Beruflich Dokumente

Kultur Dokumente

Hydraulic Pumps PDF

Hochgeladen von

tonylyfOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydraulic Pumps PDF

Hochgeladen von

tonylyfCopyright:

Verfügbare Formate

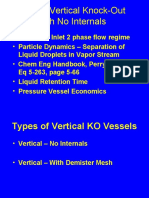

Chapter 2

Background in hydraulic systems

2.8 Hydraulic pumps

2.8.1. Introduction

A pump, which is the heart of hydraulic system, convers mechanical

energy into hydraulic energy. The mechanical energy is delivered to the pump

via a prime mover such as an electric motor. Due to mechanical action, the

pump creates partial vacuum at its inlet. This permits atmospheric pressure to

force the fluid through the inlet line and into the pump. The pump then pushes

the fluid into the hydraulic system.

pumps

Hydraustatic or positive displacement

pumps

Hydraudinamic or Non positive

displacement pumps

piston

Rotodynamic

Gear

Axial

Special Effect

Bent Axis

Redial

Swash Plate

Rotating

swatsh

plate(wabble)

Rotating cylinder

block

External

internal

Electronic

cylinder block

(Crecent)

Electronic shaft

Screw

(cam)

Lope

Axial Piston

Crank type

Inclined Piston

Fig .2.9. The Classification of hydraulic pumps

11

Vane

Pressure

balanced

Pressure

unbalanced

Chapter 2

Background in hydraulic systems

2.8.2. Classification of hydraulic pumps.

There are two board classifications of pumps as identified by the fluid power

industry.

1. Non positive displacement pumps:

This type is generally used for low-pressure, high-volume flow

applications. Because they are not capable of with standing high pressures, they

are little use in the fluid power field. Normally their maximum pressure

capacity is limited to 250-300 psi. This type of pump is primarily used for

transporting fluids from one location to another.

2. positive displacement pumps:

This type is universally used for fluid power systems. As the name

implies, a positive displacement pump ejects a fixed amount of fluid into the

hydraulic system per revolution of pump shaft rotation. Such a pump is capable

of overcoming the pressure resulting from the mechanical load on the system as

well as the resistance to flow due to friction. These are two features that are

desired of fluid power pumps. These pumps have the following advantage over

nonpositive displacement pumps:

a.

b.

c.

d.

e.

High pressure capability ( up to 10,000 psi or higher).

Small, compact size.

High volumetric efficiency.

Small change in efficiency throughout the design pressure range.

Great flexibility of performance (can operate over a wide range of

pressure requirements and speed ranges)

Positive displacement pump can be classified by the type of motion of

internal elements. The motion may be either rotary or reciprocating. Although

these pumps come in a wide verity of different designs there are essentially

three basic types:

12

Chapter 2

Background in hydraulic systems

Fig .2.10 the Classification of Positive displacement pump

2.10. Explain the operation of the displacement pump.

The pump operation is summarized in the following steps.

1- During the expansion of the pumping chamber, it is connected to the

suction line. The expansion develops an under pressure inside the

chamber, forcing the liquid to be sucked in.

2- When the volume of the chamber reaches its maximum value, the

chamber is separated from the suction line.

3- During the contraction period of the chamber, it is communicated with

the pump. delivery line. The fluid is then displaced to the pump exit line

and is acted on by the pressure necessary to overcome the system

resistance

4- The delivery stroke ends when the volume of the chamber reaches its

minimum value. Then the chamber is separated from the delivery line.

13

Chapter 2

Background in hydraulic systems

A. Rotary pumps

1. Gear pumps

Gear pumps are multiple rotor type of pumps and the rotor's are "gear

toothed". The pumping action is achieved by relative motion of the rotors. Gear

pumps are primarily of the external or internal gear type. One of the rotors

(driver) receives drive from a prime mover and it transmits drive to the other

rotor.

