Beruflich Dokumente

Kultur Dokumente

Hygard Plast - Rebtrade

Hochgeladen von

Wrec Serrano0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

346 Ansichten1 SeiteHYGARD PLAST is a two-component, flexible cementitious waterproofing coating that can be applied to interior and exterior surfaces. It contains synthetic resin dispersions and selected cement mixed with fillers. HYGARD PLAST adheres well to surfaces, is flexible to overbridge hairline cracks, and is resistant to wear, weathering, oils, and dust. The coating is applied in two layers after surface preparation and curing is protected from wind and sun. Suitable uses include roof decks, balconies, pools, and exterior walls.

Originalbeschreibung:

waterproofing

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHYGARD PLAST is a two-component, flexible cementitious waterproofing coating that can be applied to interior and exterior surfaces. It contains synthetic resin dispersions and selected cement mixed with fillers. HYGARD PLAST adheres well to surfaces, is flexible to overbridge hairline cracks, and is resistant to wear, weathering, oils, and dust. The coating is applied in two layers after surface preparation and curing is protected from wind and sun. Suitable uses include roof decks, balconies, pools, and exterior walls.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

346 Ansichten1 SeiteHygard Plast - Rebtrade

Hochgeladen von

Wrec SerranoHYGARD PLAST is a two-component, flexible cementitious waterproofing coating that can be applied to interior and exterior surfaces. It contains synthetic resin dispersions and selected cement mixed with fillers. HYGARD PLAST adheres well to surfaces, is flexible to overbridge hairline cracks, and is resistant to wear, weathering, oils, and dust. The coating is applied in two layers after surface preparation and curing is protected from wind and sun. Suitable uses include roof decks, balconies, pools, and exterior walls.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

PRODUCT

HYGARD PLAST

DESCRIPTION

INSTALLATION PROCEDURE

HYGARD PLAST is a two-component, polymer-modified

cementitious waterproofing. It is a flexible slurry coating

based on special synthetic resin dispersion & selected cement

mixed with well graded fillers. HYGARD PLAST has excellent

adhesion, flexible and can overbridge hairline cracks. It is

wear and weather resistant making it suitable on both interior

& exterior application.

Surface preparation

The substrate must be clean and sound, free of dust and loose

particles. Cement laitance, oil, grease, form release oil or curing

compound must be removed from concrete surfaces by using

a wire brush, hammer, gritblasting or by other means. Before

applying HYGARD PLAST, be sure to pre-wet the substrate

thoroughly. To avoid too high surface temperature, it is advised

to shadow areas for the period of application.

The high content of the dispersed synthetic resin particles

results in the ability to overbridge hairline cracks. Furthermore,

HYGARD PLAST coatings have excellent abrasion resistance

and anti-skid properties. Coating of HYGARD PLAST is dust

free and resistant to motor oils.

HYGARD PLAST is non-toxic and contains no chloride or other

corrosive salts which could cause efflorescence.

USES AND APPLICATIONS

HYGARD PLAST is designed to be used as an effective

membrane waterproofing in wide range of applications.

HYGARD PLAST is suitable to be used for roof decks, balconies,

terraces, parking decks, plant box, pools, kitchen, toilet and

baths, concrete gutter, exterior masonry wall.

Rough and honeycombed areas must be corrected with

REBGROUT EPOXY or REBOND with cement mortar prior to

application. For high water pressure leaks, plugging with

HYGARD PLUG and cement should be done prior to application.

For joining or caulking two different materials like concrete and

pipes, use Polyurethane sealant prior to application.

Application

Apply the well-mixed HYGARD PLAST slurry with a paint brush,

broom or rubber squeegee onto the clean and pre-wetted

substrate. It is advised to apply the second layer the following

day. Unless the ambient temperature is very high, the next layer

can be applied as soon as the preceeding one is dry enough

to walk on.

Curing

Homogeneous hardening and waterproofing are assured if

HYGARD PLAST does not dry too quickly; therefore it should

be protected after application against high wind and intense

sunshine.

Packaging & Coverage

Component A - 1 gallon liquid 3.725 kilos

Component B - 1 bag powder 8 kilos

1 gal-set covers approximately 4-5 sm. per gallon @ 2 coats.

