Beruflich Dokumente

Kultur Dokumente

Compressor Article

Hochgeladen von

Chem.EnggCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Compressor Article

Hochgeladen von

Chem.EnggCopyright:

Verfügbare Formate

CT436.

qxp

5/14/10

9:23 AM

Page 1

RECIPROCATING COMPRESSOR DESIGN OPTIMIZATION

Target Minimize Cost and Maximize Efficiency, Reliability, Flexibility and Safety

By Shelley D. Greenfield, P.Eng.; Kelly Eberle, P.Eng.; Dwayne A. Hickman

Editors Note: The following presentation is a condensed

version of a technical paper presented at the Gas Machinery

Conference in Atlanta, Georgia, U.S.A. (October 2009). The

authors want to acknowledge, and thank, Adam Long of

Piedmont for his contribution to this paper. For a full version of the paper, please visit www.betamachinery.com.

Three of the common design objectives for pipeline and

midstream compressor owners are to minimize capital

costs, maximize unit flexibility, and have the most efficient

and reliable compressor possible. All these objectives are in

conflict. Thus, achieving a well-balanced design involves

careful thought and new design methodologies and tools

because current practices make it difficult to achieve a wellbalanced design.

Beta Machinery Analysis (BETA) and ACI Services Inc.

(ACI) have collaborated over the past four years to help

owners, EPCs and packagers improve the design of reciprocating compressor packages. As a result of this research

and development, BETA and ACI have developed a unique

approach to optimize the design of reciprocating compressors for pipeline and midstream applications. Included in

this initiative is the use of a system performance model

(SPM) approach. Key features to consider when optimizing

a reciprocating compressor are outlined here. Examples are

provided based on actual projects, including a recent compressor station on the transmission system of Piedmont

Natural Gas.

Figure 1. There is a compelling business case for compressor design

optimization.

Optimization Goals

There are many documented cases where overall per-

formance and design of a reciprocating compressor system

falls short of the anticipated result. A casual observer would

consider these issues to be easily solved. Unfortunately,

that is not the case.

Current practices make it difficult to optimize a compressor package design. Historically, no individual or

team is evaluating the entire layout to assess improvement opportunities. In addition, until now, the industry

has lacked proper modeling tools to accurately and effi-

Shelley Greenfield is vice president of Engineering Design Services

at Beta Machinery Analysis (Beta), Calgary, Alberta, Canada.

She leads the companys design teams, structural, foundation

and skid design services, customer support and training initiatives. This includes managing relationships with Betas customers,

OEMs and packagers in Asia, Europe, North America and South

America. She has 25 years of direct experience in performing API

618-related design studies and actively participated in the API

618 Standard 5th edition pulsation task force. Greenfield has published technical articles and presented at various technical conferences in North America and Europe. She received a BS degree

in Mechanical Engineering from the University of Calgary and is

a Professional Engineer.

Kelly Eberle is a principal engineer at Beta with over 22 years of

design and field experience, particularly in the area of pressure

pulsation analysis and mechanical analysis of reciprocating compressor and pump installations, and structural analysis for offshore

projects. The scope of his design experience includes acoustical simulations, thermal flexibility studies, static and dynamic finite element analyses, structural analysis and foundation analysis. He directs Betas Research and Development group focusing on new

analysis tools and techniques. Eberle has published technical arti-

cles and presented at the GMRC, EFRC and The Vibration Institute.

He received his BS degree in Mechanical Engineering from the

University of Saskatchewan and is a Professional Engineer.

Dwayne A. Hickman is the Director of Software Development for

ACI Services Inc. located in Cambridge, Ohio, U.S.A. He has over

17 years of compressor performance experience and has been involved with the reciprocating compressor industry since 1992. He

developed and maintains ACIs Performance Software, eRCM

line, for modeling all types of reciprocating compressors from

1999 to present. Hickman has developed numerous compressor

performance software packages, including multiple OEMs packages. He developed and maintains Camerons OEM performance

and sizing software for Ajax Compressors (2001 to present). He

also developed and maintains the new OEM performance and

sizing software for Knox Western Compressors (2008 to present).

