Beruflich Dokumente

Kultur Dokumente

The Storage Problem

Hochgeladen von

George KyriakoulisCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Storage Problem

Hochgeladen von

George KyriakoulisCopyright:

Verfügbare Formate

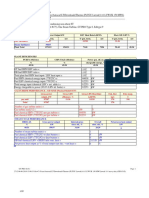

NEWS FEATURE

Vol 463|7 January 2010

NATURE|Vol

THE ENERGY

STORAGE PROBLEM

Renewable energy is not a viable option unless energy can be stored on a large scale.

David Lindley looks at five ways to do that.

ILLUSTRATIONS BY MATTHEW HODSON

n February 2008, during a sudden cold snap, the normally relentless

winds of west Texas fell silent and the thousands of wind turbines that

dot that part of the state slowed to a halt. Local utility operators, unable

to make up the shortfall with power from elsewhere in the grid, were

forced to cut service to some users for up to an hour and a half before

the winds picked up again.

That windless interval would have been a non-event if the utility

companies had had a few hundred megawatt hours of energy stored

away that they could draw on in emergencies. But they didnt. Ever

ephemeral, electrical energy is difficult and expensive to store in

large quantities.

The lack of good storage options has plagued utility operators for

generations. Obligated to provide a steady supply of electricity to meet

constantly varying demand, they have conventionally resorted to the

costly and inefficient method of adjusting the output of a coal-fired

plant, say, or by turning on a gas-powered peaker plant during periods

of high demand.

PUSHING WATER UPHILL

The need for storage is particularly acute in

densely populated northern Europe, where

many countries are building offshore turbines to harness the winds blowing across the

North Sea. Denmark already gets about 20%

of its electricity from land- and sea-based

wind farms, and it is aiming to increase that

figure to 50% by 2025. Because the North Sea

winds can drop to low levels for days at a time,

But that supply-based strategy is becoming less viable with the

increased use of renewable energy sources with unpredictable output,

notably solar arrays and wind farms. As the Texan example indicates,

the power produced by these technologies is dependent on natures

whim, not human demand. If we want to have a significant part of our

energy come from renewable sources, storage is a must, says Ali Nourai,

manager of energy storage at American Electric Power, a utility company

in Columbus, Ohio, and chairman of the Electricity Storage Association,

a trade association in Washington DC.

A number of technologies for energy storage already exist, including

some that have been around for decades. The challenge is to make

them robust, reliable and economically competitive while matching

the most suitable technology to each energy source or location. Each

technology has unique features, says Jillis Raadschelders, of energy

consulting firm KEMA in Arnhem, the Netherlands. There will never

be a winning technology. Choosing the right technology means looking at each one in some detail.

however, countries such as Denmark and the hydroelectricity requires mountains, so

Netherlands are increasing their grid connec- opportunities are limited by geography. Buildtivity to Norway, which gets the vast majority ing such storage also tends to be expensive and

of its power from hydroelectric plants. Nor- environmentally destructive, and installing

ways mountain reservoirs provide back-up high-voltage transmission lines to connect

power capacity, and also offer substantial remote storage sites to grids often triggers

amounts of pumped storage hydroelectricity, opposition on environmental grounds.

in which water is pumped uphill to a reservoir

If the capacity of pumped storage hydrousing surplus electricity, and released down- electricity is to grow significantly, it will have

hill again to turn a generator when power is to leave the mountains. One innovative conneeded. Pumped hydroelectricity has a stor- cept by KEMA would put wind turbines and

age efficiency of 7085%,

pumped hydro in the

and it is the most mature and

same place: an energy

If pumped storage

widespread technology being

in a shallow part

hydroelectricity capacity island

used for large-scale electricity

of the North Sea. An area

is to grow significantly,

storage. China, Japan and the

of perhaps 60 square kiloUnited States, for example, have

metres would be ringed

it will have to leave the

off by a dyke or levee to

numerous installations with

mountains.

