Beruflich Dokumente

Kultur Dokumente

Breechloading - Flintlock Notes PDF

Hochgeladen von

sjdarkman1930Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Breechloading - Flintlock Notes PDF

Hochgeladen von

sjdarkman1930Copyright:

Verfügbare Formate

Breech-loading Flintlock Pistol

Construction notes

S. Wardlaw, M.D.

19 December, 2012

General:

The dimensions for the drawings were taken from a breech-loading flintlock pistol I constructed a few

years ago by the 'cut and try' method, so some dimensions were normalized from the original. There

will be some fitting required, even if all the parts are made to the exact dimensions.

The web page http://tinyurl.com/breech-flint has much more information. Please see it.

A point to remember:

The barrel width is a key dimension, so get the barrel first to confirm its width and make the receiver

channel to fit it. The same is true for the lock.

Barrel:

The barrel used for this project was an old Douglas .36 caliber rifled pistol barrel in 13/16 straight

profile. Any other barrel in a straight profile could also be used. The breech section of this pistol was

made by cutting a portion from the breech end of the barrel and inserting my custom breech plug.

Lock:

The lock used here is the John Bailes lock manufactured by L&R and sold by 'Track of the Wolf'. The

lock was modified by milling the bolster on the lock plate into a rectangle to fit the slot on the side of

the receiver.

Receiver:

This receiver was fabricated from a block of 4140 steel, which was subsequently hardened by heating

to the proper temperature and then air cooling the top while placing the keel on wet newspapers. If the

piece is dunked, it will warp. After hardening, it was reheated to 550 degrees for tempering. It might be

possible to use high-strength (7075) aluminum, which would be lighter and much easier to machine.

Barrel retention:

The barrel is retained by two 10-32 screws and a 3/8 retaining/positioning pin. The pin is made from

hardened and blue-tempered 4140 steel and must be long enough to exactly fit the gap formed between

the bottoms of the slot and hole in the receiver and barrel. If not an exact fit, it is susceptible to being

upset and allowing the barrel to move out of position when fired. Also make absolutely sure the 10-32

screws holding the barrel down do not bottom out in the barrel before pulling it tight to the receiver. It

is also very important to use a material such as the #2 Permatex to seal the space between the barrel and

receiver. This material can flow enough to allow barrel positioning, but acts as if it were solid if you try

to move it quickly; thus, during firing, it acts as a strong solid bond.

Cam and breech plug:

The cam and breech plug are machined from 4140 and must be hardened and tempered to a light blue

to give good hardness; the cam-breech mechanism is the most heavily stressed during firing.

Fitting:

Before the barrel is placed, the cam and breech must be fitted so that the cam lever is under slight

tension as the eccentric contacts the bottom of the slot in the breech plug, before the lever meets the

catch. Then, the barrel adjusting screw is tightened until the breech contacts the barrel when the lever is

about 1 from the catch. This will put the required force on the breech when the catch is closed. Again,

make sure the retention screws are not bottomed out in their holes, and add the Permatex before

attempting to proof-test it.

Das könnte Ihnen auch gefallen

- Improvised Shotgun PistolDokument6 SeitenImprovised Shotgun Pistolztmp100% (1)

- 50 Caliber Rifle Construction ManualDokument65 Seiten50 Caliber Rifle Construction Manualdiglemar100% (4)

- Homemade Ammo Sample PagesDokument10 SeitenHomemade Ammo Sample PagestwatscorpseNoch keine Bewertungen

- AK-47 Souptonuts 5Dokument7 SeitenAK-47 Souptonuts 5tshirley47100% (3)

- Holmes 50Dokument65 SeitenHolmes 50The_Desolator100% (15)

- SGRImproDokument5 SeitenSGRImproAdven TuresNoch keine Bewertungen

- Condensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsDokument4 SeitenCondensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsMarcial NuñezNoch keine Bewertungen

- Adp 6Dokument3 SeitenAdp 6mohd_azhar_51Noch keine Bewertungen

- Airframe Construction and RepairDokument17 SeitenAirframe Construction and RepairJaycee QuiambaoNoch keine Bewertungen

- How To Use A Pipe Flaring ToolDokument8 SeitenHow To Use A Pipe Flaring Toolmark darrelNoch keine Bewertungen

- L - 9 Ah - SSBLF I (6.5)Dokument7 SeitenL - 9 Ah - SSBLF I (6.5)Arjun SharmaNoch keine Bewertungen

- Tail Shaft SurveyDokument5 SeitenTail Shaft SurveyRanjeet SinghNoch keine Bewertungen

