Beruflich Dokumente

Kultur Dokumente

Grundfosliterature 3347635

Hochgeladen von

warmaster81Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Grundfosliterature 3347635

Hochgeladen von

warmaster81Copyright:

Verfügbare Formate

GRUNDFOS CASE STORY

The data transmitted wirelessly by CIM 250 as seen on-screen at the wastewater treatment plants SCADA system.

Wireless data transmission keeps reliability high and costs

low at Bjerringbro Wastewater Treatment Plant, Denmark

For a wastewater treatment plant, reliability is of great importance.

The removal of wastewater and stormwater in extreme situations

must happen when required. Costs are also important, and the key is to

ensure cost-effectiveness without compromising the reliability and the

sustainability of the wastewater treatment plant.

At Bjerringbro Wastewater Treatment Plant in Denmark, data registered by Dedicated Controls is effectively transmitted wirelessly via a

CIM 250 communication interface module has reduced the need for

manual inspection, improved preventive maintenance and ensured

reliability of the wastewater facility.

The situation

Prior to the installation of the wireless solution at pumping stations

connected to the Bjerringbro Wastewater Treatment Plant, manual

inspections were necessary on a weekly basis for local pumping stations and daily for main pumping stations, to ensure correct operation

and to detect possible faults. This required that staff were present at

the treatment plant every day of the week, all year round.

Previously, the warning system at one of the local pumping stations consisted of a lamp placed high up on a

lamppost, and a reaction to a warning depended on the

lamp being seen and reported! Now, wireless transmission sends the full register of pump pit activity every ten

minutes to the SCADA system at Bjerringbro Wastewater

Treatment Plant.

Grundfos supplied

All necessary expertise for installations

Support before, during and after

commissioning

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

The Grundfos solution

Using the terrain cabinet at the Engvej st local pumping station as an

example, the robust cabinet includes a meter and a sewage pump controller (Dedicated Controls) with a CIM 250 module which has a GSM/

GPRS modem with its own IP address and mobile phone number. The

use of a SIM card to establish the wireless connection makes installation

extremely easy, as the GSM/GPRS operator delivers the communication

infrastructure.

Data is communicated wirelessly every 10 minutes to the central SCADA

system. In an alarm situation, the SCADA system ensures correct alarm

handling. Winpager software a log program for SCADA on the computer

at the treatment plant sets the schedule, ensuring the alarm is sent

to the correct person(s) at the right time, according to 5 pre-determined

levels of alarm situations and response times.

The Outcome

The immediate benefits of the wireless communication offered by the

CIM 250 arise from the system showing how a pumping station is running over an entire day. This helps save time and money by reducing

the need for manual inspections and helping make better planning

possible. In time, this means greater reliability from better preventive

maintenance.

Time is saved with alarms. Personnel only get called out if absolutely necessary and they can act earlier. In addition, the wireless system provides

operational data for control and statistics. This increases the possibility

for even greater measures for ensuring maintenance planning, operational reliability, and also for optimising efficiency in the future, because

all data is saved in a database.

Quote:

The wireless control unit with Dedicated Controls saves us time and

removes the need for routine visits to our many pumping stations, says

Kaj Lorenzen, Driftsleder, Bjerringbro Renseanlg. Wireless transmission means we get data here and now and thats data we can use.

About Bjerringbro Wastewater

Treatment Plant

Bjerringbro is located in mid-Jutland, Denmark. The Bjerringbro

Wastewater Treatment Plant is one of 22 wastewater treatment

plants serving 250 pumping stations operated by Energi Viborg.

Of these, 11 wastewater treatment plants are in the Viborg

st area, which includes Bjerringbro. Bjerringbro Wastewater

Treatment Plant has 35 pumping stations, 4 of which run

Grundfos pumps transmitting data wireless via CIM 250.

www.grundfos.com

The terrain cabinet at the Engvej st local pumping station.

The sewage pump controller (Dedicated Controls) with a

CIM 250 module and GSM/GPRS modem are to the right.

Grundfos products:

CIM 250 GSM/GPRS wireless communication module

Dedicated Controls, sewage pump

controller

SEG sewage grinders

About the CIM 250 module

The CIM 250 is a standard interface module for

remote wireless data transmission via a GSM/GPRS

network. The GSM/GPRS module can work as a

SCADA Interface enabling a SCADA system or another

PLC controller to establish a remote connection either

via GSM Call-up using the Modbus RTU protocol or

via a GPRS connection using the Modbus TCP protocol with the system.

