Beruflich Dokumente

Kultur Dokumente

Retaing Walls

Hochgeladen von

24x7civilconsultantCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Retaing Walls

Hochgeladen von

24x7civilconsultantCopyright:

Verfügbare Formate

1

Retaining walls

Prepared by : Othman.M.Rahim

Card no:4618

Retaining walls are structures designed to restrain soil to unnatural slopes. They are used to bound soils

between two different elevations often in areas of terrain possessing undesirable slopes or in areas where the

landscape needs to be shaped severely and engineered for more specific purposes like hillside farming or

roadway overpasses.

1 Definition

2 Types of retaining wall

o 2.1 Gravity

o 2.2 Cantilevered

o 2.3 Sheet piling

o 2.4 Anchored

3 Alternative retaining techniques

O 3.1 Cellular Confinement

o 3.2 Soil nailing

o 3.3 Soil-strengthened

3.3.1 Gabion meshes

o 3.4 Mechanical stabilization

4 Design example for reinforced concrete cantilever retaining wall

Definition

A retaining wall is a structure designed and constructed to resist the lateral pressure of soil when there is a

desired change in ground elevation that exceeds the angle of repose of the soil.

A basement wall is thus one kind of retaining wall. But the term usually refers to a cantilever retaining wall,

which is a freestanding structure without lateral support at its top. These are cantilevered from a footing and

rise above the grade on one side to retain a higher level grade on the opposite side. The walls must resist the

lateral pressures generated by loose soils or, in some cases, water pressures

Every retaining wall supports a wedge of soil. The wedge is defined as the soil which extends beyond the

failure plane of the soil type present at the wall site, and can be calculated once the soil friction angle is known.

As the setback of the wall increases, the size of the sliding wedge is reduced. This reduction lowers the pressure

on the retaining wall.

The most important consideration in proper design and installation of retaining walls is to recognize and

counteract the tendency of the retained material to move downslope due to gravity. This creates lateral earth

pressure behind the wall which depends on the angle of internal friction (phi) and the cohesive strength (c) of

the retained material, as well as the direction and magnitude of movement the retaining structure undergoes.

Lateral earth pressures are zero at the top of the wall and - in homogenous ground - increase proportionally to a

maximum value at the lowest depth. Earth pressures will push the wall forward or overturn it if not properly

addressed. Also, any groundwater behind the wall that is not dissipated by a drainage system causes hydrostatic

pressure on the wall. The total pressure or thrust may be assumed to act at one-third from the lowest depth for

lengthwise stretches of uniform height.

Unless the wall is designed to retain water, It is important to have proper drainage behind the wall in order to

limit the pressure to the wall's design value. Drainage materials will reduce or eliminate the hydrostatic pressure

and improve the stability of the material behind the wall. Drystone retaining walls are normally self-draining.

As an example, the International Building Code requires retaining walls to be designed to ensure stability

against overturning, sliding, excessive foundation pressure and water uplift; and that they be designed for a

safety factor of 1.5 against lateral sliding and overturning.

Types of retaining wall

Various types of retaining walls

Gravity

Construction types of gravity retaining walls

Gravity walls depend on their mass (stone, concrete or other heavy material) to resist pressure from behind and

may have a 'batter' setback to improve stability by leaning back toward the retained soil. For short landscaping

walls, they are often made from mortarless stone or segmental concrete units (masonry units). Dry-stacked

gravity walls are somewhat flexible and do not require a rigid footing in frost areas. Home owners who build

larger gravity walls that do require a rigid concrete footing can make use of the services of a professional

excavator, which will make digging a trench for the base of the gravity wall much easier.

Earlier in the 20th century, taller retaining walls were often gravity walls made from large masses of concrete

or stone. Today, taller retaining walls are increasingly built as composite gravity walls such as: geosynthetics

such as Geoweb cellular confinement earth retention or with precast facing; gabions (stacked steel wire baskets

filled with rocks); crib walls (cells built up log cabin style from precast concrete or timber and filled with soil);

or soil-nailed walls (soil reinforced in place with steel and concrete rods).