- Bottom Nut's Tack Welding On Straigth Anchor Bolt 141106Dokument2 SeitenBottom Nut's Tack Welding On Straigth Anchor Bolt 141106Asif RazaNoch keine Bewertungen

- Pontiac G8 - LSA Swap - How To GuideDokument12 SeitenPontiac G8 - LSA Swap - How To Guidethumper777Noch keine Bewertungen

- Chimera ManualDokument12 SeitenChimera ManualticocrazyNoch keine Bewertungen

- 4L80E Build Tips and TricksDokument5 Seiten4L80E Build Tips and TricksSjoling8211Noch keine Bewertungen

- Shotgun Based Pistol BlueprintDokument6 SeitenShotgun Based Pistol BlueprintGonzoGranello0% (1)

- HP Lok: 2010 EditionDokument38 SeitenHP Lok: 2010 Editiondeema saleemNoch keine Bewertungen

- Plastics Mold Eng Hand 42Dokument151 SeitenPlastics Mold Eng Hand 42eduardo_umNoch keine Bewertungen

- Crane JigDokument2 SeitenCrane Jigradio-chaserNoch keine Bewertungen

- Etnyre CentennialDokument44 SeitenEtnyre CentennialRuben E. Aguilar LazarteNoch keine Bewertungen

- 2 - How To Make A SilencerDokument5 Seiten2 - How To Make A SilencerFlavio Marçal100% (3)

- Lycoming Starter AdapterDokument11 SeitenLycoming Starter AdapterakNoch keine Bewertungen

- Item 449 Anchor Bolts: 1. DescriptionDokument3 SeitenItem 449 Anchor Bolts: 1. DescriptionIbrahim AlrabibNoch keine Bewertungen

- Jet Boat, New Thrills Afloat With ThisDokument16 SeitenJet Boat, New Thrills Afloat With ThisJim50% (2)

- Barrel Drilling and ReamingDokument9 SeitenBarrel Drilling and Reamingbigsmoke31100% (2)

- 34 5381 01 Instructions Cable CableDokument2 Seiten34 5381 01 Instructions Cable Cabletecknotron2072Noch keine Bewertungen

- BF - IOM Manual - Forged Steel ValvesDokument3 SeitenBF - IOM Manual - Forged Steel ValvesHernando DiazNoch keine Bewertungen

- RP554 ManualDokument3 SeitenRP554 ManualAdolfo Angulo100% (1)

- Rifling MachineDokument83 SeitenRifling Machinekcwelder90% (10)

- How To Drill A Rifle BarrelDokument6 SeitenHow To Drill A Rifle BarrelMaria Donoghue50% (2)

- Armaflex Install PDFDokument5 SeitenArmaflex Install PDFPeter BqkNoch keine Bewertungen

- Flight Model Sbach 342 50ccDokument61 SeitenFlight Model Sbach 342 50ccyuntanakaNoch keine Bewertungen

- Fork Gold Valve Installation: DisassemblyDokument4 SeitenFork Gold Valve Installation: DisassemblyTiyok HidrolikNoch keine Bewertungen

- A 142 17 CentDokument44 SeitenA 142 17 CentMaira Alejandra Poveda HerreraNoch keine Bewertungen

- ABL Tool ManualDokument42 SeitenABL Tool ManualSidali BenmiloudNoch keine Bewertungen

- Daisy1000tear DownguideDokument11 SeitenDaisy1000tear DownguideKarina WoodenNoch keine Bewertungen

- Aircraft FastenerDokument91 SeitenAircraft FastenerPrasanthNoch keine Bewertungen

- Specified Anchor Bolt Category Bolt Standards Nut StandardsDokument3 SeitenSpecified Anchor Bolt Category Bolt Standards Nut StandardsrefaeNoch keine Bewertungen

- 69 PDFDokument1 Seite69 PDFAnonymous p8HJKJTaFaNoch keine Bewertungen

- Fasteners and HardwareDokument42 SeitenFasteners and HardwareAyman MousaNoch keine Bewertungen

- HT Hold Down StrapsDokument4 SeitenHT Hold Down Strapsم.ذكى فضل ذكىNoch keine Bewertungen

- 1150 InstDokument5 Seiten1150 InstMohammad NorooziNoch keine Bewertungen

- Revolver ChamferingDokument6 SeitenRevolver ChamferingZardoz1090100% (1)

- Rear Sway Bar Installation InstructionsDokument4 SeitenRear Sway Bar Installation InstructionsRaduNoch keine Bewertungen

- Tech Talk: Y-Block Assembly ErrorsDokument2 SeitenTech Talk: Y-Block Assembly ErrorsMatt WheltleNoch keine Bewertungen

