Beruflich Dokumente

Kultur Dokumente

17530

Hochgeladen von

DiyaNegiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

17530

Hochgeladen von

DiyaNegiCopyright:

Verfügbare Formate

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

Important Instructions to examiners:

1) The answers should be examined by key words and not as word-to-word as given in the

model answer scheme.

2) The model answer and the answer written by candidate may vary but the examiner may try

to assess the understanding level of the candidate.

3) The language errors such as grammatical, spelling errors should not be given more

Importance (Not applicable for subject English and Communication Skills.

4) While assessing figures, examiner may give credit for principal components indicated in the

figure. The figures drawn by candidate and model answer may vary. The examiner may give

credit for any

equivalent figure drawn.

5) Credits may be given step wise for numerical problems. In some cases, the assumed

constant

values may vary and there may be some difference in the candidates answers and model

answer.

6) In case of some questions credit may be given by judgement on part of examiner of relevant

answer based on candidates understanding.

7) For programming language papers, credit may be given to any other program based on

equivalent concept.

Q1. A) Attempt any three.

a) List any four objectives of metrology.

1) To ensure that the product is as per quality standard.

2) To enhance total customer satisfaction.

3) To reduce rework and rejections.

4) To increase profitability of organization.

5) It helps in manufacture of interchangeable parts.

6) Overcome the short coming in the production process.(Any 4) 1 mark each

b) Explain the term Selective assembly.

1. The consumer not only wants quality, precision and trouble free products but also he wants them at

attractive prices.

2. This has become possible only by adopting automatic gauging for selective assembly whereby parts

manufactured to rather wide tolerances fit and function as though they were precisely manufactured

in precision laboratory to very close tolerances.

3. This is a concept which does away with old idea of inspection in which part in identified as good or

bad; good part being used for assembly and bad used to be scraped.

4. In selective assembly the components produced by a machine are classified into several groups

according to size.

5. This is done both for hole and shaft and then the corresponding groups will match properly.

6. If some parts (shaft and holes) to be assembled are manufactured to normal tolerances of 0.01 mm

(and both are within the curve of normal distribution),

Page 1 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

7. an automatic gauge can segregate them into ten different groups with a 0.001 mm limit for selective

assembly of the individual parts. Proper explanation 4 marks.

c) Define :

i) Frequency Distribution :Frequency distribution is a tabulation of data obtained from measurement, arranged in ascending

or descending order according to size.

ii) Central Tendency:The sample data is that most of the observations tend to concentrate in the center of the

distribution. This characteristic of distribution is known as Central Tendency.

iii) Dispersion:The extent to which the data is scattered about the zone of central tendency is known as

dispersion.

iv) Variance:it is the sum of the squares of the deviations from the arithmetic mean divided by the number of

observations.

1 mark for each definition

d) Draw the conventional diagram of limits and fits and define the term: i)Basic size. ii)Fundamental

Deviation.

2marks

Basic size:It is the standard size of a part, with reference to which all the limits of variations of size

are determined.

1 mark

Fundamental Deviation:The algebraic difference between size and corresponding basic size is known as deviation.

1 mark

Q1. B) Attempt any one.

Page 2 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

A) Explain with neat sketch how angle of a work piece is measured with the help of angle

dekkor.

This is also a type of an autocollimator. It contains a small illuminated scale in the focal

plane of the objective lens (collimating lens). This scale in normal position is outside the

view of the microscope eyepiece . The illuminated scale is projected as a parallel beam by the

collimating lens which after striking a reflector below the instrument is refocused by the lens

in the field of view of the eye-piece.

In the field of view of microscope there is another datum scale fixed across the center of

screen and the reflected image of the illuminated scale is received at right angle to this fixed

scale as shown in fig. and the two scales, in this position intersect each other.

Thus the reading on the illuminated scale measures angular devotions form one axis at

0

90 to the optical axis and the reading on the fixed datum scale measures the deviation about

an axis mutually perpendicular to the other two. In other words, changes in angular position

of the reflector in two planes are indicated by changes in the point of intersection of the two

scales. Readings from scale are read direct to 1 without the use of a micrometer.

It is mostly used as a comparator. The instrument measures by comparing the readings

obtained from a standard, a sine bar or combination of angle gauges with that form the work

under test. Though this is not a precise instrument in comparison to autocollimator, it has

wide field of application for general angular measurement, as angular variations are read

direct without the operation of a micrometer.

2mark(Fig.)+ 4 mark (explanation)

B) Draw the neat sketch of gear tooth vernier caliper and write the procedure for

measuring chordal tooth thickness.

Page 3 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

1. Tooth thickness and depth is calculated using for setting vertical limb of gear tooth vernier.

2. Tooth thickness (c or w) is measured by setting depth (h or d) on vertical limb of vernier, as the

distance between the fixed jaws and movable jaw by fixing distance at adjustable jaws of vertical

vernier beam.

3marks (figure)+3 marks (explanation)

Q2. Attempt Any four.

a) In measurement of surface roughness height of 20 successive peaks and valleys were

measured

from

a

datum

are

as

follows

45,

25,

35,40,25,16,40,22,25,34,25,40,20,40,20,36,28,18,20,25,30,38. If this measurement were

obtained on 10 mm length, Determine CLA & RMS value of surface roughness.

Ans:1)

CLAValue=

CLA Value = 29.35unit

2)

2 marks

RMS Value =

RMS Value =

RMS Value =

30.51unit

2 marks

b) Construct an angle of 330 19 15 using minimum number of angle gauges using standard

angle gauge set. Draw the sketch of the arrangement.

