Beruflich Dokumente

Kultur Dokumente

Finite Element Analysis of The In-Service-Welding of T Joint Pipe Connection

Hochgeladen von

Mohamed SamyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Finite Element Analysis of The In-Service-Welding of T Joint Pipe Connection

Hochgeladen von

Mohamed SamyCopyright:

Verfügbare Formate

European Journal of Scientific Research

ISSN 1450-216X Vol.40 No.4 (2010), pp.557-568

EuroJournals Publishing, Inc. 2010

http://www.eurojournals.com/ejsr.htm

Finite Element Analysis of the In-service-Welding of T Joint

Pipe Connections

Farid Vakili-Tahami

Department of Mechanical Engineering, University of Tabriz, Tabriz, Iran

E-mail: f_vakili@tabrizu.ac.ir

Tel: 0098(0)411-3392463; Fax: 0098(0)411-3354153

Mohammad Zehsaz

Department of Mechanical Engineering, University of Tabriz, Tabriz, Iran

E-mail: zehsaz@tabrizu.ac.ir

Tel: 0098(0)411-3392463; Fax: 0098(0)411-3354153

Mohammad-Ali Saeimi-Sadigh

Department of Mechanical Engineering, University of Tabriz, Tabriz, Iran

E-mail: moa_saemi@yahoo.com

Tel: 0098(0)411-3392463; Fax: 0098(0)411-3354153

Seyedreyhani

Tabriz Refinery Company, Tabriz, Iran

E-mail: seyedreyhani @yahoo.com

Tel: 0098(0)411-4293277

Abstract

In this paper the effects of two major parameters (a) main pipe thickness; and (b)

the amount of heat input (electrode diameter) have been investigated on the burn-through

risks during the in-service welding of an AISI-316 pipe branch connection on a steam

pipeline at full line pressure to perform hot tapping. A 3D Finite Element (FE) based

thermo-mechanical analysis has been carried out to model the in-service welding. To assess

the burn-through risks, current recommendations only rely on the observation of the main

pipe inner wall surface temperature. However, this criterion does not take into account the

effect of mechanical stresses due to the inline pressure. In this study, the thermomechanical stresses and temperature distribution along the main-pipe wall-thickness have

been obtained and values of the effective stress have been compared against the

temperature dependent yield stress of the material. The results show that this is a more

accurate criterion to check the burn-through risks. It has been shown that thickness of the

main pipe has a major role in the occurrence of burn-through. By increasing the pipe

thickness, heat wave from the weld-pool does not penetrate in the pipe thickness and

therefore the risk of burn-through reduces significantly. In addition, the results show that

the amount of heat input which is related to the electrode diameter plays a major role in

burn-through.

Keywords: In-service Welding, Burn-Through, Finite Element Analysis, AISI-316

Finite Element Analysis of the In-service-Welding of T Joint Pipe Connections

558

1. Introduction

Nowadays in-service welding of branch connections on pipelines while they are operating at full linepressure is becoming a necessity in industrial plants. In addition, branch connections to perform hottapping or repairing defects in pipelines are becoming common industrial problems. Although, welding

at full line pressure is a preferred technique, but it requires careful selection of the welding parameters;

otherwise burn-through may cause severe human damages or financial losses. Therefore, the

mechanism of burn-through or failure during in-service welding and its affecting parameters need to be

examined carefully. To carry out these operations safely, weld parameters must be selected so that heat

inputs remain low enough to avoid burn-through yet not so low that hot cracking occurs (API, 1995).

When the heat input is too low, hot cracking of the heat-affected zone (HAZ) may occur (Oddy, et al.,

1999). On the other hand, when the amount of heat input is high, although the main pipe wall may not

melt through completely, but it could soften locally, leak or rupture, which is called burn-through.

According to the description of the American Petroleum Institute (API) burn-through will occur

if the un-melted area beneath the weld pool can no longer contain the pressure within the pipe. Figure 1

shows the type of wall failure (burn-through) due to the in-service welding. In industry, current

practice is to follow empirical guidelines to prevent burn-through which imply that burn-through does

not occur as long as the temperature level on the inside surface never exceeds a critical level of 980C

(API, 1995). While the empirical guidelines highlight the principal role of the welding heat input, they

neglect the influence of the existing thermal stresses or the mechanical stresses due to the internal

pressure. Rupture of the main pipe can occur even when the fusion zone only penetrates partially

through the main-pipe wall. This is mostly because of the internal pressure and existing thermal or

mechanical stresses. Series of experiments have been carried out with short welds on water filled,

pressurised vessels. In these tests, slight thinning of the vessel wall has been observed with a fusion

zone penetration of only 1/3 of the main pipe wall-thickness (Oddy, et al., 1999). In another case,

partial rupture and incipient failure has been observed with a penetration of fusion zone in half of the

wall thickness (Oddy, et al., 1999).

Figure 1: Type of pipe or canal-wall failure (burn-through) during to the "in-service" welding

Due to the enormous expenses of experimental tests, there is a general trend to develop and use

numerical methods to model welding processes and also the strength or mechanical behaviour of the

weldments. These models can be divided in three different fields: a) models which study the welding

process itself; b) models which study the mechanical behaviour of the weldments; and c) models which

study the mechanical behaviour of the surrounding parts during the welding process. First and second

fields have been the subject of many research works in the past decades. However, despite its

importance, the third field or burn-through analysis have been the subject of a few works. The

following paragraphs provide a brief review of these research works.

559

Mohammad Zehsaz, Farid Vakili-Tahami, Mohammad-Ali Saeimi-Sadigh and Seyedreyhani

In 1930, an analytical method using Fourier's heat transfer equation has been developed to

study the temperature distribution for the butt-welded infinite plates (Parmar, 2002). In this model, the

governing heat transfer equations have been solved in quasi-stationary condition. Due to the

simplifying assumptions in this model, the results were significantly different from those obtained

using experimental observations. To overcome these shortcomings and to allow for the complicated

boundary and initial conditions, Hibbitt and Marcall (1973) have used a FE based numerical method to

model a single pass butt-weld. They have also studied the effect of temperature gradient on the stress

distribution for butt-welds. Goldak (2005) has used Double Ellipsoidal Power Density Distribution

method to model the heat input during the welding process. Brickstad and Josefson (1998) have

obtained the due weld residual stresses in multi-pass butt-weld using FE based computer code

ABAQUS and Element Birth and Death technique. Deng (2009) has employed Goldaks model in

computer code ABAQUS and has shown that this model can predict the weld pool shape properly. In

addition, the effect of phase change on the residual stresses has been taken into account in their model.

