Beruflich Dokumente

Kultur Dokumente

Chapter 4 B

Hochgeladen von

Andre GunawanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 4 B

Hochgeladen von

Andre GunawanCopyright:

Verfügbare Formate

CHAPTER

Construction Planning, Equipment,

and Methods

Sixth Edition

GEOTECHNICAL MATERIALS,

COMPACTION, AND STABILIZATION

A. J. Clark School of Engineering Department of Civil and Environmental Engineering

4b

By

Dr. Ibrahim Assakkaf

ENCE 420 Construction Equipment and Methods

Spring 2003

Department of Civil and Environmental Engineering

University of Maryland, College Park

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

MATERIAL PROPERTIES

Slide No. 75

ENCE 420 Assakkaf

Same weight but different volume.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Example 4

Slide No. 76

ENCE 420 Assakkaf

The soil borrow material to be used to

construct a highway embankment has a

mass unit weight 96.0 lb per cu ft (pcf)

and water content of 8%, and specific

gravity of soil solids is 2.66. The

specifications require that the soil be

compacted to dry unit weight of 112 pcf

and that the water content be held to

13%.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Example 4 (contd)

Slide No. 77

ENCE 420 Assakkaf

a) How many cubic yards of borrow are

required to construct an embankment

having a 250,000-cu-yd net section

volume?

b) How many gallons of water must be

added per cubic yard of borrow material

assuming no loss by evaporation and one

gallon of water equals 8.34 lb?

c) If the compacted fill becomes saturated at

a constant volume, what will be the water

content and mass unit weight of the soil?

Slide No. 78

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 4 (contd)

Borrow:

= 96.0

d =

lb

,

ft 3

= 8.0%,

96

lb

= 88.89 3

1 + 0.08

ft

1+

Gs = 2.66

Embankment:

d = 112.0

lb

,

ft 3

= 13.0%,

= d (1 + ) = 112(1 + 0.13) = 126.56

lb

ft 3

Slide No. 79

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 4 (contd)

(a):

Shrinkage Factor =

Compacted Dry Unit Weight

112

=

= 1.26

Bank Dry Unit Weight

88.89

Volume of Borrow Required = 1.26(250,000 cu yd) = 315,000 cu yd

(b):

Water needed in embankment :

lb

d = 126.56 112 = 14.56 3

ft

lb

Weight of Water needed = 14.56 3 250,000 yard3

ft

ft

) 27

yard

3

3

= 98,280,000 lb

Slide No. 80

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 4 (contd)

Slide No. 81

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 4 (contd)

(b) continued:

Water from borrow :

d = 96 88.89 = 7.11

lb

ft 3

27 ft 3

lb

= 60,470,550 lb

Weight of Water from Borrow = 7.11 3 315,000 yard3

3

ft

yard

Weight of Additional Water Required = 98,280,000 60,470,550 = 37,809,450 lb

37,809,450 lb

lb

= 120

315,000 yard3

cu yd

lb

1

gal

= 120

= 14.39

cu yd 8.34 lb/gal

cu yd borrow

Gallons of Req' d Water =

Slide No. 82

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 4 (contd)

(c): If the fill becomes saturated all voids between the solid soil

particles are filled with water. Therefore, the total weight

weight is

increased by the added weight of water:

Volume

voids

Vv

Total

volume

V

Volume

air

Va

Volume

water

Vw

Volume

soil solids

Vs

Weight

air = 0

Additional

Water to

AIR

replace Air

Weight

water = Ww

Total

weight W

Water

Weight

soil solids

Ws

Soil

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Example 4 (contd)

Slide No. 83

ENCE 420 Assakkaf

Total volume includes

Air

Water

Solids

Slide No. 84

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 4 (contd)

112

(c): continued G = Ws V = Ws =

= 0.675 ft 3

s

s

Vs w

Gs w 2.66(62.4)

Vw =

Ww

14.56

= 0.233 ft 3

62.4

Vv = 1.000 0.675 0.233 = 0.092 ft 3

Weight of extra water: W = V = 0.092(62.4) = 5.74 lb

w

w w

Ww (14.56 + 5.74)

=

= 0.181 = 18.1%

112

Ws

= 14.56 + 5.74 + 112 = 132.3

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

lb

ft 3

Slide No. 85

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 86

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

The engineering properties of

most soils can be improved

by compaction.

