Beruflich Dokumente

Kultur Dokumente

3196 9323 1 PB PDF

Hochgeladen von

Shumi NaharOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3196 9323 1 PB PDF

Hochgeladen von

Shumi NaharCopyright:

Verfügbare Formate

European Scientific Journal April 2014 edition vol.10, No.

12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

MEDICAL TEXTILES: SIGNIFICANCE AND

FUTURE PROSPECT IN BANGLADESH

Shilpi Akter

Assistant Professor, Dept. of Fabric Manufacturing Engineering, Bangladesh

University of Textiles, Bangladesh

Abu Yousuf Mohammad Anwarul Azim

Lecturer, Department of Textile Engineering, Primeasia University,

Bangladesh

Md. Abdullah Al Faruque

Lecturer, Dept. of Fabric Manufacturing Engineering, Bangladesh University

of Textiles, Bangladesh

Abstract

Now-a-days textiles are used in different sectors and various purposes

beyond imagination. Medical sector is one of them. An important and

emerging part of the textile industry is medical, hygiene and health sector.

The development is taking place due to the simultaneous expansion and

improvement of technology in both textile as well as medical sector. The

number of applications is huge and diverse, ranging from a single thread

suture to the complex composite structures for bone replacement and from

the simple cleaning wipe to advanced barrier fabrics used in Operation

Theater. The main object of this work is to study the types of medical textiles

used in the medical sector, information on imported items and scope of

manufacturing these items in Bangladesh. For this work we have visited

Dhaka Medical College, Sir Salimullah Medical College, Uttara Adhunik

Medical College and Hospital, BMA Bhaban Surgical Market. We have

gathered very useful and vast knowledge about the term "Medical Textiles",

as per our work and capability.

Keywords: Extracorporeal devices, Implantable materials, Non-implantable

materials, Chitin, Collagen

488

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Introduction:

Medical textiles or Medtech is one of the most important,

continuously expanding and growing field in technical textiles. Medical

textiles represent structures designed and accomplished for a medical

application. The number of applications is diverse, ranging from a single

thread suture to the complex composite structures for bone replacement and

from the simple cleaning wipe to advanced barrier fabrics used in operating

rooms. Textile materials and products, that have been engineered to meet

particular needs, are suitable for any medical and surgical application where

a combination of strength, flexibility and sometimes moisture and air

permeability are required. The medical textile industries have diversified

with new materials and innovative designs. Recently, application of textiles

has started going beyond the usual wound care, incontinence pads, plasters

etc., Latest innovation i.e., wide variety of woven, non-woven, knitted forms

of textile increasingly finding their way into a variety of surgical procedures.

As the healthcare industry is growing enormously in India, the demand for

the Medical Textile is also on the rise.

Medical Textiles are defined in various ways, such as:

David Rigby Associates.[1]

"The Medical Textile or Medtech application area "embraces all those

technical textiles used in health and hygiene applications"

"Textile Terms & Definitions" defines Medical Textiles as - "A general term

which describes a textile structure which has been designed and produced for

use in any of a variety of medical applications, including implantable

applications" [2].

Figure 1. Constituent element of Medical Textile products.

Various fibres are used to produce Medical Textiles. They are mentioned in

Table 1.

Table 1. Fibers used in medical textiles

Natural

Synthetic

Modified

489

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Cotton

Polyester

Plastic film

Chitosan

Polypropylene

Viscose

Silk

Polyethylene

Super absorbent

Cotton linters

Polyamide

Collagen

Wood fluff

Lyocell

Poly hollow polyester

Alginate

Polyurethane foam

Hollow polypropylene

Chitin

Glass fiber

Hollow silicon

membrane

Catgut

Carbon fiber

Silica fiber

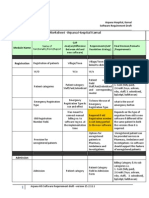

Classification of Medical Textiles:

Figure 1. shows the constituent element of midical textile products for

medical applications include materials as fibres, yarns, woven, knitted, nonwoven, PTFE felts and mesh etc.

