Beruflich Dokumente

Kultur Dokumente

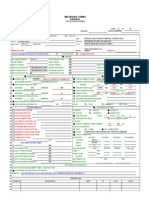

Datasheet - Sour Water Injection Pump

Hochgeladen von

geverett2765Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Datasheet - Sour Water Injection Pump

Hochgeladen von

geverett2765Copyright:

Verfügbare Formate

Equipment Data Sheet

SI UNITS

REV*

RFQ/RFP NO.

NuVista

Sour Water Injection

SERVICE

PROPOSAL

Montney

SITE:

1/23/2016

DATE

Montney

P-101

TAG

Multi Stage Centrifugal SIZE

PURCHASE

Multi Stage Centrifugal

TYPE:

REV.

VENDOR

MODEL

2 APPLICABLE TO:

OF

LOCATION

PROJECT

1 MANUFACTURER

PAGE

PROJECT NO.

CLIENT

CENTRIFUGAL PUMP

DOC NO.

QTY

SERIAL

AS BUILT

UNIT:

NO. STAGES:

GENERAL (3.1.1)

5

6 PUMP(S) TO OPERATE IN:

PARALLEL

SERIES

1 x 100%

7 CONFIGURATION:

8 GEAR ITEM NO.

NO. MOTOR DRIVEN

MOTOR ITEM NO.

NO. TURBINE DRIVEN

P-101

PUMP ITEM NO.

PM-101

PUMP ITEM NO.

TURBINE ITEM NO.

9 GEAR PROVIDED BY

MOTOR PROVIDED BY

Seller

TURBINE PROVIDED BY

10 GEAR MOUNTED BY

MOTOR MOUNTED BY

Seller

TURBINE MOUNTED BY

11 GEAR DATA SHEET NO.

MOTOR DATA SHEET NO.

TURBINE DATA SHEET NO.

12

OPERATING CONDITIONS

13

m3/h

62.5

14 CAPACITY, NORMAL

15

OTHER

16

SUCTION PRESS.

17

DISCHARGE PRESSURE

18

DIFFERENTIAL PRESSURE

19

DIFFERENTIAL HEAD

20

PROCESS VARIATIONS

21

STARTING CONDITIONS

MAX.

SITE AND UTILITY DATA

kPag

m3/h

75

RATED

345

RATED

kPag

4900

kPag

4555

464.5

CONTINUOUS

23

PARALLEL OPERATION REQ'D

INDOOR

HEATED

UNDER ROOF

OUTDOOR

UNHEATED

PARTIAL SIDES

GRADE

MEZZANINE

ELECTRICAL AREA CLASSIFICATION

1

2

Zone

Class

kPag

35.18

NPSHA

WINTERIZATION REQ'D

SITE DATA

793

m

ALTITUDE

Closed Discharge Valve

22 SERVICE:

LOCATION

INTERMITTENT (START/DAY)

LIQUID

27

28

PUMPING TEMPERATURE

10

NORM.

29

VAPOR PRESSURE

30

31

RELATIVE DENSITY (SPECIFIC GRAVITY):

1.000

NORM.

32

SPECIFIC HEAT, Cp

33

VISCOSITY

37.8

MAX.

(kPa abs)

C MIN.

@

MAX.

CORROSIVE/EROSIVE AGENT

36

CHLORIDE CONCENTRATION

H2S CONCENTRATION

DUST

10

FUMES

kJ/kg 0C

0

10

cP @

C

cP

STEAM DRIVERS:

MIN.

MAX.

kPag

kPag

MAX.

38

MIN.

23.1

C

%

MAX.

100

117963 mg/L

PPM

15.0 mg/L

PPM

FLAMMABLE

HAZARDOUS

VOLTAGE

HERTZ

PHASE

OTHER

STEAM UTILITY:

kPag

-

kPag

HEATING

CONTROL

C

SHUTDOWN

460

24VDC

24VDC

60

DRIVERS

ELECTRICITY:

39

COOLING WATER

PERFORMANCE

40

INLET TEMP.

rpm

41 PROPOSAL CURVE NO.

42

IMPELLER DIA RATED

MAX.

43

RATED POWER

kW

44

MINIMUM CONTINUOUS FLOW:

MIN.

PRESSURE

mm

EFFICIENCY

MIN RETURN

m3/h

m3/h

CHLORIDE CONCENTRATION

m3/h

TO

m3/h

INSTRUMENT AIR PRESSURE

47

ALLOWABLE OPERATING REGION

m3/h

TO

48

MAX HEAD @ RATED IMPELLER

m3/h

m

49

MAX POWER @ RATED IMPELLER

kW

50

NPSH REQUIRED AT RATED CAP

51

SUCTION SPECIFIC SPEED

52

MAX SOUND PRESS. LEVEL REQ'D

53

EST MAX SOUND PRESS LEVEL

54

REMARKS

THERMAL

kPag

STABLE

kPag

-

MAX ALLOW DP

kPag

WATER SOURCE

PREFERRED OPERATING REGION

C

kPag

DESIGN

MAX RETURN

NORMAL

46

45

-40

OTHER

UTILITY CONDITIONS

MIN.

4.192

35

38 LIQUID

1.298

MAX VISCOSITY

kPa abs

MIN.