Compaction is the art of

mechanically densifying

materials.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SOIL TYPES

Slide No. 87

ENCE 420 Assakkaf

SMALL GRAINED

< #200 MESH SIEVE

NON-COHESIVE COHESIVE

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SOIL TYPES

Slide No. 88

ENCE 420 Assakkaf

ORGANIC

SOILS

Will usually

have to remove

before

building.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 89

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

Before the specifications for a

project are prepared

representative soil samples are

usually collected and tested in

the laboratory to determine

material properties.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 90

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

SOIL CLASSIFICATION

(Atterburg Limits)

LL - Liquid limit

PL - Plastic limit

PI - Plasticity Index

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 91

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

SOIL LIMITS

Slide No. 92

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SOIL CLASSIFICATION

ENCE 420 Assakkaf

LL - Liquid limit

is the water

content of a soil

when it passes

from the plastic

to liquid state.

Slide No. 93

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

SOIL CLASSIFICATION

LL - Liquid limit

Non-cohesive or sandy soils

have low LLs -- less than 20.

Clay soils have LLs ranging

from 20 to 100.

10

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 94

ENCE 420 Assakkaf

SOIL CLASSIFICATION

PL - Liquid limit

is the lowest

water content at

which a soil

remains plastic.

1/8 inch diameter thread

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 95

ENCE 420 Assakkaf

SOIL CLASSIFICATION

PI - Plastic Index

PI = LL - PL

The higher the PI the more

clay that is present in the soil.

11

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 96

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

Normal testing would include

grain-size analysis because the

size of the grains and the

distribution of those sizes are

important properties, which

affect a soil's suitability.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 97

ENCE 420 Assakkaf

COMPACTION

Soil gradation is

the distribution,

in percent (%)

by weight, of

individual

particle sizes.

12

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 98

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

Soil Gradation (Particle-size Distribution)

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 99

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

Maximum Dry Density/Optimum

Moisture

9Critical test is the construction of a

compaction curve.

9From compaction curves the

maximum dry unit weight (density)

and the percent water required to

achieve maximum density can be

determined.

13

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 100

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 101

ENCE 420 Assakkaf

COMPACTION SPECIFICATION

AND CONTROL

Maximum Dry Density/Optimum

Moisture (contd)

9This percent of water, which

corresponds to the maximum dry

density (for a given compactive

effort), is known as the optimum

water content.

14

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 102

ENCE 420 Assakkaf

The standard laboratory tests that are

used for evaluation of maximum dry

unit weights (ds) and optimum

moisture contents for various soils are:

1. The Standard Proctor Test (ASTM

D-698 and AASHTO T-99).

2. The Modified Proctor Test (ASTM,

D-1557 and AASHTO T-180)

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 103

ENCE 420 Assakkaf

Standard Proctor Test

9The soil is compacted in a mold that

has a volume of 1/30 ft3 (943.3 cm3).

9The diameter of the mold is 4 in. (101.6

mm)

9During the laboratory test, the mold is

attached to a base plate at the bottom

and to an extension at the top (see

Figure 1).

15

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 104

ENCE 420 Assakkaf

Standard Proctor Test

9The soil is mixed with varying

amounts of water and then

compacted in three equal layers by

a hammer (Figure 2) that deliver 25

blows to each layer.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 105

ENCE 420 Assakkaf

Figure 1. Standard Proctor Test Equipment: (a) mold; (b) hammer

16

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 106

ENCE 420 Assakkaf

COMPACTION

PROCTOR TEST

Standard Proctor

or

AASHTO T-99

Soil sample 1/30 cubic foot

3 layers

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 107

ENCE 420 Assakkaf

Figure 2. Compaction

of Soil using Standard

Proctor Hammer

( courtesy of John

Hester, Carterville, IL)

17

Slide No. 108

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

COMPACTION TESTS

Standard Proctor Test (continued)

9The hammer weighs 5.5 lb (mass =

2.5 kg) and has a drop of 12 in.

(304.8 mm).

9 For each test, the moist unit weight

of compaction can be calculated as

W

Vm

(28)

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 109

ENCE 420 Assakkaf

Standard Proctor Test (continued)

Where

W = weight of compacted soil in mold

Vm = volume of mold (1/30 ft3)

9For each test, the moisture content w of

the compacted soil is determined in the

laboratory.