Vakili-Tahami et al. (2009) have also used the Element Birth and Death technique to estimate the due

weld residual stresses in a 3D-FE based model.

Goldak et al. (2005) have investigated the risk of burn-through during the welding of

pressurized gas pipe lines. For this purpose, they have obtained the temperature gradient in a transverse

T joint welding using FE analysis and have shown that the weld bead size and the fillet radius have

significant effect on the size of the weld pool and fusion zone (FZ) penetration depth. They have

shown that the weld pool size and FZ penetration depth have major role in burn-through. Thermoelasto-plastic analysis has been used by Wahab et al. (2005) and Sabapathy et al. (2001) to predict the

burn-through of pipeline welding. They have used empirical relationships to estimate the weld pool

size. They have also investigated the effect of different welding parameters. Vakili-Tahami et al.

(2009) have used a 2D-FE model to study the burn-through risk in welding process. They have shown

that the risk is high during the first pass of the welding process and this risk reduces at subsequent

passes. They have shown that this is because of the weld bead size and its location.

The main purpose in investigating the risk of burn-through is to assess the strength of the main

pipe wall to sustain the existing thermo-mechanical stresses during the in-service welding. This task is

completely different from those works that investigate the strength of the weldment itself to carry the

applied loads while the structure operates under applied loads. All the experimental observations and

recent studies have confirmed that over-heating plays a major role in burn-through occurrence (Oddy,

et al., 1999). To reduce the over-heating, electrodes with smaller diameters can be used which in turn

may lead to hot cracking due to the rapid cooling of the welding pool and HAZ. However, the mutual

effect of the thermo-mechanical stresses has not been addressed in these research works and this aspect

is the main achievement of the present study.

In this paper, the results of a numerical study have been presented for a 3D thermal-mechanical

finite element analysis of an in-service welding process on a pressurized pipeline T joint. In this work,

the in-service welding process and burn-through risks have been studied for welding of a T shape

branch connection on a super-heat steam pipeline while it is operating at full line pressure. Also, the

effect of electrode diameter size and the main pipe thickness have been investigated. For this purpose,

a 3D FE model of the T branch has been developed and the movement of the electrode has been

simulated using Element Birth and Death technique. In this model, the risk of burn-through has been

checked by comparing the temperature level at the inner wall of the main-pipe with the critical

temperature level; and also, by comparing the thermo-mechanical effective or Von-Mises stress level

along the pipe wall against the yield stress at the associated temperature.

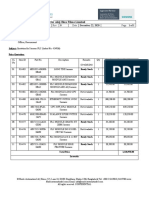

2. Materials and Models

In this model, a T joint branch with the inner diameter of 152.4 mm is welded on a main pipe with the

diameter of 219.1 mm to perform hot tapping. Table 1 shows the variation of the physical and

mechanical properties of 316 Stainless Steel with temperatures (Vakili-Tahami, 2002). During the

Finite Element Analysis of the In-service-Welding of T Joint Pipe Connections

560

welding process, the main pipe conveys superheated steam flow of 76 ton/hr at 480oC and 10.2 MPa,

while, the branch pipe is open-ended and is not under pressure or external loads.

In order to investigate the effect of the main pipe thickness in burn-through, two different wall

thicknesses of 8.2 mm and 2.8 mm have been considered. In addition, to study the effect of heat input

the welding process has been modeled using 4 and 8 weld-passes.

Table 1-a: Thermal, physical and mechanical properties of AISI 316 stainless steel (Vakili-Tahami, 2002)

Temperatu

re (0C)

20

100

300

500

700

900

1100

1300

1460

1780

Specific

Heat

(J/Kg.oC)

470

487

529

571

613

655

698

719

765

765

Conductivit

y (W/m.oC)

Density

(Kg/m3)

Yield Stress

(Pa)

Thermal

Exp. (1/ oC)

13.31

14.68

17.93

20.96

23.76

26.33

28.67

29.76

64

320

7966

7966

7966

7966

7966

7966

7966

7966

7966

7966

480e6

445e6

420e6

351.3e6

254.2e6

80.7e6

80.7e6

80.7e6

80.7e6

80.7e6

15.24e-6

15.80e-6

16.97e-6

17.85e-6

18.54e-6

19.11e-6

19.66e-6

19.95e-6

20.70e-6

20.70e-6

Young

Modulus

(Pa)

195.1e9

191.2e9

179.6e9

164.5e9

144.1e9

116.8e9

100.0e9

100.0e9

100.0e9

100.0e9

Poissons

ratio

0.267

0.273

0.310

0.313

0.282

0.240

0.223

0.223

0.223

0.223

Table 1-b: Temperature dependent Hardness Modulus of AISI 316 stainless steel (Vakili-Tahami, 2002)

Temperature(K)

Hardness Modulus

(Pa)

298

302

399

482

566

1073

5.60e9

5.64e9

6.e9

7.65e9

4.65e9

2.35e9

2.1. Finite Element Model

A 3D FE model of the T branch has been developed and the movement of the electrode has been

simulated using Element Birth and Death technique. The heat dissipation through the in-pipe steam

flow has been taken into account by imposing convection boundary conditions along the inner wall of

the main pipe. In addition, the mechanical loads due to the internal steam pressure have been taken into

account. Since the temperature gradient near the weld pool is severe, material constitutive model takes

into account the temperature dependency of the physical parameters and they have been considered

temperature dependent. In this model, the risk of burn-through has been checked by comparing the

temperature level at the inner wall of the main-pipe with the critical temperature level; and also, by

comparing the thermo-mechanical effective or Von-Mises stress level along the pipe wall against the

yield stress at the associated temperature.