The interface module is installed as an internal addon for Dedicated Controls. In addition to CIM 250

GSM/GPRS, interface modules for Dedicated Controls

are also available for the GENIbus and Modbus RTU

fieldbus using a wired RS485 connection.

97760560

The data transmitted includes the main status of pump pit and pumps

and you can request active alarms and warnings. The types of alarms

include sewage overflow, low flow, dry running, undervoltage, blocked

motor/pump, overtemperature, klixon, and others that can be adapted

according to your needs.

Currently, there are about 200 of these cabinets installed in Denmark

with Dedicated Controls transmitting wirelessly via the CIM 250 module.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- KNX System: ManualDokument48 SeitenKNX System: Manualwarmaster81Noch keine Bewertungen

- Room Thermostats: Basic DocumentationDokument38 SeitenRoom Thermostats: Basic Documentationwarmaster81Noch keine Bewertungen

- Grundfosliterature 1531Dokument18 SeitenGrundfosliterature 1531warmaster81Noch keine Bewertungen

- VLT AutomationDrive FC 300 90-0 KW - Design Guide - MG34S202 25Dokument1 SeiteVLT AutomationDrive FC 300 90-0 KW - Design Guide - MG34S202 25warmaster81Noch keine Bewertungen

- Nozasti Osiguraci GGDokument6 SeitenNozasti Osiguraci GGwarmaster81Noch keine Bewertungen

- Controlling and Monitoring Directly From A Cell Phone: CCM 164 Examples of UseDokument1 SeiteControlling and Monitoring Directly From A Cell Phone: CCM 164 Examples of Usewarmaster81Noch keine Bewertungen

- HSC01 SM10 Mta01 00001 Ou100017929 R1Dokument1 SeiteHSC01 SM10 Mta01 00001 Ou100017929 R1warmaster81Noch keine Bewertungen

- IK Impact Test Schedule: Table 1: Relation Between IK Code and Impact EnergyDokument1 SeiteIK Impact Test Schedule: Table 1: Relation Between IK Code and Impact Energywarmaster81Noch keine Bewertungen

- 451 59a PDFDokument44 Seiten451 59a PDFwarmaster81Noch keine Bewertungen

- HSC01 SM10 MEC07 00002: Duty SpecificationDokument5 SeitenHSC01 SM10 MEC07 00002: Duty Specificationwarmaster81Noch keine Bewertungen

- First Number Protection Against Solid Objects Second Number Protection Against Liquids Ik Code Protection Against Mechanical ImpactsDokument2 SeitenFirst Number Protection Against Solid Objects Second Number Protection Against Liquids Ik Code Protection Against Mechanical Impactswarmaster81Noch keine Bewertungen

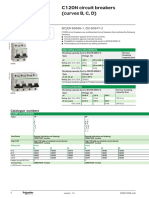

- C120N Circuit Breakers (Curves B, C, D)Dokument4 SeitenC120N Circuit Breakers (Curves B, C, D)warmaster81Noch keine Bewertungen

- Za Protok ElektromagnetDokument7 SeitenZa Protok Elektromagnetwarmaster81Noch keine Bewertungen

- Grundfosliterature 5768738Dokument36 SeitenGrundfosliterature 5768738warmaster81Noch keine Bewertungen

- Product Data Sheet: Thermal Overload Relay For Motor - Tesys Lr9 - 132... 220 A - Class 10Dokument2 SeitenProduct Data Sheet: Thermal Overload Relay For Motor - Tesys Lr9 - 132... 220 A - Class 10warmaster81Noch keine Bewertungen

- Abb PLC Phtc02u en WebDokument181 SeitenAbb PLC Phtc02u en Webwarmaster81Noch keine Bewertungen

- EX215028 Busbar CatalogueDokument164 SeitenEX215028 Busbar Cataloguewarmaster81Noch keine Bewertungen

- Grundfosliterature 3153379Dokument27 SeitenGrundfosliterature 3153379warmaster81Noch keine Bewertungen

- TermostatDokument11 SeitenTermostatwarmaster81Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20Dokument10 Seiten2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20mgalphamrn100% (1)

