Beruflich Dokumente

Kultur Dokumente

Comparison of Glass Fiber Reinforced Concrete & Geopolymer Concrete With Glass Fiber Reinforcement

Hochgeladen von

esatjournalsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Comparison of Glass Fiber Reinforced Concrete & Geopolymer Concrete With Glass Fiber Reinforcement

Hochgeladen von

esatjournalsCopyright:

Verfügbare Formate

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

COMPARISON OF GLASS FIBER REINFORCED CONCRETE &

GEOPOLYMER CONCRETE WITH GLASS FIBER REINFORCEMENT

Shrikant Harle1, Sarang Dhawade2

1, 2

Department of Civil Engineering, Ram Meghe College of Engineering, Amravati (M.S.)

Abstract

In the world most commonly used as well as durable material is concrete. In the field of concrete technology, glass fiber

reinforced concrete (GFRC) is the recently introduced material. GFRC has many advantages such as light weight material, steel

reinforcement corrosion free and structural deterioration free. So, these are the reason the researchers all over the globe are

attempting to develop high performance concrete with the use of glass fibers as well as admixtures. While the combination of fly

ash, alkaline liquids, fine and coarse aggregate and glass fibers resulted in the product called as Glass Fiber Reinforced

Geopolymer Concrete (GFRGC). This product has many advantages such as high early strength, corrosion and sulphate

resistance and low shrinkage. The present work has compared the compressive strength, split tensile strength and flexural

strength for GFRC and GFRGC. From this comparison it is observed that except for the flexural strength the normal concrete

with the addition of glass fibers shown good results as compared to the geopolymer concrete with the addition of glass fibers. This

work is only an accumulation of information about GFRC and the research work which is already carried out by other

researchers.

Key Words: GFRC, GC, Geopolymer Concrete, Glass Fiber Reinforced Concrete, Glass Fiber Reinforcement

--------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

The production rate of concrete as well as the growth rate of

infrastructure highlight and reflect the economic strength

and the degree of civilization. It is well known that concrete

is one of the most far used construction material all over the

globe [4]. Ordinary Portland Cement (OPC) becomes an

important material all over the globe in the production of

concrete which acts its binder to bind all the aggregate

together. However, the utilization of cement causes

pollution to the environment and reduction of raw material.

The manufacturing of OPC requires the burning of large

quantities of fuel as well as decomposition of limestone,

which has resulted in significant amount emissions of CO 2

[5].

The performance concrete is usually determined by its

strength and durability. By reducing the water content,

increasing the binder and aggregate content, using a well

graded aggregate and using a good curing method and better

compaction can be resulted in good quality of concrete.

Further it was observed that the strength & durability of

concrete are influenced by the amount of size and type of

pores [6].

2. REVIEW OF LITERATURE

The experimental investigation [1] was carried out on the

alkali resistant (AR) glass fibers and studied the effect on

compressive, tensile strength, split tensile and flexural

strength on M20, M30, M40 and M50 grades of concrete.

From the experimental results it was observed that

percentage increase of compressive strength of various

concrete grades of glass fiber concrete mixes compared with

28 days compressive strength to be from 20 to 25%. As well

as reduction in bleeding observed by addition of glass fibers

in the glass fiber concrete mixes.

Concrete is the most widely used construction material all

over the world and has very good as well as wide properties

like high compressive strength, stiffness and durability

under usual environmental factors. Normally reinforcement

consists of continuous deformed steel bars or pre-stressing

tendons. The study [2] was carried out and it was observed

that strength and durability of concrete can be changed by

making appropriate changes in its ingredients like

cementitious material, aggregate and water by adding some

special ingredients. Therefore concrete can be considered as

a very suitable material for a wide range of application.

The experimental study [3] was conducted to study the

mechanical properties of Geo Polymer Cement Concrete

(GPCC) which contained 90% fly ash, 10% OPC, alkaline

liquids as well as glass fibers in the percentage of 0.01%,

0.02% and 0.03% by volume of concrete and the ratio of

alkaline liquid to fly ash was 0.4. The experiment included

replacement of 10% of fly ash by OPC in the mix resulted in

an enhanced 73% compressive strength, 128% split tensile

strength and 17% flexural strength as compared to GPC

mix. Also the replacement of 10% fly ash by OPC in the

GPC mix eliminates delay in setting time and necessity of

heat curing to gain strength which resulted in GPCC mix.