330=410-90+10

19=27-9+1

Page 4 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

15=18-3

c) What is best size of wire? State the expression for the same, indicating meaning of each

term.

This wire is of such diameter that it makes contact with the flanks of the thread on the

effective diameter or pitch line. Actually effective diameter can be measured with any diameter wire

which makes contact on the true flank of the thread, but the values so obtained will differ from those

obtained with best size wires if there is any error in angle or form of thread.

It is recommended that for measuring the effective diameter, always the best size wire should

be used and for this condition the wire touches the flank at mean diameter line within

1/5 of flank

length. With best size wire, any error on the measured value of simple effective diameter due to error

in thread form or angle is minimized.

2 MARK

1 MARK

Where,

d= best wire diameter

P= pitch of thread

1 MARK MEANING.

d) Draw labeled sketch of sigma comparator

Page 5 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

figure3marks+Labelling 1 mark

e) Explain cost of quality and value of quality with the help of graph.

1.

The balance between the cost of quality and value of quality gives optimum quality of design.

2.

It is not necessary that the company should manufacture 100% quality products.

3.

The study of optimum quality of design involves Market Survey.

4.

While carrying out market survey expected sale for particular quality, profit and competition in the

market is to be considered.

Page 6 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

5.

WINTER 14 EXAMINATION

Model Answer

The quality of design should meet the needs of the customers and at the same time its

manufacturing cost should be such which will yield maximum profit.

6.

The aim should be to improve quality at lower cost.

7.

The curves representing the cost and value of quality of design are shown in fig.

8.

if we want to improve the quality of design from point 1 to point 2 the cost of quality will increase

by amount A whereas the value of quality will increase by amount B.

9.

Now B >A and therefore, improvement in quality at this level will yield more income.

10. However, if the quality is to be improved from point 2 to point 3, then from the fig.

11. D < C i.e. the increase in value of quality is less than the increase in the cost of quality.

So, the quality level at point 2 is optimum quality of design. Below this optimum the profit that

can be earned is not maximized and above this optimum it is uneconomical to improve the quality

of design.

Graph 1 mark+ 3 mark explanation.

Q.3. Attempt any four:

a) Differentiate between comparator and a measuring instrument (at least 4 points).

Sr. No.

Instrument

Comparator

01

It is not give any magnification.

It gives magnification.

02

Skilled operators are required.

Semi-skilled operators are required.

03

Observational error is occur.

Parallax error is occur.

04

Maintenance is less.

Maintenance is more.

05

Remote controlling is not possible.

It may be operate by remote.

06

Uniform response is not obtained.

Uniform response is obtained.

07

Used for checking and measurement.

Used for comparison.

08

09

Less sensitive.

Ex. Vernier calliper

More sensitive.

Sigma comparator is ex.

1 mark each for any 4 points

b) Compare inspection and quality control.

Sr. No.

01

02

03

Inspection

Quality Control

It is an effective system for integrating quality,

It is act of checking the parts at

development, maintenance and improvement

various stages and sorting out

of various groups in the organisation to

defective items.

achieve production at most economical cost.

It is part of quality control.

It is the broad terms which include inspection.

It is uses prcised measuring It uses quality tool i.e. control charts.

Page 7 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

instruments, such as vernier,

micrometre etc.

It is concern with quality of past

It is concern with future production.

production.

It is responsibility of everyone working in

It is responsibility of inspector.

organisation.

1 mark each for any 4 points

04

05

c) Interpret the meaning of 27H5f6 with respect to fit and basis system.

27 H5 means an H-hole of basic size 27mm having tolerance grade IT5. 1 mark

27 F6 means an F-shaft of basic size 27mm having tolerance grade IT6.1 mark

27 H5 F6 is fit indicated by its basic size 27mm followed by symbols representing the limits of hole

and shaft, the hole being stated first.

The type of fit is clearance fit.2 mark

d) Differentiate between Line and End Standard. (at least 4 points)

Sr.

No.

Line Standard

End Standard

02

03

04

When length is expressed as distance

When length is express as distance between

between two parallel faces is called as

two parallel line is called line standard.

end standard.

Measurement is quick and easy.

Measurement is time consuming.

It is not used for prcised measurement.

It is used for prcised measurement.

It is subjected to parallax error.

It is not subjected to parallax error.

05

It is cheaper.

06

07

It is simple in construction.

It is complicated in construction.

Ex. Steel Rule, meter tape,

Micro meter, slip gauges

1 mark each for any 4 points

01

It is costlier.

e) Explain in brief two wire method for thread measurement.

1 mark

Effective diameter can be measured by using floating carriage instrument which is more accurate. In

two wire method which consists of two identical wedges size wires.

Page 8 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

Fig. shows measurement of thread and wire dimensions. The wire are to be inserted in such way

that,

1) Inserted in such thread.

2) The flank surfaces are tangents to the wire.

The dimensions are parameters which are measured as per shown in figure and pitch value of

thread is difference between effective diameter and diameter under wire. (2 mark explanation)

The effective diameter is addition of diameter under wire and pitch value E = T + P

But,

T = R 2d

1 mark

Where,

E = effective diameter

R = Diameter over wire

P = Pitch value

d= wire diameter

T = diameter under wire

To reducing various type of error, master piece can be used at the time of measurement.

4

A) Attempt any Three:

a) State different SQC tools and explain any one.

