ConsiderationsAmarnath M Damodaran100% (1)

- The 8051 Microcontroller and Embedded Systems: Motor Control: Relay, PWM, DC and Stepper MotorsDokument51 SeitenThe 8051 Microcontroller and Embedded Systems: Motor Control: Relay, PWM, DC and Stepper MotorsAmAnDeepSingh100% (1)

- Digital Control of Switching Power ConvertersDokument6 SeitenDigital Control of Switching Power ConvertersNISHANT VATSNoch keine Bewertungen

- Digital Power Suply ControlDokument30 SeitenDigital Power Suply ControlPaul RomanNoch keine Bewertungen

- Digital Power-Conversion For The Analog EngineerDokument12 SeitenDigital Power-Conversion For The Analog EngineerfjwoemcuNoch keine Bewertungen

- Wind Turbine MPPT Regulator v2.3 120120Dokument36 SeitenWind Turbine MPPT Regulator v2.3 120120EdwinDuranJr.100% (1)

- 555 TimerDokument76 Seiten555 TimerSai Krishna KodaliNoch keine Bewertungen

- PWMDokument16 SeitenPWMRICHIHOTS2100% (2)

- Lab11 CountersDokument6 SeitenLab11 Countersjocansino4496100% (1)

- LECTURE 27 (Ch. 11) Ac Voltage Controllers: ECE 452 Power ElectronicsDokument15 SeitenLECTURE 27 (Ch. 11) Ac Voltage Controllers: ECE 452 Power ElectronicsSumukha KumarNoch keine Bewertungen

- PIC16f877a TimerDokument9 SeitenPIC16f877a Timerjohn moron100% (2)

- DC Motor Direction Control Using L293d (H Bridge)Dokument5 SeitenDC Motor Direction Control Using L293d (H Bridge)Syed Aameer100% (1)

- Duo Range Type PotentiometerDokument19 SeitenDuo Range Type Potentiometersaikarthick023Noch keine Bewertungen

- Steady State Converter Analysis: Anjana S Ap, EeeDokument23 SeitenSteady State Converter Analysis: Anjana S Ap, Eeemridul mpNoch keine Bewertungen

- Plecs Tl431Dokument11 SeitenPlecs Tl431khsniper100% (1)

- Timers Programming in AVR Microcontrollers Using AssemblyDokument19 SeitenTimers Programming in AVR Microcontrollers Using Assemblymahmoud100% (2)

- Design and Micro Controller Implementation of A Three Phase SCR Power ConverterDokument8 SeitenDesign and Micro Controller Implementation of A Three Phase SCR Power ConverterIsmael Ochoa JimenezNoch keine Bewertungen

- Slis 140 ADokument33 SeitenSlis 140 AAlvaro RoqueNoch keine Bewertungen

- Hobby Servo Motor Control Via PIC Pulse Width Modulation: Nathan Markey April 4, 2003Dokument7 SeitenHobby Servo Motor Control Via PIC Pulse Width Modulation: Nathan Markey April 4, 2003Luciana Gutierrez Salazar100% (1)

- x300 SchematicsDokument99 Seitenx300 SchematicsWondmagegn Abera DiresNoch keine Bewertungen

- AVR Motor Control PDFDokument15 SeitenAVR Motor Control PDFjp149100% (1)

- Generating 50Hz PWM Using PIC16F877ADokument2 SeitenGenerating 50Hz PWM Using PIC16F877AZarko DacevicNoch keine Bewertungen

- By Marl Us: Lighting The Right To TheDokument7 SeitenBy Marl Us: Lighting The Right To TheGiancarloRichardRivadeneyraMiranda100% (1)

- What Is The Difference Between Microcontrollers and 8051Dokument6 SeitenWhat Is The Difference Between Microcontrollers and 8051Erandi Brito100% (1)

- LCD Display 16x02 - 20x04 Allinone ENDokument44 SeitenLCD Display 16x02 - 20x04 Allinone ENcmdi100% (1)

- Guia Basica de Ejercicios-ProtonDokument59 SeitenGuia Basica de Ejercicios-ProtonFatality Joseph100% (1)

- History of The I2C BusDokument24 SeitenHistory of The I2C BusManoj Kavedia100% (1)

- Analog Devices CD ReferenceDokument8 SeitenAnalog Devices CD ReferenceAcody Ie SyNoch keine Bewertungen

- String InstructionsDokument7 SeitenString InstructionsManoj Kavedia100% (1)

- Motion Control ReportVon EverandMotion Control ReportBewertung: 4 von 5 Sternen4/5 (1)

- 12-1 p76 NXP Partial Net PDFDokument4 Seiten12-1 p76 NXP Partial Net PDFChakkaravarthiErNoch keine Bewertungen

- Technical Data SheetDokument16 SeitenTechnical Data SheetChakkaravarthiEr100% (1)

- Macro (Computer Science) - Wikipedia, The Free EncyclopediaDokument6 SeitenMacro (Computer Science) - Wikipedia, The Free EncyclopediaChakkaravarthiErNoch keine Bewertungen

- I2C Info - I2C Bus, Interface and ProtocolDokument2 SeitenI2C Info - I2C Bus, Interface and ProtocolChakkaravarthiErNoch keine Bewertungen