Depending upon the usage, they are classified as1. Healthcare and Hygiene products

2. Extracorporeal devices

3. Implantable materials

4. Non-implantable materials

The classification of Medical Textile or Medtech can be represented

in Figure 2.

Non-Implantable Materials

These materials used for external applications on the body and may or may

not make contact with skin. This includes wound care, bandages, plasters,

pressure garments, orthopedic belts etc. They are shown in Table II.

Implantable Materials

These materials are used in effecting repair to the body whether it is wound

closure (sutures) or replacement surgery (vascular grafts, artificial ligaments

etc.). They are shown in Table III.

490

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Fiber Type

Fabric Structure

Applications

Cotton, Viscose, Lyocell

Non-woven

Absorbent Pad

Alginate fiber, Chitosan, Silk,

Non-woven

Absorbent Pad

Viscose, Lyocell, Cotton

Woven, Non-woven, Knitted

Wound-contact layer

Viscose, Lyocell, Plastics film

Woven, Non-woven

Base material

Cotton, Viscose, Lyocell,

Polyamide fiber

Woven, Non-woven

Base material

Fiber Type

Fabric Structure

Applications

Elastomeric fiber yarns

Woven, Non-woven, Knitted

Simple non-elastic and

elastic bandages

Cotton, Viscose, Lyocell

Woven, Non-woven, Knitted

Simple non-elastic and

elastic bandages

Elastomeric fiber yarns

Woven, Non-woven, Knitted

High support bandages

Cotton, Viscose, Lyocell

Woven, Non-woven, Knitted

High support bandages

Elastomeric fiber yarns

Woven, Knitted

Compression bandages

Cotton, Viscose, Lyocell,

Polyester fiber

Woven, Knitted

Compression bandages

Polyurethane foam

Woven, Non-woven

Orthopaedic bandages

Cotton, Viscose, Plastics film,

Woven, Non-woven

Orthopaedic bandages

491

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Polyester fiber, Glass fiber,

Woven, Non-woven

Orthopaedic bandages

polypropylene fiber

Woven, Non-woven, Knitted

Plasters

Cotton, Viscose, Lyocell,

Alginate fiber, Chitosan

Woven, Non-woven, Knitted

Plasters, Gauze dressing

Cotton

Woven

Lint

Viscose, Cotton linters, Wood

pulp

Non-woven

Wadding

Poly lactide fiber, Poly

glycolide fiber

Non-woven

Wadding

Carbon fiber

Spunlaid, Needle punched

non-woven

Scaffold

Collagen, Catgut, Poly glycolide

Mono filament, Braided

Biodegradable sutures

fiber, Poly lactide fiber

Mono filament, Braided

Biodegradable sutures

Polyester fiber, Polyamide

fibber,

Mono filament, Braided

Biodegradable sutures

PTFE fiber, Polypropylene

Mono filament, Braided

Biodegradable sutures

Fiber Type

Fabric Structure

Applications

Polyethylene fiber

Mono filament, Braided

Non-biodegradable sutures

PTFE fiber, Polyester fiber,

Silk,

Mono filament, Braided

Non-biodegradable sutures

Collagen, Polyethylene fiber,

Mono filament, Braided

Non-biodegradable sutures

Polyamide fiber

Woven, Braided

Artificial tendon

Polyester fiber, Carbon fiber,

Collagen

Braided

Artificial ligament

Low density Polyethylene fiber

Braided

Artificial cartilage

Chitin

Non-woven

Artificial skin

Poly methyl methacrylate fiber,

Non-woven

Artificial skin

Silicon fiber, Collagen

Non-woven

Eye contact lenses and

Artificial cornea

Silicone, Poly acetyl fiber,

Non-woven

Eye contact lenses and

492

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Artificial cornea

Polyethylene fiber

Non-woven

Artificial joints/ bones

Figure 2. Classification of Medical Textiles

Table II. Non-Implantable Materials [3].

Extra Corporeal Devices

These are extra corporeally mounted devices used to support the

function of vital organs, such as kidney, liver, lung, heart pacer etc. The

extracorporeal devices are mechanical organs that are used for blood

purification and include the artificial kidney (dialyser), the artificial liver,

and the mechanical lung. The function and performance of these devices

benefit from fibre and textile technology. They are discribed in Table IV.

