Beruflich Dokumente

Kultur Dokumente

UK Aluminium Fire Fact Sheet

Hochgeladen von

Nadi Jothidan KLOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

UK Aluminium Fire Fact Sheet

Hochgeladen von

Nadi Jothidan KLCopyright:

Verfügbare Formate

UK Aluminium Industry Fact Sheet 11

Aluminium and Fire

UK Aluminium Industry Fact Sheet 11 : Aluminium and Fire

+44(0)121 601 6363 www.alfed.org.uk

1

Party was reported in the Financial Times, 24

December 1982, I am not aware of any evidence

to suggest that any ship was lost because of the

use of aluminium in its construction, nor was there

any evidence that aluminium or aluminium alloys

had burned or suffered from a series of small

explosions. Aluminium, like any other material,

has advantages and disadvantages in any given

set of circumstances. Where the balance is in

favour, aluminium should be used in warships or

elsewhere.

Introduction

Aluminium and its alloys are the most commonly

used non-ferrous metal materials and they find

wide application in transport, building, packaging,

general and electrical engineering. The excellent

physical and mechanical properties of aluminium

alloys lead to their widespread use. The alloys are

light but strong and their use in transport saves

fuel over the whole of the vehicle lifetime. The

alloys can be fabricated or cast by all conventional

processes, joined by welding or adhesive bonding

and given a variety of surface coatings. These

coatings, together with the inherent high degree

of resistance to corrosion by the alloys, allow

the use of aluminium components in aggressive

environments. Finally, after use even over many

years, the aluminium can be recycled, with a saving

of energy of 95% of that required through the

primary smelter production route.

In fire tests on aluminium materials, when the

temperature exceeds the melting point, in the

range 600-660C, the aluminium surface exposed

to the fire can be seen to melt, but it does not burn.

At the end of the fire test, the metal remains as a

resolidified pool.

Aluminium in the form of finely divided powder

or flake oxidises exothermically, but this is a very

special case because of the very large surfacearea-to-weight ratio. Aluminium then behaves

in a similar way to other finely divided materials

such as iron and titanium, tea, flour and coal, all of

which will also readily oxidise exothermically in the

powder form.

Because of the widespread use of aluminium

alloys in building, transport, home appliances and

offshore structures, it is necessary to address

the issue of aluminium and fire and to answer the

question, does aluminium burn?.

The answer is, of course, No. Each year

hundreds of thousands of tonnes of aluminium

scrap are fed into remelt furnaces and heated up

to and beyond the melting point. The aluminium

melts when the temperature exceeds the melting

point, it does not burn. If it did, the recycling of

aluminium would not be possible.

Aluminium in a Fire

If aluminium is involved in a fire and the

temperature rises to above its melting point, the

metal begins to melt. The melting point of a metal,

like its density, strength, or corrosion resistance, is

a characteristic which can be measured and used

to design the most effective component for any

particular application.

During and following the Falklands conflict

between Great Britain and Argentina, several

misleading statements appeared in the press,

suggesting that aluminium alloys, used in the

superstructure of some of the ships that were

sunk, had burned and contributed to the loss of

these ships. Of the nine ships sunk in this conflict,

only three had aluminium superstructures. All

three vessels had steel hulls and in each case the

damage inflicted suggested that these vessels

would have sunk regardless of the materials of the

superstructure. In no case did aluminium burn.

HMS Sheffield, the first British destroyer to be

sunk, was widely reported to have an aluminium

superstructure. This was, in fact, an all-steel ship

with a steel hull and a steel superstructure. The

Defence White Paper published on 14 December

1982 concluded, there is no evidence that

aluminium has contributed to the loss of any

vessel. Similar conclusions were reached by the

Ministry of Defence Working Party convened to

review ship design. The Chairman of that Working

The thermal conductivity of aluminium is around

four times that of steel and its specific heat twice

that of steel. This means that heat is conducted

away faster and a greater heat input is necessary

to bring the same mass of aluminium to a given

temperature, compared with steel. Where an

aluminium structure is exposed to the heat of a

fire, the relatively high thermal conductivity enables

the heat to be rapidly conducted away from the

exposed area. This helps to reduce hot spots

where significant localised property loss could

occur, so extending the serviceability period. It will,

however, cause the temperature to rise elsewhere.

The extent of dissipation of heat elsewhere in the

structure will depend on the degree of thermal

insulation provided to the aluminium elsewhere in

the structure, necessary to provide fire protection

in that area. The high reflectivity of weathered

UK Aluminium Industry Fact Sheet 11 : Aluminium and Fire

1

aluminium is 80% to 90%, compared with 5% for

painted steel and 25% for stainless steel. This is of

considerable benefit and will assist in prolonging

endurance of an aluminium structure in a fire.