UNUSUAL CONDITIONS

1.22

34

37

RELATIVE HUMIDITY

Sour Produced Water

26 TYPE/NAME OF LIQUID

92.0

BAROMETER

RANGE OF AMBIENT TEMPS.

24

25

IIA/IIB

Group

TROPICALIZATION REQ'D

PPM

MIN.

550

kPag

MAX.

830

kPag

REMARKS

dBA

< 85dBa

dBA

55

56

57

NOTE:

REV

A

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER

A, B, C, : INDICATES A PRE-ORDER REVISION

BY VENDOR

0: INDICATES AN ORDER REVISION

1, 2, 3, : INDICATES A POST-ORDER REVISION

DATE

BY

23-Jan-16

GJE

CHECKED

PROCESS

ELECT.

INSTR.

APPROVED

CLIENT

DESCRIPTION

Issued for Quotation

Equipment Data Sheet

SI UNITS

PAGE

PROJECT NO.

RFQ/RFP NO.

PROJECT

Montney

Sour Water Injection

P-101

TAG

5

6

OTHER

PUMP TYPE

OH2

BB1

VS1

VS6

LUBRICATION

OH3

OH4

BB2

VS2

VS6

LIMITED END FLOAT REQ'D

BB3

VS3

Note 1

SPACER LENGTH

10

OH6

BB4

VS4

BB5

VS5

MAKE

ANSI

MODEL

13

mm

SERVICE FACTOR

DRIVER HALF COUPLING MOUNTED BY

NOZZLE CONNECTIONS

PUMP MFR.

SIZE

RATING

FACING

14

SUCTION

300#

RF

15

DISCHARGE

300#

RF

16

BAL. DRUM

POSITION

DRIVER MFR.

NON-GROUT

REMARKS

NO.

SIZE (NPS)

TYPE

PRESSURE GAUGE

22

TEMP. GAUGE

23

WARM-UP

APPENDIX H CLASS

24

BALANCE/LEAK-OFF

MIN DESIGN METAL TEMP.

BARREL/CASE

26

MATERIAL

CYLINDRICAL THREADS REQUIRED

CASING MOUNTING

27

CENTERLINE

NEAR CENTERLINE

CASE/IMPELLER WEAR RINGS

28

FOOT

SEPARATE MOUNTING PLATE

SHAFT

29

30

31

32

INLINE

CASING SPLIT

AXIAL

CASING TYPE

33

34

35

COUPLING DIAPHRAGMS

REMARKS:

MULTIPLE VOLUTE

DIFFUSER

BETWEEN BEARINGS

BARREL

MAX ALLOWABLE WORKING PRESSURE

37

5103

kPag

37.8

7654.5

HYDROTEST PRESSURE

39

BEARINGS AND LUBRICATION

THRUST

REVIEW AND APPROVE THRUST BEARING SIZE

LUBRICATION: (2.10)

ROTATION: (VIEW FROM COUPLING END)

CW

43

IMPELLERS INDIVIDUALLY SECURED

NUMBER

RADIAL

SUCTION PRESS. REGIONS MUST BE DESIGNED FOR MAWP

42

TYPE

BEARING

kPag

40

41

COUPLING SPACER/HUBS

RADIAL

OVERHUNG

CASE PRESSURE RATING

38

-29

IMPELLER

BOLT OH3 TO PAD/FOUNDATION

SINGLE VOLUTE

36

(APPENDIX M)

API BASEPLATE NUMBER

21

25

PACKAGER

COUPLING PER API 671

BASEPLATES

PRESSURE CASING CONNECTIONS

18

DRAIN

kW/100 rpm

CPLG RATING

11

VENT

CCW

44

GREASE

FLOOD

RING OIL

FLINGER

PURGE OIL MIST

PURE OIL MIST

CONSTANT LEVEL OILER PREFERENCE (SEE REMARKS)

PRESSURE LUBE SYSTEM

API-610

API-614

OIL VISC. ISO GRADE

45

SHAFT

46

SHAFT DIAMETER AT COUPLING

mm

47

SHAFT DIAMETER BETWEEN BEARINGS

mm

OIL HEATER REQ'D

48

SPAN BETWEEN BEARING CENTERS

mm

OIL PRESS TO BE GREATER THAN COOLANT PRESS.

49

SPAN BETWEEN BEARING & IMPELLER

mm

50

51

52 REMARKS

53

54

55

56

57

58

59

60

61

QTY

COUPLING

API 610 11TH EDITION

20

1/23/2016

DATE

Multi Stage Centrifugal SIZE

CONSTRUCTION

APPLICABLE STANDARD

19

REV.

LOCATION

17

MODEL

12

OF

VENDOR

SERVICE

1 MANUFACTURER

NuVista

CLIENT

CENTRIFUGAL PUMP

REV*

DOC NO.

REMARKS:

ELECTRIC

STEAM

Equipment Data Sheet

SI UNITS

RFQ/RFP NO.

NuVista

OF

REV.