Currently, Hickman is developing performance and sizing software for a major high-speed compressor OEM. He has presented

many technical papers and short courses at the GMC, IPC, GSRMS

and EGCR, and has written numerous articles for

COMPRESSORTechTWO. Hickman graduated from Ohio State

University and taught college courses in mathematics and computer science for 13 years.

APRIL 2010

COMPRESSORTechTwo

CT436.qxp

5/14/10

9:23 AM

Page 2

ciently evaluate the performance of the overall system,

identify the best way to optimize the layout and quantify

financial benefits. As a result, many current designs can

suffer from excessive pressure drop, limited flexibility

when operating across a wide range and uncertainty that

the final design will meet the intended specification.

Often, the proposed design is not the best overall solution possible.

Based on our survey of pipeline owners, we understand

their ideal goals would include: higher flow and efficiency;

better operating flexibility across the entire range of operating conditions; reduced pressure drop through the piping

system; safe operation; accurate predictions of power,

forces, rod load limits, pin reversal, temperatures, emissions

and other parameters for all conditions, load steps and

speeds; and improved control of the compressor, including

performance map for the SCADA system.

Two Issues Hampering Optimization

To achieve the above design goals, an accurate performance model is required. Unfortunately, the standard performance models available in industry do not address this

requirement for two reasons:

i). Performance is predicted at the cylinder flange (flange

to flange as illustrated in Figure 2a). A generic assumption

is then made about pressure drop through the piping, coolers, pulsation bottles and other vessels. These assumptions

lead to a wide margin of error. A better approach is to have

accurate performance predictions from the inlet to outlet of

the station fence to fence as opposed to flange to flange,

which is current practice. This means an optimized design

should include the analysis of the complete compressor

piping system from fence to fence, including piping, vessels, bottles, etc.

ii). Performance is assessed for a limited number of conditions. These design points generally do not represent the

breadth of operation and may result in some design compromises. If the entire range of operating conditions is included, the design team can evaluate different reciprocating

compressor designs. For example, a number of recent projects were designed based on only five operating conditions.

This led to inefficient operation in other important areas of

the operating envelope.

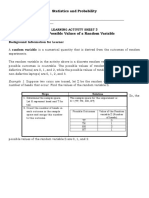

Base Case: With unloaders - no changes to system

Pressure Drop Location

Pressure Drop

Suction System

(psia)

% of total

S. Cyl. Nozzle Orifice

2.03

9.2%

Bottle (suction)

4.51

20.5%

Bottle-Header (Suc.)

1.42

6.4%

Fence to Header

0.56

2.5%

Total Suction

8.52

38.7%

Discharge System

D.Cyl. Nozzle Orifice

2.69

12.2%

Bottle_discharge

2.63

11.9%

Bottle-Cooler (inlet header)

4.01

18.2%

Across Cooler

3.35

15.2%

Header to Fence

0.83

3.8%

Total Discharge

13.51

61.3%

Total (psia)

22.03

100.0%

Table 1. Summary of system pressure drop (fence to fence).

APRIL 2010

A System Performance Model

Accurately calculating performance and efficiency requires an understanding of total pressure drop through the

piping system, including inlet filters, pulsation bottles, coolers and piping. Total pressure drop is the sum of static and

dynamic pressure drop. Dynamic pressure drop is the result

of nonlinear dynamic flow phenomena in the piping. These

nonlinear effects are then included in the performance

model, which gives a much more accurate picture of the efficiency, power, fuel requirements, rod load limits, temperatures, emissions and other parameters. This entire database

is part of the SPM approach.

The SPM overcomes the two limitations described above.

First, it is more comprehensive than a standard performance program, because it includes the effects of the entire

piping system (from fence to fence as shown in Figure 2b).