Fig .2.11 Rotary gear pump

1. a. External gear pumps

External gear pumps maybe of the straight spur gear or helical gear

type. The representation shows a spur type gear pump and this type is more

common. The suction and discharge of the pump is primarily decided by the

direction of rotation of the gears. One of the gears (driver) receives drive

from a prime mover. The driver in turn transmits motion to the driven gear.

1. b. Internal gear pumps:

The internal gear pump is a multiple rotor type of pump, and the working

primarily differs from the external gear pump in that, here an outer gear (having

internal gear tooth) meshes with a gear which is within it or inner to it. The

inner gear is off-center with respect to the casing and outer gear. In the pump

shown. The outer gear (driver) receives drive from an external source (prime

mover). The outer gear drives the inner gear or idler gear on a stationary pin.

14

Chapter 2

Background in hydraulic systems

2. Vane pumps:

Vane pumps are of the single rotor type. They are primarily of the sliding

Vane and flexible Vane (flexible impeller) design. In sliding vane pumps the

pumping action is achieved by a rigid sliding action of vanes along the casing

wall. The vanes move up-and-down inside slots in a rotor, which is eccentrically

located in the casing. These pumps can develop high suction heads and can

handle suspended non-abrasive solids. In the flexible vane (impeller) pumps, the

vanes flex against the casing wall, which is oblong at one end. The pump has

low suction capabilities.

2.1. Sliding vane pumps:

The basic, design of the pump involves a rotor, eccentrically mounted

inside a cylindrical casing. The rotor has several radial slots in which sliding

vanes are located. If the rotor is rotated, the sliding vanes are pushed against the

wall of the casing by centrifugal force and hydraulic pressure. Some design also

incorporate spring force to push the sliding vanes against the casing wall.

2.2.Flexible vane pumps

In flexible vane pumps, the rotor includes flexible vanes and the principle

of operation is very similar to the sliding vane pump except that the vanes flex

and do not rigidly slide against the casing wall.

Fig. 2.12. Flexible vane pump

Fig .2.13. Sliding vane pump

15

Chapter 2

Background in hydraulic systems

3.Rotary lope pumps:

Lobe pumps are multiple rotor type of pumps and the rotors utilize a lobe

shaped design. The pumping action is achieved by relative motion of the rotors.

They are primarily of the external lobe type and internal lobe (gerotor) type. In

the external lobe design. The relative motion between rotors is achieved by

timing gears and therefore the internal contact between the lobes is a sealing

contact and not a driving contact. Since the lobes do not directly mate, lobe

pumps are suitable for handling liquids with suspended solids.

3.1.External lope:

Lobe pumps may be of various designs and the rotors may be of bi-wing,

tri-Lobe, or multi-lobe configurations. In the model shown, the rotors are of the

bi-wing type and are supported on either side. The rotors can also be of the

over-hanging design.

3.2.Internal lope (Gerotor)

The internal lobe pump and is also called as a gerotor pump; the name

derived from the term "generated rotor". The pump is also referred to as an

internal gear pump and operates primarily on the same principle but without a

crescent.

A gerotor unit consists of an inner and outer lobe where the inner rotor

has n lobes, and the outer rotor has n+1 lobes. The prime mover transmits drive

to the inner lobe (driver), which in turn drives the outer lobe (idler).The inner

lobe is located off-center to the outer lobe.

Fig.2.14. Rotary lope pumps

16

Chapter 2

Background in hydraulic systems

4. Rotary screw pumps:

Screw pumps are unique because the flow through the pumping elements

is truly axial. It provides several advantages in many applications where liquid

agitation or churning is objectionable. Screw pumps are classified into the

single rotor (progressing cavity) and multiple rotor type. In the single screw

type, the pumping action is achieved by a rotor which mates with threads inside

a stator. In multiple rotor pumps the pumping action is achieved by the relative

motion between the rotors, which may be synchronized by gears or the drive

may be transmitted directly from one rotor to the other.