VENDOR

Sour Water Injection

SERVICE

P-101

TAG

QUENCHING FLUID

SEAL DATA

SEE ATTACHED API-682 DATA SHEET

NAME OF FLUID

NON-API 682 SEAL

FLOW RATE

APPENDIX H SEAL CODE

SEAL FLUSH PIPING PLAN

Flowserve

TUBING

Dual Pressurized

PIPE

AUXILIARY FLUSH PIPING PLAN

SEAL VENDOR

SIZE

10

TYPE

11

VENDOR CODE

CARBON STEEL

STAINLESS STEEL

53B

TUBING

SEAL CHAMBER DATA

CARBON STEEL

PIPE

PIPING ASSEMBLY

STAINLESS STEEL

13

TEMPERATURE

14

PRESSURE

kPa

THREADED

15

FLOW

m3/h

FLANGED

16

SEAL CHAMBER SIZE (TABLE 2.3)

17

TOTAL LENGTH

mm

PRESSURE GAUGE (PLAN 52/53)

mm

CLEAR LENGTH

UNIONS

SOCKET WELDED

TUBE TYPE FITTINGS

TYPE

PRESSURE SWITCH (PLAN 52/53)

SEAL CONSTRUCTION

SLEEVE MATERIAL

LEVEL GAUGE (PLAN 52/53)

20

GLAND MATERIAL

TEMP INDICATOR (PLANS 21, 22, 23, 32, 41)

21

AUX. SEAL DEVICE

23

HEAT EXCHANGER (PLAN52/53)

REMARKS

JACKET REQUIRED

GLAND TAPS

24

FLUSH (F)

DRAIN (D)

BARRIER/BUFFER (B)

25

QUENCH (Q)

COOLING (C)

LUBRICATION (G)

26

HEATING (H)

LEAKAGE

PUMPED FLUID (P)

27

28

29

NOTE: IF FLUSH LIQUID IS PUMPAGE LIQUID (AS IN FLUSH PIPING

30

PLANS 11 TO 41), FOLLOWING FLUSH LIQUID DATA IS NOT REQ'D.

MIN.

SUPPLY TEMPERATURE

33

RELATIVE DENSITY (SPEC. GRAVITY)

34

NAME OF FLUID

35

SPECIFIC HEAT, Cp

36

VAPOR PRESSURE

37

HAZARDOUS

FLOW RATE

38

TEMPERATURE REQUIRED

SUPPLY TEMPERATURE

46

47

RELATIVE DENSITY (SPECIFIC GRAVITY)

48

NAME OF FLUID

49

VAPOR PRESSURE

50

HAZARDOUS

FLOW RATE

51

STEAM AND COOLING WATER PIPING

COOLING WATER PIPING PLAN

COOLING WATER REQUIREMENTS

m3/h

SEAL JACKET/BRG HSG.

m3/h

kPa

m3/h

kPa

m3/h

MAX.

m /h

SEAL HEAT EXCHANGER

MIN.

kPa

QUENCH

MAX.

kPa

TOTAL COOLING WATER

MIN.

MAX.

MIN.

MAX.

C

C

STEAM PIPING

TUBING

kPa

m3/h

PIPE

REMARKS

53

56

57 REMARKS

@

kPa abs

FLAMMABLE

MIN.

INSTRUMENTATION

OTHER

m3/h

VIBRATION:

MAX.

m3/h

NONCONTACTING (API 670)

MIN.

kPa

PROVISIONS FOR MOUNTING ONLY

MAX.

kPa

FLAT SURFACE REQUIRED

TEMPERATURE REQUIRED

MIN.

SEE ATTACHED API-670 DATA SHEET

MAX.

MONITORS AND CABLES

54

55

PRESSURE REQUIRED

52

61

BARRIER/BUFFER FLUID

45

60

NO. OF RINGS

PACKING INJECTION REQUIRED

FLOW

m3/h

LANTERN RING

FLAMMABLE

OTHER

MIN.

43

59

kJ/kg 0C

41

58

SIZE

0

kPa abs

PRESSURE REQUIRED

42

TYPE

Pumpage

39

40

VENDOR

MAX.

32

44

PACKING DATA

BALANCE FLUID (E)

EXTERNAL FLUID INJECTION (X)

SEAL FLUIDS REQUIREMENT AND AVAILABLE FLUSH LIQUID:

31

Transmitter

TYPE

LEVEL SWITCH (PLAN 52/53)

19

22

m3/h

SEAL FLUSH PIPING: (2.7.3.19 AND APPENDIX D)

18

QTY

Multi Stage Centrifugal SIZE

MECHANICAL SEAL OR PACKING

12

1/23/2016

MODEL

DATE

Montney

LOCATION

PROJECT

1 MANUFACTURER

PAGE

PROJECT NO.

CLIENT

CENTRIFUGAL PUMP

REV*

DOC NO.

C

C

TRANSDUCER

Equipment Data Sheet

SI UNITS

SERVICE

MODEL

INSTRUMENTATION (CONTINUED)

TEMPERATURE AND PRESSURE

RADIAL BRG METAL TEMP.

PROVISION FOR INSTRUMENTS ONLY

REV.

1/23/2016

DATE

Montney

LOCATION

VENDOR

Sour Water Injection

P-101

TAG

QTY

Multi Stage Centrifugal SIZE

SURFACE PREPARATION AND PAINT (CONTINUED)

THRUST BRG METAL TEMP.

