Beruflich Dokumente

Kultur Dokumente

Bioactive Organic-Inorganic Composite Monolith Derived From Poly Vinyl Trimethoxy Silane Using Sol - Gel Process

Hochgeladen von

SEP-PublisherOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bioactive Organic-Inorganic Composite Monolith Derived From Poly Vinyl Trimethoxy Silane Using Sol - Gel Process

Hochgeladen von

SEP-PublisherCopyright:

Verfügbare Formate

Plastic and Polymer Technology (PAPT) Volume 2 Issue 3, September 2013

www.seipub.org/papt

Bioactive Organic-Inorganic Composite

Monolith Derived from Poly Vinyl

Trimethoxy Silane Using Sol- Gel Process

Mojtaba Nasr-Esfahani *1, Sohrab Nasiri 2

Department of Chemistry, Najafabad Branch, Islamic Azad University, Isfahan, Iran

m-nasresfahani@iaun.ac.ir

*1

Abstract

Homogeneous and crack-free with micron pores organicinorganic composite monoliths in a binary system of Ca and

Si, were prepared by means of a sol-gel route starting from

polymerized vinyltrimethoxysilane, about 20-mers, and an

alcoholic solutions of calcium acetate. The surfaces of the

specimens were characterized using XRD, FT-IR, SEM and

EDX analysis. In vitro bioactivity tests were performed in

SBF and showed that all composite monoliths produced

were bioactive, indicating that the composite monolith with

composition VTMS:H2O:i-PrOH:Ca(OAc)2 = 1:6:6:0.2 (mol)

can be suitable for the molecular design and fabrication of

bioactive tissue engineered scaffolds.

Keywords

Organic-Inorganic

Bioactivity

Composite;

Monolith;

Sol-Gel

Process;

Introduction

The solgel process is a chemical synthesis technique

for the preparation of glasses and ceramics. The

preparation of monolithic glasses, glass fibres, pure

fine powders and other ceramic materials from metal

alkoxides or metal salts by the gel-method has been

reported since late 1970s by Hench et. al. and Babonneau

et. al.. Sol-gel processing has been intensely studied as

an alternative method for preparing ceramics and

glasses for a wide variety of applications, including

the field of bioceramics. The high bioactivity of the solgel derived materials is related to the textural features

of the gels, i.e., pore size and pore volume associated

with the large surface area, higher rate of dissolution,

and the negative surface charge (Pereira et. al and NasrEsfahani et. al.).

In the early 1990s, Kokubo and his co-workers found

that glass or glass ceramics with lime and silica as

major ingredients formed a silica gel layer on their

surface in the body environment, and that the layer

served as nucleating sites for crystallization of

calcium-deficient apatite, which formed a bond with

bone. After that, the sol-gel processing method was

used to produce powder and monolithic samples of

the gel the CaO-SiO2 glasses for use in tissue

engineering applications (Saravanapavan et. al.).

Monolithic gels are potentially of interest because

complex shapes may be formed at room temperature

and considered at rather low temperatures without

melting. Monoliths are defined as bulk gels (smallest

dimension 1 mm) cast to shape and processed

without cracking (Brinker et. al.). The main reason for

difficulty in making bulk glass consists in the fact that

cracks and fractures are often generated when a bulk

wet gel body containing solvents is dried. One of the

methods to avoid occurrence of cracks and fracture

during drying of gels and subsequent heating for gel

to glass conversion is when an organic polymer is

incorporated. The solutions Si(OCH3)4-H2O-HNO3polymer containing poly(acrylic acid), poly(sodium

styrenesulfonate) or poly(ethylene oxide) as organic

polymer component are used to produce silica gels

consisting of interconnected micrometer size silica

networks and pores (Nakanishi et. al.). This structure

results from the concurrent occurrence of phase

separation of the solution and solgel transition of

silica-rich phase.