Second, it includes the entire operating envelope (Figure 5)

rather than a few discrete points. One benefit of the SPM is

that it summarizes pressure drop in different regions of the

system (Figure 3). This allows the team to highlight regions

where high losses occur and evaluate alternative designs to

economically reduce these losses.

Table 1 illustrates the pressure drop at these different locations and the percentage of the total losses for an existing

pipeline compressor. In this example, the suction and discharge bottles represent a large component of the pressure

drop. Modifying the system to reduce these losses can generate significant returns for the owner.

Evaluating performance from fence to fence using the

SPM program provides a number of advantages: includes

accurate pressure drop estimates through piping, vessels,

bottles, coolers, etc. (note, total pressure drop includes static plus dynamic effects); provides accurate flow, power,

emissions, etc.; verifies that the design will meet the required performance specification; identifies areas of excessive losses; and allows comprehensive comparison of alternative designs.

The compressor design must accommodate the entire operating envelope to ensure adequate operating flexibility.

Running the SPM program across this envelope generates a

powerful understanding of the overall system (Figure 5). To

provide sufficient resolution, the SPM can include more

than 500 different points, plus speed variation. With this

mesh size, the team can now view the full map and understand trade-offs in the design.

Assessing the entire operating map is critical for owners

to: identify the optimal capacity control design; pinpoint areas of unsafe operation; optimize the pulsation control solution; and check the performance in key locations.

Once the design is finalized, the SPM operating map can

be imported directly into the control system. This provides

a much higher level of control enabling operators to run

the machine more efficiently.

A common procedure is for the SPM to include 500 conditions for the operating map to provide sufficient resolution. For each condition, the speed is evaluated at 50 speed

increments, resulting in a total of 25,500 points.

Until recently, assessing the compressor over this many

conditions economically and efficiently was not possible.

The recent development of the SPM program now makes

this level of analysis (fence to fence performance, across

the entire envelope) feasible.

Six Examples of Evaluating Reciprocating

Compressor Design Using the SPM Database

Optimization will generate improved compressor designs

in many specific ways. Using an actual situation, this presentation includes six applications using the results from

the SPM database.

COMPRESSORTechTwo

CT436.qxp

5/14/10

9:23 AM

Page 3

Figure 2a. (Left) Standard performance programs provide accurate results based on

pressures at the compressor flanges. Figure 2b. (Above) A system performance model

includes effects of the piping system (from fence to fence).

(1) Optimized Capacity Control Strategy

One of the early steps in the design process is to define

the capacity control strategy. Until now, evaluating different

unloading options and the impact on performance, efficiency, rod loads and operating flexibility has been difficult.

As often happens, the operating pressures for this station

ended up substantially different from what was initially anticipated. Alternate loading scenarios for the existing (and

future) units were investigated to address the rod load concerns and to look at optimizing loading over the wider

range of operating conditions.

In this example, one solution to improve compressor

loading is to replace the finger-type valve unloaders (currently on four of six cylinders) with fixed volume pockets

on all six cylinders. The SPM database is used to compare

the calculated compressor capacity (flow) for the operating

map. In Figure 6, the darker green areas are when the

pockets-only option provides more flow. On average, the

darker green area has 5% more flow (and up to 10% in

some areas). The lighter green areas with data reflect areas

where the unloaders-only option provides more flow (average of 0.8% improvement over pockets).

Over the complete operating map, the pockets yield

about a 2% increase in flow compared to finger unloaders.

In summary, the pockets allow the unit to be run efficiently across the entire map, with considerable performance gains as the station moves to the high discharge

pressure condition.

At times, each arrangement has an advantage over the other.

However, across the entire operating map used in this study,

the pocket-only proposal yields the best long-term results.

(2) Optimized Pulsation Control

This existing pipeline compressor had a pulsation study

performed based on a limited number of conditions. The

pulsation bottle design was focused on minimizing pulsation forces in the bottles and minimizing pulsations leaving

the bottles. The static pressure drop from the bottle internals was calculated to be 15% over the API 618 guideline

for the highest pressure drop conditions.