Health Care & Hygiene Products

An important area of textile is the healthcare and hygiene sector

among other medical applications. The range of prod-ucts available for

healthcare and hygiene is vast, but they are typically used either in the

operating theatre or in the hospi-tal wards for hygiene, care and safety of the

staff and patients. They could be washable or disposable. These products are

shown in Table V.

Table IV. Extra Corporeal Devices [3]

Fiber Type

Applications

Hollow Polyester fiber, Hollow

Artificial kidney

viscose

Hollow viscose

Artificial liver

Hollow polypropylene fiber,

Hollow silicon membrane

Mechanical lungs

Function

Remove waste products from

patients' blood

Separate and dispose of patients

plasma and supply fresh plasma

Remove carbon di-oxide from

patients' blood and supply fresh

Oxygen

Table V. Health care & Hygiene Products [3]

Fiber Type

Cotton, Polyester fiber,

Polypropylene fiber

Viscose

Viscose, Polyester fiber, Glass

fiber

Fabric Structure

Applications

Woven, Non-woven

Surgical gowns

Non-woven

Surgical caps

Non-woven

Surgical masks

493

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Polyester fiber, Polyethylene fiber Woven, Non-woven

Cotton, Polyester fiber, Polyamide

Knitted

fiber, Elastomeric fiber yarns

Cotton, Polyester fiber

Woven, Knitted

Cotton

Woven

Cotton, Polyester fiber

Woven

Polyester fiber, Polypropylene

fiber

Non-woven

Super absorbent fibers, Wood

fluff

Non-woven

Surgical drapes and cloths

Surgical hosiery

Blankets

Sheets, Pillow cases

Uniform

Protective Clothing,

Incontinence, Diaper/ Sheet,

Cover stock

Absorbent layer

494

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Figure 3. Few examples of medical textiles [4-11]

Figure 4. Medical textiles available in Bangladesh (collected from BMA market)

495

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Hospital Investigation of Medical Textiles in Bangladesh:

1. Dhaka Medical College And Hospital

Table VI. Consumption of Medical Textiles in Dhaka Medical College and

Hospital

Medical Product Name

Bed sheet

Pillow

Pillow cover

Mosquito net

Towel

Quilt

Gauze

Cotton

Surgical gown

Surgical mask

Surgical cap

O. T maxi

Patience gown

Consumption/Year (Approx.)

3500 pcs

400 pcs

500 pcs

500~ 600 pcs

1000 pcs

400~ 500 pcs

130000~ 140000 yds

6000 ~ 7000 rolls

4000~ 5000 pcs

10000~ 12000 pcs

7000~ 8000 pcs

1000 pcs

1000~ 1200 pcs

2. Sir Salimullah Medical College And Hospital, Dhaka

Table VII: Consumption of Medical Textiles in Sir Salimullah Medical

College and Hospital

Medical Product Name

Consumption/Year (Approx.)

Bed sheet

2800 ~ 3 000 pcs

Pillow

300 ~ 400pcs

Pillow cover

300~ 400 pcs

Mosquito net

500 pcs

Towel

600~ 700 pcs

Quilt

400 pcs

Gauze

100000 yds

Cotton

5000 rolls

Surgical gown

3500~ 4000 pcs

Surgical mask

10000 pcs

496

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Medical Product Name

Consumption/Year (Approx.)

Surgical cap

5000~ 6000 pcs

O. T maxi

700~ 800 pcs

Patience gown

1000 pcs

3. Uttara Adhunik Medical College And Hospital

Table VIII. Consumption of Medical Textiles in Uttara Adhunik Medical

College and Hospital

Medical Product Name

Gauze

Consumption/Year

3600 yds

Cotton

1800~3000 rolls

Surgical gown

1000~2000 pcs

Surgical cap

5000~6000 pcs

Bed Sheet

1500~2000 pcs.

