Beruflich Dokumente

Kultur Dokumente

8.12.01.15 - Catálogo Chancador de Cono CH890 y CH895

Hochgeladen von

gytomanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

8.12.01.15 - Catálogo Chancador de Cono CH890 y CH895

Hochgeladen von

gytomanCopyright:

Verfügbare Formate

Mining cone crushers

CH890 and CH895

Sandvik CH890 and CH895

Dedicated by Design

Sandvik has developed two powerful 1000 hp mining cone crushers to optimize crushing operations. The CH890 is dedicated to

secondary applications and the CH895 is dedicated to tertiary and

pebbles applications. Both units have more power and increased

crushing force compared to their predecessor. They are designed to

maximize output and minimize downtime. Every possible improvement has been made to maximize strength. The heavy-duty structural design ensures durability and longevity in the most demanding mining conditions. The CH890 and CH895 are built to last.

MORE POWER AND INCREASED CRUSHING FORCE

Greater motor power and considerably increased crushing force

make the CH890 and CH895 high-performance crushers in terms

of capacity and reduction, respectively.

CH890 HIGH CAPACITY SECONDARY CRUSHER

The CH890 is dedicated to secondary crushing applications. With a

1000 hp motor, it is possible to utilize maximum throw at all times

increasing capacity while maintaining product size.

CH895 HIGH REDUCTION TERTIARY AND PEBBLE CRUSHER

The CH895 is dedicated to tertiary and pebble crushing applications. Increased crushing force facilitates higher reduction finer

product size and less circulating load in closed circuits.

Optimizing crushing operations

Easy to install

Effective crushing

Dedicated to their applications

1. CH890 secondary crusher

2. CH895 tertiary crusher

3. CH895 pebble crusher

CH895

CH890

CH890 Topshell

Dedicated topshell with

strength optimized design to

fit coarse crushing chambers

ideal for secondary crushing.

CH895 Topshell

Dedicated topshell for fine crushing

chambers with a strength optimized

design to accommodate higher

crushing force.

2

6

5

Key model commonality

1. Mainshaft - New

2. Bottomshell - New

3. Eccentric

4. Pinionshaft

5. HydrosetTM

6. External dump valve - New

7. Over pressure system - New

HEAVY-DUTY DESIGN BUILT TO LAST

The Sandvik CH890 has a topshell designed to fit

several coarse crushing chamber sizes whereas the

CH895 topshell is designed specifically for fine

crushing chambers dedicated topshells designed for

maximized strength.

External dump valve

Relocated dump valve to the side of the crusher supporting increased safety and

easier access during maintenance.

Apart from the topshells, the CH890 and CH895 are

identical in design and construction. They incorporate a mainshaft made from a new high-strength

material which is designed to withstand the toughest

treatment. The mainshaft is supported at both ends

to better absorb the crushing force and the unique

Sandvik Hydroset and ASRi systems are in place

to facilitate the online adjustment during full load.

The CH890 and CH895 bottomshell is optimized

to take greater loads than previous models and the

screw joints have been further developed to maintain

the rigid Sandvik unibody structure.

The dump valve has been relocated to facilitate safer

and easier access when maintenance is needed. To

further minimize downtime the new over pressure

system effectively keeps the dust out and the oil

clean.

Over pressure system

Clean oil is essential for the effective operation of a cone crusher. To prevent dust

ingress Sandvik has designed an improved over pressure system. A jet of air is now

directed through dedicated air channels directly to the inside of the dust seal area

securing a more efficient outflow of air over the dust seal ring.

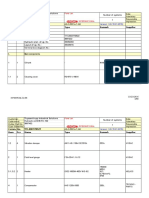

Specifications

NEW 1000 hp motor power

high-capacity crushing

Application

CH890

750 (1000)

Secondary

CH895

750 (1000)

Tertiary,Pebble EFX, EF, EEF

NEW Dedicated to their applications

CH890 is dedicated to secondary crushing

CH895 is dedicated to tertiary and pebble crushing

NEW Over pressure system

keeps dust out and oil clean

Capacity range mtph (stph)

370 (14.6)

16-70 (0.6-2.8)

268-2595 (295-2860)

120 (4.7)

10-51 (0.4-2)

178-1170 (196-1290)

CH895

mm (in)

mm (in)

5209

(205.1)

5491

(216.2)

3610

(142.1)

3610

(142.1)

6670

(262.6)

6670

(262.6)

Weights:

kg (lb)

kg (lb)

Crusher weight

77 000

(169 800)

81 000

(178 600)

89 000

(196 200)

93 000

(205 000)

Weights

Can vary depending on configuration and manufacturing tolerances.

Total weight

(incl. subframe and drive)

Capacity

Performance figures are approximate and give an indication of what the

crusher can produce with material bulk density of 1600 kg/m3 (100 lb/ft3).