9With known moisture content, the dry unit

weight d can be calculated as

18

Slide No. 110

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

COMPACTION TESTS

Standard Proctor Test (continued)

d =

1+

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

(29)

Slide No. 111

ENCE 420 Assakkaf

Standard Proctor Test (continued)

Where w = moisture content

9The values of d determined from the

above equation can be plotted

against the corresponding moisture

contents for the soil as shown the

following figure (Fig. 3), which is a

compaction for silty clay.

19

Slide No. 112

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

ENCE 420 Assakkaf

Figure 3. Standard Proctor Compaction Test Results for a Silty Clay

Figure 3

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 113

ENCE 420 Assakkaf

Standard Proctor Test (continued)

9For a given moisture content , the

theoretical maximum dry unit weight

is obtained when there is no air in

the void spaces, that is, when the

degree of saturation S equal 100%.

Thus, the maximum dry unit weight at

a given moisture content with zero air

voids can computed from

20

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 114

ENCE 420 Assakkaf

Standard Proctor Test (continued)

(30)

G

zav = s w

1+ e

For 100% saturation, e = Gs , so

G

(31)

zav = s w

1 + G s

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 115

ENCE 420 Assakkaf

Modified Proctor Test

9The soil is compacted in a mold that

has a volume of 1/30 ft3 (943.3 cm3).

9The diameter of the mold is 4 in.

(101.6 mm)

9During the laboratory test, the mold is

attached to a base plate at the

bottom and to an extension at the top

(see Figure 4).

21

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 116

ENCE 420 Assakkaf

Modified Proctor Test (contd)

9The soil is mixed with varying

amounts of water and then

compacted in five equal layers by a

hammer (Figure 2) that deliver 25

blows to each layer.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 117

ENCE 420 Assakkaf

Figure 4. Modified Proctor Test Equipment: (a) mold; (b) hammer

22

Slide No. 118

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

COMPACTION

PROCTOR TEST

Modified Proctor

or

AASHTO T-180

Soil sample 1/30 cubic foot

5 layers

Slide No. 119

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

COMPACTION TESTS

Modified Proctor Test (contd)

9The hammer weighs 10 lb (mass =

4.54 kg) and has a drop of 18 in.

(457.2 mm).

9 For each test, the moist unit weight

of compaction g can be calculated as

=

W

Vm

(32)

23

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 120

ENCE 420 Assakkaf

Modified Proctor Test (contd)

W = weight of compacted soil in mold

Vm = volume of mold (1/30 ft3)

9For each test, the moisture content of

the compacted soil is determined in the

laboratory.

9With known moisture content, the dry

unit weight d can be calculated (Eq.29)

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 121

ENCE 420 Assakkaf

Modified Proctor Test (contd)

9The values of d determined from the

above equation can be plotted

against the corresponding moisture

contents for the soil as shown the

following figure (Fig. 5).

24

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION TESTS

Slide No. 122

ENCE 420 Assakkaf

Figure 5. Standard and Modified Compaction Curves

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 123

ENCE 420 Assakkaf

Comparison between Standard

& Modified Proctor Tests

Figure 5 shows compaction

curves which illustrate the effect

of varying amounts of moisture

on the density of a soil subjected

to given compactive efforts.

The two energy levels depicted

are known as standard and

modified Proctor tests.

25

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 124

ENCE 420 Assakkaf

Comparison between Standard

& Modified Proctor Tests

It should be noted that the

modified Proctor, which is a

higher energy level, gives a

higher density at a lower

moisture content than the

standard Proctor, as shown

in Figure 5.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 125

ENCE 420 Assakkaf

Comparison between Standard

& Modified Proctor Tests

In this figure, the

optimum moisture for

the standard Proctor is

16%, versus 12% for the

modified Proctor.

26

Slide No. 126

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 5

The laboratory test data for a

standard Proctor test are given

as shown in Table 3. Find the

maximum dry unit weight and

the optimum moisture content.

