Beruflich Dokumente

Kultur Dokumente

Method Statement - Piling Work

Hochgeladen von

LookCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method Statement - Piling Work

Hochgeladen von

LookCopyright:

Verfügbare Formate

METHOD STATEMENT FOR PILING WORKS (OVERCROSSING PIPE)

PROJECT: PACKAGE 3-CONSTRUCTION AND COMPLETION OF 9ML BUKIT TAISHO RESERVOIR,

SUPPLY AND LAYING OF MILD STEEL PIPES TO BUKIT GENTAM RESERVOIR

A. OBJECTIVE

1) To outline the sequence of work or construction methodology

for Piling Works at Sg Jempol, Sg Pelangai and Sg Jemapoh

.Methodology starts from survey setting out until excess pile

cutting until as-built drawing submission for Consultant

review.

2) To outline preparation or coordination required before start

work

3) To outline quality plan or inspection test required during

project implementation.

4) To perform safe working environment and compliance to the

safety requirements.

B. SCOPE OF WORK

In general scope of work for this work method statement cover the

following:Scope of Works

Piling Works (Drop

hammer method)

Methodology starts

from pile position

setting out until asbuilt preparation for

Consultant review.

Descriptions / Details

Piling Works (Drop Hammer Method) consist

of the following items;

Soil Investigation

Survey Setting Out

Pile Driving and Pile Jointing

(welding)

Piling Records

Pile Cutting

As-built (Actual Piles Position)

Prepared by Surveyor

C. REFERENCES

BS 8004- Foundation

METHOD STATEMENT FOR PILING WORKS (OVERCROSSING PIPE)

PROJECT: PACKAGE 3-CONSTRUCTION AND COMPLETION OF 9ML BUKIT TAISHO RESERVOIR,

SUPPLY AND LAYING OF MILD STEEL PIPES TO BUKIT GENTAM RESERVOIR

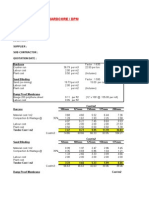

D. RECOURCES PLANNING

Material Planning

Item

Material Descriptions

1

R.C Pile (250 x 250)

2

Pile Head / Pile Toe for pile joints

Manpower Planning

Ite

m

1

2

3

4

Manpower Descriptions

Project Manager

Project Engineer / Supervisor / Surveyor

Machine Operator

Skilled and Semi Skilled Workers

Machinery & Equipment Planning

Item

1

2

3

4

Machinery & Equipment Descriptions

Drop Hammer

Pile Cutter Machine

Mobile Crane

Welding Machine with welding consumable

E. MATERIAL HANDLING & DELIVERY INSPECTION

Material Handling

a) RC Pile (Square/ Spun Piles) All material shall be loaded and

unloaded with care by mobile crane or other type of suitable

machinery to avoid pile damaged. Materials shall be placed

where the materials are not obstructing the main road access

in order to prevent material double handlings.

b) All material shall be stacked on top of the piece of timber

with proper timber shim to prevent material damaged or easy

material lifting.

Material Delivery Inspection: Checking Methodology

Material

RC Pile

(Square/

Spun) and

others

accessories

Items to be Checked or Inspected

R.C Pile shall be: Correct Specification/ Grade

Correct Size

Material delivered in good

condition, no damaged.

All accessories shall be

available and ready for use.

Method of

Inspection

Visual

Check &

Random

Sampling

METHOD STATEMENT FOR PILING WORKS (OVERCROSSING PIPE)

PROJECT: PACKAGE 3-CONSTRUCTION AND COMPLETION OF 9ML BUKIT TAISHO RESERVOIR,

SUPPLY AND LAYING OF MILD STEEL PIPES TO BUKIT GENTAM RESERVOIR

F. COORDINATION BETWEEN OTHER TRADES

1) Coordination between Others Architecture Trades (NOT APPLICABLE)

2) Coordination between Others C&S Trades (NOT APPLICABLE)

3) Coordination between Others M&E Trades (NOT APPLICABLE)

METHOD STATEMENT FOR PILING WORKS (OVERCROSSING PIPE)

PROJECT: PACKAGE 3-CONSTRUCTION AND COMPLETION OF 9ML BUKIT TAISHO RESERVOIR,

SUPPLY AND LAYING OF MILD STEEL PIPES TO BUKIT GENTAM RESERVOIR

G. WORK METHODOLOGY

1) Soil Investigation

2) Survey Setting Out (Pile Position)

The surveyor will set out the alignment of the pipe by means

of EDM using the marking on the piles and the pump house

as a reference point.