create an artificial lake.

generating capacities ranging

Wind turbines would

from tens of megawatts (MW)

to several gigawatts (GW). Pumped storage stand on the encircling dyke, and any excess

hydroelectricity is a particularly good match power would be used to pump water out of the

for wind power because water pumped into an lake and into the surrounding sea. Letting sea

upper reservoir will stay there for a long time, water flow back in would regenerate the stored

making up for potentially large gaps in wind electricity. In the absence of wind, KEMA estigeneration.

mates that the energy island could supply an

But in its conventional form, pumped storage average of 1,500 MW for as long as 12 hours.

18

2010 Macmillan Publishers Limited. All rights reserved

NEWS FEATURE

Vol 463|7 January

NATURE|Vol

463|72010

January 2010

SQUEEZING AIR UNDERGROUND

In the farmlands near Huntorf, Germany,

about 100 kilometres southwest of Hamburg,

an ordinary-looking industrial installation

performs an unusual task: when demand for

electricity in the local grid is low, the plant

uses excess power to compress air and pump

it into two underground salt caverns with a

combined volume of more than 300,000

cubic metres. Then, at times of high demand,

the compressed air is allowed to expand

through turbines on the surface to regenerate

the electricity.

The Huntorf plant, which has been working since 1978, can supply almost 300 MW of

reserve power for up to three hours, and comes

into operation about 100 times a year. But it

has not exactly spawned a legion of imitators.

A similar but smaller plant in McIntosh, Alabama, came online in 1991, and efforts to build

another such system in Iowa, begun in 2002,

are only now at the point of acquiring land for

test drilling.

The problem is that these compressed-air

energy storage (CAES) facilities are considerably more complex in practice than they are in

principle. Gas heats up when it is compressed,

which limits how much air can be pumped

underground before it becomes too hot to be

stored safely. Moreover, the longer that hot air

ELECTRICITY IN A BOX

Large-scale battery storage would be a solved

problem already if utility companies could

use the ubiquitous lead-acid technology that

has been the basis of car batteries for nearly

a century. Unfortunately, lead-acid batteries

have a low energy density they are bulky

and heavy for the amount of energy they store

and they do not stand up well to repeated

chargedischarge cycles.

A better solution is the sodiumsulphur

(NaS) battery, which stores energy by chemically dissociating sodium polysulphide into

sodium and sulphur. The energy can then be

released by allowing the two elements to react

again. NaS batteries have a high energy density

and can last through thousands of chargedischarge cycles. Their chief drawback is that the

sodium and sulphur have to be kept in separate

reservoirs in the molten state, at about 300 C.

Also, the batteries suffer irreparable damage if

they discharge completely and grow cold. The

resulting need for a robust container, along with

other technical requirements, means that NaS

batteries cost about US$3,000 per kilowatt (kW)

of available power. That compares unfavourably

with standard gas-powered plants, which cost

about $1,000/kW. Nonetheless, NaS batteries

is left in place, the more of its heat which

represents a substantial fraction of the input

energy is lost into the walls of the surrounding cavern. And then when it is released again,

the expanding air cools down. In the Huntorf

and McIntosh facilities, in fact, the released

air is fed into a standard natural gas turbine,

boosting its efficiency. So the net effect of

the air-compression system is to boost the

efficiency of a more or less conventional

natural-gas-fuelled power plant.

In the near term this kind of hybrid system

makes a great deal of sense, says Haresh

Kamath, a researcher at the Electric Power

Research Institute (EPRI) in Palo Alto, California, especially as more electricity from

renewable sources is available to recharge

the system at night. Looking further down

the road, however, the EPRI and others are

also researching improvements that would

turn CAES into a true energy storage system,

requiring no fossil fuel. Such an advanced

adiabatic system would capture and store the

heat of compression and then use it to reheat

the released air, which would spin a turbine

directly without any additional fuel. Metal

foundries and blast furnaces have for years

captured waste heat in stacks of refractory

bricks or similar materials, says Christoph

Jakiel, a researcher at MAN Turbo in Oberhausen, Germany. So applying the technique

to compressed-air storage should be straightforward.

