Beruflich Dokumente

Kultur Dokumente

SET Ingenieros Technical Specification for 2XS(FL)H-GC-WTC 1x500RM/180 40/69 (72.5)kV Cable

Hochgeladen von

edwinljbOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SET Ingenieros Technical Specification for 2XS(FL)H-GC-WTC 1x500RM/180 40/69 (72.5)kV Cable

Hochgeladen von

edwinljbCopyright:

Verfügbare Formate

Page 1 of 3

SET INGENIEROS - SEAT MERCADO SANTA ANITA

TECHNICAL SPECIFICATION

2XS(FL)H-GC-WTC 1x500RM/180 40/69 (72.5)kV AEIC CS9-06; IEC 60840

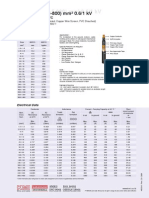

CONSTRUCTION (x)

The picture is informative only

not in scale

Round, stranded and compacted

watertight copper conductor.

Class 2.

Extruded semi-conducting

conductor screen

Insulation XLPE dry cured

Extruded semi-conducting

insulation screen

Semi-conducting swelling tapes

Metallic screen:

copper wires screen and

copper equalizing tapes

Semi-conducting swelling tapes

Longitudinal aluminum foil

Outer serving black halogen

free compound, flame retardant

Graphite coated

APPLICATION

Highest permissible conductor

temperature

TF KABLE, product name, date of

manufacture, standard, meter marking

CONSTRUCTION DATA

Conductor

material

number of wires

Nominal cross sectional area

Conductor diameter and tolerance

Thickness of semi-conducting swelling tape

Min. / Nom. thickness semi-conducting XLPE on conductor

Nominal insulation thickness XLPE

Insulation thickness: minimum at a point

Diameter over insulation nominal

Min. / Nom. thickness semi-conducting XLPE on insulation

Thickness of semi-conducting swelling tape

Metallic screen

Copper wires

Copper equalizing tape

Mean diameter over metallic screen

Thickness of semi-conducting swelling tape

Thickness of aluminum foil

Diameter over aluminum foil

Nominal thickness of outer serving / min. at any point

Thickness of graphite coated

Approximate overall diameter completed cable

(De)

Weight of complete cable (approx.)

DELIVERY DATA

Flange diameter of steel drum

Type

Maximum length per drum

Weight of heaviest reel, including cable

(x)

Diameters are calculated values and subject to manufacturing tolerances

Continuous operation 90C

Overload

130C

Short circuit

250C

( duration max 5 s )

Laying is possible without any special

measures at natural cable temperatures and

ambient temperature not lower than -5C,

under Tele-Fonika supervision

MARKING

DESCRIPTION

Laying in ground

(wet or dry locations)

Laying in air

Laying in ducts

UNIT

DETAILS

Uo/U/Um

40/69 (72.5)kV

No

mm2

mm

mm

mm /

mm

mm

mm

mm /

No x mm

mm2

No x mm

No x mm x mm

mm

No x mm

mm

mm

mm / mm

mm

mm

kg/km

Copper

60

500

26.5+0.4

2 x ~ 0.2

0.80 / 1.2 / 29.0

13.5

12.0

56.3

1.375 / 1.6 / 59.5

2 x ~ 0.35

180

48 x 2.2

2 x 10 x 0.18

64.6

2 x ~ 0.35

0.2

66.5

3.90 / 3.2

~ 0.1

74.5

9690

m

m

kg

3.0

30ZP

800

9240

Page 2 of 3

SET INGENIEROS - SEAT MERCADO SANTA ANITA

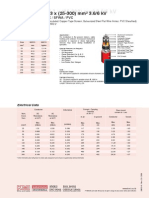

ELECTRICAL DATA at 60Hz

Maximum D.C. conductor resistance at 20C

Maximum A.C. conductor resistance at 90C

Maximum D.C. metallic screen resistance at 20C

Maximum D.C. aluminum foil resistance at 20C

Operating inductance

(*)

flat formation

(**)

trefoil formation

Induction reactance

(*)

flat formation

(**)

trefoil formation

Capacitance

Capacitance reactance

Impedance

(*)

flat formation

(**)

trefoil formation

Zero sequence reactance

Max. electric stress at conductor screen / (at insulation)

Dielectric losses (tg = 0.001) per phase

Partial discharge test at 1.5Uo

Charging current per phase

Charging power

Earth fault current per phase

MECHANICAL DATA

Recommended min. bending radius for laying

Recommended permissible bending radius at final installation

Maximum permissible pulling force:

SHORT CIRCUIT CURRENTS

Maximum permissible thermal short-circuit (IEC 60949)

Phase conductor

90 250C

Metallic screen

80 250C

(***)

AMPACITY

Bonding of the metallic screens

Cables in:

trefoil formation

TESTS

AC voltage test (2.5Uo; 30min.)