4.1. Single screw pump (Progressive cavity):

These pumps are of the single rotor type and are commonly called as

progressive cavity pumps. The pump consists of two key components; the rotor

and the stator.

4.2.Multiple screw pump:

These pumps have more than one rotor and are actually a modification of

the helical gear pumps. Here liquid is trapped and forced through the pump by

the action of rotating screws. One of the rotors receives drive from the drive

shaft while the other rotor 'is driven by timing gears. The timing gears

synchronize the mesh of the non-contacting screws.

Fig .2.15 Rotary screw pumps

17

Chapter 2

Background in hydraulic systems

5.Rotary piston pumps:

In piston pumps, the pumping action is achieved by the reciprocating

action of pistons inside a cylinder-block. However, the reciprocating action is

directly imparted by a rotating member inside the pump and therefore these

pumps are generally classified under rotary pumps. Piston pumps are

categorized into radial piston or axial piston pumps. 'In the radial type the

pistons reciprocate in a direction radial to the cylinder-block axis, while in the

axial type the pistons reciprocate in-line to the cylinder-block axis. Piston

pumps are available in a wide range of capacities and can operate in medium to

high pressure ranges. They are well suited for hydraulic services.

Fig .2.16 Rotary piston pump

5.1.Radial piston

The pump has several pistons that are uniformly spaced apart and housed

radially in a cylinder block (piston-block). The pistons reciprocate in a direction

radial to the cylinder-block axis and hence the term "radial piston pumps",

In the pump design. The drive shaft transmits drive torque to the pistonblock by means cross of disc coupling. The piston-block rotates around a pintle,

which has ducts routed to inlet and outlet connections behind the pump. There

are several pistons arranged radially inside slots in the piston-block, which abut

against a stroke ring through slipper pads. The piston is connected to the slipper

pad by means of a ball and socket joint and the slipper pad is guided in the

stroke ring by means of two overlapping rings. The stroke ring is eccentrically

located with respect to the piston block.

18

Chapter 2

Background in hydraulic systems

Fig.2.17 Radial piston

5.2.Axial piston - in-line - swash plate:

The pump is of the axial piston type. Unlike the radial piston pump, the

design consists of several pistons that are located parallel to each other inside

slots in a piston-block and the pistons reciprocated axially inside the pistonblock. The drive shaft and the piston-block axis are in-line (collinear).

The pistons are made to bear against a swash plate by suitable

arrangements like springs or a shoe plate. The swash plate is inclined to the axis

of rotation.

As observed in the cut-section, the suction and discharge ports are semicircular holes in the valve plate.

As the driver shaft rotates, it transmits drive to the piston-block. As the

piston-block rotates, the pistons follow the angled stationary swash plate,

causing the pistons to reciprocate. At the suction side, along the direction of

rotation, the distance between the piston-block and swash plate increases and

the piston are pulled out, thus resulting in suction. Alternately, the pistons are

pushed in as they pass along the discharge port, thus resulting in discharge. This

reciprocating or the pistons as the drive shaft rotates results in the pumping of

the liquid.

19

Chapter 2

Background in hydraulic systems

Fig .2.18 Axial piston - in-line - swash plate

5.3. Axial piston- in-line - wobble plate:

The cross-section of a typical wobble plate pump is depicted. Like the

swash plate, this is also an in-line axial piston type of pump. There are several

pistons (only two are shown} arranged parallel to each other inside slots in a

piston-block. The drive shaft and the piston-block axis are in-line (collinear).

The pistons are made to bear against a wobble plate by using spring force.

The wobble plate is inclined to the axis of rotation. The main difference in the

working principle of the wobble plate pump when compared to the swash plate

pump is that, here the piston-block remains stationary while it is the wobble

plate that rotates

Fig .2.19 Axial piston- in-line - wobble plate pump

20

Chapter 2

Background in hydraulic systems

5.4. Axial piston bent axis:

Like the swash plate and wobble plate pump, this pump is also of the

axial piston type. There are several pistons that are parallel to each other and

reciprocate axially in a piston-block. However unlike the swash and wobble

plate pumps, the drive shaft is inclined at all angle to 'the piston-block and

hence the term 'bent axis".

