Beruflich Dokumente

Kultur Dokumente

B Tech

Hochgeladen von

Venkat KrishnaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

B Tech

Hochgeladen von

Venkat KrishnaCopyright:

Verfügbare Formate

NATIONAL INSTITUTE OF TECHNOLOGY, TIRUCHIRAPPALLI

COURSE OUTLINE TEMPLATE

Course Title

Casting and Welding Technology

Programme

B.Tech. Production Engineering- III semester

Course Code

PRPC 11

No. of Credits : 3

Department

Production

Faculty: Dr. P.SATHIYA

Engineering

Pre-requisites

Basic concepts of chemistry, physics

Course

Coordinators (if,

applicable)

Teacher(s) /Tutor(s) psathiya@nitt.edu

Mobile no: 9443494090

Course Type

Core course

Course Overview

Casting and Welding technology explains the basic concepts of two important manufacturing

processes namely casting and welding. Casting process is covered in the first two units and

the rest of the three units deal with the welding.

This course explains in detail about the types, advantages, disadvantages, applications

associated with each type of casting and welding processes. The information given in this

course will help the students to select suitable type of welding and casting process for a

particular material by understanding the problems associated with different welding and

casting processes.

Course Objectives

To give an introduction about the fundamental concepts of manufacturing processes

To make the students understand how the different components in the day to day life,

industries are made with the help of casting and welding processes.

To make the students understand the how to select the input parameters in casting and

welding processes for controlling the product quality.

COURSE OUTCOME (CO)

Course outcomes

Aligned Programme outcomes (PO)

Summarize the fundamentals in PO 1, PO2, PO3, PO11

patterns, cores, sand properties and

molding, including special techniques

and CAD/CAM applications.

Understand

various

casting

techniques, heat treatments, defects

and inspections.

Design a casting with metallurgical,

design and economic consideration.

Understand the different types of

welding

Analyze

the

parameters

that

influences welding

Understand the application of various

welding processes

COURSE TEACHING AND LEARNING ACTIVITIES

S.No.

WEEK

Topic

1

1

Introduction to manufacturing processes,

Casting introduction, Core making

processes, gating system

2

2

Types of casting Centrifugal casting,

investment casting, continuous casting, low

pressure casting

3

3

Melting and quality control of various

steels and non-ferrous alloys, casting

defects

4

4

Inspection and testing of castings,

manufacturing of cast irons

DESCRIPTIVE ASSESSMENT-1

5

5

Arc welding power sources, Different arc

welding processes

6

6

Solid welding process, brazing and

adhesive bonding

7

7

Metal surfacing and spraying thermal

cutting processes

8

8

Welding of advanced materials, welding of

plastics, A-TIG/Hot wire TIG welding

9

9

Types of joint configuration and welding

position

10

10

Design of weldments and joints

DESCRIPTIVE ASSESSMENT-2

11

Inspection and testing of welding

IN CLASS ASSIGNMENT

12

Special welding processes

COMPENSATION ASSESSMENT

DESCRIPTIVE SEMESTER

COURSE ASSESSMENT METHODS

S.No.

Mode

of WEEK/DATE

DURATION

Assessment

1

DESCRIPTIVE End of 4 weeks

1 Hour

ASSESSMENT1

2

DESCRIPTIVE End of 10 weeks 1 Hour

ASSESSMENT2

3

In

class End of 11 weeks 1.5 hours

Assignment

4

Compensation

End

of

12 1 hour

Assessment

Weeks

Mode of Delivery

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

PPT /Chalk and talk

%

WEIGHTAGE

20 %

20 %

10%

20 %

Descriptive

End of Semester 3 hours

50 %

Semester Exam

ESSENTIAL READINGS: Textbooks, Reference books website addresses, journals, etc

TEXT BOOKS:

1.

P.L.Jain Principles of foundry Technology Tata Mc Graw Hill Publishers.

2.

Dr.R.S.Parmer Welding processes and Technology Khanna Publishers.