Recently, organically modified sol-gel-derived metal

oxides are attracted attention because of their unique

properties, such as low elastic modulus and

deformability (Mackenzie et. al. and Margarita et. al.). In

these hybrid materials, organic components are

chemically incorporated into inorganic networks at

nanometer level. It is highly probable that organic

polymers are bioactive if incorporating silanol groups

and calcium ions since they are believed to play

important roles in bioactivity. Organic-inorganic

composite coatings have been prepared, starting from

vinyltrimethoxysilane, by sol-gel processing and their

63

www.seipub.org/papt

Plastic and Polymer Technology (PAPT) Volume 2 Issue 3, September 2013

bioactivity has been confirmed (Tsuru et. al.). It is

expected that monoliths of such bioactive gels may

widen the biomedical use of organic polymer

materials. In the present study, we prepared such

monoliths in a modified procedure, studied optimum

conditions to develop homogeneous, smooth, porous

structure and crack-free, and examined changes in

bioactivity of the monoliths with respect to Ca

contents. Our goal was to obtain a more versatile

compositional system for the molecular design and

fabrication of bioactive multifunctional tissueengineered scaffolds.

Experimental

Materials

Starting materials used in this preparation were

analytical grade Vinyltrimethoxysilane (VTMS, Merck),

tertiary butyl peroxide (Merck), Ca(CH3COO)24H2O

(Merck), nitric acid (Merck), isopropanol (i-PrOH,

Merck). All materials were used as received without

further purification.

Mixture of i-PrOH and double distillated water was

used as solvent with molar ratio 1:1. 2N nitric acid

(HNO3) was used to catalyze the PVTMS hydrolysis

during the sol preparation along with molar ratios

H2O/VTMS of 6:1 (i.e. excess water) and volume (v)

ratios H2O/HNO3 of 6:1. Table 1 shows the final

mixing ratios of the chemicals.

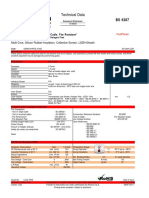

TABLE 1 THE COMPOSITIONS OF ORGANIC-INORGANIC COMPOSITE GELS

(MOL) AND THEIR GELATION TIMES (DAYS)

VTMS

Ca(CH3COO)2

Gelation

time

(day)

M1

1.0

M2

1.0

0.1

M3

1.0

0.2

M4

1.0

0.3

Gel

Mixing ratios (mol)

Description of

monolith

Transparent,

homogeneous

Opaque,

homogeneous

Opaque,

homogeneous

Opaque,

heterogeneous

added in small amount over a 30-min period. This

mixture has been maintained for a half hour to ensure

complete hydrolysis and the progression of

condensation. The calcium acetate was then added to

this mixture and allowed to dissolve. Pouring and

casting was achieved an hour later.

Monolith Synthesis

Fig. 1 schematically illustrates the process followed to

obtain cylindrical monoliths. The sol was prepared at

room temperature in Pyrex glass beakers using the

mixing order described above, and then cast into

Teflon mould with diameter 25 mm and thickness up

to 30 mm for gelation. Both aging and drying of wet

gels were conducted in a programmable oven. Aging

of the gels took place at 60C for 72 h. The drying of

the gels was then conducted reaching a maximum

temperature of 320C for 1 h in flowing nitrogen. The

drying schedule used a slow ramping rate (1C/min)

to obtain crack free monoliths.

FIG. 1 SCHEMATIC ILLUSTRATION OF THE SOL_GEL PROCESS

FOLLOWED FOR THE PREPARATION OF ORGANICINORGANIC COMPOSITE MONOLITHS

Approximately 10% shrinkage was observed during

aging and drying. The organic-inorganic composite

monoliths produced were cylindrical, with dimensions

2223 mm in diameter and 4-5 mm in height without

cracks (Fig. 2). Synthesized monolith in this process is

like a yellow slice.

Preparation of Poly Vinyltrimethoxysilane (PVTMS)

Vinyltrimethoxysilane (6 g, 0.04 mol) was polymerized

to 20-mers with tertiary butyl peroxide (0.37 ml, 5

mol%) as an initiator using refluxing for 2 h at 150C

in flowing nitrogen.