Cantilevered

Conterfort/Buttress on Cantilevered Wall

Cantilevered retaining walls are made from an internal stem of steel-reinforced, cast-in-place concrete or

mortared masonry (often in the shape of an inverted T). These walls cantilever loads (like a beam) to a large,

structural footing, converting horizontal pressures from behind the wall to vertical pressures on the ground

below. Sometimes cantilevered walls are buttressed on the front, or include a counterfort on the back, to

improve their strength resisting high loads. Buttresses are short wing walls at right angles to the main trend of

the wall. These walls require rigid concrete footings below seasonal frost depth. This type of wall uses much

less material than a traditional gravity wall.

Sheet piling

Shet pile retaining walls are usually used in soft soils and tight spaces. Sheet pile walls are made out of steel,

vinyl or wood planks which are driven into the ground. For a quick estimate the material is usually driven 1/3

above ground, 2/3 below ground, but this may be altered depending on the environment. Taller sheet pile walls

will need a tie-back anchor, or "dead-man" placed in the soil a distance behind the face of the wall, that is tied

to the wall, usually by a cable or a rod. Anchors are then placed behind the potential failure plane in the soil.

Anchored

An anchored retaining wall can be constructed in any of the aforementioned styles but also includes additional

strength using cables or other stays anchored in the rock or soil behind it. Usually driven into the material with

boring, anchors are then expanded at the end of the cable, either by mechanical means or often by injecting

pressurized concrete, which expands to form a bulb in the soil. Technically complex, this method is very useful

where high loads are expected, or where the wall itself has to be slender and would otherwise be too weak.

Alternative retaining techniques

Cellular Confinement

Cellular confinement systems, first marketed by Presto Geosystems as Geoweb, have become increasingly

popular for earth retention applications. They can be constructed as a gravity wall or a "geogrid" wall which

consists of vertical layers of geocells with geogrid reinforcement installed behind the face of the wall every few

layers of the geocell depending on design.

Soil nailing

Soil nailing is a technique in which soil slopes, excavations or retaining walls are reinforced by the insertion of

relatively slender elements - normally steel reinforcing bars. The bars are usually installed into a pre-drilled

hole and then grouted into place or drilled and grouted simultaneously. They are usually installed untensioned

at a slight downward inclination. A rigid or flexible facing (often sprayed concrete) or isolated soil nail heads

may be used at the surface.

Soil-strengthened

A number of systems exist that do not consist of just the wall, but reduce the earth pressure acting directly on

the wall. These are usually used in combination with one of the other wall types, though some may only use it

as facing, i.e., for visual purposes.

Gabion meshes

This type of soil strengthening, often also used without an outside wall, consists of wire mesh 'boxes' into

which roughly cut stone or other material is filled. The mesh cages reduce some internal movement/forces, and

also reduce erosive forces.

Mechanical stabilization

Mechanically stabilized earth

Mechanically stabilized earth, also called MSE, is soil constructed with artificial reinforcing via layered

horizontal mats (geosynthetics) fixed at their ends. These mats provide added internal shear resistance beyond

that of simple gravity wall structures. Other options include steel straps, also layered. This type of soil

strengthening usually needs outer facing walls (S.R.W.'s - Segmental Retaining Walls) to affix the layers to and

vice versa.

The wall face is often of precast concrete units that can tolerate some differential movement. The reinforced

soil's mass, along with the facing, then acts as an improved gravity wall. The reinforced mass must be built

large enough to retain the pressures from the soil behind it. Gravity walls usually must be a minimum of 50 to

60 percent as deep or thick as the height of the wall, and may have to be larger if there is a slope or surcharge

on the wall.

Retaining Wall Design Example

Design a reinforced concrete retaining wall for the

following conditions.

surcharge = qs = 400

psf

Fill: = 32

Unit wt = 100 pcf

o

fy = 60 ksi

HT = 18 ft

tf

wtoe tstem

wheel

Natural Soil: = 32

allowable bearing pressure = 5000psf

Development of Structural Design Equations. In this example, the structural design of the

three retaining wall components is performed by hand. Two equations are developed in this

section for determining the thickness & reinforcement required to resist the bending moment

in the retaining wall components (stem, toe and heel).

Equation to calculate effective depth, d: Three basic equations will be used to develop an

equation for d.

