Beruflich Dokumente

Kultur Dokumente

NDT Scope

Hochgeladen von

Anonymous AdofXEYAgE0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

94 Ansichten2 Seitendsadasdasd

Originaltitel

ndt scope

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldendsadasdasd

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

94 Ansichten2 SeitenNDT Scope

Hochgeladen von

Anonymous AdofXEYAgEdsadasdasd

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Non-Destructive Testing (as applicable):

.3

a)

NDT shall be done as per approved field assurance plan (FQP), approved field

welding schedule (FWS) and applicable codes/standards.

b)

All NDT shall be carried out after PWHT of weld joints.

c)

Sampling procedure for testing of weld joints by NDT shall be as per annexureI.

ANNEXURE-I

SAMPLING PROCEDURE FOR TESTING OF WELD JOINTS BY NDT

Whenever the quantum of check of weld joints by any NDT method is less than 100%,

following procedure for sampling / re-sampling welds for Non-Destructive testing shall be

followed:a) The group of welds for sampling shall be based on welding done by a welder in specified

continuous time (in a shift or in a day). For acceptance or rejection or for any analysis,

this group of welds shall be treated as an entity. For the purpose of sampling, group of

weld shall be defined as nos. of welds for Pipes/Tubes up to 100mm nominal bore and

small welds in any structures while for other, length of weld may be taken as basic unit.

Accordingly sampling shall be carried out in terms of nos. of weld joints or length of

weld.

b) From above weld group, selection of weld joint/weld spot shall be done by APML FQA

inspection engineer per quantum of check specified in approved Field Quality Plan,

Project specification, Field welding schedule and drawing.

c) For acceptance of welds, all samples selected from the group should meet the acceptance

norms of weld. In case of any sample(s) fails to meet the acceptance norms, following

action shall be taken:i) Rectification of defective welds and re-testing after repair.

ii)Re-sampling by APML FQA inspection engineer from the same group of

welds, with quantum of NDT being double of originally specified quantum of

check (with minimum two welds for every defective weld).

d) In case of any weld , re-sampled as per c-(ii) above, found not meeting the acceptance

norms, following action shall be taken:i) NDT of all welds of the group, which were not tested during first and second

sampling.

ii) Repair and retesting of all defective welds.

iii) Necessary action to be taken to improve the welding process and skill of

welder for eliminating recurrence of defects.

e) From the time of readiness of weld group, suitable time limit shall be prescribed for first

sampling test, re-sampling, repairing, re-testing etc. (normally not more than one days

backlog should be piled up at every step).

{Illustration:-Radiography of weld:- welding completed on Day-1, should be

tested by Day-2 and repairing & re-sampling of the group should be done by

Day-3 and further testing/repair should be completed by Day-4)}.

f)

Sampling and re-sampling procedure as specified above shall be applicable for all

NDT viz RT, UT, PT, and MT.

Das könnte Ihnen auch gefallen

- LTA Specs For CouplersDokument4 SeitenLTA Specs For CouplerssawwahwahNoch keine Bewertungen

- Pipeline welding practices guideDokument14 SeitenPipeline welding practices guideYersin Hernandez AldanNoch keine Bewertungen

- Welder Performance QualificationDokument31 SeitenWelder Performance QualificationParvee K Nakwal100% (3)

- AnnexureDokument3 SeitenAnnexureqamarNoch keine Bewertungen

- Welder Performance Qualification AsmeDokument14 SeitenWelder Performance Qualification AsmeAhmad RizkiNoch keine Bewertungen

- C1Dokument23 SeitenC1khairy2013Noch keine Bewertungen

- 2-Asme BPVC Section Ix-2013Dokument2 Seiten2-Asme BPVC Section Ix-2013Reda ElsawyNoch keine Bewertungen

- Note 7 - Welder Test - Mechanical Test and X-RayDokument29 SeitenNote 7 - Welder Test - Mechanical Test and X-RayMohamad Yusuf HelmiNoch keine Bewertungen

- IBR 73-80 Steel CastingsDokument5 SeitenIBR 73-80 Steel CastingsRajivharolikarNoch keine Bewertungen

- Welding Operator QualificationDokument3 SeitenWelding Operator QualificationHasnain TariqNoch keine Bewertungen