- PCV BurlingDokument24 SeitenPCV Burlingantony nirmalaNoch keine Bewertungen

- AT 401 - OM 7 RepairsDokument4 SeitenAT 401 - OM 7 RepairsricardozafraNoch keine Bewertungen

- CT Coveyed PerforatingDokument4 SeitenCT Coveyed PerforatingAdel Ahmed AlkhaligyNoch keine Bewertungen

- Gunpower TalonDokument4 SeitenGunpower Talonolhodeboi100% (1)

- Breech Lock B-Style Bapco Video v1Dokument18 SeitenBreech Lock B-Style Bapco Video v1tsvs58Noch keine Bewertungen

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideVon EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNoch keine Bewertungen

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesVon EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesBewertung: 5 von 5 Sternen5/5 (1)

- The Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoVon EverandThe Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoNoch keine Bewertungen

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopVon EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsVon EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNoch keine Bewertungen

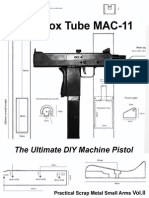

- DIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)Dokument21 SeitenDIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)fritzthecat5295% (22)

- The Construction and Operation of The Air Gun. Vol. 2 PDFDokument85 SeitenThe Construction and Operation of The Air Gun. Vol. 2 PDFsjdarkman1930100% (7)

- Long Tail BoatDokument71 SeitenLong Tail Boatceaseless_way100% (1)

- Double Stack Mag 22LR US8776419Dokument21 SeitenDouble Stack Mag 22LR US8776419sjdarkman19300% (1)

- Sistema de PropulsãoDokument50 SeitenSistema de PropulsãoEwerton MonteiroNoch keine Bewertungen

- The Box Tube MAC-11 Part 2 (Practical Scrap Metal Small Arms Vol.5)Dokument16 SeitenThe Box Tube MAC-11 Part 2 (Practical Scrap Metal Small Arms Vol.5)BangBoomBang91% (68)

- The Construction and Operation of The Air Gun. Vol. 1Dokument111 SeitenThe Construction and Operation of The Air Gun. Vol. 1sjdarkman193067% (3)

- Single Lip Cutter D-BitDokument2 SeitenSingle Lip Cutter D-Bitsjdarkman1930Noch keine Bewertungen

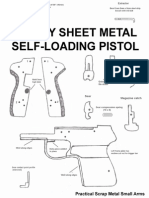

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDokument15 SeitenThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (122)

- Sas12 Shotgun ExplodedDokument8 SeitenSas12 Shotgun Explodedsjdarkman1930Noch keine Bewertungen

- Model 99 Exploded ViewDokument1 SeiteModel 99 Exploded ViewtophunterNoch keine Bewertungen

- eBOOK - Poor Man's RPG PDFDokument156 SeiteneBOOK - Poor Man's RPG PDFsjdarkman1930100% (10)

- Off Set CenterDokument1 SeiteOff Set CenterFrenchwolf420Noch keine Bewertungen

- Making and Using Reamers: Part 1Dokument50 SeitenMaking and Using Reamers: Part 1angelines123Noch keine Bewertungen

- G0355Dokument52 SeitenG0355sjdarkman1930100% (1)

- Simple Homemade Pistol Pit-Bull-1Dokument22 SeitenSimple Homemade Pistol Pit-Bull-1sjdarkman1930100% (2)

- Mk18 Mod1 SBR RifleDokument21 SeitenMk18 Mod1 SBR Riflesjdarkman1930Noch keine Bewertungen

- Breechloading Flintlock PDFDokument12 SeitenBreechloading Flintlock PDFsjdarkman1930100% (1)

- 6DZE1 Rifle Making in The Great Smokey MountainsDokument21 Seiten6DZE1 Rifle Making in The Great Smokey MountainsRobert Powell100% (3)

- RAP4 T68 Paintball Patent US8578921Dokument32 SeitenRAP4 T68 Paintball Patent US8578921sjdarkman1930Noch keine Bewertungen

- A Method of Making Reamers PDFDokument10 SeitenA Method of Making Reamers PDFsjdarkman193050% (2)

- BARRETT 2013 - Product - Brochure PDFDokument30 SeitenBARRETT 2013 - Product - Brochure PDFsjdarkman1930100% (1)

- Q Loader PatentsDokument20 SeitenQ Loader Patentssjdarkman1930Noch keine Bewertungen

- QB78 DisassemblyDokument8 SeitenQB78 Disassemblysjdarkman1930100% (2)

- Off Grid RefrigerationDokument2 SeitenOff Grid Refrigerationsjdarkman1930Noch keine Bewertungen