The pistons are housed within slots in the piston-block and they are

connected to the drive shaft flange. A universal link keys the piston-block to the

drive shaft to maintain alignment and to assure that they rotate together.

As observed in the cut-section, the suction and discharge ports are semicircular holes in the valve plate,

AS the driver shaft rotates, it transmits drive to the pistons and pistonblock. At the suction side, along 'the direction of rotation, the distance between

the piston-block and driver shaft-flange increases and the pistons are pulled out,

thus resulting in suction. Alternately, the pistons are pushed in as they pass

along the discharge port, thus resulting in discharge. This reciprocation of the

pistons as the drive shaft rotates results in the pumping of the liquid.

Fig .2.20 Axial piston bent axis pump

21

Chapter 2

Background in hydraulic systems

B.RECIPROCATING PISTON PUMPS

1.Piston pump

Piston pumps utilize a piston to reciprocate inside a cylinder to achieve

the pumping action. The pistons have circumferential piston rings, to seal the

piston top end from the bottom end. A piston rod connects the piston to the

driving member. Piston pumps are either single-acting or double acting. In

single acting pumps the liquid is pumped at only one end of the piston, while in

double acting pumps the liquid is pumped at both ends resulting in two

discharge strokes in one cycle. The pumps may be of a single cylinder or

multicylincer design. Multicylincer pumps have two or more cylinders arranged

in parallel for increased capacity. Piston pumps are well suited as power pumps,

which have to deliver larger capacity at higher heads.

Fig .2.21 Piston pump

2.Plunger pump

Plunger pumps are similar in operation to piston pumps, except that they utilize

constant-diameter plungers, which reciprocate through packing glands. The

plungers are highly polished and made relatively long so that only very little

liquid can escape through the clearances. They do not utilize piston rings as in

piston pumps. Plunger pumps are always single-acting, that is, the liquid can be

pumped at only one end of the piston. The pumps may be of a single cylinder or

multicylincer design. Multicylincer pumps have two or more cylinders arranged

in parallel for increased capacity. Plunger pumps are very much used in

metering services and are also used as power pumps.

22

Chapter 2

Background in hydraulic systems

Fig .2.22 Plunger pump

3.Diaphragm pump

Diaphragm pumps perform similarity to piston I plunger pumps, but

the reciprocating driving member is a flexible diaphragm fabricated of metal,

rubber, or plastic, The diaphragm is flexed to-ano-fro, thus decreasing and

increasing volume in a chamber, resulting in the liquid to get sucked inside and

discharged alternately. The drive may be transmitted to the diaphragm by means

of a reciprocating plunger (piston). The plunger can receive direct mechanical

drive or may be driven by magnetic force .. In some designs, the diaphragm is

hydraulically actuated by the reciprocation of a plunger in power oil. The

diaphragm may also be pneumatically driven. These pumps offer a main

advantage in that, the diaphragm completely eliminates all packing and seals

exposed to the pumped liquid. Hence the pumps are very suitable to handle

hazardous or toxic liquids. Diaphragm pumps are used in metering services and

are also used as power pumps.