Pillow

500 pcs

Pillow cover

1500~2000 pcs

Mosquito net

100~150 pcs

Towel

200~250 pcs

Quilt

250~300 pcs

Draw sheet

4000~5000 pcs

Eye sheet

100~120 pcs

O. T maxi

400 pcs

Patience gown

500 pcs

Blanket cover

5000 pcs

Mattress cover

500 pcs

Market Investigation of Medical Textiles in Bangladesh

In spite of the wide range of medical textiles, only limited items are used in

most of the hospital in Bangladesh Data in Table IX.are collected from BMA

Bhaban Surgical Market about the overall market investigation of medical

textiles in Bangladesh.

From the investigation, we can say that * Only surgical gauze, roller bandage, plastic bandage and absorbent

cotton are produced in Bangladesh.

497

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

* Maximum fabric structures of medical textiles are woven and nonwoven.

* Bangladesh imports medical textiles mainly from China and India.

Market Potentials of Medical Textiles in Bangladesh

Bsangladesh is a populous country. About 150 million people live here. For

this huge population, vast medical facilities are required as a basic need.

Since Bangladesh is a develop ing country and always tries to improve its

medical facilities for the people of the country. To fulfill such big demand,

Table IX. Overall Market investigation

Name of the

Product

Surgical

Gauze

Surgical

Gauze

Microporos

surgical tape

Microspores

surgical tape

Surgical

Mask

Waterproof

plastic

bandage

Cotton strip

Roller

bandage

Elastic

Bandage

Pouch arm

Elastic wrist

Thumb spica

Anklet

Lumber

Fabric

Structure

Woven

Brand

Origin

Al- Abi Marketing

Bangladesh

Company

Price (BDT)

Purpose

130

200/piece

Surgical

Surgical

Nonwoven

3M Health Care

Taiwan

58.30/roll

Nonwoven

Nichiban Co. Ltd.

Japan

152.50/roll

Nonwoven

Wenzhou Wuzhou

China

41.66/roll

China

1/ piece

Surgical

Bangladesh

1/ piece

Wound care

1/ piece

Wound care

Bangladesh

40/pack

Wound care

China

55 / pack

Wound care

India

India

India

India

India

200/ piece

280/ piece

250/ piece

130

180-300

Orthopedic

Orthopedic

Orthopedic

Orthopedic

Orthopedic

Nonwoven

Woven

Woven

Woven

Woven

Woven

Woven

Woven

Woven

Woven

Marketed by JMI

Bangla company

ltd.

Neostrip

Al-Abi Marketing

Company

Neo- bandage

Tynor

Tynor

Tynor

Tynor

Tynor

Surgical

purpose

Surgical

purpose

Many hospitals and clinics are set up here by government and public

finance. So, a lot of medical textile products are required in these hospitals.

There will be a huge need of medical textiles in the near future. There is no

research work about the market size of medical textile in Bangladesh. For

this we have not found sufficient data about the market size of Bangladesh.

But, by investigating hospitals and market we have reached a decision that

the market size of medical textile is increasing rapidly. the main causes are

498

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

the following * Population growth

* Consciousness development of people about health care

* Higher standard of living

* Establishment of international standard modern hospitals throughout the

country

* Technology development

So, there is huge potential of medical textile marketing in

Bangladesh. This potential is properly used by medical textile exporter

country like China, India, Taiwan, Germany, South Korea, Pakistan etc. But

we are lagging behind in this case. Our market share is very low in

comparison with these countries. It may be 2-5%. If we are able to produce

medical textile, we will be able to capture enough market share.

Manufacturing Potential of Medical Textiles in Bangladesh is well known to

the world as a traditional textile manufacturing country. But Bangladesh has

also the potential to produce technical textile especially medical textile. It

may be a great source of earning foreign currency. Our neighboring country

India and Pakistan are already going ahead in this field. They consume their

own product and also export to foreign countries. But we are lagging behind

in this sector though we are ahead in the traditional textile sector. Nowadays,

the consumption of medical textile is increasing rapidly in our country. Most

of them are imported from foreign countries like China, India, Taiwan, Japan

etc. It is a matter of sorrow that we are producing a very few medical textile

products such as gauze, bandage and apron. The possibility of medical textile

manufacturing in our country is analyzed belowCapital

There are many local and foreign industrialists who can invest their

capital in medical textile manufacturing if they get enough facilities from the

government.

