Beruflich Dokumente

Kultur Dokumente

2.4.13 Sulfates

Hochgeladen von

Mulayam Singh YadavOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2.4.13 Sulfates

Hochgeladen von

Mulayam Singh YadavCopyright:

Verfügbare Formate

2.4.12.

Potassium

EUROPEAN PHARMACOPOEIA 8.0

01/2008:20412 Reference solutions. Prepare 3 reference solutions in the same

manner as the test solution but adding 0.5 mL, 1.0 mL and

1.5 mL respectively of nickel standard solution (10 ppm Ni) R

2.4.12. POTASSIUM

in addition to the 20.0 g of the substance to be examined.

To 10 mL of the prescribed solution add 2 mL of a freshly

Set the zero of the instrument using methyl isobutyl ketone R

prepared 10 g/L solution of sodium tetraphenylborate R.

treated as described for preparation of the test solution

Prepare a standard in the same manner using a mixture of

omitting the substance to be examined. Measure the

5 mL of potassium standard solution (20 ppm K) R and 5 mL

absorbance at 232.0 nm using a nickel hollow-cathode lamp as

of water R.

source of radiation and an air-acetylene ame.

After 5 min, any opalescence in the test solution is not more

The substance to be examined contains not more than 1 ppm

intense than that in the standard.

of nickel, unless otherwise prescribed.

01/2008:20413

corrected 8.0

01/2008:20416

2.4.13. SULFATES

2.4.16. TOTAL ASH

All solutions used for this test must be prepared with distilled

water R.

Add 3 mL of a 250 g/L solution of barium chloride R to 4.5 mL

of sulfate standard solution (10 ppm SO4) R1. Shake and allow

to stand for 1 min. To 2.5 mL of this suspension add 15 mL of

the prescribed solution and 0.5 mL of acetic acid R. Prepare a

standard in the same manner using 15 mL of sulfate standard

solution (10 ppm SO4) R instead of the prescribed solution.

After 5 min, any opalescence in the test solution is not more

intense than that in the standard.

Heat a silica or platinum crucible to redness for 30 min, allow

to cool in a desiccator and weigh. Unless otherwise prescribed,

evenly distribute 1.00 g of the substance or the powdered

herbal drug to be examined in the crucible. Dry at 100 C to

105 C for 1 h and ignite to constant mass in a mufe furnace

at 600 C 25 C, allowing the crucible to cool in a desiccator

after each ignition. Flames should not be produced at any time

during the procedure. If after prolonged ignition the ash still

contains black particles, take up with hot water, lter through

an ashless lter paper and ignite the residue and the lter

paper. Combine the ltrate with the ash, carefully evaporate

to dryness and ignite to constant mass.

04/2010:20414

01/2008:20417

2.4.14. SULFATED ASH(1)

Ignite a suitable crucible (for example, silica, platinum,

porcelain or quartz) at 600 50 C for 30 min, allow to cool

in a desiccator over silica gel or other suitable desiccant and

weigh. Place the prescribed amount of the substance to be

examined in the crucible and weigh. Moisten the substance to

be examined with a small amount of sulfuric acid R (usually

1 mL) and heat gently at as low a temperature as practicable

until the sample is thoroughly charred. After cooling, moisten

the residue with a small amount of sulfuric acid R (usually

1 mL), heat gently until white fumes are no longer evolved

and ignite at 600 50 C until the residue is completely

incinerated. Ensure that ames are not produced at any

time during the procedure. Allow the crucible to cool in a

desiccator over silica gel or other suitable desiccant, weigh it

again and calculate the percentage of residue.

If the amount of the residue so obtained exceeds the prescribed

limit, repeat the moistening with sulfuric acid R and ignition,

as previously, for 30 min periods until 2 consecutive weighings

do not differ by more than 0.5 mg or until the percentage of

residue complies with the prescribed limit.

The amount of substance used for the test (usually 1-2 g) is

chosen so that at the prescribed limit the mass of the residue

(usually about 1 mg) can be measured with sufcient accuracy.