M u = M n

M n = As f y d

2

Mu = As fy d [Eqn 1]

2

C = T , 0.85 f c' a b = As f y

As = 0.85

f c'

fy

ab

strain compatibility :

[Eqn 2]

0.003 s + 0.003

,

=

a / 1

d

0.003

a

1

=

d s + 0.003

Assuming 1 = 0.85,

s

0.005

0.00785

0.010

a/d

0.319

0.235

0.196

and choosing a value for s in about the middle of the practical design range,

a

= 0.235, a = 0.235 d

d

[Eqn 3]

Retaining Wall Design Example

Substituting Eqn. 2 into Eqn. 1:

f'

c

ab f y d

M u = 0.85

2

fy

And substituting Eqn. 3 into the above:

M u = 0.85

f c'

0.235d b f y d

fy

0.235 d

0.883d

Inserting the material properties: f'c = 3 ksi and fy = 60 ksi, and b = 12in (1-foot-wide

strip of wall, in the direction out of the paper).

M u = 0.90(0.85) 3 (12 )(0.235)(0.883)d

ksi

in

Mu

k

in

= 5.71

d2

Equation for area of reinforcement, As. The area of reinforcement required is calculated

from Eqn. 1:

M u = As f y 0.883d = 0.90 As 60 ksi 0.883d

M u = 47.7ksi As d

Design Procedure

1. Determine HT. Usually, the top-of-wall elevation is determined by the client. The

bottom-of-wall elevation is determined by foundation conditions.

HT = 18 feet.

2. Estimate thickness of base. tf 7% to 10% HT (12" minimum)

Tf = 0.07 (18' x 12"/') = 15.1"

use tf = 16"

Retaining Wall Design Example

3. Design stem (tstem, Asstem). The stem is a vertical cantilever beam, acted on by the

horizontal earth pressure.

ft

in

h = 8 16 /12

ft

h =16.67

in/ft

tf = 16in

ka h

ka qs

wtoe tstem wheel

calc. d:

Pfill =

1

(k h) h (1

2 a

ka =

P fill =

ft

out of page)

1 sin 1 sin(32o )

=

= 0.31

1 + sin 1 + sin(32 o )

1

ft 2

ft

lb

(0.31)(100 pcf )(16.67 ) (1 ) = 4310

2

ft

ft

lb

Psur = k a q sur h (1 ft ) = 0.31(400 psf )(16.67 )(1 ) = 2070

h

h

M u = (Earth Pressure LoadFactor)(P fill )( ) + (Live LoadFactor)(P sur )( )

3

2

M u = (1.6)(4310 lb)(

16.67 ft

16.67 ft

) + (1.6)(2070lb )(

) = 65.9 k ft

3

2

M u = 5.71in d 2

k

in

) = 5.71in d 2 , d = 11.8in

ft

1

t stem = 11.8in + 2 in cover + (1.0in) = 14.3in , (assume #8 bars)

2

d = 15in 2 in 0.5in = 12.5in

65.9 k ft (12

use t stem = 15in

Retaining Wall Design Example

calc. As:

M u = 47.7 ksi As d

in

65.9 k ft (12 ) = 47.7 ksi As (12.5in ), As = 1.33in 2

ft

As of one #8 bar = 0.79 in 2

0.79

in 2

bar

2

12

in

1.33

ft of wall

in

= 7.13

in

use #8 @ 6 in

bar

ft

4. Choose Heel Width, wheel Select wheel to prevent sliding. Use a key to force sliding

failure to occur in the soil (soil-to-soil has higher friction angle than soil-to-concrete).

12 in

Neglect soil resistance in front of the

wall.

ft

Fresist

18

= Fsliding

FS

FS = Factor of Safety = 1.5 for sliding

Fre sist = (Vertical Force)(coefficient of friction)

Fre sist = WT (tan natural soil )

set

tf = 16in

tan natural soil = tan(32 ) = 0.62

o

15 in

WT = W fill + Wste m + W found

W fill = (100 pcf )(16.67 ft )(whee l )(1 ft ) = 1670

lb

whee l

ft

ft

in

in

12 + 15 1

(1 ft ) = 2810lb

2

12 in )