Raw materials

The raw materials of medical textile products are fibre or yarn and

different types of chemicals for finishing. These raw materials can be

imported from other countries or manufactured in our country if possible.

Technology

Mainly four manufacturing techniques are applied for medical textile

products. These are woven, knitted, braided and nonwoven.

499

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Woven - Simple elastic and non-elastic bandages, vascular grafts, gauze

dressing, surgical gowns etc.

Knitted - Vascular graft, high support bandages etc.

Braided - Bio degradable and non-biodegradable sutures, artificial tendon,

artificial ligament etc.

Nonwoven - Bandages, surgical tape, orthopaedics bandage,

absorbent pad, surgical masks, caps etc.

Among these four techniques, nonwoven is now very popular

because it can produce disposable and cost effective product. It replaces the

woven and knitted products of medical textiles. But we are not as familiar

with nonwoven technology as woven and knitted technology. There are a

very few nonwoven factories in our country. If we are able to set up enough

nonwoven factory in our country, we will be developed in the medical textile

sector.

Manpower

There is a huge manpower in our country. They may be skilled or

unskilled. Since it is a new project it may cause little problem for unskilled

manpower. But proper training can solve the problem. To produce medical

textile, it needs a combination of medical science and textile technology. So,

medical specialist and a textile technologist should work together to develop

the field. There are enough medical specialist and textile technologist in our

country to develop this new field.

Power

Power is very important factor for any kind of industry. Bangladesh

is going through an acute power crisis. There is lack of energy and power. So

it should be overcome to develop medical textile sector.

Environment

Most of the medical textiles are undyed. So, medical textiles

need not to be highly dyed or so many finishing techniques like traditional

cloth. So, it is an environmental friendly sector

which we need.

Profit

It is a profitable industry because the project cost is lower but the

products selling price is higher. In US a simple bandage is sold at a price of

1-2 US dollar.

500

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Result analysis and Recommendation:

Challenges of Medical Textile Manufacturing in Bangladesh

The main challenges are1. Power crisis

2. Need to build up skilled manpower

3. Competition with China, India and other countries.

4. Need to increase of braided and nonwoven factory.

5. Need to increase of forward and backward linkage industry

Result analysis

This is a survey about the present status, significance and prospect of

Medical Textiles in Bangladesh. Our main task was to visit the hospital and

collect data of medical textiles which are used in the hospitals to assess the

prospect of medical textiles in Bangladesh. From the hospital and market

investigation we found that many medical textile products are used in

Bangladesh. Such as1. Gauze

2. Different types of bandages

3. Different types of orthopedic items and bandages.

4. Different types of surgical items

5. Different types of healthcare and hygiene products.

But most of them are imported from foreign countries like China,

Japan, Taiwan, India etc. Very few products are produced in Bangladesh

such as gauze, bandages and diapers.

But these are not enough for our demand. The consumption of

medical textile is increasing day by day. So, we should try to set up our own

medical textile manufacturing project to fulfill the increasing demand. It will

also help us to save our money from going to foreign countries. Finally we

can say that it is possible to produce medical textiles to a large extent in

Bangladesh. It will be very much profitable for the manufacturers who will

interest to run this sort of mills in Bangladesh.

To develop this sector, we recommend the followings 1. The government should take step to solve power crisis.

2. The textile technologists of our country should come forward to encourage

the industrialist to set up medical textile manufacturing factory.

3. Collaborate with medical textile manufacturing companies

of China, India etc.

4. Try to develop educated, skill manpower.

5. Try to ensure proper safety and sound condition of the factories.

501

European Scientific Journal April 2014 edition vol.10, No.12 ISSN: 1857 7881 (Print) e - ISSN 1857- 7431

Conclusion:

The importance of medical textile for the healthier life and betterment

of human being is great. The development of new technologies and new item

will help the patients to overcome their suffering in previous days. To get

correct, hygienic products we should put our concentration to develop new

technologies as well as we should put concentration on the price of the

products.