The SPM was run on the existing (base) situation using a

nonlinear time domain pulsation algorithm.

Changes in the compressor capacity control from fingertype unloaders to pocket unloaders tend to reduce the pulsation energy generated by the compressor cylinders. This

reduction in pulsation energy means that the pulsation bottle design can be relaxed.

The team investigated minor modifications to the pulsation filter (baffles and choke tube) while maintaining the

existing pulsation bottle size. This modification can be easily installed in the existing installation.

The SPM was run and identified significant improvements

in reducing total pressure drop while still maintaining acceptable control of pressure pulsations and shaking forces.

The suction and discharge bottle pressure drop could be reduced by 66% and 37%, respectively. This relatively simple

change in the bottle internals results in an overall reduction

in the system total pressure drop of 20% (Figure 7).

(3) Incremental Flow and Net Profit

Following the above example, the minor changes to the

bottle internals were modeled using the SPM approach. For

discussion purposes, the financial evaluation focused on a

few discrete operating points including: Condition 1 low

compression ratio (1.16); Condition 2 high compression ratio (1.52); Condition 3 higher suction/discharge pressures.

A comparison was made of the calculated flow for the

base case, or existing system (Case A), and the modified

case, (Case B), which includes the pockets and new pulsation bottle internals. Figures 8a and 8b show no incremental benefit to Condition 1, but for the other conditions, a significant increase in flow occurs, varying

between 8.5% and 11.5%.

Note: The SPM database can be used to evaluate other

changes to the system. The pressure drop in the discharge

piping and through the cooler was identified as significant

and as a potential area for further investigation. It is also

possible to determine alternative pulsation bottle designs

and pulsation control devices which may result in further

improvements in flow.

Figure 3. System performance model (SPM)

calculates pressure drop

locations at different locations in the compressor system.

_P1

APRIL 2010

_P2

_P3

_P4

_P5

_P6

_P7

_P8

_P9

_P11

_P11

COMPRESSORTechTwo

Figure 4. SPM calculates pressure

drop locations at

different locations

in the compressor

system.

Page 4

{

{

Pressure Drop (psia)

9:23 AM

discharge system

5/14/10

suction system

CT436.qxp

The Net Profit financial metric [3] is an effective way to

compare different design alternatives, based on the following: Gross Profit = Flow X Transportation Value Net Profit =

Gross Profit Expenses (maintenance and fuel costs)

For each of the three conditions evaluated, the financial

analysis examines the incremental net profit (US$/year).

The key assumptions include: a range of transportation fees

were evaluated; the chart in Figure 9 illustrates the financial

metrics for two prices $0.06 and $0.18 per Dekatherm;

$5.00/MMscf is applied for fuel gas cost.

When the unit is operating at points similar to Conditions

2 and 3, the owner can realize over $1.1 million per year.

The changes resulted in increased flows when evaluated

over the entire map (average across all conditions). A common metric is Q/hph to evaluate the improved capacity.

The average increase was 2% for the minor changes in pulsation internals and modified control scheme. Additional

improvements are available in different areas of the system.

Figure 6. Difference in maximum flow: finger-type unloaders (light

green) vs. fixed volume pockets (dark green).

Figure 10 illustrates the differences in the compressor

performance for the full operating map when the pulsation effects are included. This example chart shows the

percent change in power or load. In many conditions,

the adjustment is minor at zero to 2%. However, other

conditions show a more significant change in the order

of 3 to 10%.

As a minimum, this more accurate compressor performance analysis can be used to make adjustments to the PLC

control system so the compressor operation can be better

controlled. A more powerful use for this information is to

compare the compressor performance for different station

or compressor package configurations. Higher capital costs

for some designs may be justified given the improvements

in compressor performance that could be realized.