DOMESTIC

EXPORT

EXPORT BOXING REQUIRED

OUTDOOR STORAGE MORE THAN 6 MONTHS

SPARE ROTOR ASSEMBLY PACKAGED FOR:

SEE ATTACHED API-670 DATA SHEET

NuVista

OF

SHIPMENT (4.4.1)

TEMP. GAUGES (WITH THERMOWELLS) (3.4.1.3)

OTHER

PRESS. GAUGE TYPE (3.4.2.2)

HORIZONTAL STORAGE

VERTICAL STORAGE

TYPE OF SHIPPING PREPARATION

REMARKS

LOCATION

10

11

RFQ/RFP NO.

PROJECT

1 MANUFACTURER

PAGE

PROJECT NO.

CLIENT

CENTRIFUGAL PUMP

REV*

DOC NO.

REMARKS:

12

MASSES

13

14

MOTOR DRIVEN

MOTOR DRIVE (Note 5)

15

16

VENDOR

17

18

19

kW

rpm

HORIZONTAL

FRAME

VERTICAL

1.15

20

SERVICE FACTOR

21

22

VOLTS

HERTZ

23

TYPE

24

ENCLOSURE

TEFC

25

MINI. STARTING VOLTAGE

80%

26

TEMPERATURE RISE

27

FULL LOAD AMPS

28

LOCKED ROTOR AMPS

29

INSULATION

30

STARTING METHOD

31

32

kg

kg

TOTAL MASS

kg

60

Squirrel-cage Induction

kg

MASS OF TURBINE

kg

MASS OF GEAR

kg

TOTAL MASS

kg

REMARKS

Class B

OTHER PURCHASER REQUIREMENTS

VFD

COORDINATION MEETING REQUIRED (6.1.3)

LUBE

UP

34

BEARINGS

RADIAL

REVIEW FOUNDATION DRAWINGS (2.1.27)

REVIEW PIPING DRAWINGS

N

36

37

MASS OF MOTOR

MASS OF GEAR

TURBINE DRIVEN

MASS OF BASEPLATE

PHASE

kg

kg

VERTICAL THRUST CAPACITY

33

35

460

MASS OF PUMP

MASS OF BASEPLATE

THRUST

38

DOWN

OBSERVE PIPING CHECKS

OBSERVE INITIAL ALIGNMENT CHECK

TYPE

CHECK ALIGNMENT AT OPERATING TEMPERATURE

NUMBER

CONNECTION DESIGN APPROVAL (2.11.3.5.4)

TYPE

RIGGING DEVICE REQ'D FOR TYPE OH3 PUMP (5.1.2.7)

NUMBER

HYDRODYNAMIC THRUST BRG SIZE REVIEW REQ'D (5.2.5.2.4)

39

LATERAL ANALYSIS REQUIRED (5.1.4.3/5.2.4.1)

SURFACE PREPARATION AND PAINT

40

ROTOR DYNAMIC BALANCE (5.2.4.2)

41

MANUFACTURER'S STANDARD

MOUNT SEAL RESERVOIR OFF BASEPLATE (3.5.1.4)

42

OTHER (See Note 4)

INSTALLATION LIST IN PROPOSAL (6.2.3L)

43

PUMP

44

SURFACE PREPARATION

45

PRIMER

46

FINISH COAT

47

BASEPLATE (3.3.18)

48

SURFACE PREPARATION

49

PRIMER

50

FINISH COAT

SPARE ROTOR VERTICAL STORAGE (5.2.9.2)

TORSIONAL ANALYSIS/REPORT (2.8.2.6)

PROGRESS REPORTS REQUIRED (6.3.4)

REMARKS

SPARE PARTS (TABLE 6.1)

51

52 REMARKS:

53

54

55

56

57

58

59

60

61

Electrical motor suitable for VFD control

START-UP

SPECIFY

NORMAL MAINTENANCE

Packager shall provide start-up/commissioning spares.

Packager shall provide priced 2-yr spare list with bid.

Equipment Data Sheet

SI UNITS

PAGE

PROJECT NO.

RFQ/RFP NO.

CLIENT

SERVICE

1 MANUFACTURER

MODEL

QA INSPECTION AND TEST

2

3

REVIEW VENDORS QA PROGRAM (4.1.7)

PERFORMANCE CURVE APPROVAL

SHOP INSPECTION (4.1.4)

TEST WITH SUBSTITUTE SEAL (4.3.3.1.2)

NON-WIT.

8 TESTS

PERFORMANCE (4.3.3)

11

NPSH (4.3.4.1)

12

COMPLETE UNIT TEST (4.3.4.2)

13

SOUND LEVEL TEST (4.3.4.3)

CLEANLINESS PRIOR TO

14

15

NOZZLE LOAD TEST (3.3.6)

17

BRG HSG RESONANCE TEST (4.3.4.5)

18

REMOVE/INSPECT HYDRODYNAMIC

20

OBSERV.

FINAL ASSEMBLY (4.2.3.1)

16

19

WIT.