Slide No. 127

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 5 (contd)

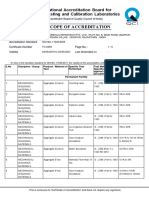

Table 3. Test Data for Example 5

Volume of Mold (ft3)

1/30

1/30

1/30

1/30

1/30

1/30

Weight of Wet Soil in the

Mold (lb)

3.88

4.09

4.23

4.28

4.24

4.19

Moisture Content (%)

12

14

16

18

20

22

27

Slide No. 128

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 5 (contd)

Volume, V (ft3)

1/30

1/30

1/30

1/30

1/30

1/30

Weight, W (lb)

3.88

4.09

4.23

4.28

4.24

4.19

(lb/ft3)

(%)

d (lb/ft3)

116.4

122.7

126.9

128.4

127.2

125.7

12

14

16

18

20

22

103.9

107.6

109.4

108.8

106.0

103.0

Sample Calculation :

Weight of Wet Soil = 4.09, = 12%, Hence

=

W

4.09

lb

=

= 122.7 3 ,

V (1 / 30)

ft

d =

1+

lb

122.7

= 107.6 3

1 + 0.14

ft

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Example 5 (contd)

Slide No. 129

ENCE 420 Assakkaf

9Plot the dry unit weight gd against the

moisture content w as shown in the

following figure(Figure 6). From the

figure find the maximum d and

optimum .

Maximum dry unit weight = 109.5 lb/ft3

Optimum moisture content = 16.5%

28

Slide No. 130

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Example 5 (contd)

Figure 6. Compaction Curve for the Data of Example 5

(lb/ft^3)

110

109

108

Dry Unit W e ight,

107

106

105

104

103

102

10

12

14

16

18

20

22

24

M oisture Conte nt, (% )

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

SPECIFICATIONS

Slide No. 131

ENCE 420 Assakkaf

Typically

specifications

give an

acceptable range

of water content,

OMC 2% for

example.

29

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 132

ENCE 420 Assakkaf

SPECIFICATIONS FOR FIELD

COMPACTION

In most specifications for earth work,

the contractor is required to achieve a

compacted field dry unit weight of 90%

to 95% of the maximum dry unit weight.

The maximum dry unit weight is the

maximum unit weight that is determined

by either the standard or modified

Proctor test.

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

SPECIFICATIONS

The specification

also sets a

minimum

density, 90% or

95% of max. dry

density for a

specific test.

Slide No. 133

ENCE 420 Assakkaf

123.

5

30

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 134

COMPACTION

SPECIFICATIONS

ENCE 420 Assakkaf

123.

5

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

SPECIFICATIONS

Must

work in

the box.

Slide No. 135

ENCE 420 Assakkaf

Lift. A layer of soil placed

on top of soil previously

placed in an embankment.

The term can be used in

reference to material as

spread or as compacted.

31

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SPECIFICATIONS FOR

FIELD COMPACTION

Slide No. 136

ENCE 420 Assakkaf

Slide No. 137

ENCE 420 Assakkaf

The specification for field

compaction can be based

either on

(1) relative compaction RC or

(2) relative density Dr

32

Slide No. 138

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

SPECIFICATIONS FOR

FIELD COMPACTION

The relative compaction (RC), is therefore,

defined as the ratio of the dry unit weight

of the soil in the field to the maximum dry

unit weight of the same soil determined in

the laboratory

RC (%) =

d (field)

d (max, lab)

100

(33)

Slide No. 139

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

SPECIFICATIONS FOR FIELD

COMPACTION

The relative density Dr is given by

Dr =

R0

1

1

(1 R0 ) RC

(34)

R0 =

d (min)

d (max)

where

d(min) = dry unit weight in the loosest condition

(at a void ratio of emax)

d(max) = dry unit weight in the densest condition

(at a void ratio of emin)

33

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SPECIFICATIONS FOR

FIELD COMPACTION

Slide No. 140

ENCE 420 Assakkaf

ASTM Test Designation D-2049

provides a procedure for the

determination of the minimum and

maximum dry unit weights of

granular soils.

For sands, this done by using a

mold with a volume of 0.1 ft3 (2830

cm3).

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SPECIFICATIONS FOR

FIELD COMPACTION

Slide No. 141

ENCE 420 Assakkaf

For determination of the minimum

dry unit weight, sand is loosely

poured into the mold from a funnel

with a 1/2-in (12.7-mm) diameter

spout.