2.4.17. ALUMINIUM

Place the prescribed solution in a separating funnel and

shake with 2 quantities, each of 20 mL, and then with one

10 mL quantity of a 5 g/L solution of hydroxyquinoline R in

chloroform R. Dilute the combined chloroform solutions to

50.0 mL with chloroform R (test solution).

Prepare a standard in the same manner using the prescribed

reference solution.

Prepare a blank in the same manner using the prescribed

blank solution.

Measure the intensity of the uorescence (2.2.21) of the test

solution (I1), of the standard (I2) and of the blank (I3) using

an excitant beam at 392 nm and a secondary lter with a

transmission band centred on 518 nm or a monochromator

set to transmit at this wavelength.

The uorescence (I1 I3) of the test solution is not greater than

that of the standard (I2 I3).

01/2008:20418

2.4.18. FREE FORMALDEHYDE

Use method A, unless otherwise prescribed. Method B is

01/2008:20415 suitable for vaccines where sodium metabisulte has been

corrected 7.0 used to neutralise excess formaldehyde.

2.4.15. NICKEL IN POLYOLS

Determine the nickel by atomic absorption spectrometry

(2.2.23, Method II).

Test solution. Dissolve 20.0 g of the substance to be examined

in a mixture of equal volumes of dilute acetic acid R and

water R and dilute to 100.0 mL with the same mixture of

solvents. Add 2.0 mL of a saturated solution of ammonium

pyrrolidinedithiocarbamate R (about 10 g/L) and 10.0 mL of

methyl isobutyl ketone R and then shake for 30 s protected

from bright light. Allow the layers to separate and use the

methyl isobutyl ketone layer.

METHOD A

For vaccines for human use, prepare a 1 in 10 dilution of the

vaccine to be examined. For bacterial toxoids for veterinary

use, prepare a 1 in 25 dilution of the vaccine to be examined.

To 1 mL of the dilution, add 4 mL of water R and 5 mL of

acetylacetone reagent R1. Place the tube in a water-bath at

40 C for 40 min. Examine the tubes down their vertical axes.

The solution is not more intensely coloured than a standard,

prepared at the same time and in the same manner, using

1 mL of a dilution of formaldehyde solution R containing 20 g

of formaldehyde (CH2O) per millilitre, instead of the dilution

of the vaccine to be examined.

(1) This chapter has undergone pharmacopoeial harmonisation. See chapter 5.8. Pharmacopoeial harmonisation.

132

See the information section on general monographs (cover pages)

Das könnte Ihnen auch gefallen

- Advanced Pharmaceutical analysisVon EverandAdvanced Pharmaceutical analysisBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterVon EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNoch keine Bewertungen

- 2.4.18 Free FormaldehydeDokument2 Seiten2.4.18 Free FormaldehydeMulayam Singh YadavNoch keine Bewertungen

- USP EP - 2.4.13 - Sulfates, 2.4.16 - Total AshDokument1 SeiteUSP EP - 2.4.13 - Sulfates, 2.4.16 - Total AshVinz Phillip LeonardoNoch keine Bewertungen

- MACROGOLSDokument16 SeitenMACROGOLSClaudiaNoch keine Bewertungen

- Xanthani GummiDokument2 SeitenXanthani GummiLaurentiu DinuNoch keine Bewertungen

- PH Eur PETDokument3 SeitenPH Eur PETSDENoch keine Bewertungen

- Crospovidone PDFDokument2 SeitenCrospovidone PDFstselvaNoch keine Bewertungen

- 2.5.5. Peroxide ValueDokument4 Seiten2.5.5. Peroxide ValuejjtedyNoch keine Bewertungen

- Usp36-Nf31 01 38Dokument2 SeitenUsp36-Nf31 01 38Salsabil Nurazizah TANoch keine Bewertungen

- PH Euro 3.1.3 PolyolefinesDokument9 SeitenPH Euro 3.1.3 Polyolefinesryad bmzaNoch keine Bewertungen