References:

Cookson PG. Deakin University. Centre for materials and fibre innovation,

Medical Application of Fibres & Textile.

Textile Terms and Defination, J. E. Mclistyre, P.N. Daniels, 10th Edition

Published by the Textile Institute. pp 206.

Anand SC and Horrocks AR. Handbook of Technical Textile, 2000, Pp. 407425.

www.wellmedlab. com/ buy- face_ma sk. Html.

www.blog.mediligence.com /tag/adhesive/

www.terumo-cvs.com/products/Product

Detail.aspx?groupId=68&familyID=506&country=1

www.aegeantech.com

www.lifetecinc.com

www.joints-surgery.com

www.en.wikipedia.org/wiki/Health_informatics?

www.sultan-ieee.blogspot.com/2009/11/design-artificial-heart-is-notrejected.html

502

Das könnte Ihnen auch gefallen

- Newmicrosoftofficepowerpointpresentation Copy2 140324095455 Phpapp01Dokument36 SeitenNewmicrosoftofficepowerpointpresentation Copy2 140324095455 Phpapp01Shumi NaharNoch keine Bewertungen

- Extraction and Application of Plant DyesDokument31 SeitenExtraction and Application of Plant DyesShumi Nahar80% (10)

- LEITAT 5 Technical Textiles 1 PDFDokument21 SeitenLEITAT 5 Technical Textiles 1 PDFShumi NaharNoch keine Bewertungen

- Gauze and BandageDokument25 SeitenGauze and BandageGowri SankarNoch keine Bewertungen

- Welcome To MY Presentation: Advanced Dyeing & PrintingDokument26 SeitenWelcome To MY Presentation: Advanced Dyeing & PrintingShumi NaharNoch keine Bewertungen

- Ipol Stu (2015) 518777 en PDFDokument44 SeitenIpol Stu (2015) 518777 en PDFShumi NaharNoch keine Bewertungen

- Latvia Univ Agricult REEP 2014proceedings 150 161 PDFDokument12 SeitenLatvia Univ Agricult REEP 2014proceedings 150 161 PDFShumi NaharNoch keine Bewertungen

- Pore and Diffusion ModelDokument19 SeitenPore and Diffusion ModelShumi NaharNoch keine Bewertungen

- 2006-2-85 - P-The Comparison of The Kinetics of Hydrolysis of Some Reactive Dyes Before and After Purification - P PDFDokument4 Seiten2006-2-85 - P-The Comparison of The Kinetics of Hydrolysis of Some Reactive Dyes Before and After Purification - P PDFShumi NaharNoch keine Bewertungen

- Animal Fiber-WoolDokument2 SeitenAnimal Fiber-WoolRan TejNoch keine Bewertungen

- PDFDokument19 SeitenPDFShumi NaharNoch keine Bewertungen

- Correct Spelling PDFDokument1 SeiteCorrect Spelling PDFShumi NaharNoch keine Bewertungen

- BB Pervious Written Math Solution by Jafar Iqbal GemDokument21 SeitenBB Pervious Written Math Solution by Jafar Iqbal GemShumi Nahar50% (2)

- Thesis PartDokument45 SeitenThesis PartShumi NaharNoch keine Bewertungen

- Problist On PPE PDFDokument6 SeitenProblist On PPE PDFShumi Nahar67% (3)

- PPE Principles and Economics PDFDokument9 SeitenPPE Principles and Economics PDFShumi NaharNoch keine Bewertungen

- Basic Classification and Definitions of Polymerization ReactionsDokument4 SeitenBasic Classification and Definitions of Polymerization ReactionsManishUpadhyayNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Pubmed - Australia - Conventional - HistoDokument234 SeitenPubmed - Australia - Conventional - HistoHNNoch keine Bewertungen

- ACKS SinisterStoneOfSakkaraDokument80 SeitenACKS SinisterStoneOfSakkarasullivbt100% (6)

- Case StudyDokument7 SeitenCase Studyapi-402806930Noch keine Bewertungen

- Ward ManagementDokument5 SeitenWard ManagementVeeresh TopalakattiNoch keine Bewertungen