The average height of the fall of

sand into the mold is kept at about

1 in (25.4 mm)

34

Slide No. 142

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SPECIFICATIONS FOR

FIELD COMPACTION

ENCE 420 Assakkaf

The value of d(min)

(min) can then be

determined as

d (min) =

Ws

Vm

(35)

where

Ws = weight of sand required to fill the mold

Vm = volume of the mold (0.1 ft3)

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

SPECIFICATIONS FOR

FIELD COMPACTION

Slide No. 143

ENCE 420 Assakkaf

9The maximum dry unit weight is

determined by vibrating sand in the

mold for 8 min.

9A surcharge of 2 lb/in2 (13.8 kN/m2) is

added to the top of the sand in the

mold.

9The mold is placed on a table that

vibrates at a frequency of 3600

cycles/min and that has an amplitude

of vibration of 0.025 in (0.635 mm).

35

Slide No. 144

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

SPECIFICATIONS FOR

FIELD COMPACTION

The value of d(max)

(max) can then be

determined at the end of the

vibrating period with the knowledge

of the weight and volume of sand.

An empirical formula has been

developed by Lee and Singh (1971)

to give a relationship between RC

and Dr.

Slide No. 145

CHAPTER 4b. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

SPECIFICATIONS FOR

FIELD COMPACTION

For granular soils, the relationship

is given as

RC (%) = 80 +0.2 Dr

(36)

According to Lee and Singh (1971), the correlation

between RC and Dr was based on the observation

of 47 soil samples.

36

Das könnte Ihnen auch gefallen

- 2010 Acoustic Response Final LuskDokument96 Seiten2010 Acoustic Response Final LuskAndre GunawanNoch keine Bewertungen

- Module 8Dokument113 SeitenModule 8Andre GunawanNoch keine Bewertungen

- 2004 Gps AtlantaDokument11 Seiten2004 Gps AtlantaAndre GunawanNoch keine Bewertungen

- Blaster's Training Modules: Prepared Under Sponsorship FromDokument14 SeitenBlaster's Training Modules: Prepared Under Sponsorship FromAndre GunawanNoch keine Bewertungen

- 2013 Facts Electronic DetonatorsDokument2 Seiten2013 Facts Electronic DetonatorsAndre GunawanNoch keine Bewertungen

- 2013 Electronic Detonators Final Lusk 092413Dokument108 Seiten2013 Electronic Detonators Final Lusk 092413Andre GunawanNoch keine Bewertungen

- Module 7Dokument38 SeitenModule 7Andre GunawanNoch keine Bewertungen

- Module4 PDFDokument27 SeitenModule4 PDFMolina WilmerNoch keine Bewertungen

- Chapter3c PDFDokument33 SeitenChapter3c PDFAndre GunawanNoch keine Bewertungen

- Soil Compaction 1Dokument42 SeitenSoil Compaction 1Francisco TavarezNoch keine Bewertungen

- Module6 PDFDokument28 SeitenModule6 PDFAndre GunawanNoch keine Bewertungen

- CalculationDokument21 SeitenCalculationVinayak VagheNoch keine Bewertungen

- Chapter 4 ADokument38 SeitenChapter 4 ARaj BakhtaniNoch keine Bewertungen

- Chapter3b PDFDokument27 SeitenChapter3b PDFAndre GunawanNoch keine Bewertungen

- Belt Conveyor SystemsDokument52 SeitenBelt Conveyor SystemsAndre GunawanNoch keine Bewertungen

- Module 5Dokument37 SeitenModule 5Andre GunawanNoch keine Bewertungen

- Construction Equipment PlanningDokument33 SeitenConstruction Equipment PlanningMohamed Moustafa ElashwahNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ijtimesv04i02150212114013 PDFDokument8 SeitenIjtimesv04i02150212114013 PDFMopidevi Vijaya Kishore0% (1)

- Compaction Characteristics of Prominent Agricultural Soils in Borno State of NigeriaDokument3 SeitenCompaction Characteristics of Prominent Agricultural Soils in Borno State of NigeriaIsabel BarrioNoch keine Bewertungen

- Keystone: GuideDokument12 SeitenKeystone: GuideczapatachueNoch keine Bewertungen

- Geotechnical EngineeringDokument3 SeitenGeotechnical EngineeringJesus Ray M. Mansayon67% (3)

- Soil Types and Properties GuideDokument13 SeitenSoil Types and Properties GuideAnonymous 59kjvq4OLB100% (1)