Mixing Order

2N HNO3 was added to the mixture of water and iPrOH and gently stirred for 5 min. PVTMS was then

64

FIG. 2 ORGANIC-INORGANIC COMPOSITE MONOLITHS

PRODUCED

Characterization

TGA curves were recorded under dynamic argon-flow

at a heating rate of 10C/min on crushed bulk

specimens from room temperature to 400C. A

Setaram1640 model was used with Al2O3 as the

Plastic and Polymer Technology (PAPT) Volume 2 Issue 3, September 2013

reference material. Scanning electron microscope

(Vega (II) Tescan) was used to determine the

morphology of monolith. The same instrument was

also used to perform electron diffraction spectroscopy

(EDS) quantitative analysis of monolith. The surfaces

of the monoliths made were analysed using a powder

diffractometer

(Philips

XpertMPD).

XRD

measurements were performed by the step scanning

method with CuKa radiation. The instrument was

operated at 40 kV and 40 mA with a 0.040 2 step and

a count rate of 30 s/step, the 2 values ranging from

10 to 50. The formation of the apatite layer was

analyzed

using

Fourier

transform

infrared

spectroscopy (FTIR) (Bomem, MB-100) in the range

2000 600 cm1.

www.seipub.org/papt

sample is only 5-6% up to 320C. No weight loss was

observed after this temperature. Considering attained

information from Fig. 3, 320C of heat was selected as

a suitable temperature for the bioactive gel stability.

In Vitro Bioactivity Testing

Simulated body fluid (SBF) soaking was used to

evaluate the in vitro bioactivity of monolith samples.

The composition of this buffer, described by Kokubo

has an ionic composition similar to that of human

blood plasma. SBF is reported to produce the same

type of hydroxyapatite layers in vitro, as it would

form on the glass surface in vivo.

The samples were immersed in simulated body fluid

and all the immersed samples were hold in a water

bath at 37C for 30 days.

Results and Discussion

Gel Properties

Table 1 describes the appearance of typical monolithic

gels. Addition of calcium acetate content decreased

homogeneity and M3 with the greatest calcium acetate

content led to a homogeneous monolithic gel.

The aged gel, termed WET, contains the most amount

of solvent while the dried samples, termed DRY,

contain hardly any solvent. Fig. 3 shows the TGA

curves of the WET and DRY gels. The WET sample

showed an initial endothermic process in the range of

130-160C, which was attributed to a residual loss of

water and alcohol, corresponding to a weight loss of 45%. A second endothermic process occured at a

temperature between 220 and 300C, with a weight

loss of 5-6%; then, the weight remained constant up to

400C. This last process was attributed to the loss of

the carbonization or the combustion of organic

compounds and decomposition of acetates used in the

sol preparation. In addition, Fig. 3 shows the TGA

curve of the gel after drying at 130C for 2 days and

grinding (DRY). The total weight loss for the DRY

FIG. 3 TGA CURVES FOR WET (A) AND DRY (B) M3 GEL

COMPOSISION

Surface Characterization

The XRD study of the monolithic gel glasses

confirmed the absence of crystalline phases in the

samples, because no diffraction maxima were observed

and only a broad band between 18 and 40 2 was

detected for all compositions. The XRD patterns of the

surfaces of M3 before and after 14 days immersion in

SBF are shown in Fig. 4 as an example. The surface

after 14 days immersion showed diffraction peaks

corresponding to the (002), (210), and (211) reflections

of

calcium

phosphate

carbonate

hydroxide

[Ca5(PO4,CO3)3(OH)]. Other less intense peaks of HCA

were also identified when the count rate of the XRD

analysis was increased to 40 s/step.