- The Frankie Original April 2009Dokument335 SeitenThe Frankie Original April 2009Francisco.PanainoNoch keine Bewertungen

- Finalized Requirements-Worksheet - Arpana Hospital KarnalDokument11 SeitenFinalized Requirements-Worksheet - Arpana Hospital KarnalMahesh PatilNoch keine Bewertungen

- Change Management in Health Care: Robert James Campbell, EddDokument17 SeitenChange Management in Health Care: Robert James Campbell, EddeossNoch keine Bewertungen

- 2014 Burn Patient Management - Clinical Practice GuidelinesDokument70 Seiten2014 Burn Patient Management - Clinical Practice Guidelinesd dNoch keine Bewertungen

- From Operasi Celah Bibir Yayasan Vivitas-Converted - EDIT ISIDokument10 SeitenFrom Operasi Celah Bibir Yayasan Vivitas-Converted - EDIT ISIBagusBhudiBhaktiNoch keine Bewertungen

- An Ideal ICU: Yogasliana FathudinDokument16 SeitenAn Ideal ICU: Yogasliana FathudinyogasNoch keine Bewertungen

- 226912228Dokument3 Seiten226912228api-5200468100% (2)

- Doctors Munich 0605 PDFDokument61 SeitenDoctors Munich 0605 PDFFarhan Bin KhalidNoch keine Bewertungen

- Peter Lee Story PRESS KefaloniaDokument2 SeitenPeter Lee Story PRESS KefaloniaAnonymous Drqem9zxJNoch keine Bewertungen

- Lance Armstrong Foundation LIVESTRONG Annual ReportDokument19 SeitenLance Armstrong Foundation LIVESTRONG Annual ReportgneymanNoch keine Bewertungen

- Adrienne Bacon ResumeDokument2 SeitenAdrienne Bacon Resumeapi-272550174Noch keine Bewertungen

- Data Dokter Dari GmailDokument12 SeitenData Dokter Dari GmailAlfen HFNoch keine Bewertungen

- Schizophrenia Case StudiesDokument3 SeitenSchizophrenia Case StudiesVierman BalweelNoch keine Bewertungen

- List of Doctors and Hospitals in Rheinland-PfalzDokument6 SeitenList of Doctors and Hospitals in Rheinland-PfalzNamerah AliNoch keine Bewertungen

- Chennai All AboutDokument48 SeitenChennai All AboutnarayanprasadnNoch keine Bewertungen

- Meconium Stained LiquorDokument4 SeitenMeconium Stained LiquorYwagar YwagarNoch keine Bewertungen

- ROP Operational Guidelines FINAL PDFDokument58 SeitenROP Operational Guidelines FINAL PDFRajan ShuklaNoch keine Bewertungen

- Multi-Speciality HospitalDokument30 SeitenMulti-Speciality Hospitaltushar rautray100% (1)

- TFN Significant Theories and TheoristDokument63 SeitenTFN Significant Theories and TheoristJaron AdisonNoch keine Bewertungen

- Non Eu Citizens - Health Insurance: National Health System (SSN)Dokument2 SeitenNon Eu Citizens - Health Insurance: National Health System (SSN)Sufian AbusninaNoch keine Bewertungen

- Health Vocabulary - Unit 6Dokument2 SeitenHealth Vocabulary - Unit 6Hind BenelgamraNoch keine Bewertungen

- Comelec Brochure2013Dokument24 SeitenComelec Brochure2013jojoNoch keine Bewertungen

- Nicu Worksheet CompletedDokument3 SeitenNicu Worksheet Completedapi-324566318Noch keine Bewertungen

- Agile Outcome Measures Ems v2 PDFDokument8 SeitenAgile Outcome Measures Ems v2 PDFjusudNoch keine Bewertungen

- Take Look: A InsideDokument4 SeitenTake Look: A InsidegenesisworldmissionNoch keine Bewertungen

- Hospita MGTDokument18 SeitenHospita MGTJaggnath DANoch keine Bewertungen