SALES OFFICE: Unit 315 AIC-Burgundy Empire Tower, ADB Ave. cor. Sapphire Rd., Ortigas Center, Pasig City, Metro Manila, Philippines TEL NOS.: 584.6070 to 71 FAX NO.: (632) 584.6079

www.rebtrade.com

Mixing of the two components of HYGARD PLAST results in a

plastic, thixotropic and easily applicable compound, even to

vertical surfaces. The very fine synthetic dispersion endows

the compound with excellent adhesion to concrete, and other

substrate.

Das könnte Ihnen auch gefallen

- Water ProofingDokument2 SeitenWater Proofingraghuram prasad100% (2)

- Specifications For Underground Water Storage Tanks For Fire ProtectionDokument5 SeitenSpecifications For Underground Water Storage Tanks For Fire ProtectionkirmaniNoch keine Bewertungen

- BoysenDokument2 SeitenBoysenAtoy Liby OjeñarNoch keine Bewertungen

- DSP Waterplug Sealocrete - Methodology AspireDokument1 SeiteDSP Waterplug Sealocrete - Methodology AspireJM SubionNoch keine Bewertungen

- Waterproofing Materials Commonly Applied To Commercial BuildingDokument21 SeitenWaterproofing Materials Commonly Applied To Commercial BuildingBer Salazar Jr100% (1)

- Poultry House Plan and DesignsDokument19 SeitenPoultry House Plan and DesignsKristy ManuelNoch keine Bewertungen

- Bostik Boscoseal PuDokument2 SeitenBostik Boscoseal Pujbonvier67% (3)

- Floor FinishesDokument23 SeitenFloor FinishesHafizah Ezani100% (1)

- Floor Finishes BCM 3Dokument29 SeitenFloor Finishes BCM 3VarunNoch keine Bewertungen

- Rececoat Base: Product Data SheetDokument2 SeitenRececoat Base: Product Data SheetAmira Ramlee100% (1)

- Paints: Building Technology 1Dokument26 SeitenPaints: Building Technology 1KC PanerNoch keine Bewertungen

- House DesignDokument9 SeitenHouse DesignercitakurniasariNoch keine Bewertungen

- ABC Tile Grout Technical Data Sheet 2020Dokument1 SeiteABC Tile Grout Technical Data Sheet 2020Airis Joy RojasNoch keine Bewertungen

- AAC Vs CLCDokument27 SeitenAAC Vs CLCHariharan100% (4)

- S# Item C Waterproofing On SurfacesDokument8 SeitenS# Item C Waterproofing On SurfacesDeepa Junnarkar Degwekar100% (1)

- 22 WaterproofingDokument25 Seiten22 WaterproofingAjithkumar100% (1)

- Scope of Work DocumentDokument11 SeitenScope of Work DocumentJethNoch keine Bewertungen

- Proposed Two Specification WritingDokument4 SeitenProposed Two Specification WritingKelly Santiago100% (1)

- Bostik Powerseal Tds Rev1Dokument2 SeitenBostik Powerseal Tds Rev1Albert OrainNoch keine Bewertungen

- AAC BlockDokument5 SeitenAAC BlockSibiyarasu Rock RiderNoch keine Bewertungen

- Lecture 2 - EIFS - SmallerDokument89 SeitenLecture 2 - EIFS - SmallertrungNoch keine Bewertungen

- Process of Tile InstallationDokument39 SeitenProcess of Tile InstallationChristian Nathaniel Ramon PalmaNoch keine Bewertungen

- TS - Rough Carpentry (Interior Fit - Out) PDFDokument4 SeitenTS - Rough Carpentry (Interior Fit - Out) PDFJo BompatNoch keine Bewertungen

- MethodsDokument3 SeitenMethodsshin orata100% (1)

- Modern WaterproofingDokument17 SeitenModern WaterproofingDileepa DissanayakeNoch keine Bewertungen

- Supercast PVC WaterstopDokument4 SeitenSupercast PVC WaterstopArun KumarNoch keine Bewertungen

- Drfixit Torchshield PDFDokument4 SeitenDrfixit Torchshield PDFshashiNoch keine Bewertungen

- ABC Tile AdhesiveDokument1 SeiteABC Tile AdhesiveTeomnerCabreraNoch keine Bewertungen