FIG. 4 XRD TRACES OF THE M3 SURFACE BEFORE (A) AND

AFTER IN VITRO TESTING FOR 14 DAYS (B). THE STANDARD

PEAKS FOR HA ARE IDENTIFIED

65

www.seipub.org/papt

Plastic and Polymer Technology (PAPT) Volume 2 Issue 3, September 2013

Scanning electron microscopy observation of the

organic-inorganic composite monoliths showed that

the surfaces of all samples were smooth, crack-free

and porous. An ideal pore structure was shown clearly,

exhibiting a homogeneous interconnected macroporous

network with open pores. The diameters of these

smaller pores varied from 5 to 10 m. The Si and Ca

content determined by quantitative EDX analysis of

the surfaces agreed with the nominal compositions

given in Table 1. Figure 5a shows the SEM

micrographs of the M3 surfaces before and after

immersion in SBF for different periods. After 14 days

of immersion, the micrograph (Fig. 5b) indicated the

nucleation and growth of spherical particles on the

glass surface.

The EDX studies revealed the inclusion of phosphorous

on the surfaces of the monolith sample M3. The results

showed that the Ca and P concentrations on the surface

increased, whereas the silicon concentration decreased.

A tiny amount of chlorine ions was also detected on the

surface of the SBF-immersed specimen. The Ca/P ratio,

determined by semiquantitative EDX analysis of the

surface layer after 14 days immersion in SBF, was

approximately 1.47 for the M3 sample. This value is

comparable to the Ca/P ratio of the human bone, as it

ranges between 1.6 and 1.7 depending on the age of the

person (Ravaglioli et. al.).

FIG. 5 SEM MICROGRAPH OF M3 SURFACES BEFORE AND

AFTER IN VITRO TESTING: (A) PREPERATION, AND AFTER (B)

3, (C) 7 AND (D) 14 IMMERSION IN SBF (ORIGINAL

MAGNIFICATION 2000)

FTIR Investigations on Monolithic Organic-Inorganic

Composite

The infrared spectra of all glasses showed an intense

band between 1100 and 1040 cm-1, attributed to an

asymmetric vibration of the Si-O-Si bond. The band

shown at 814-793 cm-1 corresponds to a symmetric

vibration of the Si-O bond. After soaking for 7 days in

66

SBF (Figure 6b), M3 displayed a band about 600 cm-1

that corresponds to the antisymmetric vibration of the

P-O bond in amorphous calcium phosphate. This band

evolved after 14 days of assay. Parts b and c of Figure

6, for illustrative purposes, show the evolution of

apatite formation on the M3 surface for different assay

times.

FIG. 6 FTIR SPECTRA OF M3 BEFORE (BLUE) AND AFTER

SOAKING FOR 7 (RED) AND 14 DAYS (GREEN) IN SBF

Conclusions

Polymerized vinyltrimethoxysilane (VTMS), about 20mers, was mixed with a alcoholic solution of calcium

acetate (Ca(OAc)2) where a typical composition of the

mixture was: VTMS:H2O: i-PrOH:Ca(OAc)2 = 1 : 6 : 6 :

0.2 (mol). The resultant sol was heated for 24 h at 60C

to produce a transparent monolithic gel. Then, the wet

monoliths were dried to maximum temperature 320C.

The surface analyses showed that the monoliths were

all amorphous, homogeneous and porous structure

with micron pores; while TGA analyses revealed that

residual organic materials, absorbed water and

Ca(OAC)2 could be removed before 300C. The in

vitro studies showed that all organic-inorganic

composite monoliths produced were bioactive. It was

concluded that the present monolith was bioactive and

can be suitable for the molecular design and

fabrication of bioactive multifunctional tissue

engineered scaffolds.

ACKNOWLEDGMENT

This research has been supported financially by

Najafabad Branch, Islamic Azad University.

REFERENCES

Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. 1990,

33, 90.

Plastic and Polymer Technology (PAPT) Volume 2 Issue 3, September 2013

Babonneau, F; in: P. Wisian-Neilson, H.R. Allcock, K.J.

Wynne (Eds.), Inorganic and Organometallic Polymers,

vol. 2, 1994, p. 134.

www.seipub.org/papt

Solids, 1992, 139, 113.

Mackenzie, JD. Structures and properties of ormosils. J. SolGel Sci. and Tech., 1994, 2,81-86.

Pereira M.M.; Hench L.L. Mechanism of hydroxyapatite

Margarita, D.; Ruiz, A.I.; Aranda, P.; Damme, H.V.; Ruiz-

formation on porous gel-silica substrates. J Sol-Gel Sci

Hitzky, E. Bio-Nanohybrids Based on Layered Inorganic

Technol, 1996, 7, 5968.