REFERENCES

1.

H.S.Bawa Manufacturing Technology-I Tata Mc Graw Hill Publishers New Delhi,

2007.

2.

S.V.Nadkarni, Modern Arc Welding Technology, Oxford & IBH Publishing Co. Pvt.

Ltd.

COURSE EXIT SURVEY (mention the ways in which the feedback about the course is

assessed and indicate the attainment also)

At the end of the semester students will give feedback online (MIS) about the various aspects

of course handling like communication, clarity in delivery the technical concepts etc.,

Suggestions are also got from the students.

COURSE POLICY (Including plagiarism, academic honesty, attendance, etc.)

Students should interact during class hours.

Students should attend the classes regularly and strict disciplines have to be

maintained in the class room.

Students absent for any of the continuous assessments due to genuine reasons are

permitted to attend the compensation assessment. If students didnt attend both of the

assessments then, compensation assessment will be held for 40 marks.

ADDITIONAL COURSE INFORMATION

The course faculty is available for discussion in the department after class hours. Students

can also interact with the faculty at psathiya@nitt.edu.

FOR SENATES CONSIDERATION

Course faculty

CC- chairperson

HOD

Das könnte Ihnen auch gefallen

- GMAT Club Guide To OG 2020Dokument153 SeitenGMAT Club Guide To OG 2020Venkat KrishnaNoch keine Bewertungen

- ISO Standards On WeldingDokument6 SeitenISO Standards On WeldingwentropremNoch keine Bewertungen

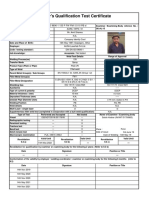

- Typical Welder Qualification CertificateDokument1 SeiteTypical Welder Qualification CertificateSatish Keskar100% (2)

- Mee 202Dokument6 SeitenMee 202favou5Noch keine Bewertungen

- CNC Machine Tools and Control Systems GuideDokument39 SeitenCNC Machine Tools and Control Systems Guidep_a_jeevaNoch keine Bewertungen

- WPS MS 01C Rev. 0Dokument1 SeiteWPS MS 01C Rev. 0alinor_tnNoch keine Bewertungen

- Drilling Reaming Tapping PDFDokument17 SeitenDrilling Reaming Tapping PDFPeter ThomasNoch keine Bewertungen

- Welding Inspection CSWIP PDFDokument683 SeitenWelding Inspection CSWIP PDFmohdrafeek83Noch keine Bewertungen

- Weld Map SampleDokument2 SeitenWeld Map SampleKhushal TripathiNoch keine Bewertungen

- Fabrication Technology Course GuideDokument11 SeitenFabrication Technology Course Guidehiren mandaliaNoch keine Bewertungen

- Guide For Welding Iron Castings: ANSI/AWS D11.2-89 (R2006) An American National StandardDokument8 SeitenGuide For Welding Iron Castings: ANSI/AWS D11.2-89 (R2006) An American National StandardCyperTCNoch keine Bewertungen

- Materials Processing: A Unified Approach to Processing of Metals, Ceramics and PolymersVon EverandMaterials Processing: A Unified Approach to Processing of Metals, Ceramics and PolymersBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Welding Visual Inspection FormatDokument2 SeitenWelding Visual Inspection Formatgst ajah100% (3)

- General Milling FormulasDokument4 SeitenGeneral Milling FormulasZanarkand RnNoch keine Bewertungen

- Metal Casting SyllabusDokument8 SeitenMetal Casting Syllabusمحمود بن ماجد نصارNoch keine Bewertungen

- Production Techniques-II: Machining and Non-Traditional ProcessesDokument16 SeitenProduction Techniques-II: Machining and Non-Traditional Processesravish kumarNoch keine Bewertungen

- Manfacturing TechnologyDokument2 SeitenManfacturing TechnologyRamu AmaraNoch keine Bewertungen