- Questions and Answers in Bridge EngineeringDokument70 SeitenQuestions and Answers in Bridge Engineeringaminjoles100% (1)

- AIPL-Scope 1 TC-8469Dokument6 SeitenAIPL-Scope 1 TC-8469Saurav KumarNoch keine Bewertungen

- Chapter 1 3 1Dokument34 SeitenChapter 1 3 1Bai Fauziyah Marohomsalic100% (1)

- Excavating and Filling EssentialsDokument12 SeitenExcavating and Filling EssentialsIlias AsimakisNoch keine Bewertungen

- Specifications of Railway FormationDokument171 SeitenSpecifications of Railway FormationKrunal ShahNoch keine Bewertungen

- E-Auction Raw Lignite Ballclay Silica Sand PDFDokument3 SeitenE-Auction Raw Lignite Ballclay Silica Sand PDFshiva1720Noch keine Bewertungen

- Hasil Lab TanahDokument4 SeitenHasil Lab TanahHamidAffandyNoch keine Bewertungen

- Stabilization of Soil - A ReviewDokument5 SeitenStabilization of Soil - A ReviewSushmit KatkaleNoch keine Bewertungen

- Sewer Install GuideDokument54 SeitenSewer Install GuideSurieduth BuskalowaNoch keine Bewertungen

- 2018 - Spagnoli - Statistical Variability of The Correlation Plasticity Index Versus Liquid Limit For Smectite and KaoliniteDokument8 Seiten2018 - Spagnoli - Statistical Variability of The Correlation Plasticity Index Versus Liquid Limit For Smectite and KaoliniteLaode Jonas TugoNoch keine Bewertungen

- TERRAZYME Seminar With Page No ReportDokument17 SeitenTERRAZYME Seminar With Page No ReportAbhinav DhayalNoch keine Bewertungen

- Asset Upload File267 118183Dokument18 SeitenAsset Upload File267 118183Anonymous MAQrYFQDzVNoch keine Bewertungen

- Compressibility Behaviour of Preloaded Highly Plastic ClaysDokument9 SeitenCompressibility Behaviour of Preloaded Highly Plastic ClaysabinNoch keine Bewertungen

- Report Karol GhatiDokument32 SeitenReport Karol GhatiMuhammad BilalNoch keine Bewertungen

- Liquid Limit by Casagrande MethodDokument4 SeitenLiquid Limit by Casagrande MethodMaica De ChavezNoch keine Bewertungen

- Characteristic Properties of Cement-Stabilized Rammed Earth BlocksDokument8 SeitenCharacteristic Properties of Cement-Stabilized Rammed Earth Blockskhaoula mouihNoch keine Bewertungen

- Upgrading Atiak-Laropi Road Project ReportDokument12 SeitenUpgrading Atiak-Laropi Road Project ReportRonald NduhuraNoch keine Bewertungen

- Module 1 - Foundation EngineeringDokument5 SeitenModule 1 - Foundation EngineeringEdmond Orena BautistaNoch keine Bewertungen

- Aggregate Base Course Specifications for Runway ConstructionDokument10 SeitenAggregate Base Course Specifications for Runway ConstructionSalahuddin MNoch keine Bewertungen

- FMLP LNG GTL CVL Spec 001 - Specification Site Preparation & EarthworkDokument10 SeitenFMLP LNG GTL CVL Spec 001 - Specification Site Preparation & EarthworkrizkyNoch keine Bewertungen

- CDOT Soil Sample PreparationDokument2 SeitenCDOT Soil Sample PreparationJenny Ann ValderramaNoch keine Bewertungen

- Construction On Expansive Soils in SudanDokument16 SeitenConstruction On Expansive Soils in SudanYtyus BlackNoch keine Bewertungen

- A Review and Study On Stabilization of Expansive Soil Using Brick DustDokument8 SeitenA Review and Study On Stabilization of Expansive Soil Using Brick DustalibuxjatoiNoch keine Bewertungen

- CBR MDD Index Correlation Study-Addis Ababa University - 2013Dokument172 SeitenCBR MDD Index Correlation Study-Addis Ababa University - 2013nimm1962Noch keine Bewertungen

- GT Report Nandauri Gaindas BujurgDokument41 SeitenGT Report Nandauri Gaindas BujurgshailenderNoch keine Bewertungen