Solids: Gelatin Nanocomposites. Current Nanoscience,

Nasr-Esfahani, M.; Ebrahimi-Kahrizsangi, R; Dadash, M.S;

Karbasi, S. Bonding Strength, Hardness and Bioactivity

2002, 2, 231.

Tsuru, K.; Hayakawa, S.; Ohtsuki, C.; Osaka, A. Bioactive

of Nano Bioglass-Titania Nano Composite Coating

Gel

Deposited on NiTi Nails. Current Nanoscience, 2011, 7,

Journal of Sol-Gel Science and Technology 1998, 13, 237

568-575.

240.

Kokubo, T. J. Ceram. Soc. Japan. 99, 965973 (1991).

Coatings

Derived

from

Vinyltrimethoxysilane,

Kokubo, T.; Huang, Z.; Hayashi, T.; Sakka, S.; Kitsugi, T.;

Saravanapavan, P.; Hench, L.L. Low-temperature synthesis,

Yamamuro, T. Ca, P-rich layer formed on high-strength

structure, and bioactivity of gel-derived glasses in the

bioactive glass-ceramic A-W. J. Biomed. Mater. Res. 24

binary CaO-SiO2 system, Journal of Biomaterial Research,

(1990) 331343.

2001, 54, 608618.

Ravaglioli, A; Krajewski, A; Celotti, GC.; Piancastelli, A.;

Saravanapavan, P.; Jones, J.R.; Verrier, S.; Beilby, R.; Shirtliff,

V.J.; Hench, L.L.; Polak, J.M. Binary CaO-SiO2 gel-glasses

for biomedical applications. Bio-Medical Materials and

Engineering, 2004, 14, 467-486.

Brinker, C.J.; Scherer, G.W. SolGel Science: The Physics and

Chemistry of SolGel Processing, Academic Press, New

York, 1990.

Nakanishi,

K.,

Sugawa,

Y.;

Soga,

N.;

Pore

surface

characteristics of macroporous silica gels prepared from

polymer-containing solution. J. Non-Cryst. Solids, 1991,

134, 3946.

Nakanishi, K.; Soga, N.; Phase separation in silica solgel

system containing polyacrylic acid I. Gel formation

Bacchini, B; Montanari, L.; Zama, G.; Piombi, L. Mineral

evolution of bone. Biomaterials 1996;17:617622.

Mojtaba Nasr Esfahani received his B.S. (1994) in Chemistry

from Sharif University and his M.S. (1997) in Inorganic

Chemistry from Shiraz University, Ph.D. (2007) in Inorganic

Chemistry from Isfahan University. In 1997, he was

employed as an Assistant Professor by Islamic Azad

University, Najafabad Branch.

Sohrab Nasiri received his B.Sc. in Material Engineering

from Islamic Azad University Najafabad Branch in 2007;

M.S. in Materials Science: Material Selection from Iranian

Azad UniversityNajafabad Branch in 2010, respectively.

His active fields of research are Nano Biocomposites and

Novel Synthesis Methods for Nanocomposites Preparation.

Behavior and effect of solvent composition. J. Non-Cryst.

67

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Copper Loops For 222 and 440MHzDokument5 SeitenCopper Loops For 222 and 440MHzBenjamin Dover100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A22009BDokument162 SeitenA22009BInstalatii CivileNoch keine Bewertungen

- Hydraulic Brake SystemDokument11 SeitenHydraulic Brake SystemRajKumawat100% (1)

- GET - Safety Presentation 2009Dokument27 SeitenGET - Safety Presentation 2009keyur1109Noch keine Bewertungen

- K-Tron Premier Rep Catalog Dec 2010 PDFDokument429 SeitenK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- Colligative Properties of SolutionsDokument11 SeitenColligative Properties of SolutionsNelsonMoseM100% (1)