- The Chemical Composition and Organoleptic Attributes of Lesser-Known Vegetables As Consumed in Njikoka Local Government Area, Anambra State, NigeriaDokument4 SeitenThe Chemical Composition and Organoleptic Attributes of Lesser-Known Vegetables As Consumed in Njikoka Local Government Area, Anambra State, NigeriaEmri CynthiaNoch keine Bewertungen

- Generic 5S ChecklistDokument2 SeitenGeneric 5S Checklistswamireddy100% (1)

- OpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSDokument42 SeitenOpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSAngelaNoch keine Bewertungen

- Leadership PresentationDokument10 SeitenLeadership Presentationapi-404415990Noch keine Bewertungen

- UK FreshTECH Jammer RecipeBook 0Dokument24 SeitenUK FreshTECH Jammer RecipeBook 0Temet NoscheNoch keine Bewertungen

- Distribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoDokument15 SeitenDistribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoaldiNoch keine Bewertungen

- Wada Defending Cannabis BanDokument18 SeitenWada Defending Cannabis Banada UnknownNoch keine Bewertungen

- Umur Ekonomis Mesin RevDokument3 SeitenUmur Ekonomis Mesin Revrazali akhmadNoch keine Bewertungen

- Mapeh 9 Aho Q2W1Dokument8 SeitenMapeh 9 Aho Q2W1Trisha Joy Paine TabucolNoch keine Bewertungen

- US Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistDokument114 SeitenUS Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistGeorges100% (2)

- Injection MouldingDokument241 SeitenInjection MouldingRAJESH TIWARINoch keine Bewertungen

- Crime Free Lease AddendumDokument1 SeiteCrime Free Lease AddendumjmtmanagementNoch keine Bewertungen

- HEYER VizOR - Product List - 1015Dokument7 SeitenHEYER VizOR - Product List - 1015kalandorka92Noch keine Bewertungen

- Quality Assurance Kamera GammaDokument43 SeitenQuality Assurance Kamera GammawiendaintanNoch keine Bewertungen

- Assignment Nutrition and HydrationDokument17 SeitenAssignment Nutrition and Hydrationmelencio olivasNoch keine Bewertungen

- SET 2022 Gstr1Dokument1 SeiteSET 2022 Gstr1birpal singhNoch keine Bewertungen

- Recipe: Patisserie Method: Eclair Cake RecipeDokument3 SeitenRecipe: Patisserie Method: Eclair Cake RecipeEisha BibiNoch keine Bewertungen

- Transmission Line Loading Sag CalculatioDokument25 SeitenTransmission Line Loading Sag Calculatiooaktree2010Noch keine Bewertungen

- Stereochemistry Chiral Molecules QuizDokument3 SeitenStereochemistry Chiral Molecules QuizSean McDivittNoch keine Bewertungen

- What Is Emergency ManagementDokument8 SeitenWhat Is Emergency ManagementHilina hailuNoch keine Bewertungen

- Community Medicine DissertationDokument7 SeitenCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- RISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Dokument17 SeitenRISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Martin NiNoch keine Bewertungen

- ICSE Class 10 HRJUDSK/Question Paper 2020: (Two Hours)Dokument9 SeitenICSE Class 10 HRJUDSK/Question Paper 2020: (Two Hours)Harshu KNoch keine Bewertungen

- EngineCleaningAndVolcanicAsh InternDokument69 SeitenEngineCleaningAndVolcanicAsh InternLucio Portuguez AlmanzaNoch keine Bewertungen

- Human Rights Law - Yasin vs. Hon. Judge Sharia CourtDokument7 SeitenHuman Rights Law - Yasin vs. Hon. Judge Sharia CourtElixirLanganlanganNoch keine Bewertungen

- INTELLECTUAL DISABILITY NotesDokument6 SeitenINTELLECTUAL DISABILITY Notesshai gestNoch keine Bewertungen

- SM FBD 70Dokument72 SeitenSM FBD 70LebahMadu100% (1)

- Week 1 Seismic WavesDokument30 SeitenWeek 1 Seismic WavesvriannaNoch keine Bewertungen

- A I R P O R T S Construction Program Management 56Dokument56 SeitenA I R P O R T S Construction Program Management 56Carl WilliamsNoch keine Bewertungen