He estimates that the efficiency of such a

system to be something under 80%, comparable with pumped storage hydroelectric systems.

The overall costs of construction and operation

would also be about the same. Suitable locations should not be hard to find in most regions

of the world, says Jakiel. Salt caverns are not

uncommon, and the proposed Iowa Stored

Energy Park, should it ever be built, will pump

compressed air into an aquifer.

have been developed commercially by NGK

Insulators in Nagoya, Japan. Japan now has an

installed capacity able to supply its grid with

about 300 MW when extra power is needed, for

up to six hours at a stretch. Other countries are

also picking up the pace. The United States, for

example, has about 10 MW of NaS capacity in

place and a similar amount on the way, led by

companies such as American Electric Power

and Xcel Energy in Minneapolis, Minnesota.

In the future, large-scale NaS storage could

face a challenge from lithium-ion technology.

Already in widespread use for mobile phones

and laptops, and under development for electric

cars, lithium-ion batteries have a high energy

density and efficiencies of more than 90%.

Their big drawback is cost, which is in part

driven by safety considerations: the batteries

use a lithium salt in an organic solution, which

is flammable, necessitating robust construction

to minimize fire hazards. Lithium-ion batteries

made for consumer electronics currently cost a

few hundred dollars per stored kW hour. But for

widespread vehicle applications, that cost must

come down closer to $100 per kW hour, and for

grid applications it needs to be lower still.

Yet Nourai, for one, remains optimistic.

Safety issues are more easily and cheaply met

for batteries in secure, fixed installations than

in hand-held devices, he says. And in Asia,

especially, there is strong support for lithium-ion technology and keen competition

between manufacturers, which he hopes will

lead to dramatic cost reductions. In China, he

recently saw a cargo-container-sized lithiumion installation, and expects to see capacities

of a megawatt or more in the coming years.

At the Massachusetts Institute of Technology in

Cambridge, materials chemist Donald Sadoway

19

2010 Macmillan Publishers Limited. All rights reserved

NEWS FEATURE

Vol 463|7 January 2010

NATURE|Vol

is trying a more radical approach to reducing

the cost. I want a battery thats dirt cheap, says

Sadoway, and the way to do it is to build it from

dirt that is, from the most abundant elements

in Earths crust. Although there is little new to

discover about the electrochemistry of these

elements such as silicon, iron and aluminium

a battery involves two reactions, one at each

electrode, along with an electrolyte that supports

the appropriate ion transfer. That makes for a

huge and largely untested combination of possible compounds and reactions to search through.

The quest is made feasible, says Sadoway, by

supercomputers that can quickly assess proposed

battery chemistries, freeing researchers from the

need to synthesize and test actual materials. In

the coming decade, he says, Im optimistic that

the rate of discovery will accelerate.

TAKING ELECTRICITY FOR A SPIN

turbines to slow down. Keeping it stable is a

challenge for utility companies everywhere.

With that in mind, Beacon Power of Tyngsboro, Massachusetts, has spent the past decade

developing a high-tech flywheel that is optimized for frequency regulation. Measuring

about 2 metres tall and 1 metre in diameter, the

flywheel consists of a cylindrical aluminium

core, which houses the motor and generator,

and a carbon-fibre composite rim. It is suspended on magnetic bearings inside a vacuum-sealed chamber, where it can spin at up

to 16,000 revolutions per minute. The devices

are designed to run for 20 years or more with

no maintenance, says Matthew Lazarewicz,

Beacons chief technical officer. They can store

energy with an efficiency of 85%, he says, and

can spin up and down for perhaps millions of

cycles during their working life, making them

far more durable than batteries.