16

15

= (150 pcf )( ft)(whee l +

ft + 3 ft )(1 ft ) = 200 plf whee l + 850

12

12

W stem = (150 pcf )(16.67 ft )(

W found

Fsliding = Pfill + Psur

1

ft 2

ft

(0.31 100 pcf )(18 ) (1 ) = 5020 lb

2

ft

ft

lb

= (0.31 400 psf )(18 )(1 ) = 2230

P fill =

Psur

Fsliding = 5020 lb + 2230lb = 7250lb

10

Retaining Wall Design Example

lb

lb

lb

lb

1670 ft w heel + 2810 + 200 ft wheel + 850 (0.62)

7250lb =

1.5

lb

1.5

ft

7250lb

= 3660lb + 1870 wheel , wheel = 7.42 ,

ft

0.62

use wheel = 7.5 ft

5. Check Overturning.

12 in

18 ft

18 ft

) + Psur (

)

3

2

= 5.02 k (6 ft ) + 2.23k (9 ft ) = 50.2 k ft

M ove r = Pfill (

M ove r

18

ft

7.5 ft 15

ft

+

ft + 3 ft ), assume wtoe = 3

12

2

ft

1.25

+ Wstem (3 ft +

)

2

11.75 ft

3' 15" 7.5'

+ W found (

)

2

= (1.67klf 7.5 ft )(8 ft ) + (2.81k )(3.625 ft ) + (0.20klf 7.5 ft + 0.85k )(5.875 ft )

M resist = W fill (

M resist

12.53k

2.35

M resist = 124.2 k ft

k ft

M resist 124.2

=

= 2.47 > 2.0 = FSove r , OK

M ove r

50.2 k ft

6. Check Bearing.

WT

L

M

+

, equation is valid only if e <

6

bL bL2

6

+ W found

v at end of toe =

WT = W fill + Wste m

WT = 12.45k + 2.81k + 2.35k = 17.69 k

7.5 ft

1.25 ft

) + Wste m (7.5 ft +

5.875 ft ) + W found (0)

2

2

12.53k (2.125 ft ) + 2.81k (2.25 ft ) = 29.9 k ft

M = M ove r W fill (5.875 ft

M = 50.2 k ft

Check that e < L/6:

e=

L 11.75 ft

m

29.9 k ft

L

ft

=

1.68

,

= 1.96 ft , e < , OK

=

=

k

WT

6

6

6

17.69

tf = 16in

11

Retaining Wall Design Example

v =

17.69 k

(1 )(11.75 )

ft

ft

29.9 k ft

1 ft

(1 )(11.75 ft ) 2

6

= 2.80 ksf < 5.0 ksf = allowable bearing capacity, OK

7. Heel Design.

Max. load on heel is due to the weight of heel + fill + surcharge as the wall tries to tip over.

Flexure:

W = Wheel + W fill + Wsur

16

W = 1.2(150 pcf )( ft)(1 ft )

12

+ 1.2(100 pcf )(16.67 ft )(1 ft )

+ 1.6(400 plf )

wu

Vu

in

16

Mu

ft

7.5

W = 2.88klf

Mu =

wu L 2

2

2.88klf (7.5 ft )2

= 81.0 k ft

2

k 2

d

in

in

k

81.0k ft (12 ) = 5.71 d 2 , d = 13.0in for flexure

ft

in

M u = 5.71

Shear:

Vu = wu (7.5 ft ) = 2.88 klf (7.5 ft ) = 21.6 k

Vc = (0.75) 2 f c' bw d = (0.75) 2 3000 psi (12 in ) d

setVu = Vc ,

21,600lb = (0.75) 2 3000 psi (12 in ) d , d = 21.9 in for shear, controls

Shear controls the thickness of the heel.

1

t heel = 21.9in + 2 in cover + in = 24.4 in (assume #8 bar),

2

use t heel = 21.5in

Reinforcement in heel:

M u = 47.7 ksi As d

in

81.0 k ft (12 ) = 47.7 ksi A s (21.9 in ), As = 1.07in 2

ft

in 2

bar in) = 8.83 in ,

(12

in 2

ft

1.07

ft

0.79

use #8 @ 8"

12

Retaining Wall Design Example

8. Toe Design.

Earth Pressure at Tip of Toe:

Mu

Wu

bL 1 2

bL

6

Wu = 1.2(W fill + Wstem + W found ) + 1.6 (Wsur )

v =

k

k

k

ksf

ft

ft

k

Wu = 1.2(12.53 + 2.81 + 2.35 ) +ft 1.6(0.4 )(18ft )(1 ) = 32.7 , (did not recalc foundation wt b.c. neglible change)