- Layers of A Floor - Anatomy, and Parts (Illustrated)Dokument8 SeitenLayers of A Floor - Anatomy, and Parts (Illustrated)Melaine A. FranciscoNoch keine Bewertungen

- CC Overall PDFDokument60 SeitenCC Overall PDFgarvit_952136515Noch keine Bewertungen

- Floor and Floor Covering Chapter 1Dokument63 SeitenFloor and Floor Covering Chapter 1amrithakhubaNoch keine Bewertungen

- ROOFINGDokument28 SeitenROOFINGSachin Kumar PatelNoch keine Bewertungen

- Damp FreeDokument3 SeitenDamp FreeblaqhaqarNoch keine Bewertungen

- Building Construction - Iii: Waterproofing in BuildingsDokument30 SeitenBuilding Construction - Iii: Waterproofing in BuildingsPulkit SainiNoch keine Bewertungen

- Finishing Schedule S.No. Description Flooring Skirting Walls Internal Ceiling Doors Windows/ Ventilators Frame Shutter Frame ShutterDokument1 SeiteFinishing Schedule S.No. Description Flooring Skirting Walls Internal Ceiling Doors Windows/ Ventilators Frame Shutter Frame ShutterAnonymous Of0C4dNoch keine Bewertungen

- Water Proofing MethodologyDokument6 SeitenWater Proofing Methodologykartick adhikaryNoch keine Bewertungen

- Content: The House of Scandinavian Finishing MaterialsDokument48 SeitenContent: The House of Scandinavian Finishing MaterialsFelimban AhmadNoch keine Bewertungen

- Waterproofing6.0 WebDokument16 SeitenWaterproofing6.0 Webakash nairNoch keine Bewertungen

- Tank Specification ReferenceDokument13 SeitenTank Specification ReferenceA.Subin DasNoch keine Bewertungen

- Sample Specs 4Dokument5 SeitenSample Specs 4Julian Castro100% (1)

- Damp FreeDokument2 SeitenDamp FreeShashi Bhushan SinghNoch keine Bewertungen

- Pacific Paint (Boysen) Philippines, IncDokument2 SeitenPacific Paint (Boysen) Philippines, IncJohny Lou LuzaNoch keine Bewertungen

- 1 Storey 3 Bedroom Model House BLK. 9 LOT 26Dokument5 Seiten1 Storey 3 Bedroom Model House BLK. 9 LOT 26The OneNoch keine Bewertungen

- Brochure Davies Epoxy EnamelDokument3 SeitenBrochure Davies Epoxy Enamelmsldimaano1845_87689100% (1)

- Building StandardDokument4 SeitenBuilding StandardJeff FauniNoch keine Bewertungen

- Zinc Chromate Primer Davies Epoxy Primer by Davies: Product DescriptionDokument12 SeitenZinc Chromate Primer Davies Epoxy Primer by Davies: Product DescriptionKarlNoch keine Bewertungen

- SPECIFICATIONS by SALVANDokument22 SeitenSPECIFICATIONS by SALVANmark manalangNoch keine Bewertungen

- Technical Specifications: Name of Project Location OwnerDokument2 SeitenTechnical Specifications: Name of Project Location OwnerLerie Lou R. PenarroyoNoch keine Bewertungen

- FLOORS Lecture BCD Final TermDokument39 SeitenFLOORS Lecture BCD Final TermShahid AliNoch keine Bewertungen

- Island Super Kinis Skim Coat (TDS)Dokument1 SeiteIsland Super Kinis Skim Coat (TDS)WILAN ENGINEERING INCNoch keine Bewertungen

- 2,1.1 How To Prepare Concrete For Acid StainingDokument14 Seiten2,1.1 How To Prepare Concrete For Acid StainingJoebert RendonNoch keine Bewertungen

- Pioneer Elastoseal Technical Datasheet PDFDokument2 SeitenPioneer Elastoseal Technical Datasheet PDFAabhas Upadhyaya0% (1)

- Bituminous WaterproofingDokument5 SeitenBituminous WaterproofingJayesh ChavdaNoch keine Bewertungen