HYDROSTATIC (4.3.2)

10

BEARINGS AFTER TEST (5.2.8.5)

AUX. EQUIPMENT TEST (4.3.4.4)

21

22

23

MATERIAL CERTIFICATION REQUIRED (2.11.1.7)

24

CASING

25

OTHER

IMPELLER

SHAFT

26

CASING REPAIR PROCEDURE APPROVAL REQ'D (2.11.2.5)

27

INSPECTION REQUIRED FOR CONNECTION WELDS (2.11.3.6)

28

MAG PARTICLE

LIQUID PENETRANT

29

RADIOGRAPHIC

ULTRASONIC

30

INSPECTION REQUIRED FOR CASTINGS (4.2.1.3)

31

MAG PARTICLE

LIQUID PENETRANT

32

RADIOGRAPHIC

ULTRASONIC

33

ADDITIONAL INSPECTION REQUIRED FOR:

34

(4.2.1.3)

35

36

MAG PARTICLE

LIQUID PENETRANT

RADIOGRAPHIC

ULTRASONIC

37

ALTERNATIVE ACCEPTANCE CRITERIA (SEE REMARKS) (4.2.2.1)

38

39

HARDNESS TEST REQUIRED FOR:

Process Wetted Parts (refer to Note 3)

40

WETTING AGENT HYDROTEST (4.3.2.5)

41

VENDOR SUBMIT TEST PROCEDURES(4.3.1.2/6.2.5)

42

RECORD FINAL ASSEMBLY RUNNING CLEARANCES

43

INSPECTION CHECKLIST (APPENDIX N)

44

45 REMARKS

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

OF

(4.2.3.2)

(4.1.6)

REV.

DATE

1/23/2016

Montney

LOCATION

VENDOR

Sour Water Injection

P-101

TAG

Multi Stage Centrifugal SIZE

REMARKS

NuVista

PROJECT

CENTRIFUGAL PUMP

REV*

DOC NO.

QTY

Equipment Data Sheet

SI UNITS

CENTRIFUGAL PUMP

REV*

1 MANUFACTURER

2

DOC NO.

PAGE

PROJECT NO.

RFQ/RFP NO.

CLIENT

NuVista

PROJECT

SERVICE

MODEL

OF

REV.

DATE

Montney

LOCATION

VENDOR

Sour Water Injection

TAG

P-101

Multi Stage Centrifugal SIZE

NOTES

3 No.

4

1 Multistage centrifugal pump required.

2 Pumps shall be 1 x 100% configuration.

3 Wetted materials shall be in accordance with NACE MR0175.

4 Painting per vendor standard.

5 Electric motor to be VFD compatible.

6 Coupling shall be provided with spacer to allow removal without disturbing pump or seal. Non-spark coupling guard shall be provided, painted to indicate the hazard.

10

7 Seller to select dual pressurized seal design and support plan. Plan 53B secondary proposed due to H2S content of produced water.

11

12

13 10

14 11

15 12

16 13

17 14

18 15

19 16

20 17

21 18

22 19

23 20

24 21

25 22

26 23

27 24

28 25

29 26

30 27

31 28

32 29

33 30

34 31

35 32

36 33

37 34

38 35

39 36

40 37

41 38

42 39

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

1/23/2016

QTY

Das könnte Ihnen auch gefallen

- Pressure Vessel Specification - WoodsideDokument48 SeitenPressure Vessel Specification - Woodsidevnedimovic100% (4)

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Dokument17 SeitenReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNoch keine Bewertungen

- VENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSDokument8 SeitenVENDOR DOCUMENT REVIEW OF PRESSURE RELIEF VALVE DATA SHEETSMichael HaiseNoch keine Bewertungen

- Piping Wall Sizing and Thickness CalculationDokument16 SeitenPiping Wall Sizing and Thickness CalculationAriNoch keine Bewertungen

- Unfired Pressure VesselDokument30 SeitenUnfired Pressure VesselSrinivasan RajenderanNoch keine Bewertungen

- Checklist For Stress Analysis-PipingDokument1 SeiteChecklist For Stress Analysis-PipingShailin ShahNoch keine Bewertungen

- Specification For Centrifugal Pumps White Oil TerminalDokument96 SeitenSpecification For Centrifugal Pumps White Oil TerminalJackfusionNoch keine Bewertungen

- Double Wall TankDokument1 SeiteDouble Wall TankFerry Triyana AnirunNoch keine Bewertungen

- B101 2001Dokument22 SeitenB101 2001geverett2765Noch keine Bewertungen

- Centrifugal Pump Data Sheet InsightsDokument1 SeiteCentrifugal Pump Data Sheet Insightspkitchen25Noch keine Bewertungen

- 674 Reciprocating Pump DatasheetsDokument6 Seiten674 Reciprocating Pump DatasheetsAKSHEYMEHTANoch keine Bewertungen

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Dokument5 SeitenSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNoch keine Bewertungen

- 135355-04-Pro-02-005 - Rev 01 - Hydrotest Procedure For Station PipingDokument19 Seiten135355-04-Pro-02-005 - Rev 01 - Hydrotest Procedure For Station PipingHanLe DuyNoch keine Bewertungen

- Diesel Fuel MSDS PDFDokument7 SeitenDiesel Fuel MSDS PDFgeverett2765Noch keine Bewertungen

- Venting Requirement According To Api 2000, Seventh Edition, Mar 2014Dokument5 SeitenVenting Requirement According To Api 2000, Seventh Edition, Mar 2014sahirprojectsNoch keine Bewertungen

- Hen 0000 Me SP 0012 - B4Dokument29 SeitenHen 0000 Me SP 0012 - B4sherviny100% (2)

- Pressure Vessel: General DescriptionDokument4 SeitenPressure Vessel: General DescriptionTiny Tấn MinhNoch keine Bewertungen