Figure 2 shows the 3D model of the T joint. The FE model has been developed using FE based

computer code ANSYS. Due to the thermo-mechanical properties of the solution, tetrahedral coupledfield element type SOLID98 with 10 nodes has been used to create the FE mesh. This element has four

degrees of freedom for each node: three for displacement and one for temperature and therefore is

capable of solving coupled thermo-mechanical analysis. Total number of elements in the FE model is

15957 with 63828 degrees of freedom including the temperature. To investigate the mesh sensitivity of

the model and also the mesh independency of the results, two other meshes have also been used in

which the number of elements have been increased and decreased by 10%. The maximum difference of

7.4% has been observed in temperature level for nodes using these FE meshes. To simulate the

movement of electrode, Element Birth and Death technique has been used. For this purpose, the whole

saddle shape of the weld has been divided into 60 blocks in each pass. In this way, each block has 8

mm length which is in accordance with Rosenthals model (Parmar, 2002). At first, the blocks are

deactivated and excluded from the global FE mesh. Once the welding starts, blocks have been activated

561

Mohammad Zehsaz, Farid Vakili-Tahami, Mohammad-Ali Saeimi-Sadigh and Seyedreyhani

successively (birth of elements) each one after 2 or 2.67 seconds to accommodate the predefined

welding speeds of 20 cm/min or 15 cm/min respectively.

Figure 2: The 3D model of the T joint and the saddle shape weldment

2.2. Thermo-Mechanical Boundary Conditions

During the welding process, the input heat melts both the filler material and the parent material

surrounding the weld pool. The amount of the heat input can be obtained using (Parmar, 2002):

Q = VI

(1)

in which usually estimated in the range of 0.6-0.7 (Parmar, 2002). According to the welding process

documents; for this welding V=30 volts and I= 70 A.

The governing partial differential equation which describes the heat transfer near the weld pool

is (Lewis et al., 2004):

T

(2)

c ( x, y, z, t ) = .q( x, y, z, t ) + Q(x, y, z)

t

The generated heat in a welding process will dissipate from the welding zone by thermal

radiation, conduction and convection. Radiation losses are dominant at high temperatures near and in

the weld zone, while the convection has a major role at low temperatures in the area away from the

weld pool. To take into account these two effects, a total temperature-dependent heat transfer

coefficient has been used (Brickstad et al., 1998):

0.0668T (W / m 2 o C) When 0 T 5000 C

(3)

h=

(0.231T 82.1)(W / m 2

C) When T 5000 C

The above thermal boundary condition has been employed on all free boundaries of the 3D

model. The main pipe conveys superheated steam flow of 76 ton/hr (21.1 kg/s) at 480oC and 10.2x106

Pa. Due to the passing steam flow with the velocity of 25.1 m/s, convection heat transfer on the inner

side of the pipe-wall has been calculated to be 2000 W/m2K using (Wanger et al 2008):

hg D

kg

= 0 . 023 (

g v g D 0 . 8 C pg g 0 . 4

) (

)

g

kg

(4)

The thermal-physical properties of super heat steam at 480oC and 10.2 x106 Pa to calculate

hg are listed in Table 2 (Wanger et al., 2008).

Table 2:

Thermo-physical properties of super heat steam at 480oC and 10.2 x106 Pa (Wanger et al., 2008)

Physical property

Thermal Conductivity

Density

Specific Heat

Viscosity

Values

Kg=0.075 (Watt/mK)

g=30 kg/m3

Cpg=2600 J/kgK

g =29x10-6 Pa.s

Finite Element Analysis of the In-service-Welding of T Joint Pipe Connections

562

2.3. Thermo-Mechanical Model

The governing equations of thermo-elasticity in terms of displacement components and in the absence

of body forces are (Eslami et al., 2009):

..

ui ,kk + ( + )uk ,ki (3 + 2 )T,i = ui

(5)

Using the strain-displacement relation, ij = 1 2(ui , j + u j ,i ) and substituting into equation (5) yields

..

ij ,kk + ( + ) kk ,ij (3 + 2 )T,ij = ij

(6)

Substituting for strain from stress-strain relations

1

(7)

ij = ( ij

kk ij ) + (T T0 ) ij

2

3 + 2

where (T-T0) is the temperature change. According to the principle of virtual work and the divergence

theorem, the equilibrium equations and the constitutive equations can be rewritten in the matrix form

as

T

(8)

[ B ] { } dV = { R } = [ K ]{ U e }

V

To model the welding process, it is necessary to solve the equations based on a non-linear

isotropic hardening elasto-plastic theory. For this purpose, a bi-linear elasto-plastic formulation of the

material behavior has been used. Also, an incremental calculation has been employed to accommodate

the nonlinearity of the nodal displacement functions in the elasto-plastic analysis. Using the thermoelasto-plastic material model, based on the Von-Mises yield criterion and the isotropic strain hardening

rule, stressstrain relations can be written as

(9)

{ e } = { Dep }[ B ]{ U e } {C th }[ M ]{ Te }

Substituting EQUATION (9) into the incremental form of EQUATION (8) yields

m +1

(10)

{K1}{U e } m +1 {K 2 }{Te } = {R}

where m+1{K1 } = [B] T {Dep }[B]dV , and m +1{ K 2 } = [ B ] T { C th }[ M ] dV . The displacement increment

V

{ U e } and stress increment { e } can be obtained from equations (9) and (10). With these results,

the displacement { U e } and stress { e } can be obtained.

3. Results

To investigate the effects of heat input and main pipe thickness, the numerical analyses have been

carried out using different number of conditions shown in Table 3. For these case studies, temperature

profiles and stress distributions along the main pipe wall have been obtained. Results are presented for

the critical position of the weldment along the path A-B of the main pipe wall (see in Figure 3).

Table 3:

Different conditions of model/solution

Case study

1

2

3

Weld Passes

8

4

8

Electrode Diameter (mm)

2.4

4

2.4

Main Pipe Thickness (mm)

2.8

8.2

8.2

Figure 4 illustrates the temperature gradient when electrode reaches to position =90 at time

t=30Sec in T joint connection. Due to steam flow in main pipe temperature is 634k in main pipe and

temperature in fusion zone is 1673k.

Figure 5 shows the temperature profile along path A-B for the case study No 1 at = 0

degrees. This position refers to the starting stage of the welding process. It can be seen that the

temperature at the inner surface of the main pipe wall is 987C (1260K) which is higher than the

563

Mohammad Zehsaz, Farid Vakili-Tahami, Mohammad-Ali Saeimi-Sadigh and Seyedreyhani

critical level of 980C (1250K). According to the API recommendations (API, 1995), there is a high

risk of burn-through for this case.