- Scope of Works, Technical Specifications AND Bill of MaterialsDokument16 SeitenScope of Works, Technical Specifications AND Bill of MaterialsRoi KimssiNoch keine Bewertungen

- Work Spec - and ScopeDokument3 SeitenWork Spec - and Scopejet toledo100% (1)

- Specification Beneath Slab Moisture BarrierDokument5 SeitenSpecification Beneath Slab Moisture BarrierBaugh Graphic DesignNoch keine Bewertungen

- 3 Final Plates PDFDokument48 Seiten3 Final Plates PDFAriane Joyze BronzalNoch keine Bewertungen

- Water ProofingDokument3 SeitenWater ProofingmichaelNoch keine Bewertungen

- Con GuardDokument2 SeitenCon Guardpravi3434Noch keine Bewertungen

- Detailers Dictionary Volume 2: The Industry StandardVon EverandDetailers Dictionary Volume 2: The Industry StandardNoch keine Bewertungen

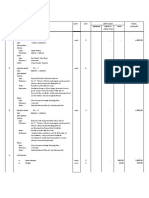

- Deliverable ListDokument112 SeitenDeliverable ListWrec Serrano50% (2)

- Rebar Cutting List Template - 2Dokument4 SeitenRebar Cutting List Template - 2Wrec SerranoNoch keine Bewertungen

- Bar Cutting List TemplateDokument4 SeitenBar Cutting List TemplateWrec SerranoNoch keine Bewertungen

- Information Bar 6 7.5 9 10.5 12 Bar No. Project Title Location Repars For Line From TO Prepared by DateDokument4 SeitenInformation Bar 6 7.5 9 10.5 12 Bar No. Project Title Location Repars For Line From TO Prepared by DateWrec SerranoNoch keine Bewertungen

- Door & WindowsDokument7 SeitenDoor & WindowsWrec SerranoNoch keine Bewertungen

- Release and Quitclaim Revised 2015 FormDokument1 SeiteRelease and Quitclaim Revised 2015 FormWrec SerranoNoch keine Bewertungen

- Combined Service & Admin Building Main Works Hardwares: HingesDokument1 SeiteCombined Service & Admin Building Main Works Hardwares: HingesWrec SerranoNoch keine Bewertungen

- Power Cables Schedule ST28 (REV.C)Dokument14 SeitenPower Cables Schedule ST28 (REV.C)Wrec SerranoNoch keine Bewertungen

- I Design Stage / Design & Development StageDokument5 SeitenI Design Stage / Design & Development StageWrec SerranoNoch keine Bewertungen

- FACILITY AREA - 07-18-14-Layout1 PDFDokument1 SeiteFACILITY AREA - 07-18-14-Layout1 PDFWrec SerranoNoch keine Bewertungen

- Neltex PPR Pricelist - 2015Dokument2 SeitenNeltex PPR Pricelist - 2015sLimExterNoch keine Bewertungen

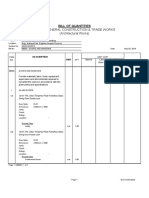

- BOQ Gate HouseDokument1 SeiteBOQ Gate HouseWrec Serrano100% (1)

- Water & Air 2016Dokument11 SeitenWater & Air 2016Wrec SerranoNoch keine Bewertungen

- Two-Wayslab Method2-2Dokument12 SeitenTwo-Wayslab Method2-2Wrec SerranoNoch keine Bewertungen

- Cast in Place Architectural Concrete - ACI 303R-12Dokument36 SeitenCast in Place Architectural Concrete - ACI 303R-12Wrec Serrano100% (1)

- Presentation Abstraction ControlDokument5 SeitenPresentation Abstraction ControlVishy AnandNoch keine Bewertungen

- Design ConceptDokument5 SeitenDesign ConceptRenniel Kent Oya-anNoch keine Bewertungen

- Telal El SokhnaDokument29 SeitenTelal El SokhnamennaNoch keine Bewertungen

- Types of Ties For and Placement of Reinforcing SteelDokument8 SeitenTypes of Ties For and Placement of Reinforcing Steelइंजि कौस्तुभ पवार100% (1)

- Doxiadis - 1974 - Architecture in Transition PDFDokument214 SeitenDoxiadis - 1974 - Architecture in Transition PDFPedro Guilherme83% (6)