- 610 10th Ed Datasheets (SI)Dokument11 Seiten610 10th Ed Datasheets (SI)sjois_hsNoch keine Bewertungen

- Typical Centrifugal Pump DatasheetDokument7 SeitenTypical Centrifugal Pump DatasheetFabioSalaNoch keine Bewertungen

- TBE Inlet Separator V 2100 FLNG2Dokument6 SeitenTBE Inlet Separator V 2100 FLNG2halipzramlyzNoch keine Bewertungen

- Pressure Vessel CalculatorDokument19 SeitenPressure Vessel CalculatorGodwinNoch keine Bewertungen

- API 610 11th Ed DatasheetDokument13 SeitenAPI 610 11th Ed DatasheetHatem ShawkiNoch keine Bewertungen

- D790 02Dokument9 SeitenD790 02Arlene AriasNoch keine Bewertungen

- Item Rev Title Notes Units Design Data Supplier Data (Note B) Operation DataDokument4 SeitenItem Rev Title Notes Units Design Data Supplier Data (Note B) Operation DataSteve WanNoch keine Bewertungen

- Crude Oil SystemDokument78 SeitenCrude Oil SystemArnel Moreno100% (2)

- Data Sheet FOR Centrifugal Pump: Page 1 of 3Dokument3 SeitenData Sheet FOR Centrifugal Pump: Page 1 of 3ThiênSứBanPhúcNoch keine Bewertungen

- Reciprocating CompressorDokument6 SeitenReciprocating CompressorEDUARDONoch keine Bewertungen

- Eductor SizingDokument13 SeitenEductor Sizingcepong89100% (2)

- PT VICO Indonesia heat exchanger designDokument4 SeitenPT VICO Indonesia heat exchanger designSoraya ZahraNoch keine Bewertungen

- FS 5095 Fuel Gas Skid New0582642418Dokument47 SeitenFS 5095 Fuel Gas Skid New0582642418Naveen Namani100% (3)

- Air Blowe DatasheetDokument1 SeiteAir Blowe DatasheetMoein PNoch keine Bewertungen

- DLL-earth-and-life - 5Dokument4 SeitenDLL-earth-and-life - 5Marilla ReybethNoch keine Bewertungen

- Coil Heat CalculationDokument2 SeitenCoil Heat CalculationTarmana Antt100% (1)

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDokument15 SeitenCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNoch keine Bewertungen

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDokument2 SeitenMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002Noch keine Bewertungen

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDokument2 SeitenPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- NSPHa CalculationDokument3 SeitenNSPHa CalculationYakubuNoch keine Bewertungen

- Air Cooled Heat Exchanger CourseDokument2 SeitenAir Cooled Heat Exchanger Courserodrigoperezsimone100% (1)

- Refrigeration IIAR 4 PR1Dokument28 SeitenRefrigeration IIAR 4 PR1geverett2765100% (3)

- 1007 DISQ 0 S MA 54008 Mechanical Handling PhilosophyDokument12 Seiten1007 DISQ 0 S MA 54008 Mechanical Handling PhilosophyAnonymous XbmoAFtI100% (1)

- Fuel Specification For Waukesha EngineDokument12 SeitenFuel Specification For Waukesha Enginezubair1951100% (3)

- Specification Datasheet For Instrument Air Compressor PackageDokument5 SeitenSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNoch keine Bewertungen

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDokument2 SeitenHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- 1007 DISQ 0 J SS 33033 Shutdown Valve SpecificationDokument15 Seiten1007 DISQ 0 J SS 33033 Shutdown Valve Specificationeng20072007100% (1)

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDokument2 SeitenHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc NguyenNoch keine Bewertungen

- API 673 3rd Ed Data SheetsDokument27 SeitenAPI 673 3rd Ed Data Sheetsjuan ninaNoch keine Bewertungen

- Air Eliminator Datasheet PDFDokument2 SeitenAir Eliminator Datasheet PDFbecpavanNoch keine Bewertungen

- Slip Form HandbookDokument301 SeitenSlip Form HandbookAhmed Mostafa AL-Aboudy67% (3)

- Liquid Sulphur Temperature, Pressure, Flow & Thermal PropertiesDokument1 SeiteLiquid Sulphur Temperature, Pressure, Flow & Thermal Propertiesgeverett2765Noch keine Bewertungen

- DATA SHEET MULTIPHASE PUMP REV0 BornermanDokument5 SeitenDATA SHEET MULTIPHASE PUMP REV0 BornermanJessika López100% (1)

- TGT M WPP DS 0012 - C - Datasheet For Caisson Sump PumpDokument7 SeitenTGT M WPP DS 0012 - C - Datasheet For Caisson Sump Pumpvovancuong8Noch keine Bewertungen

- Datasheet For Restriction OrificeDokument1 SeiteDatasheet For Restriction OrificeRajesh Rajesh50% (2)

- Vessel Data SheetDokument1 SeiteVessel Data SheetMichael HaiseNoch keine Bewertungen

- Indra: SonatrachDokument9 SeitenIndra: SonatrachhichamNoch keine Bewertungen

- Pump Data SheetDokument6 SeitenPump Data SheetmihailspiridonNoch keine Bewertungen