Figure 3: Path A-B along which the results are presented and compared

Welding start point

=0

A

B

Path A-B from

weld center

Figure 4: Temperature gradient at t=30Sec

Temperature (K)

Figure 5: Temperature profile distribution at = 0 degrees for case study No 1

1700

1650

1600

1550

1500

1450

1400

1350

1300

1250

1200

Temprature

0.5

1.5

2

Distane (mm)

2.5

3.5

Figure 6 depicts both the temperature and effective stress (Von Mises stress) distributions at

=0 degrees along path A-B for case studies 2 and 3. It can be seen that for both case studies, the main

pipe inner wall temperature is about 537oC (800K) which is lower than the critical level of 980oC

(1250K). This shows, by increasing the pipe thickness, heat wave from the weld-pool does not

Finite Element Analysis of the In-service-Welding of T Joint Pipe Connections

564

penetrate in the pipe thickness and therefore the risk of burn-through reduces significantly. However,

the weld beads applied in case 2 (with 4 weld passes) are larger than those which have been used in

case study 3 (with 8 weld passes). Therefore, in the former (case 2 with 4 weld passes), the amount of

heat input is more than the amount of heat which has been imposed in case study 3, and consequently,

as it can be seen in Figure 6, the temperature level along the main pipe wall is higher for case 2

comparing with those obtained for case 3. This leads to higher thermal stresses that also can be seen in

Figure 6. The effective stress level along the inner side of the main-pipe wall, which is the combination

of mechanical and thermal stresses, plays a major role and reflects the ability of the pipe to sustain the

internal pressure. Since the pipe is AISI 316 stainless steel, the Von-Mises failure criterion has been

used here to investigate the pipe wall failure. At the first 3 millimeters beneath the weld pool, the

temperature is above 800oC (1073K) and practically the material is unable to sustain any stresses at this

temperature. However, the bilinear isotropic hardening model and cut-off method, which have been

used in this study, leads to high values of Elastic and Hardness Modulus at this temperature level (see

Table 2) and therefore numerical solution overestimates the stresses at this region. Due to the lack of

experimental data which give the mechanical behavior of the material beyond 800oC, there was no

other choice to carry out the analysis using the available data (Vakili-Tahami, 2002). To highlight

these shortcomings, the stress distribution at beyond 800oC-zone is shown using dotted lines in the

presented figures. It should be added that the above 800oC-zone plays an insignificant role in terms

of sustaining mechanical or thermal stresses.

The effective stress distribution along the main pipe wall presented in Figure 6, shows that for

case 2, at almost 87% of the main pipe wall, the effective stress is higher than the yield stress and

therefore there is a high risk of burn-through. To reduce the risk of burn-through, in case study 3, the

number of weld passes have been increased to 8, and as it can be seen in Figure 6, only in the 37% of

the pipe wall, the effective stress is above the yield stress level, and therefore there is no risk of burnthrough. The lower stress levels in case 3 is due to the lower thermal stresses which in turn is due to the

low heat input using smaller weld beads.

1000

900

800

700

600

500

400

300

200

100

0

stress_4pass

Stress_8pass

yeild stress

Temperature_4pass

Temperature_8pass

1800

1600

1400

1200

1000

800

600

400

200

0

Temperature (k)

Stress (MPa)

Figure 6: Temperature profile and effective stress distribution at =0 degrees for case study No 2 and 3

Distance from weld center (mm)

Figure 7 illustrates both the temperature profile and effective stress distributions at =90

degrees or 30 seconds after the start of the welding. This figure shows that the inner wall temperature

does not change significantly for both case studies and it remains below the critical level. The effective

stress level for case study 2 is almost 35% larger than that obtained for case study 3. This figure also

shows that burn-through is inevitable at case study 2 because in this case study, the effective stress

565

Mohammad Zehsaz, Farid Vakili-Tahami, Mohammad-Ali Saeimi-Sadigh and Seyedreyhani

along the main pipe thickness is higher than yield stress. However, for case study 3, at 51% of the main

pipe thickness the effective stress is lower than the yield stress and therefore, the risk of burn-through

is very slim and the pipe can withstand the internal pressure during the welding process.

1000

900

800

700

600

500

400

300

200

100

0

1800

1600

1400

1200

1000

800

600

400

200

0

stress_4pass

Stress_8pass

yeild stress

Temperature_4pass

Temperature_8pass

Temperature (k)

Stress (MPa)

Figure 7: Temperature profile and effective stress distribution at =90 degrees for case study No 2 and 3

Distance from weld center (mm)

Figures 8, 9 and 10 also show the temperature profile and effective stress distributions for case

study 3 at =180, 270 and 360 degrees respectively. It can be seen that at =180o, in the range of

5.2<t<8.2mm (36.6% of the pipe wall) and at =270o in the range of 3.4<t<8.2mm (58.5% of the pipe

wall) the effective stress is below the yield stress. Figure 10 presents the data for the end of the welding

process i.e. =360o. It can be seen that at this position, in the distance of 5.4<t<8.2mm (34.1%) along the

main pipe-wall, the effective stress is below the yield stress. The results shown in these figures imply

that the end position of the weld in each pass (position =360o) is the most critical situation. This is due

to the accumulation of the existing thermal stresses during the welding process.

1000

900

800

700

600

500

400

300

200

100

0

1800

1600

1400

1200

1000

800

600

400

200

0

Stress_8pass

yeild stress

Temperature

Distance from weld center (mm)

Temperature (k)

Stress (MPa)

Figure 8: Temperature profile and effective stress distribution at =180 degrees for case study No 3

Finite Element Analysis of the In-service-Welding of T Joint Pipe Connections

566

800

700

yeild stress

600

Stress (MPa)

1800

1600

1400

1200

1000

800

600

400

200

0

Stress_8pass

Temperature

500

400

300

200

100

0

0

Distance from weld center (mm)

Temperature (k)

Figure 9: Temperature profile and effective stress distribution at =270 degrees for case study No 3

The percentage of the main pipe thickness at which the effective stress is below the yield stress

for two case studies has been given in Table 4. Comparing these results and also those shown in Figs.

6-10; leads to the conclusion that by increasing the number of weld passes (decreasing the size of the

weld bead and amount of the heat input) the risk of burn-through reduces significantly and also the

positions of =360o and =180o are the critical ones in terms of burn-through possibility. Despite the

fact that the inner wall temperature for case study 2 is below the critical level of 980oC, the results

show a high risk of burn-through at this case.