The challenge now is to bring the cost down,

which Beacon hopes to do thanks to a project

it has recently undertaken with loan guarantees from the US Department of Energy. In

Stephentown, New York, Beacon has begun

construction of a $70-million, 20-MW, 200wheel flywheel farm that will help to regulate

frequency in the regional power grid. The

budget includes a number of one-time costs

related to establishing its qualifications for the

federal loan guarantees. The company estimates that future plants of this size will cost

less than $50 million a price it hopes to bring

down to about $30 million. In late November,

the energy department awarded Beacon $24

million for half the cost of a new 20-MW plant

to be built outside Chicago, Illinois.

Conceptually, at least, one of the most straightforward ways to store energy is in a spinning

flywheel: electrical energy gets converted into

the kinetic energy of rotation by running it

through a motor, which accelerates the flywheel. And the kinetic energy is extracted

when it is needed by coupling the flywheel to

a generator, which slows the wheel down and

produces electricity.

Again, however, the reality is more

complex the flywheel has to spin very fast

yet be strong enough to keep from flying apart.

Flywheel storage systems are commercially

available as uninterruptible power supplies

that can deliver modest amounts of power for

seconds or minutes, but they are not competitive for the longer storage times needed by the

electric utility companies.

One big advantage of flywheels is that they can

absorb the energy within seconds or minutes,

and give it back just as quickly. This is exactly

what is needed for regulating the frequency of a

power grid, which is supposed to be maintained

at an even 50 or 60 cycles per second, depending

on the country, but which tends to drop whenever short-term increases in the load cause the

INTEGRATING WITH A SMART GRID

There are a number of even more exotic

technologies that could become candidates

for large-scale energy storage assuming

that researchers can eventually get the cost

down to a competitive level. Examples include

ultracapacitors that can store huge amounts

of electrical charge in atoms-thick layers

next to the electrodes, and coils of superconducting wire able to store large amounts of

circulating current indefinitely.

But by far the most cost-effective approach

to large-scale electric energy storage is to minimize the need for it. That is one of the goals

set out earlier this year in the US stimulus bill,

which allocated $4.3 billion to research and

development in renewable-energy generation,

energy efficiency and, most especially, a smart

grid. Instead of simply adjusting the supply of

electricity in response to the vagaries of unpredictable demand, a smart grid would constantly

adjust demand as well. When demand hits a

peak, for example, the grid might start cutting

power for household refrigerators, office airconditioning systems and other non-urgent

uses just for a moment in each case, and

nothing that anyone would notice, but enough

20

2010 Macmillan Publishers Limited. All rights reserved

to smooth out variations in the overall load.

In that kind of system, says Nourai, storage

and smart-grid technologies would work

together, evening out the usual peaks and

troughs in grid load to a greater extent than

either could achieve alone. Variation is never

going to go away but with storage it can be

much flatter, he says. He sees a future in which

even fairly small communities could be net

zero, meaning that on average they make as

much electricity as they need, and maintain a

reliable supply by exchanging modest amounts

of power back and forth with neighbouring

communities. Local interconnections would

be low-voltage lines, and long-distance highvoltage lines would be needed only to connect

wind farms or solar arrays in remote areas with

populated regions. That transformation, Nourai

says, will change the way we think about, run

and plan the storage of electricity.