Lower down the pile into position as in above step by using

crane mounted piling frame and adjust the position and

vertically of the pile with the aid of the surveyor.

Liaise with Consultant or Client representative to conduct

joint inspection.

3) Pile Driving and Pile Jointing

The steel pipe piles will be sand blast to removed dirt &

grease on the pipe then a layer of hot bitumen coating will be

apply on the body of the piles.

Piles shall be driven by using 1.5 tonne drop hammer type by

follow the Calculation of Setting.

Positioning Pile Machine: Piling base machine shall be placed

manoeuvre to align with the piling points.

Placement of the Pile: the initial pile segment is pitched using

a low speed hydraulic winch and then the pile is placed into

the guide or chamber of the piling machine.

Pile is driven into the ground by the drop hammer.

The driven pile should be maintained straight in line at all the

times.

Piles should not deviate more than 75mm from their designed

positions as at the working level of the piling rig.

Extension Pile: When the initial pile segment is driven close to

ground, operator shall stop driving and install the second

piles into the position for jointing.

Pile shall be jointed by using welding the mild steel plate

between piles.

Continue Pile Driving Process until Set.

Pile driving process repeated until the required resistance to

pile penetration is achieved, or the required pre-determined

penetration depth is reached. The setting is achieved when

the set taken for the final 10 blows of the hammer is within

the set as calculated. (Refer calculation attach)

4) Piling Records

All the pile reading shall be recorded in the Pile Record

Form.

All pile records shall be checked correct and signed by

relevant C&S consultant or Client representative.

5) Pile Cutting

Excess piles length shall be cut according to the piling CutOff-Level.

4

METHOD STATEMENT FOR PILING WORKS (OVERCROSSING PIPE)

PROJECT: PACKAGE 3-CONSTRUCTION AND COMPLETION OF 9ML BUKIT TAISHO RESERVOIR,

SUPPLY AND LAYING OF MILD STEEL PIPES TO BUKIT GENTAM RESERVOIR

Suitable type of pile cutter machine shall be used to ensure

pile not damaged during pile cutting process.

All the excess piles shall be collected and removed away from

site.

6) As-built (Actual Piles Position) Prepared by Surveyor

Actual piles position shall be recorded by surveyor in the

survey book.

From the actual data taken at site, surveyor will plot the Pile

As-built Drawing for C&S Design Consultant review.

If any piles out of construction tolerance (the piles should be

driven as accurately as possible to vertical or the specified

rake- piles should not more than 75mm from their design),

rectification shall be carried out according to C&S Design

Consultant instructions.

METHOD STATEMENT FOR PILING WORKS (OVERCROSSING PIPE)

PROJECT: PACKAGE 3-CONSTRUCTION AND COMPLETION OF 9ML BUKIT TAISHO RESERVOIR,

SUPPLY AND LAYING OF MILD STEEL PIPES TO BUKIT GENTAM RESERVOIR

H. QUALITY: INSPECTION & TEST PLAN

Inspection & Test Plan

No

Stage of

Work

Material

Selection

Sample

Submissio

n

(If

applicable

)

Material

Delivery

Survey

Setting

Out

(Boundary

/ pile

position

pegs)

Pile Jacked

In ( Drop

Hammer

Method)

Frequency

Once

Once

Checking Required

Check material to

be used (Grade/

Size): RC Piles either

square piles or

spun piles

Material Product

Brochure

submission

approved by Client

Method

Acceptance

Review

Catalogue

or relevant

test

certificate

Material as

per Project

Specification/

Requirements

Sample

Submission

Form /

Letter

Approved by

Client

Material as

per spec,

good

conditions

and no

damaged.