Impulse voltage (BIL)

Partial discharge test (1.5Uo)

/km

/km

/km

/km

0.0366

0.0490

0.100

0.620

mH/km

mH/km

0.708

0.549

/km

/km

F/km

k/km

0.267

0.207

0.205 (+ 8 %)

13.13

/km

/km

/km

kV/mm

W/m

pC

A/km

kVA/km

A/km

0.271

0.213

0.072

3.75 / 1.95

0.099

5

2.74

99

8.23

m

m

kN

1.90

1.15

40

Current for

kA

kA

0.5s

101.8

39.5

1.0s

72.2

28.7

5.0s

32.6

11.7

Single point

LF=0.7 / LF=1.0

A

kV

kV

kV

800

672

90

350

54

Marking:

1- line 2XS(FL)H-GC-WTC 1x500 MM2 + P180 MM2 - 40/69kV - TELE-FONIKA - year of production meters

2- line machine code

(*)

Distance between cable axes laid in flat formation 350 mm

Distance between cable axes laid in trefoil formation 350 mm

(***)

Current rating guideline (Calculated with Cymcap 5.3 based on IEC Pub. 60287 and the following conditions)

(**)

(x)

Ground temperature

25C

Ground thermal resistivity 1.5 Km/W

Concrete thermal resistivity 1.0 Km/W

Loaf Factor

0.7

Air temperature

30C

Diameters are calculated values and subject to manufacturing tolerances

Page 3 of 3

SET INGENIEROS - SEAT MERCADO SANTA ANITA

TRIANGULAR CONFIGURATION

As per Memoria Descriptiva de la Conexin 60kV SET LOS INGENIEROS SEAT MERCADO SANTA ANITA

ML2-AST-01A-D-022-GRAL-AEHVS-DIS-MD-2000_0A

Figura 3 Disposicin Tpica de cables en Ductos (profundidad del cable 1,50m)

Laying Depth 1.5m, inside ducts 160mm ( 6)

LF=0,70 (cyclic capacity)

Ampacity 800A

Laying Depth 1.5m, inside HDPE ducts 160mm ( 6)

LF=1,0 (continuous capacity)

Ampacity 672A

Date: 2016-06-08; Mp14221

Prepared by: Micha Pstrgowski

(x)

Diameters are calculated values and subject to manufacturing tolerances

Das könnte Ihnen auch gefallen

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- Wear Parts CatalogDokument12 SeitenWear Parts CatalogLuis Arman100% (2)

- Tutorial 7 - Kinetics - SOLUTIONSDokument5 SeitenTutorial 7 - Kinetics - SOLUTIONSJustin Chuong NguyenNoch keine Bewertungen

- WWW - Osha.gov Pre Test Answer Key2Dokument3 SeitenWWW - Osha.gov Pre Test Answer Key2raul_bsu100% (6)

- Data Sheet Kabel NA2XSEYDokument5 SeitenData Sheet Kabel NA2XSEYGansar KharismawanNoch keine Bewertungen

- N2XSYDokument5 SeitenN2XSYRinda_RaynaNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Sedimentation and Sedimentation TanksDokument43 SeitenSedimentation and Sedimentation TanksDevendra Sharma80% (10)

- Medium-Extra High Voltage Power CablesDokument56 SeitenMedium-Extra High Voltage Power CablesApichartj Jusuay100% (2)

- Ecoflam BurnersDokument40 SeitenEcoflam Burnerseuroused100% (1)

- Na2Xsekfgby 3 X (25-300) MM 3.6/6 KVDokument5 SeitenNa2Xsekfgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNoch keine Bewertungen

- N2 XSEKFGb YDokument5 SeitenN2 XSEKFGb YRinda_RaynaNoch keine Bewertungen

- Khushboo PriyambadaDokument121 SeitenKhushboo PriyambadanguyendaibkaNoch keine Bewertungen

- NYBYDokument5 SeitenNYBYEnnoAjeyNoch keine Bewertungen

- N2XSEBYDokument5 SeitenN2XSEBYRinda_RaynaNoch keine Bewertungen

- Single Core & Multicore Flexible CablesDokument12 SeitenSingle Core & Multicore Flexible Cablesdh24992499Noch keine Bewertungen

- Aluminium Power Cable Technical SpecificationDokument5 SeitenAluminium Power Cable Technical SpecificationAndri ProdjodiprodjoNoch keine Bewertungen

- 15kv Phelps DodgeDokument4 Seiten15kv Phelps DodgeJuan E Torres M100% (1)

- NA2 XFGB YDokument4 SeitenNA2 XFGB YRinda_RaynaNoch keine Bewertungen

- SUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSDokument2 SeitenSUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSWilliam LimNoch keine Bewertungen