- Pig Trap Data SheetDokument1 SeitePig Trap Data SheetShafqat Afridi100% (3)

- Floating Suction Arm Datasheet FormDokument2 SeitenFloating Suction Arm Datasheet FormatecotanksNoch keine Bewertungen

- API 610 Data Sheet 1 PDFDokument6 SeitenAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNoch keine Bewertungen

- TQ - Air Fin Cooler (CS) - ModificationDokument6 SeitenTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNoch keine Bewertungen

- Size Depressurization and Relief Devices For Pressurized Segments Exposed To FireDokument8 SeitenSize Depressurization and Relief Devices For Pressurized Segments Exposed To Fireromdhan88Noch keine Bewertungen

- Size Depressurization and Relief Devices For Pressurized Segments Exposed To FireDokument8 SeitenSize Depressurization and Relief Devices For Pressurized Segments Exposed To Fireromdhan88Noch keine Bewertungen

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Dokument4 SeitenDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNoch keine Bewertungen

- Pig Calc PDFDokument286 SeitenPig Calc PDFJaroslaw KoniecznyNoch keine Bewertungen

- vs1 DatasheetDokument22 Seitenvs1 DatasheetMojtabaNoch keine Bewertungen

- Flame Arrestor Data SheetDokument1 SeiteFlame Arrestor Data SheetErnesto100% (1)

- TBE For UG Knock Out Drum - Draft For Rev.C1Dokument22 SeitenTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskNoch keine Bewertungen

- CVEN9522 and CVEN9776 Rock Engineering.Dokument4 SeitenCVEN9522 and CVEN9776 Rock Engineering.Milton TeranNoch keine Bewertungen

- 2WallTank NFPA ULDokument1 Seite2WallTank NFPA ULPolo VarsanNoch keine Bewertungen

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDokument10 SeitenReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- Centrifugal Pump Api-610 Data Sheet Mks Units: Operating Conditions Site and Utility Data (Cot D)Dokument12 SeitenCentrifugal Pump Api-610 Data Sheet Mks Units: Operating Conditions Site and Utility Data (Cot D)sahrilbayunirosidikNoch keine Bewertungen

- PROJECT UNITS DATA SHEETDokument7 SeitenPROJECT UNITS DATA SHEETHatem ShawkiNoch keine Bewertungen

- DIN CatalogDokument57 SeitenDIN CatalogLuong Do DatNoch keine Bewertungen

- FLANGE DIMENSIONS - DIN PN 6-40Dokument7 SeitenFLANGE DIMENSIONS - DIN PN 6-40Dave DonohueNoch keine Bewertungen

- Engine Fuel Data R1Dokument3 SeitenEngine Fuel Data R1geverett2765Noch keine Bewertungen

- Alloys 309 310 Elevated Temperature Properties Applications Corrosion ResistanceDokument7 SeitenAlloys 309 310 Elevated Temperature Properties Applications Corrosion ResistancejpvanhoutenNoch keine Bewertungen

- Corrosion Inhibitor PigsDokument2 SeitenCorrosion Inhibitor Pigsgeverett2765Noch keine Bewertungen

- Alberta Pipeline RulesDokument56 SeitenAlberta Pipeline RulesFredrick MartinNoch keine Bewertungen

- Phased Arry PDFDokument62 SeitenPhased Arry PDFgeverett2765Noch keine Bewertungen

- Union Pump InformationDokument12 SeitenUnion Pump Informationgeverett2765Noch keine Bewertungen

- Control Valve SzingDokument10 SeitenControl Valve Szinggeverett2765Noch keine Bewertungen

- Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and VentingDokument99 SeitenDirective 060: Upstream Petroleum Industry Flaring, Incinerating, and Ventinggeverett2765Noch keine Bewertungen

- Union Pump InformationDokument12 SeitenUnion Pump Informationgeverett2765Noch keine Bewertungen

- Directive017 PDFDokument405 SeitenDirective017 PDFgeverett2765Noch keine Bewertungen

- 0C101 Pid 1200 001B R1Dokument1 Seite0C101 Pid 1200 001B R1geverett2765Noch keine Bewertungen

- Pressure Test ProceduresDokument10 SeitenPressure Test ProceduresfalidkhalifaNoch keine Bewertungen

- Fisher Tank Blanketing Manual PDFDokument19 SeitenFisher Tank Blanketing Manual PDFgeverett2765Noch keine Bewertungen

- Hy Lok Tube Fittings PDFDokument56 SeitenHy Lok Tube Fittings PDFHermanNoch keine Bewertungen

- Fisher Tank Blanketing ManualDokument4 SeitenFisher Tank Blanketing Manualgeverett2765Noch keine Bewertungen

- API Tubing TableDokument1 SeiteAPI Tubing Tablegeverett2765Noch keine Bewertungen

- Methanol MSDSDokument8 SeitenMethanol MSDSgeverett2765Noch keine Bewertungen

- Sat Jul 07 19:54:58 2007 Case: C:/Program Files/Hyprotech/HYSYS 3.2/cases/temp - HSC Flowsheet: Case (Main)Dokument1 SeiteSat Jul 07 19:54:58 2007 Case: C:/Program Files/Hyprotech/HYSYS 3.2/cases/temp - HSC Flowsheet: Case (Main)geverett2765Noch keine Bewertungen