Fig .2.23 Diaphragm pump

23

Das könnte Ihnen auch gefallen

- Hydraulic Pumps PDFDokument13 SeitenHydraulic Pumps PDFramadan ali100% (1)

- Lecture 2-Hydraulic / PumpDokument23 SeitenLecture 2-Hydraulic / PumpyujNoch keine Bewertungen

- Chapter 2 Pu8mpDokument37 SeitenChapter 2 Pu8mpOld Oromo music museumNoch keine Bewertungen

- Hydraulic Pump BasicsDokument23 SeitenHydraulic Pump BasicsSACHIN PATELNoch keine Bewertungen

- pumpالسيمنرDokument15 Seitenpumpالسيمنرعبد الرحمن قاسم البناءNoch keine Bewertungen

- Week 8 Pumps and Earthing System NotesDokument18 SeitenWeek 8 Pumps and Earthing System NotesMohammed SaqibNoch keine Bewertungen

- Hydraulic Pumps ExplainedDokument5 SeitenHydraulic Pumps ExplainedabyzenNoch keine Bewertungen

- AIS Exp No 7Dokument3 SeitenAIS Exp No 7Abhijit SomnatheNoch keine Bewertungen

- CLSSDokument74 SeitenCLSSSurya Prakash100% (9)

- MCE416 Moodle 4 Three Topics Hydraulic PumpDokument42 SeitenMCE416 Moodle 4 Three Topics Hydraulic PumpPaul KonduNoch keine Bewertungen

- Lecture 7 PDFDokument15 SeitenLecture 7 PDFpsunmoorthyNoch keine Bewertungen

- Introduction to Wonji Shoa Sugar Factory Pump ClassificationsDokument27 SeitenIntroduction to Wonji Shoa Sugar Factory Pump ClassificationssenaNoch keine Bewertungen

- Seminar Types of PumpDokument21 SeitenSeminar Types of Pump05 Dhiraj AldarNoch keine Bewertungen

- D-Pumps-3rd ClassDokument40 SeitenD-Pumps-3rd ClassFaruq. MechanicNoch keine Bewertungen

- Hydraulic Pumps Explained: Gear, Vane & Gerotor TypesDokument18 SeitenHydraulic Pumps Explained: Gear, Vane & Gerotor TypesMohamed RashedNoch keine Bewertungen

- Centrifugal PumpDokument7 SeitenCentrifugal PumptanalialayubiNoch keine Bewertungen

- Hydraulic Pumps FAQDokument5 SeitenHydraulic Pumps FAQJatadhara GSNoch keine Bewertungen

- PumpsDokument11 SeitenPumpsamk3745Noch keine Bewertungen

- 131922671739312000Dokument24 Seiten131922671739312000Emmanuel KutaniNoch keine Bewertungen

- Hydraulic PumpsDokument19 SeitenHydraulic PumpsSENANAYAKE S.H.RNoch keine Bewertungen

- An Introduction To Pumping Equipment: Principle, Operation & MaintenanceDokument13 SeitenAn Introduction To Pumping Equipment: Principle, Operation & MaintenanceSiri NalNoch keine Bewertungen

- Hyd Micro ProjectDokument20 SeitenHyd Micro ProjectOmkar Moze CE - J1 - 88Noch keine Bewertungen

- Pumps Types and ClassificationsDokument29 SeitenPumps Types and ClassificationsTalha Nabi DarNoch keine Bewertungen

- Classification of PumpsDokument7 SeitenClassification of PumpsHarizal HamidNoch keine Bewertungen

- Classification of PumpsDokument23 SeitenClassification of PumpsRam Krishna SinghNoch keine Bewertungen

- Report No (1) Haydrulic MachinesDokument15 SeitenReport No (1) Haydrulic MachinesWesame Shnoda100% (1)

- pump 111Dokument44 Seitenpump 111m7394197Noch keine Bewertungen

- Chapter 2Dokument32 SeitenChapter 2Uzair MaswanNoch keine Bewertungen

- PumpssssssDokument19 SeitenPumpssssssJedz Tuluan Maslang IIINoch keine Bewertungen

- 5 7-PumpsDokument46 Seiten5 7-PumpsMohamed Rafeek GhaniNoch keine Bewertungen

- Lecture 6-7 Pumps and Pump DesignDokument68 SeitenLecture 6-7 Pumps and Pump Designbaruhiye0020Noch keine Bewertungen