The attached photograph is a good example of

the behaviour of aluminium in the massive form

in a fire. A car, with aluminium alloy wheels, was

caught in a forest fire that swept over the car

and moved on. Afterwards it was found that the

aluminium wheels had melted, molten aluminium

had run off and collected in a pool of metal which

solidified as the fire moved on and the temperature

fell. The aluminium had not burnt.

exceeding the working limits during the design

time period.

Aluminium in Building

As with all metallic materials, as the temperature

increases the strength of aluminium alloys is

reduced at a rate dependent on the alloy, The

structural aluminium alloys have useful maximum

working temperature limits that range from 200

to 250C. Above this temperature the strength is

significantly reduced.

Aluminium alloy components are widely used

in building as cladding and roofing materials,

windows and doors. As defined by BS 476: Part

4 and the 1974 SOLAS Convention (as amended)

aluminium alloys are non-combustible and also

provide Class 1 surface spread of flame to BS 476:

Part 7. In addition, BS 476: Part 3 covers external

fire exposure roof tests and the classifications laid

down in the standard range from AA to DD. The

first letter refers to the fire penetration performance

and the second letter to the surface spread of

flame. Aluminium and its alloys are rated AA, the

highest possible under this classification system.

Materials are also tested for fire propagation

performance to BS 476: Part 6 (1989) and coating

systems are taken into account. Aluminium

achieves excellent ratings under this Standard.

Aluminium in Marine and

Offshore Applications

Aluminium alloys, particularly the aluminiummagnesium alloys, have been used since the 1930s

in many marine applications. In offshore structures

aluminium alloys are used in many applications

such as helicopter landing decks, stairs and

walkways, link bridges, housings for electrical

equipment and even complete living quarter

modules. Considerable cost savings can accrue

by the use of aluminium without any increased fire

risk. The use of aluminium also keeps the total

weight down and keeps the centre of gravity as low

as possible.

Three principal methods of fire protection are

employed, using fire resistant insulating layers

protecting an underlying aluminium component.

Examples have used ceramic fibre, intumescent

coatings applied to the aluminium element or

composite systems with aluminium external

skins. The latter have been demonstrated to be

applicable both as load-bearing elements and as

add-on panel systems. The aluminium skin on

the exposed fire side of the system is sacrificial

and melts, revealing a supported fire insulation

material which provides the required period of

fire performance and protects the remaining

aluminium elements of the system. A small

increase in insulation thickness is usually required

to take account of the lower maximum working

temperature limit of aluminium compared to steel.

The use of radiation shielding around structures

such as stair towers and walkways can provide

protection, not only to personnel during a fire but

prevent the temperature of the aluminium structure

For information on Fire Resistance Testing we

suggest contacting

http://www.warringtonfire.net/

Further information about aluminium and

aluminium alloys, their production, fabrication

and end use can be

obtained from:

(1) European Aluminium Association in Brussels

www.eaa.net

(2) International Aluminium Institute in London

www.world-aluminium.org

UK Aluminium Industry Fact Sheet 11 : Aluminium and Fire

2

Das könnte Ihnen auch gefallen

- 1oo1, 1oo2, 2oo2, 2oo3 Voting Logics in Safety Instrumented System (SIS) - Safety Instrumented System - SIS - Instrumentation Forum PDFDokument2 Seiten1oo1, 1oo2, 2oo2, 2oo3 Voting Logics in Safety Instrumented System (SIS) - Safety Instrumented System - SIS - Instrumentation Forum PDFNadi Jothidan KLNoch keine Bewertungen

- (PDF) The Effect of Partial Stroke Testing On The Reliability of Safety Valves PDFDokument24 Seiten(PDF) The Effect of Partial Stroke Testing On The Reliability of Safety Valves PDFNadi Jothidan KLNoch keine Bewertungen

- Derivation of Equations PDFDokument8 SeitenDerivation of Equations PDFNadi Jothidan KLNoch keine Bewertungen

- GE Bently Nevada System 1 Basic Ds 102M7750rD 2017 04Dokument4 SeitenGE Bently Nevada System 1 Basic Ds 102M7750rD 2017 04Nadi Jothidan KLNoch keine Bewertungen

- How To Write A Thesis Statement - IELTS AdvantageDokument9 SeitenHow To Write A Thesis Statement - IELTS AdvantageNadi Jothidan KLNoch keine Bewertungen

- Summit Archive 1493742608Dokument10 SeitenSummit Archive 1493742608Nadi Jothidan KLNoch keine Bewertungen

- 7 Types of Firewalls in I.T and Computer Networks ExplainedDokument7 Seiten7 Types of Firewalls in I.T and Computer Networks ExplainedNadi Jothidan KLNoch keine Bewertungen

