Beruflich Dokumente

Kultur Dokumente

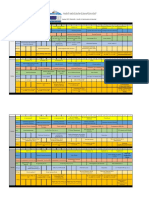

New Equipment Inspection Checklist

Hochgeladen von

NateCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

New Equipment Inspection Checklist

Hochgeladen von

NateCopyright:

Verfügbare Formate

RISK CONTROL

REDUCE RISK. PREVENT LOSS. SAVE LIVES.

New equipment inspection checklist sample

This is a sample of what a new equipment checklist might look like. This checklist doesnt address all the hazards

associated with all new equipment and that the user should develop their own based on their specific needs.

Equipment:

Date Inspected:

Yes

No

Action

Required

No Action

Required

___

___

________

________

___

___

________

________

___

___

________

________

___

___

________

________

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

Machinery guarding

1. Are all pulleys and belts, chains, sprockets, and other

power transmission sources guarded?

2. Are operations that have rotating parts, pinch points, nip

points, etc., guarded?

3. If the machine is designed for a fixed location, is it

securely anchored?

4. Are commonly used parts and hardware in stock so

people are not encouraged to improvise, at the risk of

making an unsafe repair, or postponing a repair job?

Equipment shutdown

1. Is there a single, lockable, clearly marked electrical power

disconnect?

2. Are isolation valves for air, steam, and other utilities

accessible and marked?

3. Is there an adequate number of properly located manual

reset emergency stops?

4. If equipment has pneumatic or hydraulic cylinders or

motors, does the fluid power circuit have solenoid block

and bleed valves interlocked to the emergency stop

circuit?

Also a pressure gauge to verify that pressure is vented?

5. Have employees who will perform repair, maintenance,

and servicing operations been trained in the equipmentspecific lockout/tagout or chemical handling procedures

before they have to perform these operations?

6. Have the equipment-specific procedures been put in

writing and are they easily accessible?

Walking surfaces

1. Are the floors and aisles clear of any slippery areas or

other tripping hazards?

2. Are changes in floor elevations clearly identified by color

coding, if necessary?

3. Does equipment produce discharges onto the floor that

are not adequately contained or directed to other drains?

4. Should non-slip surface coatings be applied around the

equipment?

5. Has all construction debris, packing material, and set up

equipment been removed from working areas?

PAGE 1

RISK CONTROL

New equipment inspection checklist sample

New equipment inspection checklist sample (continued)

Yes

No

Action

Required

Electrical

1. Are all conduit, cable, and wire properly attached to all

supports and tightly connected to junction and outlet

boxes?

2.

3.

4.

5.

Is there evidence of fraying on electrical cords?

Are rubber cords free of grease, oil, and chemicals?

Are cords routed so that they are not on pipes, nails, etc.?

Are switches mounted in clean, tightly closed metal

boxes?

6. Is electrical equipment secured to a surface?

7. Are the switches easily accessible and the paths to them

free of obstructions?

8.

9.

10.

11.

Are all unused openings in junction boxes plugged?

Are all electrical boxes closed?

Do switches show evidence of overheating?

If explosion-proof electricals are involved, do all devices

meet the appropriate class and division requirements as

contained in the National Electrical Code (NEC)?

No Action

Required

___

___

___

___

___

___

___

___

________

________

________

________

_______

_______

_______

_______

___

___

___

___

________

________

_______

_______

___

___

___

___

___

___

___

___

________

________

________

________

_______

_______

_______

_______

___

___

________

_______

12. Are all controls properly labeled? Do electric push buttons

have correct color coding? (Only stop buttons should be

red in color.)

___

___

________

_______

13. Have all employees who may be exposed to electrical

voltages equal or greater than 50 volts been given

electrical safety training?

___

___

________

_______

14. Are all load center panel areas accessible and clear of

obstructions?