1. Frequency Histogram

2. Frequency Polygon

3. Bar chart

4. Control Charts

5. Process capability Study

2 mark

Frequency Histogram

1) In the graph, the sides of column represent the upper and lower cell boundaries and their highest

are proportional to the frequencies of occurrences within the cells.

2) In drawing a histogram, it is assumed that, the frequency is centered at the mid-value of cell or

class.

3) Simple construction and inspection of histogram make it an effective tool.

4) A random sample is taken from the lot and measurements are performed for the selected quality

characteristic.

Page 9 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

5) When there is a large variation in the obtained data, then it may be grouped into cell.

Frequency Polygon

1) It consists of series of straight lines joining points, which are plotted at cell mid-points with a

height proportional to cell frequency.

2) Frequency polygon has the advantage of plotting several distributions on the same axis, thereby

making certain comparisons possible, which is not possible in case of histogram.

Bar chart

1) Bar chart is graphical representation of the frequency distribution, in which, the bars are centered at the

mid-point of the cells and the heights of bars are proportional to the frequencies in the respective cells.

Control Charts

1) It is a graphical representation of the collected information.

2) The information may pertain to measure quality characteristics like length, diameter, thickness etc.

3) In general, control chart is a

1) Device to specify the state of statistical control.

2) Procedure to attain statistical control.

3) Tool to judge whether a state of statistical control is attained.

2 mark any one of above.

b) Why it is necessary to calibrate measuring instruments and unit gauges?

1) The calibration of any measuring system is very important to get meaningful results.

2) In case where the sensing system and measuring system are different, then it is

imperative to calibrate the system as an integrated whole in order to take into account the

error producing properties of each component.

3) Calibration is usually carried out by making adjustments such that readout device

produces zero output for zero-measured input, and similarly it should display an output

equivalent to the known measured input near the full-scale input value.

Page 10 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

4) It is important that any measuring system calibration should be performed under

environmental conditions that are as close as possible to those conditions under which

actual measurements are to be made.

5) It is also important that the reference measured input should be known to as much greater

degree of accuracy usually the calibration standard for the system should be at least one

order of magnitude more accurate than the desired measurement system accuracy.

4 marks proper explanation.

c) Define reliability. State the factors to be considered for achieving a reliable design.

Definition:- The reliability of a system or device is the probability that it will give satisfactory

performance for a specified period of time under specified conditions

OR

Definition:- A measure of the ability of the product to function successfully, when required

period in the specific manner.

OR

Definition:- Reliability is the capacity of an equipment not to breakdown in operation.

OR

Definition:- Reliability is the probability of a device performing its purpose adequately for the

period of time intended under the operating conditions encountered. Any 1 of above 2 marks

factors to be considered for achieving a reliable design:

1) Simplicity of product

2) De-rating

3) Redundancy Safe operation

4) Protection from extreme environmental conditions

5) Maintainability and Serviceability

2 marks for any 4 factors

`

d) Explain with neat sketch how angle is measured using clinometer.

Page 11 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

Clinometer is one type of application of spirit level. It consists of one spirit level mounted

on rotary member carried in housing. The bottom face of housing forms base of the instrument, for the

measurement purpose clinometers is first kept on one side of the inclined surface and reading is taken

when vapour bubble is at centre position ,similarly it is kept on another side and reading in terms of angle

is taken which is shown in fig.

B) Attempt any One:

A) Explain the principle and working of Taylor Hobson Talysurf with block diagram.

The Talysurf is an electronic instrument working on carrier modulating principle. This instrument

gives the information much more rapidly and accurately.

The measuring head of this instrument consists of a diamond stylus of about 0.002mm tip radius and

skid or shoe which is drawn across the surface by means of a motorized driving unit (gearbox), which

provides three motorized speeds giving respectively X 20 and X 100 horizontal magnification and a speed

suitable for average reading.

A neutral position in which the pick-up can be traversed manually is also provided. the arm carrying

the stylus forms an armature which pivots about the center piece of E-shaped stamping as shown in fig.

on two legs of (outer pole pieces) the E shaped stamping there are coils carrying an a. c. current. These

two coils with other two resistances form an oscillator. As the armature is pivoted about the central leg,

any movement of the stylus causes the air gap to very and thus the amplitude of the original a. c. current

flowing in the coils is modulated.

The out-put of the bridge thus consists of modulation only as shown in fig. This is further

demodulated so that the current now is directly proportional to the vertical displacement of the stylus

only.

The demodulated output is caused to operate a pen recorder to produce a permanent record and a meter to

give a numerical assessment directly. In recorder of this statement the marking medium is an electric

discharge through a specially treated paper which blackens at the point of the stylus, so this has no

distortion due to drag and the record strictly rectilinear one.

2 mark fig.+4 mark explanation.

B) What is LVDT? Explain its principle of working with neat sketch.

Page 12 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

L.V.D.T. is work as a electrical comparator. It is most popular electro-mechanical device to

convert mechanical displacement into electrical signal.

Construction:It consist of one primary and two secondary windings. The movable soft iron core is placed inside

the coil, shown in figure. The core is attached to the work piece which is to be compare.

The secondary winding have equal number of terns and placed symmetrically on both the side of

primary winding.

The primary winding is connected to an A.C. supply. A magnetic flux generated by this coil is cut

by the soft iron core and hence the voltage is induced in the two secondary windings.

The total assembly is kept in stainless steel housing.