- Ceiling Rate - Islamic Bankers Resource CentreDokument11 SeitenCeiling Rate - Islamic Bankers Resource CentreNadi Jothidan KLNoch keine Bewertungen

- Dog Eat Dog - SeaDemon SaysDokument5 SeitenDog Eat Dog - SeaDemon SaysNadi Jothidan KLNoch keine Bewertungen

- GoodDokument13 SeitenGoodNadi Jothidan KLNoch keine Bewertungen

- Shell vision statement vs mission statementDokument1 SeiteShell vision statement vs mission statementNadi Jothidan KLNoch keine Bewertungen

- Viewpoint On Isa Tr8402 Simplified Equations and Fault Tree AnalysisDokument15 SeitenViewpoint On Isa Tr8402 Simplified Equations and Fault Tree AnalysisNadi Jothidan KLNoch keine Bewertungen

- Writing Task 2 - Take IELTSDokument2 SeitenWriting Task 2 - Take IELTSNadi Jothidan KLNoch keine Bewertungen

- LOPA ArticlesDokument31 SeitenLOPA ArticlesShri.krsnaNoch keine Bewertungen

- Ielts-Simon - Band 9 Opinion EssayDokument5 SeitenIelts-Simon - Band 9 Opinion EssayNadi Jothidan KL100% (1)

- 3 Secrets For Crafting A Great Business School Resume PDFDokument5 Seiten3 Secrets For Crafting A Great Business School Resume PDFNadi Jothidan KLNoch keine Bewertungen

- LOPA-Validating Human IPLs and IEs-Updated 2011 PDFDokument35 SeitenLOPA-Validating Human IPLs and IEs-Updated 2011 PDFNadi Jothidan KLNoch keine Bewertungen

- Why International MBAs May Have A Tough Time Finding Jobs in UK - BusinessBecause PDFDokument6 SeitenWhy International MBAs May Have A Tough Time Finding Jobs in UK - BusinessBecause PDFNadi Jothidan KLNoch keine Bewertungen

- Delete All Rows & Columns With Zero Balaces (Solved)Dokument2 SeitenDelete All Rows & Columns With Zero Balaces (Solved)Nadi Jothidan KLNoch keine Bewertungen

- LOPA Performed When and by Whom - FINALDokument12 SeitenLOPA Performed When and by Whom - FINALNadi Jothidan KLNoch keine Bewertungen

- Curriculum Vitae - Differences Between The US and The UK - CVcorrectDokument2 SeitenCurriculum Vitae - Differences Between The US and The UK - CVcorrectNadi Jothidan KLNoch keine Bewertungen

- 1oo1, 1oo2, 2oo2, 2oo3 Voting Logics in Safety Instrumented System (SIS) - Safety Instrumented System - SIS - Instrumentation Forum PDFDokument2 Seiten1oo1, 1oo2, 2oo2, 2oo3 Voting Logics in Safety Instrumented System (SIS) - Safety Instrumented System - SIS - Instrumentation Forum PDFNadi Jothidan KLNoch keine Bewertungen

- Online Mba Ranking 2019Dokument1 SeiteOnline Mba Ranking 2019Nadi Jothidan KLNoch keine Bewertungen

- 3 Secrets For Crafting A Great Business School Resume PDFDokument5 Seiten3 Secrets For Crafting A Great Business School Resume PDFNadi Jothidan KLNoch keine Bewertungen

- ETF Index Fund Selection Process and Criteria, Single ETF - Setup and Forget - Strategy - EuropeFIREDokument6 SeitenETF Index Fund Selection Process and Criteria, Single ETF - Setup and Forget - Strategy - EuropeFIRENadi Jothidan KLNoch keine Bewertungen

- All You Need To Know About Sending Money OverseasDokument6 SeitenAll You Need To Know About Sending Money OverseasNadi Jothidan KLNoch keine Bewertungen

- Borderless Accounts and Tax - TransferWise Help CentreDokument4 SeitenBorderless Accounts and Tax - TransferWise Help CentreNadi Jothidan KLNoch keine Bewertungen

- What Is Annualized Return in Mutual Funds - How Is It Calculated - Upwardly BlogDokument12 SeitenWhat Is Annualized Return in Mutual Funds - How Is It Calculated - Upwardly BlogNadi Jothidan KLNoch keine Bewertungen

- Why International MBAs May Have A Tough Time Finding Jobs in UK - BusinessBecauseDokument6 SeitenWhy International MBAs May Have A Tough Time Finding Jobs in UK - BusinessBecauseNadi Jothidan KLNoch keine Bewertungen

- TransferWise Borderless Account Review - My Personal Experience PDFDokument15 SeitenTransferWise Borderless Account Review - My Personal Experience PDFNadi Jothidan KLNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- VOS Stone Vessel ParticularsDokument1 SeiteVOS Stone Vessel ParticularsBirdNoch keine Bewertungen