(4) Pulsation Effects Can Result in up to 10%

Adjustments to OEM Performance Program

The SPM program identifies the required correction to

the OEM performance program to account for system effects. This correction is because of predicted static and dynamic pressure drop through all components of the system

(at each operating condition). The accurate pressure drop

information is necessary to update the performance calculations. Also, pressure pulsations at the compressor valves

impact the compressor performance. This effect can be

quantified by the pulsation model.

Figure 7. SPM comparison of existing units (base case) and with minor

adjustments to pulsation bottles and pocket unloaders. Over 20% reduction in pressure drop was achieved.

Figure 5. Assess performance across the entire operating map.

APRIL 2010

(5) Safety Map Improves Reliability

Another set of data that helps when comparing alternative solutions is a Full Map Safety Check. In this plot,

safe means reliable compressor operation such as adequate rod load, allowable discharge temperatures, within

pin reversal limits and within volumetric efficiency limits.

Excessive pulsation forces can also be included in the

safety map.

This safety map (Figure 11) can be generated by the

SPM database. Green areas are safe for all load steps regardless of speed, pressures or suction gas temperatures.

Red areas are unsafe for all load steps at any speed and

any suction temperature. Yellow areas identify areas

COMPRESSORTechTwo

CT436.qxp

5/14/10

9:23 AM

Page 5

Figure 8a: (Left) Flow comparison of base case (A) and modified case (B) over three common conditions. Figure 8b. (Right) Incremental flow (Case

B vs. Base Case A in %).

where unit safety is a function of load step, speed and gas

temperatures requiring special attention to the control to

operate safely. Thus, when maps show a lot of yellow

area, then a properly programmed PLC is prudent for optimal unit control.

(6) Compressor Control

Very often, the compressors performance characteristics

(for the entire operating envelope) must be imported into a

PLC or compressor control system. A fully automated compressor with an accurate SPM database enables the unit to

run more efficiently and generate higher throughput (e.g.,

reducing fuel, compressing more gas, lowering emissions

and total carbon footprint, reducing wasted energy, avoiding areas of high rod load, etc.).

End users effectively benefit from compressor optimization only when the unit is properly controlled. Proper unit

control requires effective and accurate unit performance

prediction. Thus, the last step of integrating the SPM database into the controlling PLC is very important. Figure 10

highlights how performance predictions can vary significantly between models that do and do not reflect the effects of pulsation. Furthermore, system pressure drops affect not only load and flow, but inherently, pressure, which

in turn affects rod loads, pin reversals, compression ratios,

volumetric efficiencies and discharge temperatures. These

items consequentially determine what operating areas are

safe and what areas are unsafe.

While incorporation of simple lookup tables into PLCs is

a common task, the incorporation of a larger, more complex database is a bit more challenging, but nothing that

talented PLC programmers cannot handle. Alternatively,

other routes of SPM-based performance incorporation are

becoming available. In fact, one company currently markets

an add-on panel that specifically handles all of the compressor performance predictions (both eRCM and SPM)

see Figure 12.

Conclusion

Many challenges are associated with optimizing the reciprocating compressor design. Various owners interviewed

on this subject agreed that they would like to see improvements with the operation of their compressors.

Based on the authors experience, the following suggestions have proven to be effective at optimizing the comAPRIL 2010

pressor design: early in the design process, the engineering team uses a System Performance Model (SPM) to assess different capacity control schemes, pulsation solutions, cooler designs and other factors that influence the

system performance (e.g., fence to fence performance);

problems occur when only a few operating points are

evaluated. It is recommended that the performance and

operating factors are evaluated over the entire operating

envelope. This allows the owner to ensure the system will

meet the intended requirements; the SPM allows the team

to quickly compare different design alternatives and implement an optimized design before the package is tendered for fabrication. This optimization helps avoid costly

changes or rework later in the fabrication stage; and, address the conflicting design goals and balance the need

for lowest capital cost with operating flexibility and system efficiency.