- PH Euro 3.1.6Dokument10 SeitenPH Euro 3.1.6ryad bmzaNoch keine Bewertungen

- 2.5.5. SOP Peroxide ValueDokument2 Seiten2.5.5. SOP Peroxide ValueDhoni W Fadliansyah100% (1)

- USP 231 Heavy MetalsDokument2 SeitenUSP 231 Heavy MetalsKIMKWANSOONoch keine Bewertungen

- Isoxsuprine HydrochlorideDokument2 SeitenIsoxsuprine HydrochlorideYuli HdyNoch keine Bewertungen

- 2.4.10. Lead in SugarsDokument1 Seite2.4.10. Lead in SugarsMulayam Singh YadavNoch keine Bewertungen

- PH Euro 3.1.8Dokument4 SeitenPH Euro 3.1.8ryad bmzaNoch keine Bewertungen

- Usp31nf26s1 - c211, General Chapters - 211 - ARSENICDokument2 SeitenUsp31nf26s1 - c211, General Chapters - 211 - ARSENICEfsha KhanNoch keine Bewertungen

- CPCB - So2Dokument11 SeitenCPCB - So2Sudipto GhoshNoch keine Bewertungen

- Ep4.0 01 105Dokument1 SeiteEp4.0 01 105Salsabil Nurazizah TANoch keine Bewertungen

- Water For InjectionsDokument4 SeitenWater For InjectionsAlvina Arum PuspitasariNoch keine Bewertungen

- 2.5.13. Aluminium in Adsorbed VaccinesDokument1 Seite2.5.13. Aluminium in Adsorbed VaccinesFabricio AmorimNoch keine Bewertungen

- 231 RBDokument2 Seiten231 RBadil budimanNoch keine Bewertungen

- Additive 211 PDFDokument4 SeitenAdditive 211 PDFChandrakantNoch keine Bewertungen

- Ethylene Oxide and DioxanDokument2 SeitenEthylene Oxide and DioxanMulayam Singh YadavNoch keine Bewertungen

- Macrogols BPDokument4 SeitenMacrogols BPASHOK KUMAR LENKANoch keine Bewertungen

- ArsenicDokument2 SeitenArsenicVanNoch keine Bewertungen

- AOCS CD 8 53 Peroxido Con CL PDFDokument2 SeitenAOCS CD 8 53 Peroxido Con CL PDFIvone Sulistya92% (13)

- Cyproheptadine Hydrochloride WordDokument4 SeitenCyproheptadine Hydrochloride WordFathur Rahman YusufNoch keine Bewertungen

- Albumin Solution, HumanDokument3 SeitenAlbumin Solution, HumanMulayam Singh Yadav67% (3)

- 〈211〉 ARSENICDokument2 Seiten〈211〉 ARSENICSiska Rotua Uli SihombingNoch keine Bewertungen

- As PDFDokument4 SeitenAs PDFShikha AgrawalNoch keine Bewertungen

- Metais Pesados USPDokument3 SeitenMetais Pesados USPDiego HenriqueNoch keine Bewertungen

- Diethyl PhthalateDokument2 SeitenDiethyl PhthalateMulayam Singh YadavNoch keine Bewertungen

- Eucalyptus OilDokument2 SeitenEucalyptus Oilsheenali0% (1)

- Antacid Suspension With Oxetacaine & SimethiconeDokument5 SeitenAntacid Suspension With Oxetacaine & SimethiconePatricia Joyce Malabanan Sunglao100% (1)

- 3.1.13. Plastic AdditivesDokument3 Seiten3.1.13. Plastic AdditivesPamela FioravantiNoch keine Bewertungen

- Chemical Oxygen Demand (Cod) : Equipment RequiredDokument4 SeitenChemical Oxygen Demand (Cod) : Equipment RequiredecotechconsultantsNoch keine Bewertungen

- FluoxetineDokument7 SeitenFluoxetineNatali CecanNoch keine Bewertungen

- Quantitative Estimation of Amino Acids by Ninhydrin: TheoryDokument11 SeitenQuantitative Estimation of Amino Acids by Ninhydrin: TheoryNamrata KulkarniNoch keine Bewertungen