- Technical InformationDokument8 SeitenTechnical Informationmyusuf_engineerNoch keine Bewertungen

- Bizantska MornaricaDokument31 SeitenBizantska MornaricaDubravko AladicNoch keine Bewertungen

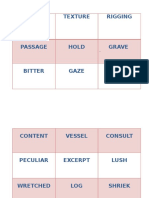

- OMEN TEXTURE RIGGINGDokument5 SeitenOMEN TEXTURE RIGGINGMeg ElisabethNoch keine Bewertungen

- TG43-22 Throttle and Kill Cord Position For Powerboat 1 - 2 CoursesDokument2 SeitenTG43-22 Throttle and Kill Cord Position For Powerboat 1 - 2 CoursesdhrhsjNoch keine Bewertungen

- Main Idea II: Pre-TestDokument3 SeitenMain Idea II: Pre-TestJane DoNoch keine Bewertungen

- 2006 03 01-SeabasingDokument329 Seiten2006 03 01-SeabasingsithusoemoeNoch keine Bewertungen

- STCW 95Dokument44 SeitenSTCW 95Kalyan Ram Vemulapalli100% (1)

- Programmable Logic Controllers 5th Edition Petruzella Test BankDokument36 SeitenProgrammable Logic Controllers 5th Edition Petruzella Test Bankslogmaying7y5g100% (47)

- Paper - GST2012 - Understanding The Physics of Trim - Nikolaj Lemb Larsen PDFDokument10 SeitenPaper - GST2012 - Understanding The Physics of Trim - Nikolaj Lemb Larsen PDFIonut SmokeNoch keine Bewertungen

- Latihan Soal Cadet BSM 2015Dokument112 SeitenLatihan Soal Cadet BSM 2015Alifia Rachma100% (1)

- Mechanization of Okha Port FinalDokument20 SeitenMechanization of Okha Port FinalKushal2187Noch keine Bewertungen

- Employment Contract of Commercial Vessel's FishermanDokument6 SeitenEmployment Contract of Commercial Vessel's FishermanCarlota TejeroNoch keine Bewertungen

- Daily Progress ReporDokument6 SeitenDaily Progress ReporRobert WilliamsNoch keine Bewertungen

- BL Copy - Berlian Anugerah (Reuse)Dokument1 SeiteBL Copy - Berlian Anugerah (Reuse)Ricky RezaNoch keine Bewertungen

- Supreme Court Rules on Liability for Passenger Injuries from Firecracker Explosion in BusDokument31 SeitenSupreme Court Rules on Liability for Passenger Injuries from Firecracker Explosion in BusChieDelRosarioNoch keine Bewertungen

- MV Willy: Report On The Investigation of The Grounding ofDokument33 SeitenMV Willy: Report On The Investigation of The Grounding ofLyubomir IvanovNoch keine Bewertungen

- NP285 PDFDokument451 SeitenNP285 PDFЕвгений Лущай100% (9)

- Shipping Part3Dokument32 SeitenShipping Part3mohdsuhail2k3055Noch keine Bewertungen

- DP Fmea Trials Report2018 - Pms 17Dokument71 SeitenDP Fmea Trials Report2018 - Pms 17Mohammed BasionyNoch keine Bewertungen

- Safe Port Issues in The Context of Chittagong Port - PPTDokument11 SeitenSafe Port Issues in The Context of Chittagong Port - PPTmohiuddin_kadirNoch keine Bewertungen

- SMH Saturday 1 May 1915Dokument24 SeitenSMH Saturday 1 May 1915Fairfax MediaNoch keine Bewertungen

- Hydro Electric BoatsDokument2 SeitenHydro Electric BoatsRhiannon BallardNoch keine Bewertungen

- Compliant TowerDokument4 SeitenCompliant TowerjohariakNoch keine Bewertungen

- Cargoes Chapter4Dokument8 SeitenCargoes Chapter4matmaricNoch keine Bewertungen

- Ecdis Manual Rev.1Dokument56 SeitenEcdis Manual Rev.1Руслан Дроголюбов100% (3)

- Vintage Airplane - Nov 2002Dokument36 SeitenVintage Airplane - Nov 2002Aviation/Space History LibraryNoch keine Bewertungen

- Steel Vessel Systems RulesDokument718 SeitenSteel Vessel Systems RulesAnis KacemNoch keine Bewertungen

- Maritime Commerce Bar Exam Questions and AnsDokument3 SeitenMaritime Commerce Bar Exam Questions and AnsChristian ViernesNoch keine Bewertungen

- WoodenBoat 228 SepOct 2012Dokument156 SeitenWoodenBoat 228 SepOct 2012Edson PereiraNoch keine Bewertungen