1000

yeild stress

800

Stress (MPa)

1800

1600

1400

1200

1000

800

600

400

200

0

Stress_8pass

Temperature

600

400

200

0

0

Distance from weld center (mm)

Temperature (k)

Figure 10: Temperature profile and effective stress distribution at =360 degrees for case study No 3.

567

Mohammad Zehsaz, Farid Vakili-Tahami, Mohammad-Ali Saeimi-Sadigh and Seyedreyhani

Table 4:

Percentage of the main pipe thickness in which the effective stress is below the yield stress

Position =

Case Study 2 (4 weld pass)

Case Study 3 (8 weld pass)

0

13%

63%

90

0%

51%

180

0%

36.6%

270

0%

58.5%

360

0%

34%

5. Conclusion

In this study, the thermo-mechanical stresses as well as the temperature distribution along the pipe wall

thickness have been obtained. The results highlight the fact that to evaluate the risk of burn-through,

not only the inner wall temperature of the main pipe should be checked against the critical level of

980oC, but also the level of the effective stresses must be compared against the temperature dependent

yield stress of the material. The results and industrial observations show that this is a more accurate

criterion to check the risk of burn-through.

According to the results, the following points can be concluded:

1) The thickness of the main pipe has a major role in the occurrence of burn-through. By

increasing the pipe thickness, the Fusion Zone and the heat wave from the weld-pool does

not penetrate in the pipe thickness and therefore the risk of burn-through reduces

significantly.

2) The results shown in these figures imply that the end position of the weld in each pass is

the most critical situation.3) The results also show the importance of the amount of heat

input during the welding process. In excessive heat input, the risk of burn-through

increases drastically.

3) By increasing the number of weld passes, the size of the weld beads and consequently the

amount of heat input reduces which all lead to lower risk of burn-through.

4) To prevent burn-through, in addition to the main pipe inner surface wall temperature, the

effective stress along the main pipe wall should be checked against the yield stress at the

same temperature.

Acknowledgement

The authors would like to express their gratitude for the technical and financial support provided by the

Tabriz Refinery Company and for the help of R&D centre of this plant for providing valuable

information, infield observations and technical data.

Symbols

[B]

c

{Cth}

D

{Dp}

h

I

[K]

kg

[M]

Q

t

T

u

Operator matrix

Specific heat (J/kgK)

Thermal stiffness matrix

Diameter(m)

Plastic stiffness matrix

Heat transfer coefficient (W/m2K)

Current (A)

Stiffness matrix

Thermal conductivity (W/mK)

Temperature shape function

Heat generation (J)

Time (s)

Temperature (K)

Displacement (m)

{Ue}

V

vg

{T}

{e}

{e}

Nodal displacement

Voltage (V)

Velocity of steam (m/s)

Thermal expansion coefficient (K-1)

Temperature increment matrix

Nodal stress increment matrix

Nodal strain increment

Welding efficiency

Lame constant (Pa)

Lame constant (Pa)

Viscosity (Pa.s)

Density (kg/m3)

Strain

Kronecker delta

Finite Element Analysis of the In-service-Welding of T Joint Pipe Connections

568

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

American Petroleum Institute (API), 1995. Procedures for Welding or Hot-Tapping on

Equipment in Service: Recommended Practice 2201, 4th Edition, Northwest, Washington.

ASM (American Society of Metals) Handbook, 2005. Properties and Selections: Irons, steels

and high performance Alloys, ASM International, Vol. 1, USA.

Brickstad B., B.l., Josefson, 1998. A parametric study of residual stresses in multi-pass buttwelded stainless steel pipes, Journal of Pressure Vessel and Piping 75, pp. 11-25.

Deng D., 2009. FEM prediction of welding residual stress and distortion in carbon steel

considering phase transformation effects, Journal of Material Design 30, pp. 359-366.

Eslami M.R., R.B., Hetnarski, 2009. Thermal stresses advance theory and applications

Springer, Netherlands.

Goldak J.A., M., Akhlagi, 2005. Computational welding mechanics, Springer, New York; 2235.

Hibbitt H.D., P.V., Marcal, 1973. A numerical thermo mechanical model of welding and

subsequent loading of fabricated structure, Journal of Computers and Structures 3, pp. 11451174.

Incropera F.P., D., Witt, B., Bergman, J., Lavine, 2006. Fundamentals of heat and mass

transfer, Wiley & Sons, New Jersey.

Lewis RW, P., Nithiarasu, K.N., Seetharamu, 2004. Fundamentals of finite element method

for heat and fluid flow John Wiley & Sons, New Jersey.

Oddy A.S., J.M.J., Mcdilll, 1999. Burn-through prediction in pipe line welding, International

Journal of Fracture 97, pp. 249-261.

Parmar R.S., 2002. Welding engineering and technology, Khanna Publishers, Delhi.

Sabapathy P.N., M.A., Wahab, M.J., Painter, 2001. Numerical models of in-service welding of

gas pipelines, Journal of Material Process Technology 118, pp. 14-21.

Vakili-Tahami F, H., Masoumi, 2009. A two dimensional thermo-mechanical analysis of burnthrough at in-service welding of pressurised canals, Journal of Applied Science 9, pp. 615-626.

Vakili-Tahami F., A.H., Daei-Sorkhabi, M.A., Saeimi, A., Homayounfar, 2009. 3D finite

element analysis of the residual stresses in butt-welded plates with modeling of electrodemovement, JZUS 10, pp. 37-43.

Vakili-Tahami, F., 2002. CDM analysis of damage and creep crack growth in weldments,

phD thesis, UMIST University.

Wahab M.A., P.N., Sabapathy, M.J., Painter, 2005. The onset of pipe-wall failure during inservice welding of gas pipe line, Journal of Material Process and Technology 168, pp. 414422.

Wanger W., H.J., Kvetzschmar, 2008. International steam table, Berlin Heidelberg, SpringerVerlag.