Working:As a secondary windings S1 & S 2 are connected in series opposition as shown in figure. The

net output from the transformer is the difference between secondary windings.

When the core is perfectly at centre equal but opposite E.M.F. is induced in secondary winding

and zero output is recorded.

The voltage induced in secondary winding S 2 increases, if the core is shifted towards left.

If the core is shifted toward right then S1 increases as compare to S 2 . By taking the

difference between S1 & S 2 we can judge the position of core. 3 mark fig.+3 mark explanation.

Q.5. Attempt any Two:

a) Explain Parkinsons Gear Tester.

Use:By using this instrument instead of measuring individual error composite error are checked.

Principle:The gear to be tested is rolled in meshed with master gear and error will indicated by dial

gauge.

Page 13 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

3 marks

Construction:1) The fixed spindle and other movable spindle is mounted on flat plate.

2) The movable spindle moves with the base by rolling axle on main base plate.

3)

The master gear is mounted on fixed spindle where the gear to be tested is to mounted on

movable spindle.

4)

The dial gauge is to set to note the error which shown in fig.

2 marks

Working:1)

Master gear rotated slowly a gear to be tested will also get rotation because of meshing.

2)

The error in the manufacturing gear (tested gear) caused to gear to moved away center line of

spindle.

3)

When gear is moves, the floating body is also moves by same displacement.

4)

The vibrations in the reading can be observed and plotted in graphical format.

2 marks

1 mark

b) Explain flowing trends of X control chart.

1) Extreme Variation:Extreme variation is recognized by the points falling outside the upper and lower control

limits. The width of the control limits on the control chart represents the variation due to the

inherent characteristics of the process, that is, the normal permissible variation in machines,

materials and men.

Causes of extreme variation:1. Error in measurement and calculations

2. Samples chosen at a peak position of temperature, pressure and such other factors.

Page 14 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

3. Wrong setting of machine, tools etc.

4. Samples chosen at the commencement or end of an operation.

2) Shift:When a series of consecutive points fall above or below the center line on either X or R

chart it can be assumed that shift in the process has takes place indicating presence of some

assignable cause. It is generally assumed that when 7 consecutive points lie above or below the

center line, the shift has occurred.

Causes of shift:1. Change in material

2. Change in operator, inspector, inspection equipment.

3. Change in machine setting

4. New operator, carelessness of the operator

5. Loose fixture etc.

3) Erratic Fluctuations:This may be due to single causes or a group of causes affecting the process level and

spread. The cause of erratic fluctuations is rather difficult to identify. It may be due to different

causes acting at different times on the process.

Causes of Erratic Fluctuations:1. Frequent adjustment of machine

2. Different types of material being processed

3. Change in operator, machine, test equipment etc.

4) Indication of Trend:If the consecutive points on X or R chart tent to move steadily either towards LCL or

UCL, it can be assumed that process is indicating a Trend i.e. change is taking place

slowly and though all the points are lying within control limits, after some time it is likely

that the process may go out of control If proper care or corrective action is not taken.

Causes of Trend:1. Tool wear

2. Wear of threads on clamping device.

3. Effects of temperature and humidity

4. Accumulation of dirt and clogging of fixtures and holes.

2 mark each

c) Describe with neat sketch:

i. Straightness checking using spirit level.

1) Draw a line on the surface as a reference line. Define the line into the sections such that each

section equal to length of base of spirit level. [01 mark]

2) Move the block along with the lines with the steps equal to pitch distance between the center

lines of feet. [01 mark]

3) Generally a spirit level is to be fitted in a cover with two feet so that only feet have line contact

with the surface, also check the bed for traverse direction by taking readings of spirit levels.

[01 mark]

Page 15 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

ii. Alignment testing of lathe centers in vertical plane.

2marks

It is necessary to check the relative position of the axes also. Both the axes may be parallel to

carriage movement but they may not be coinciding. So when a job is fitted between the centers, the

axis of the job will not be parallel to the carriage movement. This test is to be carried out in vertical

plane only. A mandrel is fitted between the two centers and dial gauge on the carriage. The feeler of

the dial gauge is pressed against the mandrel in vertical plane the carriage is moved and the error

noted down. 2marks

Page 16 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

Q.6.Attempt any Two:

a)

Determine the control limits for X and R charts if X = 357.50 and R = 9.90. Number of

subgroups = 20. It is given that A2=0.18, D3=0.41, D4=1.59 and d2=3.735. Draw control charts and

write your conclusions. Also find the process capability.

2 MARK

2 MARK

1 MARK

Page 17 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

1 MARK

1 MARK

1 MARK

b) In a manufacturing process, the number of defectives found in the inspection of 10 lots if 400

items each are given below:

Lot no.

1

2 3

4

5

6

7

8 9

10

No. of Defectives

14

18

Determine the trial control limits for np chart and state whether the process is in control.

np= Total number of defective=107

1 mark

n=total number inspected= 10 X 400=4000

1 mark

p=

=0.0267

n p = 400 X 0.0267 =10.7

1 mark

2 MARK

Page 18 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

2 MARK

Conclusion:- It is observed that the all lot are in control. Therefore, the process is in control. 1 MARK

C) Define TQM. Describe any 3 principal elements of TQM.

Definition :It is the control of transformation process of an organisation to best satisfaction to the

customer needs in most economical manner.