- 212-Chpt 4Dokument6 Seiten212-Chpt 4zainabcomNoch keine Bewertungen

- Broc CarmitaBrochureDokument2 SeitenBroc CarmitaBrochureschiZ0prEniNoch keine Bewertungen

- Roofing Estimate ShingleDokument2 SeitenRoofing Estimate Shingletribsa67Noch keine Bewertungen

- Fundamentals of Structural Analysis: Solutions ManualDokument654 SeitenFundamentals of Structural Analysis: Solutions ManualArtur Flosi100% (3)

- 1Dokument6 Seiten1meor_azrinNoch keine Bewertungen

- Project BrochureDokument16 SeitenProject BrochureAbhishek SharmaNoch keine Bewertungen

- Wde PMH GundalaDokument307 SeitenWde PMH GundalaSubbharaju KalidindiNoch keine Bewertungen

- SECTION 15081: Duct Insulation 15081Dokument5 SeitenSECTION 15081: Duct Insulation 15081fatREVITNoch keine Bewertungen

- Typical Pile - Pile Cap Detail: Pile Cut Off Within Pile Cap 1 Typical Pile - Pile Cap Detail: Pile Cut-Off Below Pile Cap 2Dokument1 SeiteTypical Pile - Pile Cap Detail: Pile Cut Off Within Pile Cap 1 Typical Pile - Pile Cap Detail: Pile Cut-Off Below Pile Cap 2Bao Gia LuongNoch keine Bewertungen

- Lift Slab SystemDokument14 SeitenLift Slab SystemAjith AdityaNoch keine Bewertungen

- Regionalism Art and Architecture of The Regional Styles 750 AD To c.1200 (Deccan and South India)Dokument21 SeitenRegionalism Art and Architecture of The Regional Styles 750 AD To c.1200 (Deccan and South India)AnabilMahantaNoch keine Bewertungen

- Ready Mix ConcreteDokument28 SeitenReady Mix ConcreteLance Sabu100% (1)

- Edinburgh University Press Islamic ArchitectureDokument4 SeitenEdinburgh University Press Islamic ArchitectureRezart BekaNoch keine Bewertungen

- Varanasi Silk Weaving Atelier Thesis SynopsisDokument4 SeitenVaranasi Silk Weaving Atelier Thesis Synopsisshreyash gupta0% (1)

- I.M. Pei - A Profile in American Architecture (Art Ebook) PDFDokument328 SeitenI.M. Pei - A Profile in American Architecture (Art Ebook) PDFRazvan LuscovNoch keine Bewertungen

- 1.9. Minimum Requirements For A Dwelling UnitDokument2 Seiten1.9. Minimum Requirements For A Dwelling UnitGian SanchezNoch keine Bewertungen

- ORIGINALDokument146 SeitenORIGINALAmanuelNoch keine Bewertungen

- CHP 6 - Effects OF RA 9266 To RA 544Dokument4 SeitenCHP 6 - Effects OF RA 9266 To RA 544Darren Dela CruzNoch keine Bewertungen

- Architectural & Structural Drawing of Double Storey HouseDokument3 SeitenArchitectural & Structural Drawing of Double Storey HouseNur HazimahNoch keine Bewertungen

- Dormitory: DormitoriumDokument5 SeitenDormitory: DormitoriumCEZ NICOLE BAYUNNoch keine Bewertungen

- TEC-033000 - MET-DoR-PIV-P623 (Cast in Place Concrete For Sub Structures) (C)Dokument13 SeitenTEC-033000 - MET-DoR-PIV-P623 (Cast in Place Concrete For Sub Structures) (C)Haymanot BaynesagnNoch keine Bewertungen

- RDW Morello Rainier Brochure Update v25 LR 2Dokument31 SeitenRDW Morello Rainier Brochure Update v25 LR 2ESNoch keine Bewertungen

- Layouts & Plans Tamarind SuitesDokument33 SeitenLayouts & Plans Tamarind SuitesFendiNazri100% (2)

- PIDS Installation DetailsDokument1 SeitePIDS Installation Detailsmohamed ghazyNoch keine Bewertungen

- Bernard Tschumi 1Dokument4 SeitenBernard Tschumi 1MellanieRahmahNoch keine Bewertungen