- Enbridge Pipeline Repair Workplan Welding PDFDokument23 SeitenEnbridge Pipeline Repair Workplan Welding PDFquiron2014Noch keine Bewertungen

- Eddy Current SpecificationsDokument7 SeitenEddy Current SpecificationsBhavani PrasadNoch keine Bewertungen

- Page 40 From API-1104-2016Dokument1 SeitePage 40 From API-1104-2016Riaz AhmadNoch keine Bewertungen

- Enbridge Pipeline Repair Workplan WeldingDokument23 SeitenEnbridge Pipeline Repair Workplan WeldingJesus MaestreNoch keine Bewertungen

- S18-CnS Splice Sleeve PDFDokument2 SeitenS18-CnS Splice Sleeve PDFLukeNoch keine Bewertungen

- 01 Samss 022Dokument6 Seiten01 Samss 022aamirtec301Noch keine Bewertungen

- Part2 Notice 1Dokument21 SeitenPart2 Notice 1Danem Halas100% (1)

- 1 0 ITP Pole Inspection and Test Plan R1Dokument7 Seiten1 0 ITP Pole Inspection and Test Plan R1omarqasimNoch keine Bewertungen

- Thermite WeldingDokument10 SeitenThermite WeldingOmid BeygiNoch keine Bewertungen

- Asme Section IxDokument71 SeitenAsme Section Ixranjitkumar1977100% (1)

- NDT of WeldsDokument4 SeitenNDT of WeldsVu Tung Linh100% (2)

- Astm D2290-00Dokument5 SeitenAstm D2290-00T Mathew TholoorNoch keine Bewertungen

- NDT For Steel Pipe PilingDokument2 SeitenNDT For Steel Pipe PilingSaid Alauddeen FaiszNoch keine Bewertungen

- Building Standards ActDokument2 SeitenBuilding Standards ActLungisaniNoch keine Bewertungen

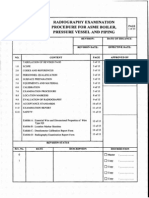

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingDokument15 SeitenRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- ASME Section IX Welding Qualification RequirementsDokument5 SeitenASME Section IX Welding Qualification Requirementskirubha_karan2000Noch keine Bewertungen

- G10 PDFDokument3 SeitenG10 PDFSameer Sa100% (1)

- Sti - Is - 3589Dokument5 SeitenSti - Is - 3589hhr2412Noch keine Bewertungen

- Concrete Pole Inspection & Test PlanDokument7 SeitenConcrete Pole Inspection & Test PlaniobtecNoch keine Bewertungen

- API 650 12th Edition 2013 PTDokument2 SeitenAPI 650 12th Edition 2013 PTRonel John Rodriguez CustodioNoch keine Bewertungen

- Measuring Length of Concrete Cores: Standard Test Method ForDokument3 SeitenMeasuring Length of Concrete Cores: Standard Test Method ForJesus Luis Arce GuillermoNoch keine Bewertungen

- PCNGENC1Dokument23 SeitenPCNGENC1Pubg addictedNoch keine Bewertungen

- LAB22 Ed 1Dokument9 SeitenLAB22 Ed 1yasiribrahim85Noch keine Bewertungen

- Dimensional Control ProcedureDokument12 SeitenDimensional Control ProcedureBethel NdifonNoch keine Bewertungen

- Saep 1146Dokument8 SeitenSaep 1146Ronanki RaviNoch keine Bewertungen

- Section 1 General Requirements: 1.1 ScopeDokument5 SeitenSection 1 General Requirements: 1.1 ScopethanghanvicoNoch keine Bewertungen

- C1 For UTDokument23 SeitenC1 For UTMung Duong XuanNoch keine Bewertungen

- PCNGENC1Dokument23 SeitenPCNGENC1thinhlvtNoch keine Bewertungen

- ASTM D 2290Dokument5 SeitenASTM D 2290Pablo AlcázarNoch keine Bewertungen

- Proc SopDokument90 SeitenProc SopJohn Dolan100% (1)

- 3600 1Dokument2 Seiten3600 1shanmugasundaram_rNoch keine Bewertungen

- API 570 Final Exam ClosedDokument12 SeitenAPI 570 Final Exam Closedtbmari100% (3)