OR

It is the control of rating an organising culture committed to the continuous improvement

through skill, team work, processes, and product quality and customer satisfaction. 2 MARK

(2 MARK EACH FOR ANY 3 ELEMENTS)

Customer-focused- The customer ultimately determines the level of quality. No matter what an

organization does to foster quality improvementtraining employees, integrating quality into the

design process, upgrading computers or software, or buying new measuring toolsthe customer

determines whether the efforts were worthwhile.

Total employee involvement. All employees participate in working toward common goals. Total

employee commitment can only be obtained after fear has been driven from the workplace, when

empowerment has occurred, and management has provided the proper environment. Highperformance work systems integrate continuous improvement efforts with normal business

operations. Self-managed work teams are one form of empowerment.

Process-centered. A fundamental part of TQM is a focus on process thinking. A process is a

series of steps that take inputs from suppliers (internal or external) and transforms them into

outputs that are delivered to customers (again, either internal or external). The steps required to

carry out the process are defined, and performance measures are continuously monitored in order

to detect unexpected variation.

Integrated system. Although an organization may consist of many different functional

specialties often organized into vertically structured departments, it is the horizontal processes

interconnecting these functions that are the focus of TQM.

Micro-processes add up to larger processes, and all processes aggregate into the business

processes required for defining and implementing strategy. Everyone must understand the vision,

Page 19 of 20

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 17530

WINTER 14 EXAMINATION

Model Answer

mission, and guiding principles as well as the quality policies, objectives, and critical processes of

the organization. Business performance must be monitored and communicated continuously.

Every organization has a unique work culture, and it is virtually impossible to achieve excellence

in its products and services unless a good quality culture has been fostered. Thus, an integrated

system connects business improvement elements in an attempt to continually improve and exceed

the expectations of customers, employees, and other stakeholders.

Strategic and systematic approach. A critical part of the management of quality is the strategic

and systematic approach to achieving an organizations vision, mission, and goals. This process,

called strategic planning or strategic management, includes the formulation of a strategic plan that

integrates quality as a core component.

Continual improvement. A major thrust of TQM is continual process improvement. Continual

improvement drives an organization to be both analytical and creative in finding ways to become

more competitive and more effective at meeting stakeholder expectations.

Fact-based decision making. In order to know how well an organization is performing, data on

performance measures are necessary. TQM requires that an organization continually collect and

analyze data in order to improve decision making accuracy, achieve consensus, and allow

prediction based on past history.

Communications. During times of organizational change, as well as part of day-to-day

operation, effective communications plays a large part in maintaining morale and in motivating

employees at all levels. Communications involve strategies, method, and timeliness.

Page 20 of 20

Das könnte Ihnen auch gefallen

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionVon EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNoch keine Bewertungen

- Model Answer Winter 2014Dokument20 SeitenModel Answer Winter 2014Prashant KasarNoch keine Bewertungen

- 2015 Summer Model Answer PaperDokument17 Seiten2015 Summer Model Answer PaperAishwarya DhuttargavkarNoch keine Bewertungen

- PM Examiner's Report March June 2022Dokument23 SeitenPM Examiner's Report March June 2022NAVIN JOSHINoch keine Bewertungen

- MEC560 Chapter 2 Metrology v1.2Dokument42 SeitenMEC560 Chapter 2 Metrology v1.2razlan ghazaliNoch keine Bewertungen

- Introduction to N.C.M., a Non Contact Measurement ToolVon EverandIntroduction to N.C.M., a Non Contact Measurement ToolNoch keine Bewertungen

- Important Instructions To ExaminersDokument30 SeitenImportant Instructions To ExaminersDiyaNegiNoch keine Bewertungen

- Embedded Mechatronic Systems: Analysis of Failures, Predictive ReliabilityVon EverandEmbedded Mechatronic Systems: Analysis of Failures, Predictive ReliabilityNoch keine Bewertungen

- Industrial Engineering & Enterprise Resource Planning: Statistical Quality ControlDokument41 SeitenIndustrial Engineering & Enterprise Resource Planning: Statistical Quality ControlVaibhav Vithoba Naik100% (1)

- Subject Name:-Inspection and Quality Control Paper Code: - 121762/031762 Branch/Sem.: - Mechanical Engg./6thDokument30 SeitenSubject Name:-Inspection and Quality Control Paper Code: - 121762/031762 Branch/Sem.: - Mechanical Engg./6thKaran KushwahaNoch keine Bewertungen

- Me8513 MMDokument2 SeitenMe8513 MMSiva RamanNoch keine Bewertungen

- IGCSE Physics Paper 3 Summer 2009Dokument41 SeitenIGCSE Physics Paper 3 Summer 2009Adi Sut WijanantoNoch keine Bewertungen

- Internal Assessment Test 2Dokument15 SeitenInternal Assessment Test 2Don bhauNoch keine Bewertungen

- Internal Assessment Test 2Dokument15 SeitenInternal Assessment Test 2Don bhauNoch keine Bewertungen

- Faculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, PuneDokument57 SeitenFaculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, Puneraghav maskeNoch keine Bewertungen

- ELEC3117-2010 Exam PaperDokument6 SeitenELEC3117-2010 Exam PaperKris KrisNoch keine Bewertungen

- Plate 6Dokument8 SeitenPlate 6Sleepy SpettoNoch keine Bewertungen

- 11Dokument1 Seite11chetanursNoch keine Bewertungen

- Quality Control - Assignment - 2Dokument4 SeitenQuality Control - Assignment - 2emaaa abdelfatahNoch keine Bewertungen