- Arsen.01 ImprimirDokument6 SeitenArsen.01 ImprimirLautaro Valentin QuirogaNoch keine Bewertungen

- Sodium Hydrogen Chloride EPDokument2 SeitenSodium Hydrogen Chloride EPASHOK KUMAR LENKANoch keine Bewertungen

- Pharmaceutical CGMP Guidelines Water TestingDokument24 SeitenPharmaceutical CGMP Guidelines Water TestingloisetapiceriaNoch keine Bewertungen

- USP - Choline ChlorideDokument3 SeitenUSP - Choline Chloridehh.8968Noch keine Bewertungen

- AOAC970Dokument2 SeitenAOAC970Luisa Fernanda GonzálezNoch keine Bewertungen

- Method of Analysis For Sodium Citrate - Pharmaceutical Guidelines PDFDokument3 SeitenMethod of Analysis For Sodium Citrate - Pharmaceutical Guidelines PDFsumit guptaNoch keine Bewertungen

- Chloramphenicol EP 6.0Dokument2 SeitenChloramphenicol EP 6.0calvin fabianusNoch keine Bewertungen

- Method of Analysis For Sodium Citrate: PharmaguidelineDokument3 SeitenMethod of Analysis For Sodium Citrate: Pharmaguidelinedimiz77Noch keine Bewertungen

- PH Euro 3.1.1Dokument30 SeitenPH Euro 3.1.1ryad bmzaNoch keine Bewertungen

- Chemical Oxygen Demand (Cod)Dokument8 SeitenChemical Oxygen Demand (Cod)evreddy05100% (4)

- Drotaverine HCL MOADokument15 SeitenDrotaverine HCL MOASachin KumarNoch keine Bewertungen

- PH Eur 2.4.27. Heavy Metals in Herbal Drugs and Fatty OilsDokument2 SeitenPH Eur 2.4.27. Heavy Metals in Herbal Drugs and Fatty OilsLuis SanabriaNoch keine Bewertungen

- ColestyramineDokument2 SeitenColestyramineLaurentiu DinuNoch keine Bewertungen

- Iodine ValueDokument4 SeitenIodine ValueRobert Gilmore100% (4)

- Practical Manual of Analytical ChemistryVon EverandPractical Manual of Analytical ChemistryBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterVon EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNoch keine Bewertungen

- Experimental approaches to Biopharmaceutics and PharmacokineticsVon EverandExperimental approaches to Biopharmaceutics and PharmacokineticsNoch keine Bewertungen

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastVon EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastNoch keine Bewertungen

- Standard methods for the examination of water and sewageVon EverandStandard methods for the examination of water and sewageNoch keine Bewertungen

- Butterfly Ayurveda Private Limited 198, Sec-8, IMT Manesar, Gurgaon (Haryana)Dokument2 SeitenButterfly Ayurveda Private Limited 198, Sec-8, IMT Manesar, Gurgaon (Haryana)Mulayam Singh YadavNoch keine Bewertungen

- Documents List For Calibration LaboratoryDokument18 SeitenDocuments List For Calibration LaboratoryMulayam Singh YadavNoch keine Bewertungen

- Purified Water DOCUMENTATION: S.No. Name of Document Full FormDokument34 SeitenPurified Water DOCUMENTATION: S.No. Name of Document Full FormMulayam Singh Yadav100% (1)

- List of EquipmentsDokument10 SeitenList of EquipmentsMulayam Singh YadavNoch keine Bewertungen

- Addresses of Some Dealers in Medicinal PlantsDokument3 SeitenAddresses of Some Dealers in Medicinal PlantsMulayam Singh YadavNoch keine Bewertungen

- Dhupana KalpanaDokument3 SeitenDhupana KalpanaMulayam Singh YadavNoch keine Bewertungen

- Nabl - Scope of IIIM JammuDokument28 SeitenNabl - Scope of IIIM JammuMulayam Singh YadavNoch keine Bewertungen