Significant benefits accrue when using this optimized

design approach: ability to operate across a much wider

Figure 9. Incremental net profit/year (Case B).

COMPRESSORTechTwo

CT436.qxp

5/14/10

9:23 AM

Page 6

Discharge Pressure

Performance Should Be Corrected for Pulsation

Effects and System Losses (compared to the

OEM performance program).

Figure 12: Advanced control panel monitoring and controlling a reciprocating compressor.

Suction Pressure

Figure 10. Percent adjustments to OEM performance program to account for pulsation effects.

Discharge Pressure

YELLOW = safety is a function of load step, speed

and gas temperatures. Pay special attention to

operate safely. A properly programmed PLC is

prudent for optimal unit control in this area.

GREEN = safe for all load steps regardless of

speed, pressures or suction temp.

RED = unsafe (all load steps,

speed and suction temp.).

Suction Pressure

Figure 11. SPM database used to generate safety map.

REPRINTED FROM APRIL 2010

COMPRESSORTech

Two

operating envelope; improved flow in the key conditions

(mid to higher discharge pressure) and equivalent efficiency in other conditions; improved pulsation control

(lower forces, less losses); more accurate control of PLC

system; and significant financial improvement, often with

relatively minor changes. g

References

[1] William Couch and Mark Noall, El Paso Pipeline

Group, Designing & Operating Compressor Stations, Gas

Machinery Conference, 2007.

[2] Gordon Q. Sun, Kelly Eberle, Beta Machinery Analysis

Ltd.; Dwayne A. Hickman, ACI Systems Inc., System

Performance Affected By Dynamic Pressure Drop, Gas

Machinery Conference, 2008.

[3] Randy Raymer and Tim Canton, El Paso, The Value ($$)

of Compressor Efficiency, Gas Machinery Conference, 2006.

[4] W. Norm Shade, Dwayne A. Hickman and Chad D.

Brahler, Performance Control of Reciprocating

Compressors: Devices for Managing Load and Flow, Gas

Machinery Conference, 2008.

Copyright Diesel & Gas Turbine Publications

Printed in U.S.A.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Pressure Vessels and Piping TutorialDokument441 SeitenPressure Vessels and Piping TutorialAditya Ranjan Pathak100% (10)

- Centrifugal Compressor GuidenceDokument4 SeitenCentrifugal Compressor GuidenceChem.Engg100% (1)

- Magnetic Compass ErrorDokument36 SeitenMagnetic Compass ErrorNimesh Perera67% (3)

- Sequence Impedance in Different Power EquipmentsDokument7 SeitenSequence Impedance in Different Power EquipmentsMadhusudhan Srinivasan0% (1)

- Reduce Gas Entrainment in Liquid LinesDokument3 SeitenReduce Gas Entrainment in Liquid LinesChem.EnggNoch keine Bewertungen

- Construction Cost IndicesDokument1 SeiteConstruction Cost IndicesWade ColemanNoch keine Bewertungen

- Distillation Column ModellingDokument1 SeiteDistillation Column ModellingChem.EnggNoch keine Bewertungen

- Transmix ProcessingDokument4 SeitenTransmix ProcessingChem.Engg100% (3)

- Cot2 DLPDokument5 SeitenCot2 DLPLowie D GacetaNoch keine Bewertungen

- Htfs ManualsDokument151 SeitenHtfs Manualsgion_ro401100% (4)

- 6m YTD 1y: Max, Min and Average Temperature (°c) ZoomDokument1 Seite6m YTD 1y: Max, Min and Average Temperature (°c) ZoomChem.EnggNoch keine Bewertungen

- Chemical Engineering - July 2011 15Dokument1 SeiteChemical Engineering - July 2011 15Chem.EnggNoch keine Bewertungen

- A Modern Approach To Solvent Selection - Mar-06 PDFDokument14 SeitenA Modern Approach To Solvent Selection - Mar-06 PDFChem.EnggNoch keine Bewertungen