- Manufacturing Tech SyllDokument4 SeitenManufacturing Tech SyllJagjit SinghNoch keine Bewertungen

- Course File EditED 1.1.1...Dokument54 SeitenCourse File EditED 1.1.1...jyothi bogaNoch keine Bewertungen

- 5 MPDokument3 Seiten5 MPASIST MechNoch keine Bewertungen

- Principles of Casting Technology: Pradeep Kumar JhaDokument1 SeitePrinciples of Casting Technology: Pradeep Kumar Jhaupesh1996.1Noch keine Bewertungen

- Manufaturing ProcessDokument2 SeitenManufaturing ProcessSakshi VermaNoch keine Bewertungen

- PDFDokument4 SeitenPDFGeorge CamachoNoch keine Bewertungen

- Lect 1Dokument16 SeitenLect 1SagnikMukherjeeNoch keine Bewertungen

- Introducción A Los Procesos de ManufacturaDokument9 SeitenIntroducción A Los Procesos de ManufacturaLuis EstebanNoch keine Bewertungen

- MMS Course FileDokument22 SeitenMMS Course Filejohn_raju17Noch keine Bewertungen

- B.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesDokument1 SeiteB.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesAmin FarukiNoch keine Bewertungen

- IM112Manufacturing Technology PDFDokument2 SeitenIM112Manufacturing Technology PDFEmurhohwo JeremiahNoch keine Bewertungen

- Course Outline - Research Methods and Presentation - ECE - 2019Dokument2 SeitenCourse Outline - Research Methods and Presentation - ECE - 2019Bilisuma DamiteNoch keine Bewertungen

- 2013-S2 CVEN9822x2474Dokument5 Seiten2013-S2 CVEN9822x2474April IngramNoch keine Bewertungen

- Ucmp Crouse FileDokument37 SeitenUcmp Crouse Filehari0118Noch keine Bewertungen

- Emg 4102 CN 1Dokument3 SeitenEmg 4102 CN 1MaxwellNoch keine Bewertungen

- MAKAUT Manufacturing Processes SyllabusDokument2 SeitenMAKAUT Manufacturing Processes SyllabusRTET Plagiarism CheckNoch keine Bewertungen

- Manufacturing Engineering 2 Course OutlineDokument1 SeiteManufacturing Engineering 2 Course OutlineLayike AlemayehuNoch keine Bewertungen

- Introduction to Engineering Profession CourseDokument2 SeitenIntroduction to Engineering Profession CourseAshenafi GebrelibanosNoch keine Bewertungen

- ME311 Manufacturing Processes 3-0-0-3 2016 Prerequisite: NilDokument2 SeitenME311 Manufacturing Processes 3-0-0-3 2016 Prerequisite: NilaslamNoch keine Bewertungen

- Designing an Adjustable Welding Stand for Safety and ConvenienceDokument26 SeitenDesigning an Adjustable Welding Stand for Safety and ConvenienceRachel TipudanNoch keine Bewertungen

- ME3162 Module OutlineDokument4 SeitenME3162 Module OutlinedabudhabicozNoch keine Bewertungen

- RTM Nagpur University Syllabus (Theory)Dokument5 SeitenRTM Nagpur University Syllabus (Theory)Milind KshirsagarNoch keine Bewertungen

- Course Outline MEFB213Dokument10 SeitenCourse Outline MEFB213lucasNoch keine Bewertungen

- MS Handout and II Unit QuestionsDokument13 SeitenMS Handout and II Unit QuestionsSrinivas naidu KotyadaNoch keine Bewertungen

- SYLL Proses Manu Updated Feb 2023Dokument4 SeitenSYLL Proses Manu Updated Feb 2023Ilham AyuningNoch keine Bewertungen

- Course OverviewDokument14 SeitenCourse OverviewVinayaka G PNoch keine Bewertungen

- Course Plan: Faculty of Engineering Technology Mechanical Engineering DepartmentDokument5 SeitenCourse Plan: Faculty of Engineering Technology Mechanical Engineering DepartmentayhamNoch keine Bewertungen

- BGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomesDokument23 SeitenBGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomeshemarajuNoch keine Bewertungen

- Fitting ManualDokument72 SeitenFitting Manualayush bindalNoch keine Bewertungen

- Workshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadDokument28 SeitenWorkshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadECE 33 Sahil ManglaNoch keine Bewertungen

- MEC207Dokument4 SeitenMEC207Senthil Muthu Kumar TNoch keine Bewertungen

- Course Profile 2015CVEN9822-270715Dokument6 SeitenCourse Profile 2015CVEN9822-270715Mohammed YazidiNoch keine Bewertungen

- Kom Course File New Format M V ReddyDokument44 SeitenKom Course File New Format M V ReddyVenkateswar Reddy MallepallyNoch keine Bewertungen

- De G631 HandoutDokument3 SeitenDe G631 HandoutYogesh DanekarNoch keine Bewertungen

- MSE 667A: Selection and Design of Engineering Materials: Kbalani@iitk - Ac.in Rishow@iitk - Ac.inDokument1 SeiteMSE 667A: Selection and Design of Engineering Materials: Kbalani@iitk - Ac.in Rishow@iitk - Ac.inAnmol GuptaNoch keine Bewertungen

- Manufacturing ProcessDokument3 SeitenManufacturing ProcessReham EltuhamyNoch keine Bewertungen

- Me770, Me770a - Course OutlineDokument3 SeitenMe770, Me770a - Course OutlinePrakhar GuptaNoch keine Bewertungen

- Course Outine (Production Engineering I)Dokument2 SeitenCourse Outine (Production Engineering I)GetahunNoch keine Bewertungen

- Materials and Their Behaviour: Course & CSWIP Examination Package Course Ref: VenueDokument1 SeiteMaterials and Their Behaviour: Course & CSWIP Examination Package Course Ref: VenueAwais TariqNoch keine Bewertungen

- MECH421 Outline 2017Dokument5 SeitenMECH421 Outline 2017mralex11Noch keine Bewertungen

- L0 MEC205 Zero Lecture UpdatedDokument42 SeitenL0 MEC205 Zero Lecture UpdatedJames PrakashNoch keine Bewertungen

- MukeshDokument22 SeitenMukeshVikram NikhilNoch keine Bewertungen

- ME3450 Syllabus 2011 Fall v3Dokument7 SeitenME3450 Syllabus 2011 Fall v3petkirstNoch keine Bewertungen

- Advance Surface TreatmentDokument48 SeitenAdvance Surface TreatmentdelramdaniawatiNoch keine Bewertungen

- StructuresDokument4 SeitenStructuresChen Inn TanNoch keine Bewertungen

- EME1226 Lab Sheet Tri2-2013rev2Dokument10 SeitenEME1226 Lab Sheet Tri2-2013rev2Sharwes AnanthanNoch keine Bewertungen

- Optimization of Process Parameters in SheetDokument24 SeitenOptimization of Process Parameters in SheetThiru MoorthyNoch keine Bewertungen

- MP 24july PDFDokument130 SeitenMP 24july PDFMaloth PrakashNoch keine Bewertungen

- Mechanical Technology Production Major CurriculumDokument97 SeitenMechanical Technology Production Major CurriculumNahid HasanNoch keine Bewertungen

- Module Syllabus: MMEE 522: Powder Metallurgy: Basic DetailsDokument4 SeitenModule Syllabus: MMEE 522: Powder Metallurgy: Basic DetailsResego PhiriNoch keine Bewertungen

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringDokument49 SeitenRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringAbhi SharmaNoch keine Bewertungen

- We 7102Dokument3 SeitenWe 7102linsonNoch keine Bewertungen

- SECTION I: Course Information and Learning Outcomes: Substantial EmphasisDokument4 SeitenSECTION I: Course Information and Learning Outcomes: Substantial Emphasislaura sageNoch keine Bewertungen