The study [9] was made to determine the mechanical

properties of Geopolymer concrete composites (GPCC),

which contains fly ash, alkaline liquids and glass fibers. The

______________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

263

IJRET: International Journal of Research in Engineering and Technology

ratio for alkaline liquids to fly ash was fixed as 0.4 and in

the experiment they replaced 100% ordinary Portland

cement with fly ash. The addition of glass fibers made to the

mix with 0.01%, 0.02% and 0.03%. From the experiments

performed it was observed that the geopolymer concrete

composite had relatively higher strength in one day short

curing time than the geopolymer concrete and ordinary

Portland cement.

Author

Yogesh murthy, et al

(2012)

eISSN: 2319-1163 | pISSN: 2321-7308

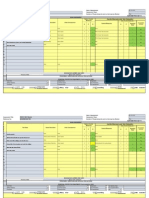

3. RESULTS AND COMPARISON

The comparison is done for adding varying amount of glass

fibers in normal concrete and geopolymer concrete with

zero percent fiber with the same material. The results of the

compressive strength, flexural strength and split tensile

strength are as presented in the following table.

Table 1: Comparison of Compressive strength

types of concrete

grade of

no of days

concrete

Normal Concrete with waste

glass fiber (replacement of

aggregate)

Normal Concrete with AR glass

fiber (addition)

Geopolymer Concrete (100%

replacement of OPC)

M30

28

M30

28

-----

28

K. Vijay, et al (2012)

Geopolymer Concrete (100%

replacement of OPC)

-----

28

Author

types of concrete

Chandramouli K, et al

(2010)

Satish Kumar, et al

(2012)

Table 2: Comparison of Flexural strength

grade of

no of days

concrete

compressive strength

with gf

(MPa)

38.22 (0.5 %)

wihtout gf

(MPa)

38

48.56 (0.03

%)

27.58

(0.03%)

41.5

25.87

(0.03%)

28.49

Flexural strength

M30

28

Chandramouli K, et al

(2010)

Normal Concrete with waste

glass fiber (replacement of

aggregate)

Normal Concrete with AR glass

fiber (addition)

with gf

(MPa)

4.5 (0.5 %)

M30

28

4.78 (0.03 %)

-----

28

K. Vijay, et al (2012)

Geopolymer Concrete (100%

replacement of OPC)

Yogesh murthy, et al

(2012)

Author

Chandramouli K, et al

(2010)

Satish Kumar, et al

(2012)

K. Vijay, et al (2012)

5.31 (0.03 %)

Table 3: Comparison of Split Tensile strength

types of concrete

grade of concrete

no of days

Normal Concrete with AR glass

fiber (addition)

Geopolymer Concrete (100%

replacement of OPC)

M20

28

------

28

Geopolymer Concrete (100%

replacement of OPC)

------

28

24.26

wihtout gf

(MPa)

4.1

4.12

5.4

Split Tensile strength

with gf

(MPa)

4.2 (0.03%)

wihtout gf

(MPa)

3.62

2.33 (0.03%)

1.93

1.83 (0.03%)

3.02

______________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

264

IJRET: International Journal of Research in Engineering and Technology

4. CONCLUSION

From the above results and comparison following point are

observed:

The compressive strength is found to be much

more for normal concrete with the addition of glass

fibers as compared to the geopolymer concrete with

the addition of glass fibers.

The flexural strength for geopolymer concrete with

the addition of glass fibers found to be more as

compared to the normal concrete with the addition

of glass fibers.

Split tensile strength is found to be more for normal

concrete with the addition of glass fibers as

compared to the geopolymer concrete with the

addition of glass fibers.

eISSN: 2319-1163 | pISSN: 2321-7308

[10]. Yogesh Iyer Murthy, Apporv Sharda and Gourav Jain

(2012), Performance of glass fiber reinforced concrete,

International journal of engineering and innovative

technology, vol 1, Issue 6.

REFERENCES

[1]. Chandramouli K, Seshadri Sekhar T, Sravana P,

Pannirselvam N and Srinivasa Rao P (2010), Strength

properties of glass fiber concrete, ARPN journal of

Engineering and Applied sciences, vol. 5, no. 4.

[2]. Dr. P. Srinivasa Rao, Chandra Mouli K and Dr. T.

Seshadri Sekhar (2012), Durability studies on glass fiber

reinforced concrete, journal of civil engineering science: An

international journal, vol 1 no 1-2, pp 37-42.

[3]. K. Vijai, R. Kumutha and B.G. Vishnuram (2012),

Properties of glass fiber reinforced geopolymer concrete

composites, Asian journal of civil engineering (Building and

housing), vol 13, no 4, pages 511-520.

[4]. M. Fareed Ahmed, M. Fadhil Nuruddin and Nasir

Shafiq (2011), Compressive strength and workability

characteristics of low calcium fly ash based self compacting

geopolymer concrete, International journal of civil and

environmental engineering, vol 3, issue 2, pp 72-78.