M u = 1.6 M ove r 1.2(Wsoil 2.125 + Wstem 1.0 )

7.5'

3' 1.25'

M u = 1.6(50.2k ft ) 1.2 12.53k (2.125 ft ) + 2.81k (1 ft ) = 45.0k ft

k ft

45.0

32.7 k

+

ft

ft

1

ft

ft 2

(1 )(11.75 )

(1 )(11.75 )

6

ksf

v A = 2.78 ksf + 1.96

= 4.74ksf

v =

vC = 2.78ksf

v B = 0.82 ksf +

d for flexure:

1.96ksf

= 0.82ksf

4.74 ksf 0.82 ksf

(8.75 ft ) = 3.74ksf

ft

11.75

M u = (3.74 ksf )(3 ft )(1 ft )(

3 ft

1

2

) + (1.00ksf )(3 ft )(1 ft )( 3 ft ) = 19.8k ft

2

2

3

k 2

d

in

in

k

19.8k ft (12 ) = 5.71 d 2 , d = 6.5in for flexure

ft

in

M u = 5.71

d for shear:

Assume theel = ttoe = 21.5in

Critical section for shear occurs at "d" from face of stem, d = 21.5" 3"cover-1/2"=18"

vcritical sec tion = 0.82 ksf +

4.74 ksf 0.82 ksf

11.75

ft

(8.75 ft +

18

ft) = 4.24 ksf

12

1

18

ft)(1 ft ) = 6.74 k

(4.74 ksf + 4.24 ksf )(3 ft

2

12

Vc = (.75)2 3000 psi (12in )(18in ) = 17,750lb > Vu , OK , d for flexure controls

Vu =

Retaining Wall Design Example

Reinforcement in toe:

M u = 47.7 ksi As d

19.8k ft (12

in

) = 47.7 ksi As (18in ), As = 0.28in 2

ft

in 2

bar (12 in ) = 33 in , try sm aller bars, say #4

ft

in 2

0.28

ft

0.79

in 2

bar (12 in ) = 8.6in

ft

in 2

0.28

ft

0.20

use #4@8"

13

Das könnte Ihnen auch gefallen

- Swimming Pool EstimatesDokument1 SeiteSwimming Pool Estimatesgreatgenius100% (1)

- GFRCDokument4 SeitenGFRCrahulchandokNoch keine Bewertungen

- Wallap Soldier PileDokument10 SeitenWallap Soldier Pile24x7civilconsultantNoch keine Bewertungen

- Building Stones Group2 (1d)Dokument38 SeitenBuilding Stones Group2 (1d)Rachelle SiwaNoch keine Bewertungen

- 03 B Building Finishing 2020 2021 Stone Cladding Group3 RevisedDokument43 Seiten03 B Building Finishing 2020 2021 Stone Cladding Group3 RevisedRama AlzabenNoch keine Bewertungen

- Lecture 3 - 23312 StonesDokument75 SeitenLecture 3 - 23312 StonesVaishnav SathishNoch keine Bewertungen

- 04 10 00 MasonryDokument17 Seiten04 10 00 MasonryKiran D Anvekar100% (1)

- 01 Wall Cladding & Paving UnistoneDokument12 Seiten01 Wall Cladding & Paving UnistonejahnvighoghariNoch keine Bewertungen

- Classification of RocksDokument58 SeitenClassification of RocksJJG ABVNoch keine Bewertungen

- MKBP 222 (Chapter II - Building Stones)Dokument4 SeitenMKBP 222 (Chapter II - Building Stones)RHOWELLE TIBAYNoch keine Bewertungen

- Stone Masonry: Presentation By-Ar. Roopa Chikkalgi 1Dokument19 SeitenStone Masonry: Presentation By-Ar. Roopa Chikkalgi 1SaumiaNoch keine Bewertungen

- Presentation By-Prof. Ms - Sherkar G.CDokument27 SeitenPresentation By-Prof. Ms - Sherkar G.CSmart Dick KaloloNoch keine Bewertungen

- Stones and RockDokument26 SeitenStones and RockAntonio JacksonNoch keine Bewertungen