- IntroDokument17 SeitenIntroChakkaravarthiErNoch keine Bewertungen

- Java PrintingDokument1 SeiteJava PrintingChakkaravarthiErNoch keine Bewertungen

- Misra C 2004Dokument4 SeitenMisra C 2004ChakkaravarthiErNoch keine Bewertungen

- Asian RegionalismDokument15 SeitenAsian RegionalismLiezel AalaNoch keine Bewertungen

- Ielts Reading Actual Tests With Suggested Answers Oct 2021 JDokument508 SeitenIelts Reading Actual Tests With Suggested Answers Oct 2021 JHarpreet Singh JohalNoch keine Bewertungen

- The Senior High School in The Phillipines: The Way To The WorldDokument5 SeitenThe Senior High School in The Phillipines: The Way To The WorldRodel Ramos DaquioagNoch keine Bewertungen

- Two Occult Philosophers in The Elizabethan Age: by Peter ForshawDokument10 SeitenTwo Occult Philosophers in The Elizabethan Age: by Peter ForshawFrancesco VinciguerraNoch keine Bewertungen

- NBCC 2015 Seismic Design Examples in S-FRAME AnalysisDokument91 SeitenNBCC 2015 Seismic Design Examples in S-FRAME AnalysisMike Smith100% (1)

- Ashfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)Dokument36 SeitenAshfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)surajnayak77Noch keine Bewertungen

- Anansi and His Six Sons An African MythDokument3 SeitenAnansi and His Six Sons An African MythShar Nur JeanNoch keine Bewertungen

- Assignment On Unstable or Astatic Gravimeters and Marine Gravity SurveyDokument9 SeitenAssignment On Unstable or Astatic Gravimeters and Marine Gravity Surveyraian islam100% (1)

- Paper 1 Set 2 PDFDokument531 SeitenPaper 1 Set 2 PDFabdul rehman aNoch keine Bewertungen

- Primefaces Users Guide 3 5cDokument497 SeitenPrimefaces Users Guide 3 5calvarolucasNoch keine Bewertungen

- Factsheet AMRT 2023 01Dokument4 SeitenFactsheet AMRT 2023 01arsyil1453Noch keine Bewertungen

- RTRT User GuideDokument324 SeitenRTRT User GuideAlae Khaoua100% (3)

- Test Bank For Body Structures and Functions 11th Edition Ann ScottDokument27 SeitenTest Bank For Body Structures and Functions 11th Edition Ann Scottpellucidutter.uka6lr100% (38)

- Enable Modern Authentication in Exchange OnlineDokument2 SeitenEnable Modern Authentication in Exchange Onlinedan.artimon2791Noch keine Bewertungen

- Solutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriDokument5 SeitenSolutions For Tutorial Exercises Association Rule Mining.: Exercise 1. AprioriMarkib Singh AdawitahkNoch keine Bewertungen

- Test Iii Cultural Social and Political OrganizationDokument2 SeitenTest Iii Cultural Social and Political OrganizationTin NatayNoch keine Bewertungen

- Simulation of 1,3-Butadiene Extractive Distillation Process Using N-Methyl-2-Pyrrolidone SolventDokument7 SeitenSimulation of 1,3-Butadiene Extractive Distillation Process Using N-Methyl-2-Pyrrolidone SolventAA0809Noch keine Bewertungen

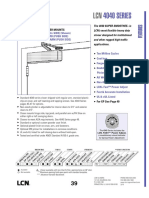

- 4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Dokument11 Seiten4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Melrose FabianNoch keine Bewertungen

- Bluesil Ep 150 A3: Insulator Grade Silicone RubberDokument2 SeitenBluesil Ep 150 A3: Insulator Grade Silicone RubberNagendra KumarNoch keine Bewertungen

- KRPL Shahjahanpur Check List For Arc Welding MachineDokument1 SeiteKRPL Shahjahanpur Check List For Arc Welding MachineA S YadavNoch keine Bewertungen

- Language Loss in Waray: Ni Voltaire Q. UyzonDokument23 SeitenLanguage Loss in Waray: Ni Voltaire Q. UyzonMary Rose OmbrogNoch keine Bewertungen

- Only Great Minds Can Read This Based On Cambridge University StudyDokument7 SeitenOnly Great Minds Can Read This Based On Cambridge University StudyabotNoch keine Bewertungen

- IAU Logbook Core 6weeksDokument7 SeitenIAU Logbook Core 6weeksbajariaaNoch keine Bewertungen

- Accenture MockDokument1 SeiteAccenture Mockrajyogesh487Noch keine Bewertungen

- Ericsson AXE 810: Switch (ROTD)Dokument4 SeitenEricsson AXE 810: Switch (ROTD)Kao Sun HoNoch keine Bewertungen

- Cisco Nexus 7000 Introduction To NX-OS Lab GuideDokument38 SeitenCisco Nexus 7000 Introduction To NX-OS Lab Guiderazzzzzzzzzzz100% (1)

- IO5 Future Skills Foresight 2030 ReportDokument96 SeitenIO5 Future Skills Foresight 2030 ReportjuliavalleNoch keine Bewertungen

- Structural Engineering Formulas Second EditionDokument224 SeitenStructural Engineering Formulas Second Editionahmed_60709595194% (33)

- Text Descriptive Tentang HewanDokument15 SeitenText Descriptive Tentang HewanHAPPY ARIFIANTONoch keine Bewertungen