Das könnte Ihnen auch gefallen

- Gas Tungsten Arc WeldingDokument11 SeitenGas Tungsten Arc WeldingIrshadNoch keine Bewertungen

- Test AceptDokument6 SeitenTest AceptAlvina DayantiNoch keine Bewertungen

- Approvals Management Responsibilities and Setups in AME.B PDFDokument20 SeitenApprovals Management Responsibilities and Setups in AME.B PDFAli LoganNoch keine Bewertungen

- Residual Stress Analysis of Pipeline Girth Weld JointsDokument289 SeitenResidual Stress Analysis of Pipeline Girth Weld JointsGabriel Vazquez Vega100% (1)

- Topic: Grammatical Issues: What Are Parts of Speech?Dokument122 SeitenTopic: Grammatical Issues: What Are Parts of Speech?AK AKASHNoch keine Bewertungen

- Temporarypermanent Pipe Repair - GuidelinesDokument70 SeitenTemporarypermanent Pipe Repair - Guidelinesqinaip100% (1)

- Temporarypermanent Pipe Repair - GuidelinesDokument70 SeitenTemporarypermanent Pipe Repair - Guidelinesqinaip100% (1)

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2Dokument13 SeitenComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2IAEME PublicationNoch keine Bewertungen

- FEM of Welded JointDokument34 SeitenFEM of Welded JointbysktyvktoNoch keine Bewertungen

- InsulationDokument76 SeitenInsulationDiego Trinidad100% (3)

- Refinery PDFDokument22 SeitenRefinery PDFromulussikalitNoch keine Bewertungen

- Welding Project Report PDFDokument61 SeitenWelding Project Report PDFEzzadin Baban50% (6)

- Eccentric FootingDokument3 SeitenEccentric FootingVarunn VelNoch keine Bewertungen

- Corrosion Prevention at Pipe SupportDokument6 SeitenCorrosion Prevention at Pipe SupportMohamed SamyNoch keine Bewertungen

- Corrosion Protection of Ductile Iron PipeDokument6 SeitenCorrosion Protection of Ductile Iron PipeMohamed SamyNoch keine Bewertungen

- BKR WhitePaper WaterHammerDokument4 SeitenBKR WhitePaper WaterHammerThuc TruongNoch keine Bewertungen

- Guide Inspection Plan For CUIDokument6 SeitenGuide Inspection Plan For CUIMohamed SamyNoch keine Bewertungen

- Transportation of CementDokument13 SeitenTransportation of CementKaustubh Joshi100% (1)

- Score Klasikal Paps 23 Juli 2015 Unit Pengembangan Alat Psikodiagnostika (Upap) Fakultas Psikologi Ugm No Nomor Tes TGL Lahir TotalDokument11 SeitenScore Klasikal Paps 23 Juli 2015 Unit Pengembangan Alat Psikodiagnostika (Upap) Fakultas Psikologi Ugm No Nomor Tes TGL Lahir TotalIwan VitryawanNoch keine Bewertungen

- Lab 4.6.2 Challenge Security ConfigurationDokument4 SeitenLab 4.6.2 Challenge Security ConfigurationConfucius WillsonNoch keine Bewertungen

- Technical Specs GeotextileDokument1 SeiteTechnical Specs GeotextileDipak VaghelaNoch keine Bewertungen

- Kunci Latihan Soal Matematika Dasar Um Undip 2010 PDFDokument6 SeitenKunci Latihan Soal Matematika Dasar Um Undip 2010 PDFMeinita Dian PratiwiNoch keine Bewertungen

- Technology Training That Works Technology Training That WorksDokument30 SeitenTechnology Training That Works Technology Training That Worksmahad100% (1)

- Tutorial Mikrotik KompletDokument284 SeitenTutorial Mikrotik KompletDze AttharizzNoch keine Bewertungen

- Form Pre InterviewDokument2 SeitenForm Pre InterviewcikalmechNoch keine Bewertungen

- Kelompok 4 Proses Transfer 2019Dokument7 SeitenKelompok 4 Proses Transfer 2019Retnaning Setyo RiniNoch keine Bewertungen

- 7206 9292 1 PB PDFDokument11 Seiten7206 9292 1 PB PDFMichael SerraNoch keine Bewertungen

- De Aqui Vas A Sacar El Caso de Estudio de SoldaduraDokument16 SeitenDe Aqui Vas A Sacar El Caso de Estudio de Soldadurakaren villalobo sierraNoch keine Bewertungen

- Research Paper FSWDokument10 SeitenResearch Paper FSWsahith palikaNoch keine Bewertungen

- Coeficiente de Fricción LinealDokument9 SeitenCoeficiente de Fricción LinealTaguis VelascoNoch keine Bewertungen

- 1 Ijmmseaug20181Dokument10 Seiten1 Ijmmseaug20181TJPRC PublicationsNoch keine Bewertungen

- Prediction of Welding Distortions and Residual Stresses in A Pipe - Ange Joint Using The Finite Element TechniqueDokument17 SeitenPrediction of Welding Distortions and Residual Stresses in A Pipe - Ange Joint Using The Finite Element TechniqueRami GhorbelNoch keine Bewertungen

- 7 Meceng-2014-0028 PDFDokument11 Seiten7 Meceng-2014-0028 PDFkandanNoch keine Bewertungen

- 11 2002 BANG SDokument10 Seiten11 2002 BANG SsumoomusNoch keine Bewertungen

- Friction Stir WeldingDokument17 SeitenFriction Stir WeldingklausoshoNoch keine Bewertungen

- Numerical Simulation To Study The Effect of Tack Welds and Root Gap On Welding Deformations and Residual Stresses of A Pipe-Flange JointDokument12 SeitenNumerical Simulation To Study The Effect of Tack Welds and Root Gap On Welding Deformations and Residual Stresses of A Pipe-Flange JointAr PanNoch keine Bewertungen

- Risco Perfuração PenetraçãoDokument13 SeitenRisco Perfuração PenetraçãomariliaNoch keine Bewertungen

- Heat Transfer Analysis During Friction Stir Welding of Al6061-T6 AlloyDokument8 SeitenHeat Transfer Analysis During Friction Stir Welding of Al6061-T6 AlloyfabiskrujaNoch keine Bewertungen

- A Study On Rotary Friction Welding of Titanium AllDokument10 SeitenA Study On Rotary Friction Welding of Titanium AllmadhukarNoch keine Bewertungen

- 1 s2.0 S1359835X05003957 Main PDFDokument14 Seiten1 s2.0 S1359835X05003957 Main PDFabiliovieiraNoch keine Bewertungen