Every

Delivery

Material delivered

as per material

order, No Damaged

(Quantity, Quality &

Spec)

During

Survey

Setting

Out

Mark and Check: Building

Boundary

Pile Position

Pile (Cut-Off

Level)

Visual Check

Pegs per

& Random

construction

Measureme

drawing

nt

Before Pile

Jacked In

Process

Check initial piles

Correct Size

Correct Grade

Correct Positions

Straight

Alignment

(Pile/Helmet/Ha

mmer)

Pile driving as

per

construction

Visual Check drawing and

visually

straight

alignment

During Pile

Jacked In

and Pile

Jointing

Check the all in

straight alignment

and joint

satisfactorily done

Ensure all pile

records in Pile

Records Form

6

Random

Sampling

Check

Visually

straight

alignment

Visual Check and pile joint

was

satisfactory

done

Visual Check Proper

& Recorded records with

authorized

METHOD STATEMENT FOR PILING WORKS (OVERCROSSING PIPE)

PROJECT: PACKAGE 3-CONSTRUCTION AND COMPLETION OF 9ML BUKIT TAISHO RESERVOIR,

SUPPLY AND LAYING OF MILD STEEL PIPES TO BUKIT GENTAM RESERVOIR

signature

Upon

completio

n of piling

works

Pile

Cutting

As-Built:

Data &

Info:

plotting

and

Consultant

submissio

n

Upon

completio

n of pile

cutting

Check the

following: All the piles shall

be cut follow the

marked CutOff-Level

Suitable

machine

Surveys pick up info

and data for AsBuilt drawing

preparation and

submission.

As-built review by

C&S Design

Consultant

Visual &

Measured

Field Survey

and plotting

Review AsBuilt

Drawing

Pile cutting as

per Cut-OffLevel and

suitable pile

cutter

machine, No

pile damaged.

All piles within

construction

tolerances/

Acceptable by

Consultant

Relevant Construction Standard & References

NIL

QC Documents or Relevant Checklist

Attachment B: Inspection Checklist for Pile Records Form

I. OCCUPATIONAL SAFETY AND HEALTH (OSH)

All occupational safety and health (OSH) measures shall be as per

FACTORY AND MACHINERY ACT 1967 under: Building Operation and Works of Engineering Construction

(BOWEC) Safety Regulations 1986. Relevant Regulations

further details please refer to the following regulations: Part II : General Provision

Part XII : Excavation Work

Part IX : Material Handling and Storage, Use and

Disposal

Part XVI : Hand and Power Tools

J. ATTACHMENT

Appendix A : Inspection Checklist for Pile Records Form

Das könnte Ihnen auch gefallen

- Bored Cast In-Situ Pile Method StatementDokument10 SeitenBored Cast In-Situ Pile Method StatementVijay JamadarNoch keine Bewertungen

- Method Statement Sheet PilingDokument9 SeitenMethod Statement Sheet PilingAMA MUTTAHIZI AHADAN AUHAN100% (1)

- 01 Method Statement For Pile Cap Foundations (Findal)Dokument8 Seiten01 Method Statement For Pile Cap Foundations (Findal)Joe PS83% (6)

- Method Statement For Pile Cap ConcretingDokument8 SeitenMethod Statement For Pile Cap ConcretingArifur Rahman Apu100% (5)

- Steel Sheet Pile InstallationDokument59 SeitenSteel Sheet Pile InstallationDevapradatta Nath100% (10)

- Method Statement For Pile BreakingDokument3 SeitenMethod Statement For Pile BreakingAnonymous YxBTH8lhZ100% (4)

- Method Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)Dokument7 SeitenMethod Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Pile DrivingDokument2 SeitenMethod Statement For Pile DrivingLim Han Jian100% (5)

- Method Statement For Piling Work (Edited)Dokument18 SeitenMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- Pile Foundation Testing MethodsDokument12 SeitenPile Foundation Testing MethodsJoe PSNoch keine Bewertungen

- MS Remedial Spun Pile A2p6Dokument29 SeitenMS Remedial Spun Pile A2p6AlsonChinNoch keine Bewertungen

- Method Statement For GeotextileDokument17 SeitenMethod Statement For GeotextileGökhan Gökçe0% (1)

- Method Statement For GunitingDokument2 SeitenMethod Statement For GunitingAlsonChin100% (1)

- Method Statement For Piling WorksDokument2 SeitenMethod Statement For Piling Worksshahul_hamid_277% (22)

- Method Statement For Formwork Falsework PDFDokument34 SeitenMethod Statement For Formwork Falsework PDFbryanNoch keine Bewertungen

- Method Statement For Micropiling Works-Jbt. Kedua Sg. YongDokument2 SeitenMethod Statement For Micropiling Works-Jbt. Kedua Sg. YongKelvin LauNoch keine Bewertungen

- Sheet Piles Method StatementDokument3 SeitenSheet Piles Method StatementLandon Mitchell100% (5)

- Method Statement For Turfing WorkDokument2 SeitenMethod Statement For Turfing WorkMohd Syaril Mohd AliNoch keine Bewertungen