- N2XCYDokument5 SeitenN2XCYRinda_RaynaNoch keine Bewertungen

- TM 5-811-6 Generator and Electrical Facilities DesignDokument26 SeitenTM 5-811-6 Generator and Electrical Facilities DesignrockclaudiuNoch keine Bewertungen

- Cable Technical SpecificationDokument66 SeitenCable Technical SpecificationKurama_MinatoNoch keine Bewertungen

- Heavy Duty Power Cable for Distribution and TransmissionDokument5 SeitenHeavy Duty Power Cable for Distribution and TransmissionSemar AngNoch keine Bewertungen

- Beggs & Brill MethodDokument9 SeitenBeggs & Brill Methodmatrix69Noch keine Bewertungen

- Optical Con Field Assembly - Technical Info v1.0Dokument14 SeitenOptical Con Field Assembly - Technical Info v1.0Mariano AcostaNoch keine Bewertungen

- A2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Dokument3 SeitenA2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Anonymous LNdiNQNoch keine Bewertungen

- Control Bus CablesDokument2 SeitenControl Bus CablesVeronica Jeldes PonceNoch keine Bewertungen

- SP-12-276 C.ws.v.y.e-Sw 1CDokument3 SeitenSP-12-276 C.ws.v.y.e-Sw 1CQuantudogon DangNoch keine Bewertungen

- High Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableDokument3 SeitenHigh Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableShailendra Kumar VermaNoch keine Bewertungen

- High Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YDokument3 SeitenHigh Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YNeven Ahmed HassanNoch keine Bewertungen

- H Hseku423p1 enDokument3 SeitenH Hseku423p1 enMarius VasiloiuNoch keine Bewertungen

- Power MVDokument39 SeitenPower MVFani Dwi PutraNoch keine Bewertungen

- N2XYDokument5 SeitenN2XYRinda_RaynaNoch keine Bewertungen

- 3c Cu Xlpe PVC 6.35 (11) KV Heavy Duty CwsDokument2 Seiten3c Cu Xlpe PVC 6.35 (11) KV Heavy Duty Cwsgari_monsantoNoch keine Bewertungen

- BS7870-4.10 33kv Single Core Un ArmouredDokument3 SeitenBS7870-4.10 33kv Single Core Un Armouredrudypl100% (1)

- NYSYDokument5 SeitenNYSYsaturasatuNoch keine Bewertungen

- Lumino Conductor SpecificationDokument5 SeitenLumino Conductor SpecificationSatish MishraNoch keine Bewertungen

- Na2Xsefgby 3 X (25-300) MM 3.6/6 KVDokument5 SeitenNa2Xsefgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNoch keine Bewertungen

- 1c Cu Xlpe PVC 6.35 (11) KV Heavy Duty CwsDokument2 Seiten1c Cu Xlpe PVC 6.35 (11) KV Heavy Duty Cwsgari_monsantoNoch keine Bewertungen

- 1c Cu Xlpe PVC 1.9 (3.3) KV Heavy Duty CwsDokument2 Seiten1c Cu Xlpe PVC 1.9 (3.3) KV Heavy Duty Cwsgari_monsantoNoch keine Bewertungen

- LSF (Lsoh) Power Cable 600 1000v Xlpe Swa Bs6724 CableDokument6 SeitenLSF (Lsoh) Power Cable 600 1000v Xlpe Swa Bs6724 CablerocketvtNoch keine Bewertungen

- Cu/XLPE cable specifications for 3.6/6 kV, 6/10 kV and 8.7/15 kV voltagesDokument3 SeitenCu/XLPE cable specifications for 3.6/6 kV, 6/10 kV and 8.7/15 kV voltagesRahmawan fiberhomeNoch keine Bewertungen

- B Span 330m Silec Technical Offer Ref 5890636827terDokument9 SeitenB Span 330m Silec Technical Offer Ref 5890636827terUdriste DanielNoch keine Bewertungen

- Traycontrol 600 C 2Dokument2 SeitenTraycontrol 600 C 2ikuzma_1Noch keine Bewertungen

- 1 Core 33kv CC NewDokument3 Seiten1 Core 33kv CC NewAnandvikash SinghNoch keine Bewertungen

- 18-30 KV Al Rhz1-OlDokument5 Seiten18-30 KV Al Rhz1-OlAna Cristina CedeñoNoch keine Bewertungen

- RZ1-K Power CableDokument5 SeitenRZ1-K Power CablegarysNoch keine Bewertungen

- Cordaflex (SMK) (N) ShtoeuDokument3 SeitenCordaflex (SMK) (N) Shtoeufikri abu kassimNoch keine Bewertungen

- UC400 S23 Cat.6: U/FTP Installation CableDokument3 SeitenUC400 S23 Cat.6: U/FTP Installation CablepeachykristaNoch keine Bewertungen