- Me366 Advanced Metal Joining TechnologyDokument3 SeitenMe366 Advanced Metal Joining TechnologyDrKim J SeelanNoch keine Bewertungen

- Online MBA Ranking 2020: University of North Carolina: Kenan-FlaglerDokument2 SeitenOnline MBA Ranking 2020: University of North Carolina: Kenan-FlaglerVenkat KrishnaNoch keine Bewertungen

- Global MBA Ranking 2020: University of Pennsylvania: WhartonDokument2 SeitenGlobal MBA Ranking 2020: University of Pennsylvania: WhartonVenkat KrishnaNoch keine Bewertungen

- Online MBA Ranking 2020: Warwick Business SchoolDokument2 SeitenOnline MBA Ranking 2020: Warwick Business SchoolVenkat KrishnaNoch keine Bewertungen

- Online MBA Ranking 2020: IE Business SchoolDokument2 SeitenOnline MBA Ranking 2020: IE Business SchoolVenkat KrishnaNoch keine Bewertungen

- Online Mba Ranking 2020 PDFDokument1 SeiteOnline Mba Ranking 2020 PDFVenkat KrishnaNoch keine Bewertungen

- European Business School Rankings 2019Dokument1 SeiteEuropean Business School Rankings 2019Venkat KrishnaNoch keine Bewertungen

- Masters in Finance Post Experience 2018Dokument1 SeiteMasters in Finance Post Experience 2018Venkat KrishnaNoch keine Bewertungen

- Online Mba Ranking 2020 PDFDokument1 SeiteOnline Mba Ranking 2020 PDFVenkat KrishnaNoch keine Bewertungen

- Masters in Management 2019Dokument1 SeiteMasters in Management 2019Venkat KrishnaNoch keine Bewertungen

- Global MBA Ranking 2020: Stanford Graduate School of BusinessDokument2 SeitenGlobal MBA Ranking 2020: Stanford Graduate School of BusinessVenkat KrishnaNoch keine Bewertungen

- Executive MBA Ranking 2019: Table NotesDokument1 SeiteExecutive MBA Ranking 2019: Table NotesVenkat KrishnaNoch keine Bewertungen

- Executive Education - Customised - 2019: Table NotesDokument1 SeiteExecutive Education - Customised - 2019: Table NotesVenkat KrishnaNoch keine Bewertungen

- Building and Driving Business Market StrategiesDokument10 SeitenBuilding and Driving Business Market StrategiesVenkat KrishnaNoch keine Bewertungen

- 44 - Application For Provisional CertificateDokument1 Seite44 - Application For Provisional CertificateVenkat KrishnaNoch keine Bewertungen

- Wel-Come To NIT, Tiruchirappalli PDFDokument1 SeiteWel-Come To NIT, Tiruchirappalli PDFVenkat KrishnaNoch keine Bewertungen

- Work Breakdown Structure and Project Management ToolsDokument17 SeitenWork Breakdown Structure and Project Management ToolsVenkat KrishnaNoch keine Bewertungen

- Olumbia Niversity: Ms in Industrial Engineering Program PlanDokument1 SeiteOlumbia Niversity: Ms in Industrial Engineering Program PlanVenkat KrishnaNoch keine Bewertungen

- Classify inventory items using XYZ analysisDokument10 SeitenClassify inventory items using XYZ analysisVenkat KrishnaNoch keine Bewertungen

- Work Breakdown Structure and Project Management ToolsDokument17 SeitenWork Breakdown Structure and Project Management ToolsVenkat KrishnaNoch keine Bewertungen

- TestDokument2 SeitenTestVenkat KrishnaNoch keine Bewertungen

- Metrology Lab & TheoryDokument3 SeitenMetrology Lab & TheoryVenkat KrishnaNoch keine Bewertungen

- Win Ken Bach 2016Dokument22 SeitenWin Ken Bach 2016Venkat KrishnaNoch keine Bewertungen