- A Study of The Thermal Behavior in Resistance Spot WeldsDokument9 SeitenA Study of The Thermal Behavior in Resistance Spot WeldsLee Linky LeeNoch keine Bewertungen

- Ijmet: ©iaemeDokument9 SeitenIjmet: ©iaemeIAEME PublicationNoch keine Bewertungen

- Optimizing Tensile Strength of Low-Alloy Steel Joints in Upset WeldingDokument5 SeitenOptimizing Tensile Strength of Low-Alloy Steel Joints in Upset Weldingabraham silva hernandezNoch keine Bewertungen

- Pengaruh Preheat Dan Thermal Kualitas Sambungan Las Allumunium 6061Dokument6 SeitenPengaruh Preheat Dan Thermal Kualitas Sambungan Las Allumunium 6061Edo Putra AgustyraNoch keine Bewertungen

- Preprints201810 0249 v1Dokument34 SeitenPreprints201810 0249 v1kenneth lohNoch keine Bewertungen

- Nik Weld ParameterDokument5 SeitenNik Weld ParameterHarmish BhattNoch keine Bewertungen

- Numerical Simulation and Experimental Research OnDokument11 SeitenNumerical Simulation and Experimental Research OnSiul Otrebla AtelavazNoch keine Bewertungen

- Finite Element Simulation of Hydrostatic Extrusion Process To Produce Thin Bimetallic PartsDokument10 SeitenFinite Element Simulation of Hydrostatic Extrusion Process To Produce Thin Bimetallic Parts李庆森Noch keine Bewertungen

- Numerical Simulation of Tube Manufacturing ConsistDokument15 SeitenNumerical Simulation of Tube Manufacturing Consistmahmoud yarahmadiNoch keine Bewertungen

- Effect of Heat Input On Dilution and Heat Affected Zone in Submerged Arc Welding Process PDFDokument23 SeitenEffect of Heat Input On Dilution and Heat Affected Zone in Submerged Arc Welding Process PDFbiancogallazziNoch keine Bewertungen

- Finite Element Model For The Effect of Heat Input & Speed On Residual Stress During WeldingDokument6 SeitenFinite Element Model For The Effect of Heat Input & Speed On Residual Stress During WeldingInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Amm 24-25 305Dokument6 SeitenAmm 24-25 305Armm IsMeNoch keine Bewertungen

- Welding Research Paper TopicsDokument8 SeitenWelding Research Paper Topicscaqllprhf100% (1)

- Analysis of Tube-To-Tubesheet Welding in Carbon STDokument17 SeitenAnalysis of Tube-To-Tubesheet Welding in Carbon STmohamed fayasNoch keine Bewertungen

- Welding DissertationDokument5 SeitenWelding DissertationCustomWrittenPapersClarksville100% (1)

- Experimental and Analytical Study of Thermally Induced Residual Stresses For Stainless Steel Grade Using Gmaw ProcessDokument6 SeitenExperimental and Analytical Study of Thermally Induced Residual Stresses For Stainless Steel Grade Using Gmaw ProcessPavan KallempudiNoch keine Bewertungen

- 05 AbstractDokument7 Seiten05 AbstractMahender ThotakuriNoch keine Bewertungen

- Materials and Design: Farid Vakili-Tahami, Ali Ziaei-AslDokument9 SeitenMaterials and Design: Farid Vakili-Tahami, Ali Ziaei-AslHaile SolomonNoch keine Bewertungen

- Sadhana PaperDokument16 SeitenSadhana PaperPearl IPNoch keine Bewertungen

- RESID. STRESS - Experiments and Numerical Simulations of The Annealing Temperature Influence in S700MCDokument26 SeitenRESID. STRESS - Experiments and Numerical Simulations of The Annealing Temperature Influence in S700MCGabriel PaesNoch keine Bewertungen

- Materials Science and Engineering ADokument9 SeitenMaterials Science and Engineering AСергей СкргейNoch keine Bewertungen

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDokument13 SeitenComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1Noch keine Bewertungen

- Titipan ZahraDokument7 SeitenTitipan ZahraDikaAfriandiNoch keine Bewertungen

- Journal of Materials Processing Technology: Se-Yun Hwang, Yooil Kim, Jang-Hyun LeeDokument12 SeitenJournal of Materials Processing Technology: Se-Yun Hwang, Yooil Kim, Jang-Hyun LeeGrantHermanNoch keine Bewertungen

- Effect of Heat Treatment On Corrosion Resistance of Friction Stir Welded AA 2024 Aluminum Alloy - Hani Aziz AmeenDokument10 SeitenEffect of Heat Treatment On Corrosion Resistance of Friction Stir Welded AA 2024 Aluminum Alloy - Hani Aziz AmeenHani Aziz AmeenNoch keine Bewertungen

- Friction Stir Welding Material ABSDokument23 SeitenFriction Stir Welding Material ABSBambang KusharjantaNoch keine Bewertungen

- Investigations Into Effect of Weld-Deposition Pattern On ResidualDokument17 SeitenInvestigations Into Effect of Weld-Deposition Pattern On Residualfereidoon marefatNoch keine Bewertungen

- Control of Longitudinal Bending Distortion of Built-Up Beams by High-Frequency Induction HeatingDokument6 SeitenControl of Longitudinal Bending Distortion of Built-Up Beams by High-Frequency Induction Heatinglaz_kNoch keine Bewertungen

- Friction Welding of St-A1 and A1-Cu MaterialsDokument13 SeitenFriction Welding of St-A1 and A1-Cu Materialsarun_prasath_41Noch keine Bewertungen

- Investigation On Hot Stamping Process For Door Beam of Ultra-High Strength SteelDokument9 SeitenInvestigation On Hot Stamping Process For Door Beam of Ultra-High Strength SteelselvinNoch keine Bewertungen

- Materials: Finite Element Analysis and In-Situ Measurement of Out-of-Plane Distortion in Thin Plate TIG WeldingDokument17 SeitenMaterials: Finite Element Analysis and In-Situ Measurement of Out-of-Plane Distortion in Thin Plate TIG WeldingHussain AlsaadyNoch keine Bewertungen

- Research Paper On Ultrasonic WeldingDokument5 SeitenResearch Paper On Ultrasonic Weldingafeawobfi100% (1)

- Selection of Equation of State Models For Process SimulatorsDokument1 SeiteSelection of Equation of State Models For Process SimulatorsmusaveerNoch keine Bewertungen