- A Modern Approach To Solvent Selection - Mar-06 PDFDokument14 SeitenA Modern Approach To Solvent Selection - Mar-06 PDFChem.EnggNoch keine Bewertungen

- VFD For Centrifugal PumpsDokument11 SeitenVFD For Centrifugal PumpsChem.EnggNoch keine Bewertungen

- Moments 2Dokument1 SeiteMoments 2Zaman Ali RajaNoch keine Bewertungen

- Flexmix IntroDokument18 SeitenFlexmix Intromostafa faroukNoch keine Bewertungen

- Point-Biserial Correlation CoefficientDokument3 SeitenPoint-Biserial Correlation Coefficientisabella343Noch keine Bewertungen

- Lateral Pile Response During EarthquakesDokument14 SeitenLateral Pile Response During EarthquakesSelda DurmazNoch keine Bewertungen

- Lesson 4 Etech IctDokument25 SeitenLesson 4 Etech IctWinnie AguilarNoch keine Bewertungen

- Statistics Important QuestionsDokument26 SeitenStatistics Important QuestionsAkshit JunejaNoch keine Bewertungen

- ABB Automation: Commander 501Dokument8 SeitenABB Automation: Commander 501safyanNoch keine Bewertungen

- Course Description CatalogDokument56 SeitenCourse Description CatalogstefNoch keine Bewertungen

- Project & Quality ManagementDokument15 SeitenProject & Quality ManagementJayson SoguilonNoch keine Bewertungen

- DFT Scan Cells Network DesignDokument3 SeitenDFT Scan Cells Network Designrahul m sNoch keine Bewertungen

- 02 CH4 Part 01 RT and MicrooperationDokument28 Seiten02 CH4 Part 01 RT and MicrooperationAli KocherNoch keine Bewertungen

- Assignment 3 (Measurable Functions)Dokument2 SeitenAssignment 3 (Measurable Functions)EDU CIPANANoch keine Bewertungen

- Statistics and Probability 12 LAS 3Dokument3 SeitenStatistics and Probability 12 LAS 3Cfourr SteelWorksNoch keine Bewertungen

- Chapter 2: Discrete Probability Distributions: Dr. Suresh KumarDokument62 SeitenChapter 2: Discrete Probability Distributions: Dr. Suresh KumarARYAN CHAVANNoch keine Bewertungen

- Box-Behnken Design An Alternative For The OptimizationDokument8 SeitenBox-Behnken Design An Alternative For The OptimizationlorencorumbaNoch keine Bewertungen

- PhysyllDokument48 SeitenPhysyllThanviomNoch keine Bewertungen

- Sunk CostDokument35 SeitenSunk CostAhmedSaad647Noch keine Bewertungen

- Lesson 3 Homework Practice Functions AnswersDokument4 SeitenLesson 3 Homework Practice Functions Answersacfhfnapd100% (1)

- Chemical ReactionsDokument42 SeitenChemical Reactionsapi-403742992Noch keine Bewertungen

- A Genetic Algorithm-Based Classification Approach For Multicriteria ABC Analysis.Dokument32 SeitenA Genetic Algorithm-Based Classification Approach For Multicriteria ABC Analysis.Fernando GómezNoch keine Bewertungen

- Khubaib Agha - Add Maths Form IIIDokument7 SeitenKhubaib Agha - Add Maths Form IIIKhubaib AghaNoch keine Bewertungen

- 10 Permutation & Combination Part 3 of 4Dokument4 Seiten10 Permutation & Combination Part 3 of 4zayagopinatheNoch keine Bewertungen

- Preamble Heat TransferDokument8 SeitenPreamble Heat TransferkdsahooNoch keine Bewertungen

- Finance at NSUDokument31 SeitenFinance at NSUDuDuWarNoch keine Bewertungen

- HelloDokument53 SeitenHelloDaniel WertinNoch keine Bewertungen