- 14-083 Rev 3Dokument1 Seite14-083 Rev 3geverett2765Noch keine Bewertungen

- 341417Dokument4 Seiten341417geverett2765Noch keine Bewertungen

- 0D107Line ListDokument1 Seite0D107Line Listgeverett2765Noch keine Bewertungen

- Evaporators For Co2 Refrigeration: BackgroundDokument26 SeitenEvaporators For Co2 Refrigeration: BackgroundgamunozdNoch keine Bewertungen

- Z Graph ReportDokument14 SeitenZ Graph ReportS Kiong TingNoch keine Bewertungen

- Psychrometric Chart Psychrometric Chart: Normal Temperature SI Units Sea Level Normal Temperature SI Units Sea LevelDokument1 SeitePsychrometric Chart Psychrometric Chart: Normal Temperature SI Units Sea Level Normal Temperature SI Units Sea LevelAnoop RastogiNoch keine Bewertungen

- 2 Constitutive Models: Theory and Implementation: Section 2.2.1Dokument144 Seiten2 Constitutive Models: Theory and Implementation: Section 2.2.1mybestloveNoch keine Bewertungen

- Buckling State 0Dokument13 SeitenBuckling State 0Ag SodaNoch keine Bewertungen

- Coalescence of Surfactant-Laden Drops by A Phase Field MethodDokument20 SeitenCoalescence of Surfactant-Laden Drops by A Phase Field MethodAlfredo SoldatiNoch keine Bewertungen

- Moment Distribution MethodDokument13 SeitenMoment Distribution MethodMD. SHUVO RAHMANNoch keine Bewertungen

- Dynamic Response of Concrete Subjected To High Rate of Loading: A Parametric StudyDokument17 SeitenDynamic Response of Concrete Subjected To High Rate of Loading: A Parametric StudyJhuma DebnathNoch keine Bewertungen

- Lecture-5-Kinematics of Fluid FlowDokument34 SeitenLecture-5-Kinematics of Fluid FlowRIZWAN KHANNoch keine Bewertungen

- DTMB 1966 2173Dokument38 SeitenDTMB 1966 2173benadam10Noch keine Bewertungen

- Effect of Principal Stress Rotation and Intermediate Principal Stress Changes On The Liquefaction Resistance and Undrained Cyclic Response of Ottawa SandDokument12 SeitenEffect of Principal Stress Rotation and Intermediate Principal Stress Changes On The Liquefaction Resistance and Undrained Cyclic Response of Ottawa SandberkanNoch keine Bewertungen

- Humidity and Heat in MinesDokument45 SeitenHumidity and Heat in MinesAhsan AliNoch keine Bewertungen

- Activity Ans AssessmentDokument2 SeitenActivity Ans AssessmentOhmark VeloriaNoch keine Bewertungen

- Fluid Flow Velocity Steel Pipe Schedule 40 Metric UnitsDokument1 SeiteFluid Flow Velocity Steel Pipe Schedule 40 Metric UnitsRobert ThanhNoch keine Bewertungen

- AIAA 1394992 An A&odynamic Model For Symmetric Sabotl SeparationDokument12 SeitenAIAA 1394992 An A&odynamic Model For Symmetric Sabotl SeparationLalNoch keine Bewertungen

- Hilti Advanced Base Plate Technical BackgroundDokument23 SeitenHilti Advanced Base Plate Technical BackgroundFelipe Mora CanoNoch keine Bewertungen

- Compressibl E Aerodynamic S: Dr. Dilip A Shah Dr. Vishnu Kumar G CDokument11 SeitenCompressibl E Aerodynamic S: Dr. Dilip A Shah Dr. Vishnu Kumar G CGCVishnuKumarNoch keine Bewertungen

- Weaver (1976) - On Flow Induced Vibrations in Hydraulic Structures and Their AlleviationDokument12 SeitenWeaver (1976) - On Flow Induced Vibrations in Hydraulic Structures and Their AlleviationEmerson Borges Santana100% (1)

- Tensile Stress-Strain Behavior of Metallic Alloys: Transactions of Nonferrous Metals Society of China November 2017Dokument12 SeitenTensile Stress-Strain Behavior of Metallic Alloys: Transactions of Nonferrous Metals Society of China November 2017nick amirNoch keine Bewertungen

- PVT & Eos Modelling: Using Pvtsim SoftwareDokument71 SeitenPVT & Eos Modelling: Using Pvtsim SoftwareMario HuasasquicheNoch keine Bewertungen

- Solid Mechanics-8 PDFDokument8 SeitenSolid Mechanics-8 PDFchetanNoch keine Bewertungen

- Dynamic Responses of Marine RisersPipesDokument9 SeitenDynamic Responses of Marine RisersPipesRajeuv GovindanNoch keine Bewertungen

- Modeling Plastics in ANSYSDokument14 SeitenModeling Plastics in ANSYSashutosh.srvNoch keine Bewertungen

- Refrigeration Systems SyllabusDokument1 SeiteRefrigeration Systems SyllabusSumeet SinghNoch keine Bewertungen

- ME 450/550 Computational Fluid Dynamics: CFD Lab 3Dokument12 SeitenME 450/550 Computational Fluid Dynamics: CFD Lab 3api-273690515Noch keine Bewertungen