[5]. Mohd. Mustafa Al Bakri, H. Mohammed, H.

Kamarudin, I. Khairul Niza and Y. zarina (2011), Review on

fly ash based geopolymer concrete without Portland cement,

Journal of Engineering and technology research, vol 3, issue

1, pp 1-4.

[6]. Monita Olivia and Hamid R. Nikraz (2011), Strength

and water penetrability of fly ash geopolymer concrete,

ARPN journal of engineering and applied sciences, Vol 6,

issue 7, pp 70-78.

[7]. M. I. Abdul Aleem and P. D. Arumairaj (2012),

Geopolymer concrete A review, International journal of

engineering sciences & emerging technologies, vol 1, issue

2, pp 118-122.

[8]. Sandeep G. Sawant, A. B. Sawant and M. B.

Kumthekar (2013), Strengthening of R.C.C. beamusing

different glass fibers, International journal of inventive

engineering and sciences, vol 1, issue 2.

[9]. Sathish Kumar V, Blessen Skariah Thomas and Alex

Christopher (2012), An experimental study on the properties

of glass fiber reinforced geopolymer concrete, International

journal of engineering research and application, vol 2, issue

6, pp 722-726.

______________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

265

Das könnte Ihnen auch gefallen

- PTE 3 Week Study ScheduleDokument3 SeitenPTE 3 Week Study ScheduleesatjournalsNoch keine Bewertungen

- An Efficient Information Retrieval Ontology System Based Indexing For Context PDFDokument7 SeitenAn Efficient Information Retrieval Ontology System Based Indexing For Context PDFesatjournalsNoch keine Bewertungen

- An Improved Geo-Encryption Algorithm in Location Based Services PDFDokument4 SeitenAn Improved Geo-Encryption Algorithm in Location Based Services PDFesatjournalsNoch keine Bewertungen

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDokument4 SeitenAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNoch keine Bewertungen

- Analysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFDokument5 SeitenAnalysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFesatjournalsNoch keine Bewertungen

- Analytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFDokument5 SeitenAnalytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFesatjournalsNoch keine Bewertungen

- Analysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFDokument5 SeitenAnalysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFesatjournalsNoch keine Bewertungen

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDokument7 SeitenAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNoch keine Bewertungen

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDokument8 SeitenA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNoch keine Bewertungen

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDokument6 SeitenAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNoch keine Bewertungen

- An Octa-Core Processor With Shared Memory and Message-Passing PDFDokument10 SeitenAn Octa-Core Processor With Shared Memory and Message-Passing PDFesatjournalsNoch keine Bewertungen

- A Review On Fake Biometric Detection System For Various ApplicationsDokument4 SeitenA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNoch keine Bewertungen

- A Review Paper On Smart Health Care System Using Internet of ThingsDokument5 SeitenA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNoch keine Bewertungen

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDokument6 SeitenAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsNoch keine Bewertungen

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDokument3 SeitenA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNoch keine Bewertungen

- A Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFDokument7 SeitenA Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFesatjournalsNoch keine Bewertungen

- A New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFDokument8 SeitenA New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFesatjournalsNoch keine Bewertungen

- A Servey On Wireless Mesh Networking ModuleDokument5 SeitenA Servey On Wireless Mesh Networking ModuleesatjournalsNoch keine Bewertungen

- A Servey On Wireless Mesh Networking ModuleDokument5 SeitenA Servey On Wireless Mesh Networking ModuleesatjournalsNoch keine Bewertungen

- I JR Et 20160503007dfceDokument5 SeitenI JR Et 20160503007dfcegtarun22guptaNoch keine Bewertungen

- A Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFDokument7 SeitenA Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFesatjournalsNoch keine Bewertungen

- Ad Hoc Based Vehcular Networking and ComputationDokument3 SeitenAd Hoc Based Vehcular Networking and ComputationesatjournalsNoch keine Bewertungen

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDokument8 SeitenA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNoch keine Bewertungen

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDokument6 SeitenA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNoch keine Bewertungen

- I JR Et 20160503007dfceDokument5 SeitenI JR Et 20160503007dfcegtarun22guptaNoch keine Bewertungen

- A Review Paper On Smart Health Care System Using Internet of ThingsDokument5 SeitenA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNoch keine Bewertungen

- A Review On Fake Biometric Detection System For Various ApplicationsDokument4 SeitenA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNoch keine Bewertungen

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDokument6 SeitenA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNoch keine Bewertungen

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Dokument3 SeitenA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNoch keine Bewertungen

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDokument9 SeitenA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Kinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide CatalystsDokument9 SeitenKinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide Catalysts李国俊Noch keine Bewertungen