- Mill's Critique of Bentham's UtilitarianismDokument9 SeitenMill's Critique of Bentham's UtilitarianismSEP-PublisherNoch keine Bewertungen

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDokument5 SeitenMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNoch keine Bewertungen

- Quantum Meditation: The Self-Spirit ProjectionDokument8 SeitenQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNoch keine Bewertungen

- Mindfulness and Happiness: The Empirical FoundationDokument7 SeitenMindfulness and Happiness: The Empirical FoundationSEP-PublisherNoch keine Bewertungen

- Cold Mind: The Released Suffering StabilityDokument3 SeitenCold Mind: The Released Suffering StabilitySEP-PublisherNoch keine Bewertungen

- Focus On The Fundamentals of Shielded MV Power CableDokument3 SeitenFocus On The Fundamentals of Shielded MV Power CableMrNoch keine Bewertungen

- Suction Cups/grippers: Duraflex® BagDokument2 SeitenSuction Cups/grippers: Duraflex® BagBe HappyNoch keine Bewertungen

- Fired Heaters - Improving Energy Efficiency in FurnacesDokument2 SeitenFired Heaters - Improving Energy Efficiency in FurnacesReyes SanchezNoch keine Bewertungen

- Carrier FCUDokument140 SeitenCarrier FCUInventor SolidworksNoch keine Bewertungen

- Turbine Start Up Curve in Cold Start Up: Automatic Speed IncreaseDokument2 SeitenTurbine Start Up Curve in Cold Start Up: Automatic Speed Increasekumarmm1234Noch keine Bewertungen

- NBK TA Brochure 2016-EmailDokument11 SeitenNBK TA Brochure 2016-EmailPietrus NimbusNoch keine Bewertungen

- Sae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsDokument3 SeitenSae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsAnonymous 7ZTcBn100% (1)

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDokument1 SeiteSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNoch keine Bewertungen

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDokument3 Seiten100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalNoch keine Bewertungen

- Abb PDFDokument24 SeitenAbb PDFFreddy Mauricio LucayNoch keine Bewertungen

- DokaDokument23 SeitenDokaKarthik U WCFANoch keine Bewertungen

- Turboflow XL 32Dokument10 SeitenTurboflow XL 32Chris StroudNoch keine Bewertungen

- L&T Pipeline Ball Valves PDFDokument19 SeitenL&T Pipeline Ball Valves PDFSanjeev KachharaNoch keine Bewertungen

- HR Datasheet RotoscanDokument2 SeitenHR Datasheet RotoscanRaúl Jiménez AcevesNoch keine Bewertungen

- CI Injection P&ID (Printable)Dokument2 SeitenCI Injection P&ID (Printable)Mehtab Alam ShaikhNoch keine Bewertungen

- Binder 1Dokument6 SeitenBinder 1Andy SoxxNoch keine Bewertungen

- Fuel Field ManualDokument18 SeitenFuel Field ManualFREDIELABRADORNoch keine Bewertungen

- B&M Series 1000 SwitchesDokument12 SeitenB&M Series 1000 SwitchesscribdkhatnNoch keine Bewertungen

- ACADIA 2019 Papers BUGA WOOD NocoverDokument11 SeitenACADIA 2019 Papers BUGA WOOD NocoverBarbiPetőNoch keine Bewertungen

- XLIGHT Revestimientos InterioresDokument4 SeitenXLIGHT Revestimientos InterioresdandragutescuNoch keine Bewertungen

- AcryGuard TDS 2020Dokument3 SeitenAcryGuard TDS 2020sarah magdyNoch keine Bewertungen

- Geotechnical Instrumentation and Monitoring For EarthworksDokument6 SeitenGeotechnical Instrumentation and Monitoring For EarthworksAnonymous E0FEYfaNoch keine Bewertungen

- Hardtop XP Alu: Technical Data SheetDokument5 SeitenHardtop XP Alu: Technical Data SheetAfrizal Albar RamadhanNoch keine Bewertungen

- Quicseal Fabric: DescriptionDokument2 SeitenQuicseal Fabric: DescriptionJet ToledoNoch keine Bewertungen