Beruflich Dokumente

Kultur Dokumente

Techniques For Breaking Free

Hochgeladen von

William's Mamani MancillaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Techniques For Breaking Free

Hochgeladen von

William's Mamani MancillaCopyright:

Verfügbare Formate

Techniques for Breaking Free

Prevention of stuck pipe s far more economic than even the best of freeing procedures. But

when prevention fails, the operator must move swiftly to select the most effective treatment.

Here are some basics of unsticking pipefrom pills to jarring to fishingthat may help speed

that decision.

Freeing stuck pipe involves finding the right combination of gentle persuasion and brute force.

Geitle persuasion involves changing downhole conditions to reduce sticking so the pipe conies

free on its own or is more responsive to force. And force is used when the holes gril) on the

pipe cannot be coaxed loose and must be overcome by a greater force.

Force is delivered by pulling on the pipe, slacking off or applying and holding torque. Stuck

pipe can also be banged free with a jaran impact device installed in the drill string that

delivers a blow up, down or both to free the pipe (see Jars, Jarring and Jar Placement, paxe

52), Repeatedly opening and closing the head valve in the mud pump several times causes

pressure surges in the mud flow that may also vibrate and shake the pipe free.

The tools of persuasion are spotting fluids, hole conditioning and changes in hydro slatic

pressure. A spotting fluid is a volume, or spill, of fluid containing ILibricants and surfactants

pumped downhole and placed in the annulus opposite the interval of pipe held by the

wellbore, the stuck point.

Diesel oil products prove successful half the time and are used most commonly, but

environmental agencies have recently encouraged use of less toxic mineral oils.2

Sorne major oil companies have abandoned diesel allogeiher. Regardless of which base is

used, spotting fluids contain additives that enable them to act as both a lubricant to help slide

pipe around bends and through tight spots, and as a surfactant to weaken cohesion between

the mudcake and pipe.

Occasionally, in carbonale formations a pill of 15 to 25% by vol time mud acid is used to

partially dissolve hole bridges, cuttings or sloughed formation. Hole conditioning once stuck

involves increasing mud flow rate or changing mud properties (such as density, solids and pH)

to enhance solids removal, such as a cuttings bed in a high-angle well or a plugged interval.

Reduction in hydrostatic pressure is used mainly to free differentially stuck pipe.

This can be achieved by lowering mud weight or the level of mud in the annulus if well

conditions permitno risk of gas in flow and good hole stability. An alternative is to U-tube

the drilipipe and annulus, leading to drainage of the annulus and, more elaborately, backing

off and installing a drillsteni test (DST) tool (see Freeing Stuck Pipe: An Overview of Two Tech

niques, next pase). An increase in hydro static pressure, by raising mud weigh, is used to

treat sticking in unconsolidated, mobile or geopressured formations.

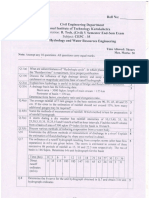

Ditterenti

al sticking

.

Sticking

occurs

when

drillstring Is stationary

. Drillstring cannot be rotated

or moved up or downor if

drillstring can be moved, high

overpull at connections and

while tripping, and high torque

rght after a connection.

Generafly no significant

pressure

variations

in

circulation

. Porous and impermeable

1, Stop or reduce circulation to lower

effective mud weight at stuck point.

Pull with maximum allowable force.

Start jarring at once at maximum force. Jar

upward for first hour then both ways. Try

rotating. Make elongation measurements

while varying pipe tension to estimate

location of stuck point.

2. As soon as possible, add surfactant slug

while working dnllstring.

Be sure to give the additive time to work

before washing out the slug.

zones present in the openhole

interval May be a depleted

zone.