- GSR Azure High Level ArchitectureDokument4 SeitenGSR Azure High Level ArchitectureCSKNoch keine Bewertungen

- Marcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerDokument8 SeitenMarcel Breuer: Hungarian-American Designer, Architect and Bauhaus PioneerYosaphat Kiko Paramore DiggoryNoch keine Bewertungen

- Y-Site Drug Compatibility TableDokument6 SeitenY-Site Drug Compatibility TableArvenaa SubramaniamNoch keine Bewertungen

- Pass Microsoft 74-343 Exam: Number: 74-343 Passing Score: 800 Time Limit: 120 Min File Version: 40.2Dokument26 SeitenPass Microsoft 74-343 Exam: Number: 74-343 Passing Score: 800 Time Limit: 120 Min File Version: 40.2tapera_mangeziNoch keine Bewertungen

- Research career paths in Spain: funding opportunities overviewDokument7 SeitenResearch career paths in Spain: funding opportunities overviewfidalgocastroNoch keine Bewertungen

- Marking SchemeDokument8 SeitenMarking Schememohamed sajithNoch keine Bewertungen

- An - APX18 206516L CT0Dokument2 SeitenAn - APX18 206516L CT0Maria MartinsNoch keine Bewertungen

- Air Purification Solution - TiPE Nano Photocatalyst PDFDokument2 SeitenAir Purification Solution - TiPE Nano Photocatalyst PDFPedro Ortega GómezNoch keine Bewertungen

- Washington State Employee - 4/2010Dokument8 SeitenWashington State Employee - 4/2010WFSEc28Noch keine Bewertungen

- 9643 SoirDokument38 Seiten9643 SoirpolscreamNoch keine Bewertungen

- Learn About Intensifiers and How to Use Them Effectively in WritingDokument3 SeitenLearn About Intensifiers and How to Use Them Effectively in WritingCheryl CheowNoch keine Bewertungen

- Chapter 7 - Trade and Investment EnvironmentDokument7 SeitenChapter 7 - Trade and Investment EnvironmentMa. Cristel Rovi RibucanNoch keine Bewertungen

- Create Email Alerts For Mulitple People or Group - XpoDokument79 SeitenCreate Email Alerts For Mulitple People or Group - XponiravmodyNoch keine Bewertungen

- Individual TaxpayersDokument3 SeitenIndividual TaxpayersJoy Orena100% (2)

- CANDIDATE'S BIO DATADokument2 SeitenCANDIDATE'S BIO DATAAamir ArainNoch keine Bewertungen

- Data IntegrationDokument7 SeitenData IntegrationHan MyoNoch keine Bewertungen

- Sample Cover Letter Oil and GasDokument1 SeiteSample Cover Letter Oil and GasNadira Aqilah67% (3)

- What is Software Development Life Cycle (SDLC)? Key Phases and ActivitiesDokument11 SeitenWhat is Software Development Life Cycle (SDLC)? Key Phases and ActivitiessachinNoch keine Bewertungen

- PartlowControllerCatalog PDFDokument98 SeitenPartlowControllerCatalog PDFvinh nguyen theNoch keine Bewertungen

- POLS219 Lecture Notes 7Dokument7 SeitenPOLS219 Lecture Notes 7Muhammad Zainal AbidinNoch keine Bewertungen

- Costs-Concepts and ClassificationsDokument12 SeitenCosts-Concepts and ClassificationsLune NoireNoch keine Bewertungen

- Task Based Risk Assesment FormDokument2 SeitenTask Based Risk Assesment FormKolluri SrinivasNoch keine Bewertungen

- Reinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsDokument6 SeitenReinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsJosé Miguel Palomino GarciaNoch keine Bewertungen

- OilField Review 2016 Cement EvaluationDokument10 SeitenOilField Review 2016 Cement EvaluationLuisNoch keine Bewertungen

- The Mpeg Dash StandardDokument6 SeitenThe Mpeg Dash Standard9716755397Noch keine Bewertungen

- Holmes 1993Dokument8 SeitenHolmes 1993Rumaisa KrubaNoch keine Bewertungen

- z2OrgMgmt FinalSummativeTest LearnersDokument3 Seitenz2OrgMgmt FinalSummativeTest LearnersJade ivan parrochaNoch keine Bewertungen

- About Kia Motors Corporation: All-NewDokument19 SeitenAbout Kia Motors Corporation: All-NewWessam FathiNoch keine Bewertungen

- HTTP://WWW - Authorstream.com/presentation/kunalcmehta 1123128 Exim PolicyDokument2 SeitenHTTP://WWW - Authorstream.com/presentation/kunalcmehta 1123128 Exim PolicyPranesh KumarNoch keine Bewertungen