- FentanylDokument2 SeitenFentanylMulayam Singh YadavNoch keine Bewertungen

- FluconazoleDokument2 SeitenFluconazoleMulayam Singh YadavNoch keine Bewertungen

- Fludarabine PhosphateDokument3 SeitenFludarabine PhosphateMulayam Singh YadavNoch keine Bewertungen

- Eplerenone (2765)Dokument2 SeitenEplerenone (2765)Mulayam Singh YadavNoch keine Bewertungen

- Affidavit: Witness With Full AdressDokument4 SeitenAffidavit: Witness With Full AdressMulayam Singh YadavNoch keine Bewertungen

- ANSI 173 Draft DS 2011 6B Targeted Verification 9-22-2011 DRAFTDokument42 SeitenANSI 173 Draft DS 2011 6B Targeted Verification 9-22-2011 DRAFTMulayam Singh YadavNoch keine Bewertungen

- Fenoterol Hydrobromide 2220Dokument2 SeitenFenoterol Hydrobromide 2220Mulayam Singh YadavNoch keine Bewertungen

- FluconazoleDokument2 SeitenFluconazoleMulayam Singh YadavNoch keine Bewertungen

- Ethylene Oxide and DioxanDokument2 SeitenEthylene Oxide and DioxanMulayam Singh YadavNoch keine Bewertungen

- Fentanyl CitrateDokument2 SeitenFentanyl CitrateMulayam Singh YadavNoch keine Bewertungen

- Eye PreparationsDokument3 SeitenEye PreparationsMulayam Singh YadavNoch keine Bewertungen

- Esomeprazole Magnesium TrihydrateDokument2 SeitenEsomeprazole Magnesium TrihydrateMulayam Singh YadavNoch keine Bewertungen

- Ethanol (96 Per Cent) (1317)Dokument2 SeitenEthanol (96 Per Cent) (1317)Mulayam Singh Yadav100% (1)

- ExtractsDokument3 SeitenExtractsMulayam Singh YadavNoch keine Bewertungen

- Du Taste RideDokument3 SeitenDu Taste RideMulayam Singh YadavNoch keine Bewertungen

- Eplerenone (2765)Dokument2 SeitenEplerenone (2765)Mulayam Singh YadavNoch keine Bewertungen

- Erythropoietin Concentrated Solution (1316)Dokument5 SeitenErythropoietin Concentrated Solution (1316)Mulayam Singh YadavNoch keine Bewertungen

- Ephedrine HydrochlorideDokument2 SeitenEphedrine HydrochlorideMulayam Singh YadavNoch keine Bewertungen

- Enalapril MaleateDokument3 SeitenEnalapril MaleateMulayam Singh YadavNoch keine Bewertungen

- Ephedrine Hydrochloride, RacemicDokument1 SeiteEphedrine Hydrochloride, RacemicMulayam Singh YadavNoch keine Bewertungen

- Docetaxel TrihydrateDokument2 SeitenDocetaxel TrihydrateMulayam Singh YadavNoch keine Bewertungen

- Terminology of Helical SpringDokument4 SeitenTerminology of Helical Springsandeep c sNoch keine Bewertungen

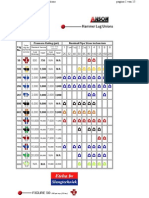

- 2015-05 Alto Motorcycle CatalogDokument97 Seiten2015-05 Alto Motorcycle CatalogGeorgi AleksievNoch keine Bewertungen

- A Process Model For EAF Steelmaking: NtroductionDokument9 SeitenA Process Model For EAF Steelmaking: NtroductionacetilenNoch keine Bewertungen

- CSTR Excel Model TemplateDokument83 SeitenCSTR Excel Model TemplatefitzggNoch keine Bewertungen

- Swd-Csa-A23.3-04 (Etabs2013)Dokument81 SeitenSwd-Csa-A23.3-04 (Etabs2013)BJERNoch keine Bewertungen