- Appendix 1 Part 1b Ultrasonic AUT & MEPAUT 4th Edition February 2016Dokument17 SeitenAppendix 1 Part 1b Ultrasonic AUT & MEPAUT 4th Edition February 2016Brandon EricksonNoch keine Bewertungen

- d6347 d6347m 05Dokument18 Seitend6347 d6347m 05Kanwar P SinghNoch keine Bewertungen

- Monitoring and testing of roof bolts in coal minesDokument2 SeitenMonitoring and testing of roof bolts in coal minesshadeNoch keine Bewertungen

- C 233 Â " 00 QZIZMY1SRUQDokument6 SeitenC 233 Â " 00 QZIZMY1SRUQJorge CarrascoNoch keine Bewertungen

- Collapse Tests of Pipe Casing and Tubing: February 2000Dokument10 SeitenCollapse Tests of Pipe Casing and Tubing: February 2000Ankit LonareNoch keine Bewertungen

- IACS - REC - 20 NDT of Ship Hull Steel StructuresDokument11 SeitenIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tnNoch keine Bewertungen

- Asme-Ix PDFDokument9 SeitenAsme-Ix PDFMuhammad ThohirNoch keine Bewertungen

- Contract SpecificationsDokument23 SeitenContract SpecificationsAbriel RiveraNoch keine Bewertungen

- C1719-11 (Vacuum) Test Prior To BackfillDokument2 SeitenC1719-11 (Vacuum) Test Prior To Backfilldiego rodriguezNoch keine Bewertungen

- D 7003 - 03Dokument2 SeitenD 7003 - 03luis-12Noch keine Bewertungen

- Api 570Dokument2 SeitenApi 570Andriani 'andin' Karunia PrameiswariNoch keine Bewertungen

- D 6768 - 03Dokument3 SeitenD 6768 - 03luis-12Noch keine Bewertungen

- API 510 Exam May 2016Dokument5 SeitenAPI 510 Exam May 2016abdoNoch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Applied Metrology for Manufacturing EngineeringVon EverandApplied Metrology for Manufacturing EngineeringBewertung: 5 von 5 Sternen5/5 (1)

- Digital Circuit Testing: A Guide to DFT and Other TechniquesVon EverandDigital Circuit Testing: A Guide to DFT and Other TechniquesNoch keine Bewertungen

- Kurma Rao Saini - CVDokument1 SeiteKurma Rao Saini - CVAnonymous AdofXEYAgENoch keine Bewertungen

- 7.interview PersonalDokument1 Seite7.interview PersonalAnonymous AdofXEYAgENoch keine Bewertungen

- Kurma Rao Saini - Introduction Form040Dokument2 SeitenKurma Rao Saini - Introduction Form040Anonymous AdofXEYAgENoch keine Bewertungen

- Kurma Rao Saini - Qualification Certificate044Dokument10 SeitenKurma Rao Saini - Qualification Certificate044Anonymous AdofXEYAgENoch keine Bewertungen

- Kommuji Eswar A Rao - Intro FormDokument2 SeitenKommuji Eswar A Rao - Intro FormAnonymous AdofXEYAgENoch keine Bewertungen

- JD FormDokument1 SeiteJD FormAnonymous AdofXEYAgENoch keine Bewertungen

- JD FormDokument1 SeiteJD FormAnonymous AdofXEYAgENoch keine Bewertungen

- Kurma Rao Saini - CVDokument1 SeiteKurma Rao Saini - CVAnonymous AdofXEYAgENoch keine Bewertungen

- JD FormDokument1 SeiteJD FormAnonymous AdofXEYAgENoch keine Bewertungen

- Mohammad Mukhtar Ali-CvDokument15 SeitenMohammad Mukhtar Ali-CvAnonymous AdofXEYAgENoch keine Bewertungen

- Vantakula Rambabu-Resume PDFDokument1 SeiteVantakula Rambabu-Resume PDFAnonymous AdofXEYAgENoch keine Bewertungen

- Pyarechand Kumar - Qualification Certificate064Dokument1 SeitePyarechand Kumar - Qualification Certificate064Anonymous AdofXEYAgENoch keine Bewertungen