- Method Statement For Shrinkage CracksDokument2 SeitenMethod Statement For Shrinkage Cracksluvvie87Noch keine Bewertungen

- Install Micropile Method StatementDokument9 SeitenInstall Micropile Method Statementkazauser67% (3)

- Caisson Method Statement For Pipe JackingDokument2 SeitenCaisson Method Statement For Pipe JackingTeddy TP100% (1)

- Method Statement Bored PileDokument9 SeitenMethod Statement Bored PileAsma Farah100% (3)

- Bridge Construction MethodologyDokument11 SeitenBridge Construction MethodologyMAYMODERN STEELNoch keine Bewertungen

- 012 Piling WorkDokument17 Seiten012 Piling WorkFara Atika Bha Ney100% (3)

- Section S: Drainage Works: JKR MalaysiaDokument7 SeitenSection S: Drainage Works: JKR MalaysiaPipi KNoch keine Bewertungen

- Method Statement For Driven Precast Concrete PilesDokument27 SeitenMethod Statement For Driven Precast Concrete PilesMohammed Wahhab67% (6)

- Method Statement For Earth WorkDokument5 SeitenMethod Statement For Earth Workgvs raoNoch keine Bewertungen

- Method Statement BorepileDokument47 SeitenMethod Statement BorepileIera Jamil100% (1)

- METHOD OF STATEMENT-Mackintosh Probe TestDokument3 SeitenMETHOD OF STATEMENT-Mackintosh Probe TestAzmi SabriNoch keine Bewertungen

- Method Statement EarthworkDokument5 SeitenMethod Statement EarthworkNurul Abdul Jalil80% (10)

- Appendix 5 D Method Statement For Construction ActivitiesDokument48 SeitenAppendix 5 D Method Statement For Construction ActivitiesNajmul QamarNoch keine Bewertungen

- Method Statement For Installation of Soil Nails With For Slope StabilizationDokument11 SeitenMethod Statement For Installation of Soil Nails With For Slope StabilizationDelon Yau100% (2)

- Method of Statement For R.C Piling WorkDokument10 SeitenMethod of Statement For R.C Piling WorkMacgjoyner SaLauNoch keine Bewertungen

- MOS DrainageDokument16 SeitenMOS DrainageMohammad Hadoumi Saldan100% (1)

- PDA Testing Method for Bored Piles & Micro PilesDokument12 SeitenPDA Testing Method for Bored Piles & Micro PilesWee Chek83% (6)

- ITP Temporary HoardingDokument1 SeiteITP Temporary HoardingMohd Azrin100% (1)

- Diamond Concrete Coring Work Sequence Method StatementDokument1 SeiteDiamond Concrete Coring Work Sequence Method StatementAnonymous wTTx1L100% (1)

- MOS Temporary HoardingDokument4 SeitenMOS Temporary Hoardinganiesbaek88% (8)

- Method Statement For Excavation (Earth Works)Dokument2 SeitenMethod Statement For Excavation (Earth Works)Badhur Zaman100% (1)

- Rusty Railing Rectification Method StatementDokument5 SeitenRusty Railing Rectification Method Statementjhaydhee0331Noch keine Bewertungen

- Construction Methodology of Rockfill EmbankmentDokument4 SeitenConstruction Methodology of Rockfill Embankmentvenkateswara rao PothinaNoch keine Bewertungen

- Method Statement of Driven PileDokument5 SeitenMethod Statement of Driven Pilenght794233% (3)

- RC Piling Method for Elevated Water TankDokument6 SeitenRC Piling Method for Elevated Water TankPUI CHEE KHIAN100% (3)

- Method Statement For PILINGDokument7 SeitenMethod Statement For PILINGcworld86% (7)

- Method Statement FOR Retaining Wall Construction: ProjectDokument6 SeitenMethod Statement FOR Retaining Wall Construction: ProjectKelvin Lau83% (6)

- Method of Statement Road Drain RockDokument6 SeitenMethod of Statement Road Drain RockAlister PangNoch keine Bewertungen

- Method Statement For Installation of Soil Nails SK Kauluan, Ranau .Dokument9 SeitenMethod Statement For Installation of Soil Nails SK Kauluan, Ranau .Asdia Aseffah FathiyaNoch keine Bewertungen

- Method Statement - Drainage WorksDokument6 SeitenMethod Statement - Drainage WorksKhiril Hanaffi67% (3)