- Anionic PolymerisationDokument3 SeitenAnionic PolymerisationChayanAnandNoch keine Bewertungen

- 01 Cleveland Ruth 1997 PDFDokument21 Seiten01 Cleveland Ruth 1997 PDFMarianne Zanon ZotinNoch keine Bewertungen

- 2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarDokument8 Seiten2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarCatherineNoch keine Bewertungen

- Week 3 Earth Science FINALDokument4 SeitenWeek 3 Earth Science FINALMichael DelivaNoch keine Bewertungen

- Mark Scheme For Papers 1 and 2: Science TestsDokument60 SeitenMark Scheme For Papers 1 and 2: Science TestsDavid MagasinNoch keine Bewertungen

- Thermodynamic Optimization of A Trigeneration System Based On Biomass CombustionDokument9 SeitenThermodynamic Optimization of A Trigeneration System Based On Biomass CombustionTiago HenriquesNoch keine Bewertungen

- Prediction and Visualization of Supersonic Nozzle Ows Using OpenfoamDokument22 SeitenPrediction and Visualization of Supersonic Nozzle Ows Using OpenfoamSai Manohar RamachandranNoch keine Bewertungen

- Hamerlug Unions (Anson)Dokument15 SeitenHamerlug Unions (Anson)Leonardo ViannaNoch keine Bewertungen

- Complete Notes On 9th Physics by Asif RasheedDokument82 SeitenComplete Notes On 9th Physics by Asif RasheedAsif Rasheed Rajput75% (28)

- Form 5 Math Notebook 2021-2022Dokument183 SeitenForm 5 Math Notebook 2021-2022Kyra AmbroseNoch keine Bewertungen

- Experimestnt 1 (Structure Lab)Dokument32 SeitenExperimestnt 1 (Structure Lab)AZem AziZi Mirza50% (2)

- Mactor Report - Taller de Prospectiva D 2Dokument39 SeitenMactor Report - Taller de Prospectiva D 2Giovani Alexis Saez VegaNoch keine Bewertungen

- Physical Sciences PDFDokument51 SeitenPhysical Sciences PDFfarooqi111Noch keine Bewertungen

- Chapter 2 Process ControllDokument29 SeitenChapter 2 Process ControllWeldush BrightNoch keine Bewertungen

- RDM-chapter 1Dokument35 SeitenRDM-chapter 1Mat MatttNoch keine Bewertungen

- Indoor Ballistic Test Ranges For Small Arms and Fragmentation Testing of Ballistic-Resistant ItemsDokument4 SeitenIndoor Ballistic Test Ranges For Small Arms and Fragmentation Testing of Ballistic-Resistant ItemsAlevj DbNoch keine Bewertungen

- CS3205 A8Dokument10 SeitenCS3205 A8Rian BattlaxNoch keine Bewertungen

- Seminar On Wireless Charging of Mobile DevicesDokument24 SeitenSeminar On Wireless Charging of Mobile DevicesGourish Amonkar100% (1)

- Integration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmDokument1 SeiteIntegration Atmospheric Stability CFD Modeling MeteodynWT For Wind Resource Assessment AEP Validation Real Case Wind FarmMeteodyn_EnergyNoch keine Bewertungen

- Anchor Bolts Design of Headed Anchor BoltsDokument12 SeitenAnchor Bolts Design of Headed Anchor BoltsDoug LambNoch keine Bewertungen

- Pollen and Spore Morphology, Plant Taxonomy - ErdtmanDokument178 SeitenPollen and Spore Morphology, Plant Taxonomy - ErdtmanAndres Elgorriaga100% (1)

- Iec STD ListsDokument6 SeitenIec STD Listssasenthil241464Noch keine Bewertungen

- 3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityDokument7 Seiten3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityDorianNoch keine Bewertungen

- Cross ArmsDokument46 SeitenCross Armshalel111Noch keine Bewertungen

- Plastic MaterialDokument8 SeitenPlastic MaterialSenthil Kumar GanesanNoch keine Bewertungen