- Hydraulic pumps explainedDokument22 SeitenHydraulic pumps explainedSiraj BusseNoch keine Bewertungen

- Pump Working PrinciplesDokument7 SeitenPump Working PrinciplesamirulbznNoch keine Bewertungen

- Centrifugal Pump: How it WorksDokument6 SeitenCentrifugal Pump: How it Works962943415xNoch keine Bewertungen

- Unit2 Cetrifugal PumpsDokument23 SeitenUnit2 Cetrifugal PumpseyobNoch keine Bewertungen

- Chapter 5Dokument24 SeitenChapter 5Bassant FadelNoch keine Bewertungen

- InducerDokument54 SeitenInducerYaswanthNoch keine Bewertungen

- Hydraulic Components - NotesDokument49 SeitenHydraulic Components - NotesRuth MwendaNoch keine Bewertungen

- Study of A Centrifugal Pump, Pipe Fittings and Valves - Ch.E 206Dokument30 SeitenStudy of A Centrifugal Pump, Pipe Fittings and Valves - Ch.E 206Synthia100% (1)

- Chapter 2:-Reciprocating Pump 2.1: IntroducationDokument7 SeitenChapter 2:-Reciprocating Pump 2.1: IntroducationParth VyasNoch keine Bewertungen

- Floating Cup PrincipleDokument27 SeitenFloating Cup Principlemanilrajkrr6302Noch keine Bewertungen

- 2.0 Rotodynamic PumpsDokument21 Seiten2.0 Rotodynamic Pumpsghgh140Noch keine Bewertungen

- Centrifugal PumpDokument4 SeitenCentrifugal PumpPt PrakashNoch keine Bewertungen

- Positive Displacement PumpDokument43 SeitenPositive Displacement Pumpvenkeeku100% (2)

- Hydraulic Pumps ExplainedDokument33 SeitenHydraulic Pumps ExplainedNebiyou KorraNoch keine Bewertungen

- Pumps - Hassan ElBanhawiDokument20 SeitenPumps - Hassan ElBanhawijesus_manrique2753Noch keine Bewertungen

- Me 2305 - Applied Hydraulics and Pneumatics Two Mark Question and Answer Unit - IiDokument4 SeitenMe 2305 - Applied Hydraulics and Pneumatics Two Mark Question and Answer Unit - IirajasekaranvgNoch keine Bewertungen

- Lesson 6 PumpsDokument9 SeitenLesson 6 PumpsBon Adrian IsabedraNoch keine Bewertungen

- Hydraulic and PneumaticDokument156 SeitenHydraulic and PneumaticbassemNoch keine Bewertungen

- Linear ActuatorsDokument4 SeitenLinear ActuatorsAndres Felipe Ospino CatañoNoch keine Bewertungen

- Sheet 3 SectionDokument6 SeitenSheet 3 SectionOmar HishamNoch keine Bewertungen

- Characteristic Features of Common Fluid Machines: Objective: Is To Transfer To A Flow MediumDokument26 SeitenCharacteristic Features of Common Fluid Machines: Objective: Is To Transfer To A Flow MediumYohannes EndaleNoch keine Bewertungen

- EMERGENCY STEERING IN SHIPDokument34 SeitenEMERGENCY STEERING IN SHIPMayilai AshokNoch keine Bewertungen

- Classification of PumpsDokument21 SeitenClassification of Pumpssharathchandra prabhuNoch keine Bewertungen

- Chapter 3Dokument17 SeitenChapter 3mohamedbadawyNoch keine Bewertungen

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineVon EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineBewertung: 5 von 5 Sternen5/5 (1)

- Siphons and The Siphon Effect - That Sucking Sound PDFDokument4 SeitenSiphons and The Siphon Effect - That Sucking Sound PDFtonylyfNoch keine Bewertungen