- Heat Exchanger Inspection PDFDokument23 SeitenHeat Exchanger Inspection PDFInnasi Arokiasamy100% (2)

- Welding MetallurgyDokument34 SeitenWelding MetallurgyPeter PushpanathanNoch keine Bewertungen

- Paper AIM - Attaining Operational ExcellenceDokument5 SeitenPaper AIM - Attaining Operational ExcellenceMohamed SamyNoch keine Bewertungen

- Understandingt He Mechanisms of Hydrate Nucleationa ND InhibitationDokument6 SeitenUnderstandingt He Mechanisms of Hydrate Nucleationa ND InhibitationMohamed SamyNoch keine Bewertungen

- QuickGuide Internal MicrometersDokument2 SeitenQuickGuide Internal MicrometersMohamed SamyNoch keine Bewertungen

- Paper The Safety of Offshore StructuresDokument6 SeitenPaper The Safety of Offshore StructuresMohamed SamyNoch keine Bewertungen

- Corrosion of PipelinesDokument14 SeitenCorrosion of PipelinesMohamed SamyNoch keine Bewertungen

- Firetube FailureDokument1 SeiteFiretube FailureMohamed SamyNoch keine Bewertungen

- Guide BP Riser WrappingDokument8 SeitenGuide BP Riser WrappingMohamed SamyNoch keine Bewertungen

- World Pipelines - Risk Modelling - 2015-06Dokument4 SeitenWorld Pipelines - Risk Modelling - 2015-06Mohamed Samy0% (1)

- Underground Leak Detection MethodsDokument23 SeitenUnderground Leak Detection MethodsiradankeNoch keine Bewertungen

- A Failure Analysis Investigation of Pitting in Type 316L PipingDokument53 SeitenA Failure Analysis Investigation of Pitting in Type 316L PipingMohamed SamyNoch keine Bewertungen

- Carmagen 10 - 04 - Flange Leakage & Piping VibrationDokument5 SeitenCarmagen 10 - 04 - Flange Leakage & Piping VibrationMohamed SamyNoch keine Bewertungen

- World Pipelines - Calculating Pressure - 2015-01Dokument4 SeitenWorld Pipelines - Calculating Pressure - 2015-01Mohamed SamyNoch keine Bewertungen

- Corrosion at Pipe Supports Causes and SolutionsDokument17 SeitenCorrosion at Pipe Supports Causes and SolutionsMohamed SamyNoch keine Bewertungen

- Polymer & Material Selection Guide: Hardness Range Temperature Range Advantages in PerformanceDokument10 SeitenPolymer & Material Selection Guide: Hardness Range Temperature Range Advantages in PerformanceAmmar ElSheikhNoch keine Bewertungen

- Paper Repairing Internal Corrosion Defects in PipelinesDokument26 SeitenPaper Repairing Internal Corrosion Defects in PipelinesMohamed SamyNoch keine Bewertungen

- Article CO2 CorrosionDokument4 SeitenArticle CO2 CorrosionMohamed SamyNoch keine Bewertungen

- Page 2internal Corrosion Mechanisms and MitigationDokument1 SeitePage 2internal Corrosion Mechanisms and MitigationMohamed SamyNoch keine Bewertungen

- Hard DiskDokument9 SeitenHard DiskAmarnath SahNoch keine Bewertungen

- 53 English Work Book XDokument292 Seiten53 English Work Book XArun DhawanNoch keine Bewertungen

- 23 Ray Optics Formula Sheets Getmarks AppDokument10 Seiten23 Ray Optics Formula Sheets Getmarks AppSiddhant KaushikNoch keine Bewertungen

- Calculating Free Energies Using Adaptive Biasing Force MethodDokument14 SeitenCalculating Free Energies Using Adaptive Biasing Force MethodAmin SagarNoch keine Bewertungen

- TIA Guidelines SingaporeDokument24 SeitenTIA Guidelines SingaporeTahmidSaanidNoch keine Bewertungen

- Engineering Management: Class RequirementsDokument30 SeitenEngineering Management: Class RequirementsMigaeaNoch keine Bewertungen

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Dokument5 Seitenبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedNoch keine Bewertungen

- Leveriza Heights SubdivisionDokument4 SeitenLeveriza Heights SubdivisionTabordan AlmaeNoch keine Bewertungen

- TPDokument10 SeitenTPfaisal gaziNoch keine Bewertungen

- OTP User Manual For English) v1,0Dokument15 SeitenOTP User Manual For English) v1,0auyinNoch keine Bewertungen

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Dokument2 SeitenLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNoch keine Bewertungen

- BDokument28 SeitenBLubaNoch keine Bewertungen

- CL Honours Report NamanDokument11 SeitenCL Honours Report NamanNaman VermaNoch keine Bewertungen

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Dokument85 SeitenME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNoch keine Bewertungen

- Swelab Alfa Plus User Manual V12Dokument100 SeitenSwelab Alfa Plus User Manual V12ERICKNoch keine Bewertungen

- File RecordsDokument161 SeitenFile RecordsAtharva Thite100% (2)

- FT2020Dokument7 SeitenFT2020Sam SparksNoch keine Bewertungen

- Object Oriented ParadigmDokument2 SeitenObject Oriented ParadigmDickson JohnNoch keine Bewertungen

- AP8 Q4 Ip9 V.02Dokument7 SeitenAP8 Q4 Ip9 V.02nikka suitadoNoch keine Bewertungen

- Cash Flow July 2021Dokument25 SeitenCash Flow July 2021pratima jadhavNoch keine Bewertungen

- Clustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaDokument18 SeitenClustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaAji LaksonoNoch keine Bewertungen

- Engineering Ethics in Practice ShorterDokument79 SeitenEngineering Ethics in Practice ShorterPrashanta NaikNoch keine Bewertungen

- Sensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguDokument4 SeitenSensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguSMA N 1 TOROHNoch keine Bewertungen

- BECED S4 Motivational Techniques PDFDokument11 SeitenBECED S4 Motivational Techniques PDFAmeil OrindayNoch keine Bewertungen

- SievesDokument3 SeitenSievesVann AnthonyNoch keine Bewertungen

- My BaboogDokument1 SeiteMy BaboogMaral Habeshian VieiraNoch keine Bewertungen