- EURAMET Cg-2 V 2.0 Calibration of Gauge Block ComparatorsDokument9 SeitenEURAMET Cg-2 V 2.0 Calibration of Gauge Block ComparatorsBoris KozjanNoch keine Bewertungen

- MIE1727 Quality Assurance I Assignment 1 AnalysisDokument4 SeitenMIE1727 Quality Assurance I Assignment 1 AnalysisYash PatelNoch keine Bewertungen

- Dwnload Full Introduction To Management Accounting 16th Edition Horngren Test Bank PDFDokument36 SeitenDwnload Full Introduction To Management Accounting 16th Edition Horngren Test Bank PDFcalymene.perdurel7my100% (14)

- MEC560 Chapter 2 Metrology v1.2Dokument45 SeitenMEC560 Chapter 2 Metrology v1.2Hazim NazarudinNoch keine Bewertungen

- GD T ExamplesDokument10 SeitenGD T ExamplesJuan Posada GNoch keine Bewertungen

- Magnification GellerDokument2 SeitenMagnification GellerVrusGogNoch keine Bewertungen

- XXXXX: Important Instructions To ExaminersDokument23 SeitenXXXXX: Important Instructions To ExaminersMc stanNoch keine Bewertungen

- TE-440 Optical Fiber Communication - Mid-Term - v4Dokument3 SeitenTE-440 Optical Fiber Communication - Mid-Term - v4Muhammad ImranNoch keine Bewertungen

- 3 8 A Precision Accuracy MeasurementDokument7 Seiten3 8 A Precision Accuracy Measurementapi-31004543160% (5)

- Engineering Metrology Question BankDokument5 SeitenEngineering Metrology Question BankTrupti Ranjan SahuNoch keine Bewertungen

- Metrology Lab w2014Dokument15 SeitenMetrology Lab w2014ObaidNoch keine Bewertungen

- DKD 4 2 Sheet 1Dokument12 SeitenDKD 4 2 Sheet 1sandeepNoch keine Bewertungen

- DKD-R - 4-2 Calibration of RoughnessDokument16 SeitenDKD-R - 4-2 Calibration of RoughnessRafael GarzónNoch keine Bewertungen

- Behavior of Castellated Beam With Sinusoidal OpeningsDokument3 SeitenBehavior of Castellated Beam With Sinusoidal OpeningsAdnan NajemNoch keine Bewertungen

- Types of Metrology and Measurement ErrorsDokument5 SeitenTypes of Metrology and Measurement ErrorsWaqaar JowataNoch keine Bewertungen

- Robust Design Question Bank-3-8-2011Dokument15 SeitenRobust Design Question Bank-3-8-2011Thamarai Kannan RamajayamNoch keine Bewertungen

- METROLOGYDokument11 SeitenMETROLOGYarvan singhNoch keine Bewertungen

- Online quality monitoring of welding parameters to detect weld defectsDokument5 SeitenOnline quality monitoring of welding parameters to detect weld defectsEizanie MuhamadNoch keine Bewertungen

- EP60003 Product DevelopmentDokument3 SeitenEP60003 Product DevelopmentadfadfNoch keine Bewertungen

- C584 81 (2016)Dokument3 SeitenC584 81 (2016)werrteNoch keine Bewertungen

- Strategic Cost Management - Assignment June 2023 eVYtbt4jDrDokument3 SeitenStrategic Cost Management - Assignment June 2023 eVYtbt4jDrMansi SharmaNoch keine Bewertungen

- Astm Compression MethodDokument3 SeitenAstm Compression MethodhamidrezaghezelNoch keine Bewertungen

- Volvo Group standard for process capability analysisDokument34 SeitenVolvo Group standard for process capability analysisFJNovaes454Noch keine Bewertungen

- 3-D Measurements On PistonsDokument4 Seiten3-D Measurements On PistonsRajaSekarsajjaNoch keine Bewertungen

- Optimization of Crosspiece of Washing MachineDokument4 SeitenOptimization of Crosspiece of Washing MachineInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Introduction To Linear MetrologyDokument71 SeitenIntroduction To Linear MetrologyDivakaran MullathNoch keine Bewertungen

- Study of Feasibility of Six Sigma Implementation in A Manufacturing Industry: A Case StudyDokument5 SeitenStudy of Feasibility of Six Sigma Implementation in A Manufacturing Industry: A Case StudyThasarathan RavichandranNoch keine Bewertungen

- COURSE Project (25%) : Electromechanical Motion Devices EE 321Dokument10 SeitenCOURSE Project (25%) : Electromechanical Motion Devices EE 321Assma MohamedNoch keine Bewertungen

- Fi LiDokument17 SeitenFi LiFikaduNoch keine Bewertungen

- MGMT203 HW4Dokument2 SeitenMGMT203 HW4sansalbakkalNoch keine Bewertungen

- Tutorial 1Dokument3 SeitenTutorial 1鼠哥哥Noch keine Bewertungen

- Cambridge International AS & A Level: Chemistry 9701/33 March 2020Dokument10 SeitenCambridge International AS & A Level: Chemistry 9701/33 March 2020Trang NguyenNoch keine Bewertungen

- 2015 Summer Model Answer PaperDokument17 Seiten2015 Summer Model Answer Paper52. YASHRAJ RANSHURNoch keine Bewertungen

- Good Practice Guide For Form and Diameter Measurements For Large ShaftsDokument14 SeitenGood Practice Guide For Form and Diameter Measurements For Large ShaftsNg Wei LihNoch keine Bewertungen