- Xple Low Voltage Cable Hal58 Nfa2x PDFDokument1 SeiteXple Low Voltage Cable Hal58 Nfa2x PDFAgung Tri PamungkasNoch keine Bewertungen

- Katalog KmiDokument4 SeitenKatalog Kmisheila fitriaNoch keine Bewertungen

- 33kV 3 Core XLPE SWA Stranded Copper Conductor HV CableDokument3 Seiten33kV 3 Core XLPE SWA Stranded Copper Conductor HV Cableerkamlakar2234Noch keine Bewertungen

- F Mini™ Hec 75 Ohm Coaxial Cable Digital Broadband Drop CableDokument1 SeiteF Mini™ Hec 75 Ohm Coaxial Cable Digital Broadband Drop CableBenito CamelaNoch keine Bewertungen

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Dokument3 Seiten(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNoch keine Bewertungen

- 3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws ArmouredDokument2 Seiten3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws Armouredgari_monsantoNoch keine Bewertungen

- Cu/PVC/SFWA/PVC cable specs (1.5-50 mm2, 0.6/1 kVDokument4 SeitenCu/PVC/SFWA/PVC cable specs (1.5-50 mm2, 0.6/1 kVRahul DevaNoch keine Bewertungen

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFDokument2 Seiten15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezNoch keine Bewertungen

- Aerial Bundle Cables (ABC)Dokument6 SeitenAerial Bundle Cables (ABC)Sang SekNoch keine Bewertungen

- 3c Cu Xlpe PVC 3.8 (6.6) KV Light Duty CwsDokument2 Seiten3c Cu Xlpe PVC 3.8 (6.6) KV Light Duty Cwsgari_monsantoNoch keine Bewertungen

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PVon EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNoch keine Bewertungen

- Grammar Worksheet: If You Turn Off The Lights, You Will Save EnergyDokument2 SeitenGrammar Worksheet: If You Turn Off The Lights, You Will Save EnergybkksmkturenNoch keine Bewertungen

- FMCG Sector Analysis - Long Term ProfitabilityDokument33 SeitenFMCG Sector Analysis - Long Term ProfitabilityADITYA RANJANNoch keine Bewertungen

- Brochure Husker RollsDokument2 SeitenBrochure Husker RollsEmerson OliveiraNoch keine Bewertungen

- Tantalum Niobium EtchantsDokument2 SeitenTantalum Niobium EtchantsmitgraNoch keine Bewertungen

- Insulation system thermal classesDokument2 SeitenInsulation system thermal classesVictor Hutahaean100% (1)

- IS-216 Queens Boiler Pit Leak RepairDokument8 SeitenIS-216 Queens Boiler Pit Leak RepairShamsherHussainNoch keine Bewertungen

- Flow Diagram SymbolsDokument5 SeitenFlow Diagram SymbolshussainNoch keine Bewertungen

- An Accelerator Free Peroxide Vulcanization TechniqueDokument17 SeitenAn Accelerator Free Peroxide Vulcanization TechniqueClinton ThomsonNoch keine Bewertungen

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDokument146 SeitenBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNoch keine Bewertungen

- Pds-Cassida Rls GR 0Dokument3 SeitenPds-Cassida Rls GR 0Milena GonzalezNoch keine Bewertungen

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDokument40 SeitenJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemNoch keine Bewertungen

- Textile and Garments InformationDokument7 SeitenTextile and Garments InformationMd.Tipu SultanNoch keine Bewertungen

- Integrated LabDokument36 SeitenIntegrated LabBeki WalkerNoch keine Bewertungen

- Asco CC T LL Coalescer Cartridges 035A CCT 22 UK 7Dokument2 SeitenAsco CC T LL Coalescer Cartridges 035A CCT 22 UK 7Masoud AmirzadehfardNoch keine Bewertungen

- Aci 318R 08Dokument1 SeiteAci 318R 08Sayed Diab AlsayedNoch keine Bewertungen

- Cane Ite PDFDokument4 SeitenCane Ite PDFJim HaigNoch keine Bewertungen

- AS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection StandardsDokument7 SeitenAS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection Standardslastwest1Noch keine Bewertungen

- A Case Study To Bottle The Biogas in Cylinders As Source ofDokument4 SeitenA Case Study To Bottle The Biogas in Cylinders As Source ofSamir VahoraNoch keine Bewertungen

- Manufacturing Engineer or CNC Programmer or CNC Set Up or CNC OpDokument2 SeitenManufacturing Engineer or CNC Programmer or CNC Set Up or CNC Opapi-77548017Noch keine Bewertungen

- Ministry of Steel Presentatation On MSFDokument27 SeitenMinistry of Steel Presentatation On MSFDebashis SarkarNoch keine Bewertungen

- Furniture Locksand CatchesDokument15 SeitenFurniture Locksand CatchesNishant DeoNoch keine Bewertungen