- Cenfarce PDFDokument4 SeitenCenfarce PDFNinad SherawalaNoch keine Bewertungen

- ChemicalHandling 9 PDFDokument20 SeitenChemicalHandling 9 PDFtonylyfNoch keine Bewertungen

- The Format of The 16-Section SDS Should Include The Following SectionsDokument20 SeitenThe Format of The 16-Section SDS Should Include The Following SectionstonylyfNoch keine Bewertungen

- ChemicalHandling 12 PDFDokument20 SeitenChemicalHandling 12 PDFtonylyfNoch keine Bewertungen

- 1.5 How Will The GHS Be Maintained and Updated?Dokument40 Seiten1.5 How Will The GHS Be Maintained and Updated?tonylyfNoch keine Bewertungen

- States With Approved PlansDokument20 SeitenStates With Approved PlanstonylyfNoch keine Bewertungen

- Pre Commission Cleaning of Pipework Systems (Sample)Dokument18 SeitenPre Commission Cleaning of Pipework Systems (Sample)tonylyfNoch keine Bewertungen

- ChemicalHandling 13 PDFDokument20 SeitenChemicalHandling 13 PDFtonylyfNoch keine Bewertungen

- Hazard Assessment Survey Data Sheet Example: Town of Sunflower, Public Works DepartmentDokument20 SeitenHazard Assessment Survey Data Sheet Example: Town of Sunflower, Public Works DepartmenttonylyfNoch keine Bewertungen

- ChemicalHandling 7 PDFDokument20 SeitenChemicalHandling 7 PDFtonylyfNoch keine Bewertungen

- ChemicalHandling 8 PDFDokument20 SeitenChemicalHandling 8 PDFtonylyfNoch keine Bewertungen

- 1.5 How Will The GHS Be Maintained and Updated?Dokument20 Seiten1.5 How Will The GHS Be Maintained and Updated?tonylyfNoch keine Bewertungen

- ChemicalHandling 5 PDFDokument20 SeitenChemicalHandling 5 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 14 PDFDokument20 SeitenBasicElectricity 14 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 15 PDFDokument18 SeitenBasicElectricity 15 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 13 PDFDokument20 SeitenBasicElectricity 13 PDFtonylyfNoch keine Bewertungen

- ChemicalHandling 2 PDFDokument20 SeitenChemicalHandling 2 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 12 PDFDokument20 SeitenBasicElectricity 12 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 10 PDFDokument20 SeitenBasicElectricity 10 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 1 PDFDokument20 SeitenBasicElectricity 1 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 7 PDFDokument20 SeitenBasicElectricity 7 PDFtonylyfNoch keine Bewertungen

- BacTSampling 13 PDFDokument20 SeitenBacTSampling 13 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 5 PDFDokument20 SeitenBasicElectricity 5 PDFtonylyfNoch keine Bewertungen

- BacTSampling 15 PDFDokument14 SeitenBacTSampling 15 PDFtonylyfNoch keine Bewertungen

- BacTSampling 10 PDFDokument20 SeitenBacTSampling 10 PDFtonylyfNoch keine Bewertungen

- BasicElectricity 4 PDFDokument20 SeitenBasicElectricity 4 PDFtonylyfNoch keine Bewertungen

- BacTSampling 14 PDFDokument20 SeitenBacTSampling 14 PDFtonylyfNoch keine Bewertungen

- BacTSampling 12 PDFDokument20 SeitenBacTSampling 12 PDFtonylyfNoch keine Bewertungen

- BacTSampling 6 PDFDokument20 SeitenBacTSampling 6 PDFtonylyfNoch keine Bewertungen

- Science 2010, 330, 933 (P450) PDFDokument6 SeitenScience 2010, 330, 933 (P450) PDFCarlotaNoch keine Bewertungen

- Student's blood bromide results analyzedDokument11 SeitenStudent's blood bromide results analyzedBio CeramicsNoch keine Bewertungen