- Vantakula Rambabu-Experience CertificatesDokument10 SeitenVantakula Rambabu-Experience CertificatesAnonymous AdofXEYAgENoch keine Bewertungen

- Intro FormDokument2 SeitenIntro FormAnonymous AdofXEYAgENoch keine Bewertungen

- Receipt Report IE-2485530Dokument1 SeiteReceipt Report IE-2485530Anonymous AdofXEYAgENoch keine Bewertungen

- Pandi Devaraju Reddy p6303778 CVDokument36 SeitenPandi Devaraju Reddy p6303778 CVAnonymous AdofXEYAgENoch keine Bewertungen

- Pradhan Bhagirathi CVDokument1 SeitePradhan Bhagirathi CVAnonymous AdofXEYAgENoch keine Bewertungen

- Behra Dombo l9997839 CVDokument28 SeitenBehra Dombo l9997839 CVAnonymous AdofXEYAgENoch keine Bewertungen

- 1144 TWI Diploma in Welding Engineering July 2012 PDFDokument1 Seite1144 TWI Diploma in Welding Engineering July 2012 PDFdaimaheshNoch keine Bewertungen

- Department of Clinical Biochemistry Liver Function TestDokument1 SeiteDepartment of Clinical Biochemistry Liver Function TestAnonymous AdofXEYAgENoch keine Bewertungen

- Bus Service 103Dokument2 SeitenBus Service 103Anonymous AdofXEYAgENoch keine Bewertungen

- Rabindra Nayak - Qualification Certificate025Dokument6 SeitenRabindra Nayak - Qualification Certificate025Anonymous AdofXEYAgENoch keine Bewertungen

- Pradhan Bhagirathi - JD Manpower FormDokument1 SeitePradhan Bhagirathi - JD Manpower FormAnonymous AdofXEYAgENoch keine Bewertungen

- Agent Application FormDokument1 SeiteAgent Application FormAnonymous AdofXEYAgENoch keine Bewertungen

- Transcript of Marks: Name: Date of BirthDokument2 SeitenTranscript of Marks: Name: Date of BirthAnonymous AdofXEYAgENoch keine Bewertungen

- Agent Profile SheetDokument1 SeiteAgent Profile SheetAnonymous AdofXEYAgENoch keine Bewertungen

- Transcript of Mark List: Harish RDokument2 SeitenTranscript of Mark List: Harish RAnonymous AdofXEYAgENoch keine Bewertungen

- String Weave and Heat InputDokument4 SeitenString Weave and Heat InputAnonymous AdofXEYAgENoch keine Bewertungen

- Curriculum Vitae HariprasadDokument2 SeitenCurriculum Vitae HariprasadAnonymous AdofXEYAgENoch keine Bewertungen

- BPVC-IX-Interp Stnd-63 2015 Jan PDFDokument6 SeitenBPVC-IX-Interp Stnd-63 2015 Jan PDFAnonymous AdofXEYAgENoch keine Bewertungen

- Betriebsanleitung Operating Instructions GLOBALlift R ATE V01R00 EN 2Dokument14 SeitenBetriebsanleitung Operating Instructions GLOBALlift R ATE V01R00 EN 2Alexandru RizescuNoch keine Bewertungen

- My Study Plan Guide For AmcDokument7 SeitenMy Study Plan Guide For Amc0d&H 8Noch keine Bewertungen

- Homes & Diamonds of Liz TaylorDokument42 SeitenHomes & Diamonds of Liz TaylorFridayFunStuffNoch keine Bewertungen

- 22Dokument22 Seiten22vanhau24Noch keine Bewertungen

- Manual NSD70D EnglishDokument155 SeitenManual NSD70D Englishnarvis1Noch keine Bewertungen

- wk4 Stdconferencereflection ElmoreajaDokument4 Seitenwk4 Stdconferencereflection Elmoreajaapi-316378224Noch keine Bewertungen

- Report Information From Proquest: February 24 2014 06:18Dokument19 SeitenReport Information From Proquest: February 24 2014 06:18Emma Elena StroeNoch keine Bewertungen

- Reglas para Añadir Al Verbo Principal: Am Is Are ReadDokument8 SeitenReglas para Añadir Al Verbo Principal: Am Is Are ReadBrandon Sneider Garcia AriasNoch keine Bewertungen