- Method Statement For PilingDokument13 SeitenMethod Statement For Pilingfree4bruce100% (1)

- Method Statement - Anticlimb FencingDokument1 SeiteMethod Statement - Anticlimb FencingfatinNoch keine Bewertungen

- Method Statement For Water Stopper-BSMMUDokument5 SeitenMethod Statement For Water Stopper-BSMMUEngr. Masud RahmanNoch keine Bewertungen

- TNB Sub-Station Pile Foundation Method StatementDokument3 SeitenTNB Sub-Station Pile Foundation Method StatementAishah Zakaria86% (7)

- Construction Method of StatementDokument11 SeitenConstruction Method of Statementperunding thd100% (2)

- Method Statement For Sonic Tube GroutingDokument22 SeitenMethod Statement For Sonic Tube GroutingKaushalye Mahanama DissanayakeNoch keine Bewertungen

- Method Statement For PilecapDokument6 SeitenMethod Statement For PilecapMohd Nizamuddin Mohamad Noor100% (2)

- TR-CA-MS-003 - B Concrete FoundationDokument31 SeitenTR-CA-MS-003 - B Concrete Foundationsamer8saifNoch keine Bewertungen

- Submission of Construction Methodology of Piling Works - Reg.Dokument5 SeitenSubmission of Construction Methodology of Piling Works - Reg.SHYAMA PRASAD SAMANTA100% (1)

- MOS - PipeBridge SG SebatangDokument13 SeitenMOS - PipeBridge SG Sebatang7e1a8821100% (1)

- Method Statement For PCC & RCC WorksDokument11 SeitenMethod Statement For PCC & RCC WorkspoovazhaganNoch keine Bewertungen

- RCC CHIMNEY METHOD STATEMENTDokument17 SeitenRCC CHIMNEY METHOD STATEMENTpoovazhagan100% (3)

- Nehemiah Geosynthetics QuotationDokument1 SeiteNehemiah Geosynthetics QuotationLookNoch keine Bewertungen

- Price - uPVC Pipe PDFDokument1 SeitePrice - uPVC Pipe PDFLook100% (2)

- Prices - Timber (2015)Dokument1 SeitePrices - Timber (2015)LookNoch keine Bewertungen

- PreliminariesDokument1 SeitePreliminariesLookNoch keine Bewertungen

- Wire Mesh Steel ReinforcementDokument6 SeitenWire Mesh Steel ReinforcementnextreaderNoch keine Bewertungen

- BUR - Fencing (Labour Only)Dokument2 SeitenBUR - Fencing (Labour Only)Look50% (2)

- JKR Spec 2005Dokument188 SeitenJKR Spec 2005rex79x98% (60)

- Reinforcement Bar Sizes and Sectional AreasDokument1 SeiteReinforcement Bar Sizes and Sectional AreasLookNoch keine Bewertungen

- Pipe Laying Method StatementDokument6 SeitenPipe Laying Method StatementLook100% (9)

- Cost AnalysisDokument19 SeitenCost AnalysisJimmy HanNoch keine Bewertungen

- Build Up Rate Format - BrickwallDokument2 SeitenBuild Up Rate Format - BrickwallFaiz Ahmad88% (16)

- Precast ManholeDokument6 SeitenPrecast ManholeLookNoch keine Bewertungen

- Built Up Rate For HoardingDokument1 SeiteBuilt Up Rate For HoardingLook0% (1)

- Build Up Rate Format - ConcretorDokument6 SeitenBuild Up Rate Format - ConcretorFaiz Ahmad80% (10)

- Price - Piling (Detail)Dokument28 SeitenPrice - Piling (Detail)Look100% (2)

- Build Up Rate Format - ScreedingDokument1 SeiteBuild Up Rate Format - ScreedingFaiz Ahmad100% (2)

- Build Up Rate Format - HardcoreDokument2 SeitenBuild Up Rate Format - HardcoreFaiz Ahmad94% (16)

- Built Up Rate - PreliminariesDokument4 SeitenBuilt Up Rate - PreliminariesLook100% (2)

- Piling RatesDokument4 SeitenPiling RatesMatt Crane50% (2)

- Demolition Plant Cost BreakdownDokument4 SeitenDemolition Plant Cost BreakdownLook100% (4)

- Labour RatesDokument15 SeitenLabour RatesAzian Khalil100% (5)