- Charisis2018 Article DRTRouteDesignForTheFirstLastM PDFDokument29 SeitenCharisis2018 Article DRTRouteDesignForTheFirstLastM PDFVenkat KrishnaNoch keine Bewertungen

- Wel-Come To NIT, Tiruchirappalli PDFDokument1 SeiteWel-Come To NIT, Tiruchirappalli PDFVenkat KrishnaNoch keine Bewertungen

- Lettre Recommandation ANGDokument4 SeitenLettre Recommandation ANGVenkat KrishnaNoch keine Bewertungen

- 34.request For Transcripts-V3Dokument2 Seiten34.request For Transcripts-V3Venkat KrishnaNoch keine Bewertungen

- Supply Chain ManagementDokument41 SeitenSupply Chain ManagementVenkat KrishnaNoch keine Bewertungen

- Master Double Degree Programmes: Version: April 2018Dokument36 SeitenMaster Double Degree Programmes: Version: April 2018Venkat KrishnaNoch keine Bewertungen

- Untitled DiagramDokument1 SeiteUntitled DiagramVenkat KrishnaNoch keine Bewertungen

- Lamda Exothermic Welding ChartDokument93 SeitenLamda Exothermic Welding ChartAgus Nur SetiawanNoch keine Bewertungen

- Pemrograman NCDokument3 SeitenPemrograman NCPurwadyaziNoch keine Bewertungen

- Drilling MachineDokument35 SeitenDrilling MachineVikky HariNoch keine Bewertungen

- Casting Technology 03Dokument4 SeitenCasting Technology 03Felix Wahyu UtomoNoch keine Bewertungen

- Lesson Plan Model-1newDokument4 SeitenLesson Plan Model-1newSatheesh KumarNoch keine Bewertungen

- Advances in Casting TechnologiesDokument26 SeitenAdvances in Casting TechnologiesMohd munafNoch keine Bewertungen

- Welding Procedure SpecificationDokument3 SeitenWelding Procedure SpecificationMark Jason M. BrualNoch keine Bewertungen

- 2 Lab - Report - MillingDokument1 Seite2 Lab - Report - MillingAbu Rectify100% (1)

- Quality Casting ManualDokument27 SeitenQuality Casting ManualvisitabhinavNoch keine Bewertungen

- Production Technology R10 JntukDokument4 SeitenProduction Technology R10 JntukSrimanthula SrikanthNoch keine Bewertungen

- Sand Casting: - The Pattern Is Intentionally Made Larger Than The Cast Part To Allow For Shrinkage During CoolingDokument21 SeitenSand Casting: - The Pattern Is Intentionally Made Larger Than The Cast Part To Allow For Shrinkage During CoolingPalaash ChaudharyNoch keine Bewertungen

- TOPICS COVEREDDokument64 SeitenTOPICS COVEREDManjunatha GrNoch keine Bewertungen

- Daily Fit-Up/Welding Inspection ReportDokument7 SeitenDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNoch keine Bewertungen

- Technical Info About Die CastingDokument5 SeitenTechnical Info About Die CastingSanoj KumarNoch keine Bewertungen

- Welding A514 GR.B QuestionsDokument2 SeitenWelding A514 GR.B QuestionsRodolfoMarínNoch keine Bewertungen

- CastingDokument18 SeitenCastingNeelu TiruvayipatiNoch keine Bewertungen

- ME3162 Module OutlineDokument4 SeitenME3162 Module OutlinedabudhabicozNoch keine Bewertungen

- Fan Cover GP-129JXK: Product NameDokument13 SeitenFan Cover GP-129JXK: Product NameBoby SaputraNoch keine Bewertungen

- Foundry and Casting Techniques Question BankDokument4 SeitenFoundry and Casting Techniques Question BankGeetu KumariNoch keine Bewertungen

- Welding Procedure For BOXNR Wagon (WPS)Dokument8 SeitenWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)