- Stone Masonry, Stone Mortars - Stone Work Types of Masonry Ashlar Facing RubbleDokument2 SeitenStone Masonry, Stone Mortars - Stone Work Types of Masonry Ashlar Facing RubbleManish ShashikantNoch keine Bewertungen

- BT 1 M03 - Rock Stone Masonry EditedDokument29 SeitenBT 1 M03 - Rock Stone Masonry EditedReyvel Sapaden CorcueraNoch keine Bewertungen

- Stones: Commonly Used Stones in IndiaDokument4 SeitenStones: Commonly Used Stones in IndiaVishal NaikNoch keine Bewertungen

- StoneDokument69 SeitenStoneMd. Mahbub Morshed ShimantoNoch keine Bewertungen

- Stone: SEM I, F.Y. B.ArchDokument42 SeitenStone: SEM I, F.Y. B.ArchRISHABH JAISWAL100% (1)

- Stone: Presented By:-Sikandar AliDokument15 SeitenStone: Presented By:-Sikandar AliSikandar SiddiquiNoch keine Bewertungen

- Module 6 - Stone Work: Construction & Materials - Iii (Rar - 302) Section B: Building Construction TechnologyDokument68 SeitenModule 6 - Stone Work: Construction & Materials - Iii (Rar - 302) Section B: Building Construction TechnologyjashndeepNoch keine Bewertungen

- Chapter-1 StonesDokument117 SeitenChapter-1 StonesMalabar CivilNoch keine Bewertungen

- Building StoneDokument38 SeitenBuilding StoneSheikh M Hassaan AdilNoch keine Bewertungen

- Stones PDFDokument14 SeitenStones PDFTZShengNoch keine Bewertungen

- Building StonesDokument49 SeitenBuilding StonesJim Jeus dela CruzNoch keine Bewertungen

- StonesDokument19 SeitenStonesSiddharth SureshNoch keine Bewertungen

- StoneDokument70 SeitenStonektnatashaNoch keine Bewertungen

- ARTB01: Building Stones, Gypsum and Limes Wood and Wood ProductsDokument26 SeitenARTB01: Building Stones, Gypsum and Limes Wood and Wood ProductsImae BalijoNoch keine Bewertungen

- Stonemasonry 170919111555Dokument30 SeitenStonemasonry 170919111555hari prasad100% (1)

- Stone CladdingDokument11 SeitenStone CladdingTanishaNoch keine Bewertungen

- Curing Cement PlasterDokument3 SeitenCuring Cement PlasterChristian LlagasNoch keine Bewertungen

- RT Reading MaterialDokument6 SeitenRT Reading Materialxjsddjwef100% (1)

- Lecture Note: Civil Engineering Materials & Construction Course Code: Bt-204Dokument74 SeitenLecture Note: Civil Engineering Materials & Construction Course Code: Bt-204Akansh JainNoch keine Bewertungen

- Stone MasonaryDokument8 SeitenStone MasonarySachin RanaNoch keine Bewertungen

- 04 20 00 Stone AssembliesDokument21 Seiten04 20 00 Stone AssembliesKiran D AnvekarNoch keine Bewertungen

- Cultured MarbleDokument9 SeitenCultured Marblesaira tahirNoch keine Bewertungen

- Construction Technology II Lesson 1Dokument68 SeitenConstruction Technology II Lesson 1sydney augustNoch keine Bewertungen

- Laterite StoneDokument3 SeitenLaterite StoneIndraja Rm100% (1)

- Field Tests On BricksDokument3 SeitenField Tests On Bricksdongrey331Noch keine Bewertungen

- Lay Natural StoneDokument27 SeitenLay Natural StoneDawit Awash100% (6)

- Volume Ii: Specifications (Wall Cladding) : Issue: FINAL, 14th FEB 2013Dokument10 SeitenVolume Ii: Specifications (Wall Cladding) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNoch keine Bewertungen

- STONES and STONEWORKSDokument29 SeitenSTONES and STONEWORKSBackupFilesNoch keine Bewertungen

- Stability Problems With Natural Stone Tiles: (Ardex Technical Article TP005.002)Dokument10 SeitenStability Problems With Natural Stone Tiles: (Ardex Technical Article TP005.002)sanchit2203100% (1)