- Icy Ball ManualDokument6 SeitenIcy Ball Manualsjdarkman1930Noch keine Bewertungen

- DP Price List 2018 1Dokument99 SeitenDP Price List 2018 1Anonymous w6GMxAPOYBNoch keine Bewertungen

- Handguns of The World - EC Ezell 1981Dokument728 SeitenHandguns of The World - EC Ezell 1981Edy MorarNoch keine Bewertungen

- The Illustrated Catalog of Rifles and ShotgunsDokument14 SeitenThe Illustrated Catalog of Rifles and ShotgunsFirearms - Modern, Historic and Collectible Guns93% (14)

- Army Ordnance & Inertia Toward A Change in Small Arms Through The Civil WarDokument62 SeitenArmy Ordnance & Inertia Toward A Change in Small Arms Through The Civil Warhwelch5792Noch keine Bewertungen

- Lyman: User's Guide For Black Powder ProductsDokument48 SeitenLyman: User's Guide For Black Powder Productsdougpfaff100% (1)

- Pruebas Museo AustríacoDokument13 SeitenPruebas Museo AustríacoJuan Diego Conde EguiletaNoch keine Bewertungen

- Evolution of Military Small Arms Instructor GuideDokument2 SeitenEvolution of Military Small Arms Instructor GuideJuusjjsNoch keine Bewertungen

- Firearms in America 1600 - 1899Dokument310 SeitenFirearms in America 1600 - 1899Mike100% (3)

- Forensic BallisticsDokument14 SeitenForensic BallisticsCatherine AcedoNoch keine Bewertungen

- Colt Single Action: From Patersons To PeacemakersDokument12 SeitenColt Single Action: From Patersons To PeacemakersFirearms - Modern, Historic and Collectible Guns67% (6)

- Gunsmithing Fundamentals A Guide For Professional Results - Ocr PDFDokument176 SeitenGunsmithing Fundamentals A Guide For Professional Results - Ocr PDFv1335432100% (5)

- Guns Guns GunsDokument146 SeitenGuns Guns GunsDimitrije Vasiljević75% (4)

- Armas y FabricantesDokument101 SeitenArmas y FabricantespepondeAviles100% (2)

- Firearms - An Illustrated HistoryDokument322 SeitenFirearms - An Illustrated HistoryMarco Rezende86% (36)

- Hunters Lodge 8-2014Dokument1 SeiteHunters Lodge 8-2014HGNoch keine Bewertungen

- Saxony 1699-1721Dokument1 SeiteSaxony 1699-1721Steffen SeitterNoch keine Bewertungen

- Alternity ProfessionsDokument26 SeitenAlternity ProfessionsJoel100% (1)

- The Illustrated Encyclopedia of HandgunsDokument303 SeitenThe Illustrated Encyclopedia of HandgunsMarcus100% (2)

- Way of The Gun Kata GM BinderDokument3 SeitenWay of The Gun Kata GM BinderBrandon ButlerNoch keine Bewertungen

- Smithsonian ArtifactsDokument6 SeitenSmithsonian ArtifactsJames LewisNoch keine Bewertungen

- The Drafter Class: by M. W. TierneyDokument16 SeitenThe Drafter Class: by M. W. Tierneyasdfa asdfNoch keine Bewertungen

- Muzzleloader Blank Black Powder Charge Pressure: Are Double Charges Dangerous?Dokument3 SeitenMuzzleloader Blank Black Powder Charge Pressure: Are Double Charges Dangerous?Herman KarlNoch keine Bewertungen

- Arms and Armor Honor IntrigueDokument2 SeitenArms and Armor Honor IntriguelunaNoch keine Bewertungen

- Firearms Catlg 1910Dokument152 SeitenFirearms Catlg 1910Pedro Burka100% (2)

- Unturned Ids, Cheats, AchievmentsDokument76 SeitenUnturned Ids, Cheats, AchievmentsKael GrayNoch keine Bewertungen

- El Ejercito ContinentalDokument471 SeitenEl Ejercito ContinentalBlas De Lezo100% (2)

- Origins of FirearmsDokument3 SeitenOrigins of FirearmsElizabeth Veloso100% (1)

- Man Behind FirearmsDokument3 SeitenMan Behind FirearmsXel J. Diamante100% (1)

- A Guide To Firearms (5E)Dokument5 SeitenA Guide To Firearms (5E)Damon HeltonNoch keine Bewertungen

- Skinner Science Technology and ClocksDokument172 SeitenSkinner Science Technology and Clockspancholopez2014Noch keine Bewertungen