- B-144 - Datasheet - PSVDokument6 SeitenB-144 - Datasheet - PSVRameez AhmedNoch keine Bewertungen

- Calculating Wind Loads on a Steel Mill BuildingDokument135 SeitenCalculating Wind Loads on a Steel Mill BuildingKaraline MarcesNoch keine Bewertungen

- Atomic Structure: Atomic Structure: Overview of Bohr's Atomic ModelDokument38 SeitenAtomic Structure: Atomic Structure: Overview of Bohr's Atomic Modelmanoj kumarNoch keine Bewertungen

- X Tan G : CE Review For Nov 2022 - Hydraulics 7Dokument1 SeiteX Tan G : CE Review For Nov 2022 - Hydraulics 7JuDeNoch keine Bewertungen

- Brochure DVE Laser Film 201505Dokument2 SeitenBrochure DVE Laser Film 201505RDII YANMEDRSDSNoch keine Bewertungen

- BNT Quartet BrochureDokument2 SeitenBNT Quartet BrochureAnonymous 0oFWTQFNoch keine Bewertungen

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDokument5 SeitenHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaNoch keine Bewertungen

- Aib - Ga75vsd+ Api868168Dokument104 SeitenAib - Ga75vsd+ Api868168SNOOPY YTNoch keine Bewertungen

- Introducción WPS ISODokument41 SeitenIntroducción WPS ISOCarlos Eduardo Castillo LanderosNoch keine Bewertungen

- Marcet BoilerDokument7 SeitenMarcet BoilerSt Oong100% (1)

- Corrosion SlidesDokument65 SeitenCorrosion SlidesAnshul ShuklaNoch keine Bewertungen

- Temp RTDDokument8 SeitenTemp RTDShambhavi VarmaNoch keine Bewertungen

- New Steel Construction Technical Digest 2019Dokument32 SeitenNew Steel Construction Technical Digest 2019tein teinNoch keine Bewertungen

- Heat Shrinking AllDokument46 SeitenHeat Shrinking AllCaylie KirbyNoch keine Bewertungen

- Polymers PDFDokument11 SeitenPolymers PDFMy StudymateNoch keine Bewertungen

- ETABS Examples ManualDokument50 SeitenETABS Examples ManualnasrNoch keine Bewertungen

- Dropped Object AnalysisDokument34 SeitenDropped Object AnalysisSivaNoch keine Bewertungen

- A Review of Methods of Molecular Weight Determination of PolymersDokument4 SeitenA Review of Methods of Molecular Weight Determination of PolymerspejvakNoch keine Bewertungen

- 1 StsumDokument2 Seiten1 StsumElleiram ArellanoNoch keine Bewertungen

- KO VesselDokument28 SeitenKO VesselMahroosh KhawajaNoch keine Bewertungen

- ChemistryDokument75 SeitenChemistrysureshNoch keine Bewertungen

- WPS - 006Dokument13 SeitenWPS - 006MAT-LIONNoch keine Bewertungen

- Pump CavitationDokument5 SeitenPump Cavitationjrri16Noch keine Bewertungen

- SNI 4658-2008-Pelek Kategori LDokument4 SeitenSNI 4658-2008-Pelek Kategori LDimazNugrahaNoch keine Bewertungen

- Lab 7-3 Interpreting Weather Station ModelsDokument4 SeitenLab 7-3 Interpreting Weather Station Modelsapi-55192583150% (2)

- Design of Concrete Structures 15th Edition Ebook PDFDokument61 SeitenDesign of Concrete Structures 15th Edition Ebook PDFmario.becker25297% (37)

- FP 17 32754 06Dokument3 SeitenFP 17 32754 06Murugan RaghuNoch keine Bewertungen

- Air-Cooled Chiller With Variable-Speed Screw Compressor: Performance InformationDokument2 SeitenAir-Cooled Chiller With Variable-Speed Screw Compressor: Performance InformationVu Manh ThangNoch keine Bewertungen