- R AnushreeDokument15 SeitenR AnushreeJuvilasri VigneshNoch keine Bewertungen

- Principle For Supervision of Stone MasonryDokument1 SeitePrinciple For Supervision of Stone MasonrysuryakantameNoch keine Bewertungen

- Marble Material Fact Sheet 022509Dokument2 SeitenMarble Material Fact Sheet 022509abobeedoNoch keine Bewertungen

- Bricks Final PDFDokument77 SeitenBricks Final PDFRana HamzaNoch keine Bewertungen

- 3 Final Plates PDFDokument48 Seiten3 Final Plates PDFAriane Joyze BronzalNoch keine Bewertungen

- The Brownstone Guide: Maintenance & Repair Facts For Historic Property OwnersDokument12 SeitenThe Brownstone Guide: Maintenance & Repair Facts For Historic Property OwnerspajinaNoch keine Bewertungen

- Marble AssignmentDokument8 SeitenMarble AssignmentRahul RanganathanNoch keine Bewertungen

- Brick Lecture NotesDokument13 SeitenBrick Lecture NoteschinmayihyNoch keine Bewertungen

- LIME Perspective by Vaishali Latkar (Compatibility Mode)Dokument28 SeitenLIME Perspective by Vaishali Latkar (Compatibility Mode)Vaishali LatkarNoch keine Bewertungen

- Company Profile PDFDokument128 SeitenCompany Profile PDFClef GonadanNoch keine Bewertungen

- Masonary StructureDokument10 SeitenMasonary StructureRachana GoliNoch keine Bewertungen

- Stone Masonry and Brick Stone MasonryDokument3 SeitenStone Masonry and Brick Stone MasonryMuhafeez GoolabNoch keine Bewertungen

- Civil Engineering Cracks Types and CausesDokument8 SeitenCivil Engineering Cracks Types and Causeskatia diaNoch keine Bewertungen

- Utilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentDokument25 SeitenUtilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentLarisa ChindrișNoch keine Bewertungen

- Appendix 5 Tile-Care-MaintenanceDokument35 SeitenAppendix 5 Tile-Care-Maintenancemohsin.meizaNoch keine Bewertungen

- Floors: ARC 2380 Construction and Materials-IiiDokument60 SeitenFloors: ARC 2380 Construction and Materials-IiiAlisha KhanNoch keine Bewertungen

- Categorization of General Problems and Defects in Historical BuildingDokument10 SeitenCategorization of General Problems and Defects in Historical BuildingRafiq FitriNoch keine Bewertungen

- Manufacturing Process of BricksDokument26 SeitenManufacturing Process of Bricksranga100% (1)

- Sustainable Masonry: Stability and Behavior of StructuresVon EverandSustainable Masonry: Stability and Behavior of StructuresNoch keine Bewertungen

- FHWA CRCP Design & Construction GuidelinesDokument24 SeitenFHWA CRCP Design & Construction Guidelines24x7civilconsultantNoch keine Bewertungen

- 9.3 Strut Design ISMB (Hor)Dokument7 Seiten9.3 Strut Design ISMB (Hor)24x7civilconsultantNoch keine Bewertungen

- Bms 1000 SpecDokument20 SeitenBms 1000 Spec24x7civilconsultantNoch keine Bewertungen

- InclinometerDokument5 SeitenInclinometer24x7civilconsultantNoch keine Bewertungen

- 7 Unrestrained Beams HandoutDokument3 Seiten7 Unrestrained Beams HandoutKenaia AdeleyeNoch keine Bewertungen

- Mononobe OkabeDokument11 SeitenMononobe Okabe24x7civilconsultantNoch keine Bewertungen

- Isoterm JurnalDokument6 SeitenIsoterm JurnalKatherineSabatiniNoch keine Bewertungen

- KSP RBT P1 Rac SD H2ZZ DWG Arc 60 1000 00 PDFDokument11 SeitenKSP RBT P1 Rac SD H2ZZ DWG Arc 60 1000 00 PDFUzer KhanNoch keine Bewertungen

- Some Engineering Aspects of Expansive Soils: J. David RogersDokument17 SeitenSome Engineering Aspects of Expansive Soils: J. David RogersRivaiNoch keine Bewertungen

- Item Brief Description of Item No No L B D Qty No: Plinth BeamsDokument4 SeitenItem Brief Description of Item No No L B D Qty No: Plinth BeamsRakshit JainNoch keine Bewertungen