- Built Up RateDokument6 SeitenBuilt Up RateSEENNoch keine Bewertungen

- Tapping SaddleDokument2 SeitenTapping SaddleLookNoch keine Bewertungen

- ASM Architecture ASM Disk Group AdministrationDokument135 SeitenASM Architecture ASM Disk Group AdministrationVamsi ChowdaryNoch keine Bewertungen

- I-Parcel User GuideDokument57 SeitenI-Parcel User GuideBrian GrayNoch keine Bewertungen

- Iqvia PDFDokument1 SeiteIqvia PDFSaksham DabasNoch keine Bewertungen

- Storage Reservior and Balancing ReservoirDokument19 SeitenStorage Reservior and Balancing ReservoirNeel Kurrey0% (1)

- Unit 13 AminesDokument3 SeitenUnit 13 AminesArinath DeepaNoch keine Bewertungen

- Guardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicDokument110 SeitenGuardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicTarun BharadwajNoch keine Bewertungen

- FC Bayern Munich Marketing PlanDokument12 SeitenFC Bayern Munich Marketing PlanMateo Herrera VanegasNoch keine Bewertungen

- Kunci Jawaban Creative English 3BDokument14 SeitenKunci Jawaban Creative English 3BLedjab Fatima67% (3)

- Hilti X-HVB SpecsDokument4 SeitenHilti X-HVB SpecsvjekosimNoch keine Bewertungen

- Anomaly Sell Out Remap December 2019 S SUMATRA & JAMBIDokument143 SeitenAnomaly Sell Out Remap December 2019 S SUMATRA & JAMBITeteh Nha' DwieNoch keine Bewertungen

- Discount & Percentage Word Problems SolutionsDokument4 SeitenDiscount & Percentage Word Problems SolutionsrheNoch keine Bewertungen

- Brightline Guiding PrinciplesDokument16 SeitenBrightline Guiding PrinciplesdjozinNoch keine Bewertungen

- Safety interlock switches principlesDokument11 SeitenSafety interlock switches principlesChristopher L. AlldrittNoch keine Bewertungen

- WPB Pitch DeckDokument20 SeitenWPB Pitch Deckapi-102659575Noch keine Bewertungen

- Fact Sheet Rocket StovesDokument2 SeitenFact Sheet Rocket StovesMorana100% (1)

- Request Letter To EDC Used PE PipesDokument1 SeiteRequest Letter To EDC Used PE PipesBLGU Lake DanaoNoch keine Bewertungen

- ADC Driver Reference Design Optimizing THD, Noise, and SNR For High Dynamic Range InstrumentationDokument22 SeitenADC Driver Reference Design Optimizing THD, Noise, and SNR For High Dynamic Range InstrumentationAdrian SuNoch keine Bewertungen

- Safety of High-Rise BuildingsDokument14 SeitenSafety of High-Rise BuildingsHananeel Sandhi100% (2)

- Password CrackingDokument13 SeitenPassword CrackingBlue MagicNoch keine Bewertungen

- (EMERSON) Loop CheckingDokument29 Seiten(EMERSON) Loop CheckingDavid Chagas80% (5)

- Chapter 1 - Introduction To Computer NetworksDokument32 SeitenChapter 1 - Introduction To Computer NetworksHuluNoch keine Bewertungen

- Sierra Wireless AirPrimeDokument2 SeitenSierra Wireless AirPrimeAminullah -Noch keine Bewertungen

- Pike River Case StudyDokument7 SeitenPike River Case StudyGale HawthorneNoch keine Bewertungen

- Analysis of Trend Following SystemsDokument52 SeitenAnalysis of Trend Following SystemsClement Li100% (1)

- Method Statement of Static Equipment ErectionDokument20 SeitenMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- High Frequency Voltage Probe Non-Availability on GeMDokument2 SeitenHigh Frequency Voltage Probe Non-Availability on GeMjudeNoch keine Bewertungen

- Oscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionDokument6 SeitenOscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionOscar Ortega LopezNoch keine Bewertungen

- Sound Wave Interference and DiffractionDokument79 SeitenSound Wave Interference and DiffractionMuhammad QawiemNoch keine Bewertungen

- Research Design Elements for ScenariosDokument25 SeitenResearch Design Elements for Scenariosrohizal ibrahimNoch keine Bewertungen

- Duty Entitlement Pass BookDokument3 SeitenDuty Entitlement Pass BookSunail HussainNoch keine Bewertungen