- 9 Practical Cswip 3.0 Practical Visual Inspection PDFDokument13 Seiten9 Practical Cswip 3.0 Practical Visual Inspection PDFAzim Samiin77% (13)

- Aerospace Assembly Task REF - DEFDokument9 SeitenAerospace Assembly Task REF - DEFazeem sheikhNoch keine Bewertungen

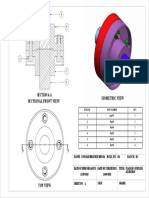

- Flange Coupling AssemblyDokument1 SeiteFlange Coupling AssemblyDiyaNegiNoch keine Bewertungen

- J EBillSub KK 0366Dokument1 SeiteJ EBillSub KK 0366dukarNoch keine Bewertungen

- Flange Coupling AssemblyDokument1 SeiteFlange Coupling AssemblyDiyaNegiNoch keine Bewertungen

- New Ticket For SundayDokument2 SeitenNew Ticket For SundayDiyaNegiNoch keine Bewertungen

- Photography Format For Imigration CanadaDokument1 SeitePhotography Format For Imigration CanadaFlamur SallahuNoch keine Bewertungen

- French - Grammar - Tense - Booklet and Y12 Summer Task PDFDokument13 SeitenFrench - Grammar - Tense - Booklet and Y12 Summer Task PDFAnonymous LVibFVNoch keine Bewertungen

- Parts of PBLDokument1 SeiteParts of PBLDiyaNegiNoch keine Bewertungen

- Install Notes (Please Read)Dokument1 SeiteInstall Notes (Please Read)DiyaNegiNoch keine Bewertungen

- Install Notes (Please Read)Dokument1 SeiteInstall Notes (Please Read)DiyaNegiNoch keine Bewertungen

- Prepare for Your Trade Entrance ExamDokument37 SeitenPrepare for Your Trade Entrance ExamWattsoft100% (2)

- Parts of Launch PadDokument1 SeiteParts of Launch PadDiyaNegiNoch keine Bewertungen

- 6.0L Engine Removal PDFDokument10 Seiten6.0L Engine Removal PDFDiyaNegi100% (1)

- PBL Drawing Launch PadDokument1 SeitePBL Drawing Launch PadDiyaNegiNoch keine Bewertungen

- eTicketLucknow2Delhi PDFDokument2 SeiteneTicketLucknow2Delhi PDFDejau ZodenNoch keine Bewertungen

- Sample Doc File 100kbDokument13 SeitenSample Doc File 100kbakshay mishraNoch keine Bewertungen

- New Rich Text DocumentDokument5 SeitenNew Rich Text DocumentDiyaNegiNoch keine Bewertungen

- MSBTETE WINTER EXAMINATION MODEL ANSWERDokument17 SeitenMSBTETE WINTER EXAMINATION MODEL ANSWERtomsonNoch keine Bewertungen

- TD ImportantsDokument6 SeitenTD ImportantsDiyaNegiNoch keine Bewertungen

- MSBTETE Winter Exam Model Answers for Technical Subject 17529Dokument17 SeitenMSBTETE Winter Exam Model Answers for Technical Subject 17529DiyaNegiNoch keine Bewertungen

- Mind Map: Coreldraw X5: Foundational Skills, Art Production & Special EffectsDokument53 SeitenMind Map: Coreldraw X5: Foundational Skills, Art Production & Special EffectsDiyaNegiNoch keine Bewertungen

- Model Answer Winter 2015Dokument16 SeitenModel Answer Winter 2015DiyaNegiNoch keine Bewertungen

- Model Answer Winter 2014Dokument16 SeitenModel Answer Winter 2014DiyaNegiNoch keine Bewertungen

- Summer 2015 Model Answer PaperDokument23 SeitenSummer 2015 Model Answer PaperDiyaNegiNoch keine Bewertungen

- IELTS Advantage. Writing Skills PDFDokument129 SeitenIELTS Advantage. Writing Skills PDFDiyaNegiNoch keine Bewertungen

- Microcontroller Development BoardsDokument2 SeitenMicrocontroller Development BoardsDiyaNegiNoch keine Bewertungen

- The Workshop Manual W26, Edition June 2000Dokument230 SeitenThe Workshop Manual W26, Edition June 2000DiyaNegiNoch keine Bewertungen

- CapstoneDokument41 SeitenCapstoneDiyaNegiNoch keine Bewertungen

- Design of Belt Conveyors Part 1Dokument32 SeitenDesign of Belt Conveyors Part 1anirban687Noch keine Bewertungen

- Design of Input Gear-Shaft-ExamplerDokument11 SeitenDesign of Input Gear-Shaft-ExamplerGuru PrasadNoch keine Bewertungen

- Assembly To DetailDokument1 SeiteAssembly To DetailDiyaNegiNoch keine Bewertungen

- Introduction To Management NotesDokument37 SeitenIntroduction To Management NotesSaurabh Suman100% (2)

- PEST Analysis: P E S TDokument12 SeitenPEST Analysis: P E S TMurtaza MakatiNoch keine Bewertungen

- ABC: Activity-based costingDokument12 SeitenABC: Activity-based costingDurga Tripathy DptNoch keine Bewertungen

- Braasduasn Ma3 Sasdfsadfm 10Dokument63 SeitenBraasduasn Ma3 Sasdfsadfm 10Kia PottsNoch keine Bewertungen