Installation, material properties and crusher configuration can all affect performance of the crusher.

CH890

00

Rubber damper position corrected

01

2010-12-20

kru

kru

2011-02-28

abn

abn

A B

Hydroset system

ASRi Automatic Setting Regulation

CLP crushing chambers Constant Liner Performance

Simple and strong design philosophy

Adjustable throw

CSS range

mm (in)

Nominal capacity

NEW Heavy-duty design built to last

SMART CRUSHING BY SANDVIK INCLUDES:

EC, C, MC, M, MF, F

Max. feed

size mm (in)

Dimensions:

NEW External dump valve

increased safety and ease of access

Crushing chambers

NEW Increased crushing force

higher reduction

Max. motor

power kW (hp)

Highlights

Sandvik is a high-technology engineering group with

world-leading positions in selected areas tools for metal

working, advanced materials technology, and mining and

construction. We are represented in 130 countries.

SANDVIK MINING AND CONSTRUCTION www.sandvik.com

Sandvik is a registered trademark of the Sandvik Group. 2011 Sandvik. B5-541ENG

Sandvik Mining and Construction represents one third of

the overall Sandvik Group and serves a broad range of

customers in construction, mineral exploration, mining

and bulk materials handling. Our construction expertise

covers quarrying, tunneling, demolition and recycling, and

other civil engineering applications. Our mining products

and services support customers on the surface and under

ground, in all mineral, coal and metal mining applications

from exploration to ore transportation.

Das könnte Ihnen auch gefallen

- New Paradigms in Ergonomics The Positive ErgonomicsDokument22 SeitenNew Paradigms in Ergonomics The Positive ErgonomicsgytomanNoch keine Bewertungen

- Indications For The Spare Parts List: 1) Meaning: I II IIIDokument17 SeitenIndications For The Spare Parts List: 1) Meaning: I II IIIgytomanNoch keine Bewertungen

- Doing Business in PeruDokument61 SeitenDoing Business in PerugytomanNoch keine Bewertungen

- Customer: Date: Code-Word: Hydraulic Unit 945-RC-100 Subsidiary Hydac Mat - No. 3897402 Responsible Cust.-Order-No.:-Impression: AG-3-5631e-7-ABDokument58 SeitenCustomer: Date: Code-Word: Hydraulic Unit 945-RC-100 Subsidiary Hydac Mat - No. 3897402 Responsible Cust.-Order-No.:-Impression: AG-3-5631e-7-ABgytomanNoch keine Bewertungen

- Loose Parts For Start-UpDokument14 SeitenLoose Parts For Start-UpgytomanNoch keine Bewertungen

- 8.12.01.04 - Cross Sectional CH890Dokument1 Seite8.12.01.04 - Cross Sectional CH890gytomanNoch keine Bewertungen

- 8.12.01.12 - Datasheet ASRi 2.0Dokument4 Seiten8.12.01.12 - Datasheet ASRi 2.0gytoman100% (2)

- Instrucciones de Operación y Montaje Faja Descarga GSSFDokument150 SeitenInstrucciones de Operación y Montaje Faja Descarga GSSFgytomanNoch keine Bewertungen

- 01 Gyramatic-Operator Manual V2-4-1Dokument30 Seiten01 Gyramatic-Operator Manual V2-4-1gytoman100% (2)

- 8.12.01.03 - Technical Data CH890Dokument8 Seiten8.12.01.03 - Technical Data CH890gytoman100% (1)

- Instrucciones de Operación y Montaje SMCP 63x75Dokument138 SeitenInstrucciones de Operación y Montaje SMCP 63x75gytomanNoch keine Bewertungen

- Instrucciones de Operación y Montaje KB 63x75Dokument296 SeitenInstrucciones de Operación y Montaje KB 63x75gytoman100% (3)

- Flex Check Series 851Dokument2 SeitenFlex Check Series 851gytomanNoch keine Bewertungen

- MML45Semi Mobile Primary Gyratory Crushing Plant GADwgs Technical InformationDokument19 SeitenMML45Semi Mobile Primary Gyratory Crushing Plant GADwgs Technical Informationgytoman0% (1)

- LINK BELT - Catalog 1050 PDFDokument646 SeitenLINK BELT - Catalog 1050 PDFgytoman100% (27)

- LINK BELT - Catalog 1000 PDFDokument596 SeitenLINK BELT - Catalog 1000 PDFgytoman100% (30)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 4 - Cir Vs San Roque Power CorpDokument15 Seiten4 - Cir Vs San Roque Power CorpcloudNoch keine Bewertungen

- Perhitungan Produktivitas Alat Berat Jenis BulldozerDokument2 SeitenPerhitungan Produktivitas Alat Berat Jenis Bulldozerarno viraNoch keine Bewertungen