- Case Study - BronchopneumoniaDokument45 SeitenCase Study - Bronchopneumoniazeverino castillo91% (33)

- RL Procedure Hard Natural Rubber PT - SURYA SAKTI SUKSESDokument7 SeitenRL Procedure Hard Natural Rubber PT - SURYA SAKTI SUKSESMuhammad ZakiNoch keine Bewertungen

- XFY1548移动式筛分站术规格书Dokument16 SeitenXFY1548移动式筛分站术规格书abangNoch keine Bewertungen

- Dasar Genetik GandumDokument282 SeitenDasar Genetik GandumAlekkyNoch keine Bewertungen

- Properties of X-Rays and Gamma RaysDokument13 SeitenProperties of X-Rays and Gamma RaysjishnusajiNoch keine Bewertungen

- High Containment Labs and Other Facilities of The US Bio Defense ProgramDokument1 SeiteHigh Containment Labs and Other Facilities of The US Bio Defense ProgramHRCNoch keine Bewertungen

- Shell Alexia 40 cylinder oil designed for IMO 2020 complianceDokument2 SeitenShell Alexia 40 cylinder oil designed for IMO 2020 complianceStefas DimitriosNoch keine Bewertungen

- Dermato Venerology ScienceDokument11 SeitenDermato Venerology ScienceAQis AQishNoch keine Bewertungen

- Step by Step To The Perfect PedicureDokument6 SeitenStep by Step To The Perfect PedicurepinkyNoch keine Bewertungen

- Police Constable - GK MCQsDokument56 SeitenPolice Constable - GK MCQsSk Abdur RahmanNoch keine Bewertungen

- LENZE E84AVxCx - 8400 StateLine-HighLine-TopLine 0.25-45kW - v9-0 - ENDokument291 SeitenLENZE E84AVxCx - 8400 StateLine-HighLine-TopLine 0.25-45kW - v9-0 - ENClaudioNoch keine Bewertungen

- Humiseal Thinner 73 MSDSDokument3 SeitenHumiseal Thinner 73 MSDSibnu Groho Herry sampurnoNoch keine Bewertungen

- Evonik-BREAK THRU Brochure Microbials EN Asset 2214205Dokument5 SeitenEvonik-BREAK THRU Brochure Microbials EN Asset 2214205李雷Noch keine Bewertungen

- The Human Excretory System: A 40-Character GuideDokument3 SeitenThe Human Excretory System: A 40-Character GuideMelvel John Nobleza AmarilloNoch keine Bewertungen

- Mulching Paper Laying Machine SynopsisDokument17 SeitenMulching Paper Laying Machine SynopsisSiddhesh Zirpe50% (2)

- The Following Present A List of Different Attributes and Rules For Assigning Numbers To Objects. Try ToDokument4 SeitenThe Following Present A List of Different Attributes and Rules For Assigning Numbers To Objects. Try Togetacdeme2011Noch keine Bewertungen

- FAQ For Company Law 2013Dokument24 SeitenFAQ For Company Law 2013Archanat07100% (1)

- Entrenamiento de Fuerza y Salud Pediátrica Ingles PDFDokument9 SeitenEntrenamiento de Fuerza y Salud Pediátrica Ingles PDFGiiovanny PardoNoch keine Bewertungen

- Series NRX With PXR - Type NF Low Voltage Power (Air) Circuit Breaker Instruction ManualDokument70 SeitenSeries NRX With PXR - Type NF Low Voltage Power (Air) Circuit Breaker Instruction ManualHamilton GutierrezNoch keine Bewertungen

- Optimize soil preparation with a versatile mini tillerDokument2 SeitenOptimize soil preparation with a versatile mini tillerRickson Viahul Rayan C100% (1)

- CEP Lesson Plan Form: Colorado State University College of Health and Human Sciences Page 1Dokument13 SeitenCEP Lesson Plan Form: Colorado State University College of Health and Human Sciences Page 1Apple AterradoNoch keine Bewertungen

- Three-Phase SCR Battery Charger Installation GuideDokument20 SeitenThree-Phase SCR Battery Charger Installation GuideJohnTPNoch keine Bewertungen