3. If previous atterrts fail, hole is stable and

there Is no risk of gas inflow: (a) back off as

deep as possible, (b) run in with a DST tool

and screw into fish. Open tester for 1

minute; do not flow well. Ths relieves

differential pressure on formation der noflow condition.1

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Determination of Laminar Flame Speed of Diesel Fuel For Use in ADokument9 SeitenDetermination of Laminar Flame Speed of Diesel Fuel For Use in AOkta YamaNoch keine Bewertungen

- 4 Rules of Fired Heater OperationDokument17 Seiten4 Rules of Fired Heater OperationIman KhavvajiNoch keine Bewertungen

- Pressure Reduction Controller Afd / VFG 2, VFG 21, Vfgs 2: Data SheetDokument8 SeitenPressure Reduction Controller Afd / VFG 2, VFG 21, Vfgs 2: Data SheetDavid HayesNoch keine Bewertungen

- Permeability, Group 5aDokument21 SeitenPermeability, Group 5aComfort MaccarthyNoch keine Bewertungen

- Filtr PDFDokument10 SeitenFiltr PDFtiwaribcetNoch keine Bewertungen

- CFD Analysis of Flow and Heat Transfer in An Inclined Double-Glazing WindowDokument12 SeitenCFD Analysis of Flow and Heat Transfer in An Inclined Double-Glazing WindowEnis AtikNoch keine Bewertungen

- B.tech Dec2022 Civil CEPC-35 Sem5Dokument2 SeitenB.tech Dec2022 Civil CEPC-35 Sem5012 Diksha KumariNoch keine Bewertungen

- Detail Engineering MethodologyDokument11 SeitenDetail Engineering MethodologyKumarJR86100% (1)

- Charging Kit - PCMDokument2 SeitenCharging Kit - PCMSrikanth ReddyNoch keine Bewertungen

- BFC10403Dokument28 SeitenBFC10403Norhafizah Khairol Anuar0% (1)

- Air PreheaterDokument8 SeitenAir Preheaterabhishek01raiNoch keine Bewertungen

- 4th Quarter Exam PS 2019 2020Dokument2 Seiten4th Quarter Exam PS 2019 2020Franklin AdremesinNoch keine Bewertungen

- Rahmani NTRP 2009Dokument10 SeitenRahmani NTRP 2009Vignesh AlagesanNoch keine Bewertungen

- EXERCISE 1 - SolDokument19 SeitenEXERCISE 1 - SolkelvinNoch keine Bewertungen

- Paten Asm Astat Dari Asetaldehid TH1975Dokument4 SeitenPaten Asm Astat Dari Asetaldehid TH1975Agus PurnamaNoch keine Bewertungen

- An Overview of The Hydraulics of Water Distribution NetworksDokument35 SeitenAn Overview of The Hydraulics of Water Distribution NetworksBoos yousufNoch keine Bewertungen

- Hydraulics TrainingDokument47 SeitenHydraulics Trainingmdhyderali100% (4)

- Manual de Transmisión de CalorDokument36 SeitenManual de Transmisión de CalorLuis Alfonso Martinez FdezNoch keine Bewertungen

- Amot ValvesDokument10 SeitenAmot Valvesenop75Noch keine Bewertungen

- Designing A Divided Wall ColumnDokument12 SeitenDesigning A Divided Wall ColumnArash AbbasiNoch keine Bewertungen

- Sedimentation Practicum - Unit Operation in Enviornmental EngineeringDokument23 SeitenSedimentation Practicum - Unit Operation in Enviornmental EngineeringNaufal BariqueNoch keine Bewertungen

- Flare Gas 1Dokument21 SeitenFlare Gas 1AKASH BNoch keine Bewertungen

- EXPIIDokument2 SeitenEXPIIsamsularief03Noch keine Bewertungen

- 7.4 Le Chatelier Notes StudentDokument6 Seiten7.4 Le Chatelier Notes StudentMichelle NgNoch keine Bewertungen

- Transfer de Caldura Si MasaDokument75 SeitenTransfer de Caldura Si Masavele2ionutNoch keine Bewertungen

- Btech Ce 3 Sem Fluid Mechanics Kce303 2021Dokument2 SeitenBtech Ce 3 Sem Fluid Mechanics Kce303 2021akash GuptaNoch keine Bewertungen

- MEC551 Thermal Engineering Heat ExchangerDokument95 SeitenMEC551 Thermal Engineering Heat ExchangerFaris HalimNoch keine Bewertungen

- Uop7mkii PDFDokument4 SeitenUop7mkii PDFalijadoonNoch keine Bewertungen

- Exp 1 PhenDokument5 SeitenExp 1 Phensoran najebNoch keine Bewertungen

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDokument14 SeitenLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezNoch keine Bewertungen