- Review Questions Materials Alvin IbcDokument22 SeitenReview Questions Materials Alvin IbcJd CarreonNoch keine Bewertungen

- SOILEROSIONDokument25 SeitenSOILEROSIONNaga Sai Anitha NidumoluNoch keine Bewertungen

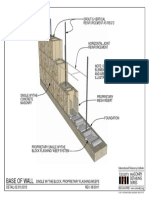

- 02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsDokument1 Seite02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsYolanda Leah UrbanoNoch keine Bewertungen

- Understanding Your Soil TestDokument60 SeitenUnderstanding Your Soil TestSupriyadi100% (1)

- Constituent Materials of Concrete: by Nick Gromicko, CMI® and Kenton ShepardDokument9 SeitenConstituent Materials of Concrete: by Nick Gromicko, CMI® and Kenton ShepardWalterNoch keine Bewertungen

- 13a. Road Construction MethodsDokument18 Seiten13a. Road Construction MethodsSheeraz AhmedNoch keine Bewertungen

- 3 Propagation Methods in PlantsDokument10 Seiten3 Propagation Methods in PlantsRaquel Husayan ParanNoch keine Bewertungen

- The Book of Pears: Chapter 1 - The PearDokument20 SeitenThe Book of Pears: Chapter 1 - The PearChelsea Green PublishingNoch keine Bewertungen

- PDA - NotesDokument2 SeitenPDA - NotesAbdul RahmanNoch keine Bewertungen

- Protect Orchards With Wind BreaksDokument3 SeitenProtect Orchards With Wind BreaksDr.Eswara Reddy SiddareddyNoch keine Bewertungen

- Grade Vi Epp Agri TQ, Tos, Answers KeyDokument9 SeitenGrade Vi Epp Agri TQ, Tos, Answers KeyHydon Biñas Libradilla100% (2)

- Manpower and Equipment Productivity RatioDokument6 SeitenManpower and Equipment Productivity RatioBenchNoch keine Bewertungen

- How To Mix MortarDokument3 SeitenHow To Mix MortarRi Sovannaphumi100% (1)

- Residue Management Machinery For CA - Dr. H.S. SidhuDokument48 SeitenResidue Management Machinery For CA - Dr. H.S. SidhuCSISA ProjectNoch keine Bewertungen

- Framed StructureDokument28 SeitenFramed Structureashenafi.aNoch keine Bewertungen

- How Do I Tell If It's A Damas Tree?: Who To Contact?Dokument2 SeitenHow Do I Tell If It's A Damas Tree?: Who To Contact?DavidNoch keine Bewertungen

- FIR0667 RibRaft Technical Manual 2020Dokument34 SeitenFIR0667 RibRaft Technical Manual 2020DoreenNoch keine Bewertungen

- Mechanical Properties of Sustainable Concrte Using Local Limestone Powder As Partial Replacement of CementDokument4 SeitenMechanical Properties of Sustainable Concrte Using Local Limestone Powder As Partial Replacement of CementIsaias Garcia SanchezNoch keine Bewertungen

- PortaltoiDokument2 SeitenPortaltoicontraNoch keine Bewertungen

- Alternative Building MaterialsDokument4 SeitenAlternative Building MaterialsZubin Kenneth SamuelNoch keine Bewertungen

- Quiz On PlantsDokument3 SeitenQuiz On Plantsapi-311729077Noch keine Bewertungen

- Concrete Mix Design Workshop-Group 3.1Dokument18 SeitenConcrete Mix Design Workshop-Group 3.1Chuckie EntocNoch keine Bewertungen

- Deciduous Fruit Production in ZimbabweDokument12 SeitenDeciduous Fruit Production in Zimbabwemsamala09Noch keine Bewertungen

- Alsterworthia v15 1Dokument28 SeitenAlsterworthia v15 1Gerardo Moscoso100% (1)

- Maples Common Name Japanese Maple Trident Maple Amur Maple Botanical Name Acer Palmatum Acer Buergerianum Acer Ginnala PDFDokument47 SeitenMaples Common Name Japanese Maple Trident Maple Amur Maple Botanical Name Acer Palmatum Acer Buergerianum Acer Ginnala PDFLuis CruzNoch keine Bewertungen