David Lindley is a freelance writer in

Alexandria, Virginia.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- SolarPower Europe - Global Market Outlook 2019 2023Dokument94 SeitenSolarPower Europe - Global Market Outlook 2019 2023Alexander Maura EcheniqueNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- VVER ReactorsDokument42 SeitenVVER ReactorsmonicanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- 03.report CCPP Luwuk 150 MWDokument2 Seiten03.report CCPP Luwuk 150 MWgancanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Jpee 2019012515395175Dokument49 SeitenJpee 2019012515395175Afzaal AshrafNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- CGPDokument21 SeitenCGPnileshhalderNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Assignment No-1 Simulation and Modelling of Solar PV Pannel: TheoryDokument7 SeitenAssignment No-1 Simulation and Modelling of Solar PV Pannel: Theorypooja chirdeNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hydrogen Fuel Cell: Manash Jyoti Deori Khushbu Kumari Raj Kapur Kumar Akshit AggarwalDokument13 SeitenHydrogen Fuel Cell: Manash Jyoti Deori Khushbu Kumari Raj Kapur Kumar Akshit AggarwalRaj KapurNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Evaluation of PV-Wind Hybrid Energy System For A Small IslandDokument3 SeitenEvaluation of PV-Wind Hybrid Energy System For A Small Islandhamza malikNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- 1152au133 - Hydrogen Engines - Question BankDokument5 Seiten1152au133 - Hydrogen Engines - Question BankKunal Dudhraj BiswakarmaNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Gea33037 Steam 600 Series 2017Dokument2 SeitenGea33037 Steam 600 Series 2017Dheeraj DheeruNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Caterpillar Electric Power Ratings GuideDokument60 SeitenCaterpillar Electric Power Ratings GuideToto Arianto100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Solar Power PlantDokument3 SeitenSolar Power Plantjobpei2Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Renewable Energy Systems: Lecture 2 & 3Dokument40 SeitenRenewable Energy Systems: Lecture 2 & 3abdul wakeelNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- CTP035 Fabrication of Thermoelectric Cooler by Peltier PrincipleDokument2 SeitenCTP035 Fabrication of Thermoelectric Cooler by Peltier PrincipleANAND KRISHNANNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Solar Energy ApplicationsDokument16 SeitenSolar Energy ApplicationssbmmkushanNoch keine Bewertungen

- Photovoltaic CellDokument17 SeitenPhotovoltaic CellSubarna MondalNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Time Sheet Bulanan Periode April 2023Dokument13 SeitenTime Sheet Bulanan Periode April 2023Suto WijoyoNoch keine Bewertungen

- Maintenance: Solar Power Installation, Operation andDokument2 SeitenMaintenance: Solar Power Installation, Operation andXYZNoch keine Bewertungen

- Cogeneration Heat Power CHPDokument10 SeitenCogeneration Heat Power CHPMKOZERDEMNoch keine Bewertungen

- Solar PV Design ProblemDokument4 SeitenSolar PV Design ProblemAjala Oladimeji DurotoluwaNoch keine Bewertungen

- Economics: Swanson's LawDokument2 SeitenEconomics: Swanson's LawKiran KumarNoch keine Bewertungen

- Pet Coke Gasification - InfoDokument12 SeitenPet Coke Gasification - Inforaj355Noch keine Bewertungen

- More About Energy 5: Class-VIII Physics Question BankDokument12 SeitenMore About Energy 5: Class-VIII Physics Question BankRonnith NandyNoch keine Bewertungen

- Fuel Value Calculator PDFDokument3 SeitenFuel Value Calculator PDFSterlingNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Financing RE - DOEDokument18 SeitenFinancing RE - DOEMicrofinanceCouncil OfthePhilsNoch keine Bewertungen

- 2 - Genealogy of CANDU ReactorsDokument40 Seiten2 - Genealogy of CANDU ReactorsDeni Abu GaozhanNoch keine Bewertungen

- Summer Training Report On Dadri Thermal Power StationDokument11 SeitenSummer Training Report On Dadri Thermal Power StationRamraj SinghNoch keine Bewertungen

- BP Statistical Review of World Energy 2017 Underpinning DataDokument69 SeitenBP Statistical Review of World Energy 2017 Underpinning DatadairandexNoch keine Bewertungen

- Excel Furnace (Recovered)Dokument25 SeitenExcel Furnace (Recovered)Bunga Rajhana Ragil GayatriNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Flargent Products 2015 PDFDokument41 SeitenFlargent Products 2015 PDFFabricioNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)