- Boise Cascade Corporation Case Study Solution - Performance MeasurementDokument2 SeitenBoise Cascade Corporation Case Study Solution - Performance MeasurementPiotr BartenbachNoch keine Bewertungen

- Accounting PracticeDokument14 SeitenAccounting PracticeHamza RaufNoch keine Bewertungen

- Chapter 10: Market Power: Monopoly and Monopsony: P MC 1 + 1 EDokument5 SeitenChapter 10: Market Power: Monopoly and Monopsony: P MC 1 + 1 EKalyan SaikiaNoch keine Bewertungen

- Taxpayers' Tax Compliance Behavior - Business Profit Taxpayers' of Addis Ababa City AdministrationDokument126 SeitenTaxpayers' Tax Compliance Behavior - Business Profit Taxpayers' of Addis Ababa City AdministrationGELETAW TSEGAW80% (5)

- MarketingDokument27 SeitenMarketingNeradabilli EswarNoch keine Bewertungen

- CFAP 04 BFD PracticeKitDokument441 SeitenCFAP 04 BFD PracticeKittahirfarid100% (7)

- Ch8 LPDokument17 SeitenCh8 LPparavpNoch keine Bewertungen

- Busniness Plan PDFDokument28 SeitenBusniness Plan PDFSasha King0% (1)

- NFM Annual Report and Financial AnalysisDokument44 SeitenNFM Annual Report and Financial AnalysisRyanRuceMelvilleNoch keine Bewertungen

- CHAPTER 2 Basic Cost Management ConceptsDokument23 SeitenCHAPTER 2 Basic Cost Management ConceptsMudassar Hassan100% (1)

- Cesim - RedDokument24 SeitenCesim - RedPhá LấuNoch keine Bewertungen

- Industrial Management NotesDokument301 SeitenIndustrial Management NotesVidhya Ds75% (4)

- Step 1 - 0 MANUAL FOR INSTRUCTORS The Fresh ConnectionDokument30 SeitenStep 1 - 0 MANUAL FOR INSTRUCTORS The Fresh ConnectionRicky Ramirez67% (3)

- Textile Mill Scheduling and Lockbox OptimizationDokument6 SeitenTextile Mill Scheduling and Lockbox OptimizationCharlotte Ellen0% (1)

- Practical Accounting 2 With AnswersDokument11 SeitenPractical Accounting 2 With Answerskidrauhl0767% (6)

- SSI Daily Call On Factory and FPT and NTP - BMP 4Q13Dokument8 SeitenSSI Daily Call On Factory and FPT and NTP - BMP 4Q13Cương TiếnNoch keine Bewertungen

- Business Plan Project Report On: "Fruit Juice Processing, Tetrapackaging & Supply in Delhi, Ghaziabad & Noida"Dokument26 SeitenBusiness Plan Project Report On: "Fruit Juice Processing, Tetrapackaging & Supply in Delhi, Ghaziabad & Noida"Mohammad Shehata0% (1)

- Team 6 - Pricing Assignment 2 - Cambridge Software Corporation V 1.0Dokument7 SeitenTeam 6 - Pricing Assignment 2 - Cambridge Software Corporation V 1.0SJ100% (1)

- Session 9 LPP Solver Problem Par Inc Sensitivity Report Template For StudentsDokument22 SeitenSession 9 LPP Solver Problem Par Inc Sensitivity Report Template For Studentsmanee4uNoch keine Bewertungen

- Chapter - IDokument60 SeitenChapter - IAnil ThakurNoch keine Bewertungen

- Asian PaintsDokument25 SeitenAsian PaintsAnonymous ty7mAZNoch keine Bewertungen

- Balanced ScorecardDokument71 SeitenBalanced Scorecardandriwiryanto8493100% (1)

- Profit Controller Concepts Reference GuideDokument74 SeitenProfit Controller Concepts Reference Guiderameshkarthik8100% (1)

- Industrial EnggDokument75 SeitenIndustrial EnggAlthaf VANoch keine Bewertungen

- Mitsubishi Chemical Group's Annual Report Highlights Strong Performance and Sustainable Growth PlanDokument67 SeitenMitsubishi Chemical Group's Annual Report Highlights Strong Performance and Sustainable Growth PlanzakariaasmNoch keine Bewertungen

- Export Tax IC DISC RevenueDokument13 SeitenExport Tax IC DISC RevenueInternational Tax Magazine; David Greenberg PhD, MSA, EA, CPA; Tax Group International; 646-705-2910Noch keine Bewertungen

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsVon EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 2Von EverandBuilding Construction Technology: A Useful Guide - Part 2Bewertung: 5 von 5 Sternen5/5 (1)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (241)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsVon EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNoch keine Bewertungen

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- An Architect's Guide to Construction: Tales from the Trenches Book 1Von EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Noch keine Bewertungen

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryVon EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryBewertung: 4 von 5 Sternen4/5 (5)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeVon EverandCivil Engineer's Handbook of Professional PracticeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundVon EverandField Guide for Construction Management: Management by Walking AroundBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Design for How People Think: Using Brain Science to Build Better ProductsVon EverandDesign for How People Think: Using Brain Science to Build Better ProductsBewertung: 4 von 5 Sternen4/5 (8)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsVon EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNoch keine Bewertungen

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItVon EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItBewertung: 4 von 5 Sternen4/5 (16)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Markup & Profit: A Contractor's Guide, RevisitedVon EverandMarkup & Profit: A Contractor's Guide, RevisitedBewertung: 5 von 5 Sternen5/5 (11)