- Ethical Issues in FinanceDokument34 SeitenEthical Issues in FinanceKrupa MehtaNoch keine Bewertungen

- IntroDokument24 SeitenIntroBinod Kumar PadhiNoch keine Bewertungen

- Update of Span DesignDokument7 SeitenUpdate of Span DesignBaga YoiceNoch keine Bewertungen

- Preliminary Economic Assessment Mayaniquel ProjectDokument171 SeitenPreliminary Economic Assessment Mayaniquel ProjectSamuel MonroyNoch keine Bewertungen

- Construction Sector Driving Somalia's Economic RecoveryDokument3 SeitenConstruction Sector Driving Somalia's Economic RecoveryAMISOM Public Information ServicesNoch keine Bewertungen

- Rio Tinto Big Miners Playing The Cost Curve PDFDokument2 SeitenRio Tinto Big Miners Playing The Cost Curve PDFSaurabh GuptaNoch keine Bewertungen

- Financial Reporting in The Mining IndustryDokument192 SeitenFinancial Reporting in The Mining IndustryerlanggaherpNoch keine Bewertungen

- Reliability and Six SigmaDokument20 SeitenReliability and Six SigmaFahad Izhar100% (2)

- Argus-Sulphuric-Acid PriceDokument9 SeitenArgus-Sulphuric-Acid PricesharemwNoch keine Bewertungen

- Excel Journal of Engineering Technology & Manaement ScienceDokument121 SeitenExcel Journal of Engineering Technology & Manaement ScienceLipi AgarwalNoch keine Bewertungen

- Terraria Progression GuideDokument7 SeitenTerraria Progression GuideLucas .R100% (1)

- Rocketbit - Making Larger Chips Out of Soft Rock: Secoroc Rock Drilling ToolsDokument4 SeitenRocketbit - Making Larger Chips Out of Soft Rock: Secoroc Rock Drilling ToolsJackChanNoch keine Bewertungen

- Modelling TricksDokument5 SeitenModelling TricksNandan ChoudharyNoch keine Bewertungen

- GP Rotary DrillingDokument40 SeitenGP Rotary Drillingjhon jairo trujilloNoch keine Bewertungen

- 2008 Norscot CatalogDokument12 Seiten2008 Norscot CatalogAdriano Godinho100% (2)

- TAKRAF Image Eng Ilovepdf CompressedDokument20 SeitenTAKRAF Image Eng Ilovepdf CompressedJesus Sing Robles100% (1)

- Romania Presentation Baita Plai and Remin 05.05.15Dokument17 SeitenRomania Presentation Baita Plai and Remin 05.05.15Alexandra Catalina StefanNoch keine Bewertungen

- Geotechnical Engineering For Mine Waste Storage Facilities PDFDokument641 SeitenGeotechnical Engineering For Mine Waste Storage Facilities PDFodo18100% (1)

- Business Plan - Template EG&JC-statupDokument5 SeitenBusiness Plan - Template EG&JC-statupShakaib HassanNoch keine Bewertungen

- As 1473.3-2001 Wood Processing Machinery - Safety Finishing Machinery - Circular Sawing MachinesDokument8 SeitenAs 1473.3-2001 Wood Processing Machinery - Safety Finishing Machinery - Circular Sawing MachinesSAI Global - APACNoch keine Bewertungen

- West Bengal Statistical Handbook 2008Dokument90 SeitenWest Bengal Statistical Handbook 2008Jagdish Rajan0% (2)

- Kingston Industrial Brochure 12072012Dokument16 SeitenKingston Industrial Brochure 12072012mkpasha55mp100% (1)

- LKAB Kiruna's New Haulage Level ABB Mine Hoist Upgrade For Production IncreaseDokument6 SeitenLKAB Kiruna's New Haulage Level ABB Mine Hoist Upgrade For Production IncreasesvarteridderNoch keine Bewertungen

- Exploring Macroeconomics Canadian 4Th Edition Sexton Solutions Manual Full Chapter PDFDokument27 SeitenExploring Macroeconomics Canadian 4Th Edition Sexton Solutions Manual Full Chapter PDFeirlysrubyxn5ik100% (8)

- Review Patricia Crone S Book Arabia Without SpicesDokument35 SeitenReview Patricia Crone S Book Arabia Without SpicesphotopemNoch keine Bewertungen

- Material HANDLING PowerPoint PresentationDokument34 SeitenMaterial HANDLING PowerPoint PresentationSamiul AlamNoch keine Bewertungen

- Seligdar Annual Report 2019Dokument107 SeitenSeligdar Annual Report 2019ivanushk417Noch keine Bewertungen

- Interfacing in Crushing and Screening PlantsDokument27 SeitenInterfacing in Crushing and Screening PlantsAnku PandeyNoch keine Bewertungen