___

___

________

_______

___

___

___

___

________

________

_______

_______

___

___

___

___

___

___

________

________

________

_______

_______

_______

Ladders, platforms and stairs

1. Are platforms that are more than 4 feet above the floor

level equipped with standard railings and toe boards?

2. Are fixed ladders properly secured against movement?

3. Are ladders that are more than 20 feet in unbroken length

provided with safety cages that start between 7 and 8 feet

off the floor and extend at least 42 above the top landing?

4. Do stairs have handrails on them?

5. Do crossovers over conveyors have hand rails?

PAGE 2

RISK CONTROL

New equipment inspection checklist sample

New equipment inspection checklist sample (continued)

Yes

No

Action

Required

No Action

Required

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

3. Are controls easy to reach and laid out in a manner that

makes them easy to read and use for the equipment

operators?

___

___

________

_______

4. Are displays easy to view and laid out in a manner that

makes them easy to reach and use for the equipment

operators?

___

___

________

_______

___

___

________

_______

6. Does operation of the equipment require operators to

engage in highly repetitive hand, wrist, arm, and finger

movements or exertions?

___

___

________

_______

7. Does operation of the equipment require frequent

reaching in front of the body, below the knees, over the

shoulder or with elevated elbows?

___

___

________

_______

8. Does operation of the equipment require employees to

stand for extended periods of time?

___

___

________

_______

Are floor mats provided at standing workstations?

___

___

________

_______

___

___

________

_______

___

___

________

_______

Ergonomics

1. Does the equipment require employees to manually lift or

lower raw materials or finished product?

If it does, have the ergonomic risks associated with those

tasks been evaluated from a standpoint of weight,

distance, frequency of task, etc.?

Are special material handling fixtures required?

2. Does the equipment require employees to manually push,

pull or carry raw materials or finished product?

If it does, have the ergonomic risks associated with those

tasks been evaluated from a standpoint of weight,

distance, frequency of task, etc.?

Are special materials handling fixtures required?

5. Are audio feedback sources easy to hear and differentiate

in tones?

9. Have operators been thoroughly trained in the operation of

the equipment, manufacturer's requirements for operation

and maintenance, equipment safeguards, warning

systems, etc.?

10. Are there sharp edges on the equipment that could cut or

injure operators or others passing by the equipment?

PAGE 3

RISK CONTROL

New equipment inspection checklist sample

New equipment inspection checklist sample (continued)

Industrial hygiene

1. If any chemical agents are required for the operation,

servicing, or maintenance of the equipment, haveSafety

Data Sheets (SDS) been obtained?

Have employees been trained in the chemical hazards and

required PPE?

2. Does the equipment emit any hazardous chemicals,

excessive noise levels, radiation, heat, or other physical

hazards?

Have those hazards been evaluated and documented by

testing?

3. Are there any hot surfaces?

If so, do they require guarding and labeling?

4. Are appropriate chemical and physical hazard warning

labels provided on the equipment?

5. If ventilation systems are required on the equipment, are

flow indicators provided and have operators been trained

in the use and interpretation of them? Have low-flow

alarms been evaluated as a best practice in critical

ventilation systems?

Emergency procedures

1. Have employees been trained in emergency shut-down

procedures?

2. Does the placement of the equipment present any

evacuation hazards in the event of a serious equipment

malfunction?

Fire hazards

1. Does the equipment present any inherent fire hazards

such as open flames, flammable liquids, solids and gases,

etc.?

Are these hazards properly controlled by safeguards built

into the equipment or provided outside, over, and around

the equipment?

2. Are fire extinguishers or other fixed extinguishing systems

required?

PAGE 4

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

___

___

________

_______

RISK CONTROL

New equipment inspection checklist sample

New equipment inspection checklist sample (continued)

Recommendations:

Inspected by:

PAGE 5

RISK CONTROL

New equipment inspection checklist sample

For more information, log in to the Risk Control Customer Portal at travelers.com/riskcontrol. (Need help? Read

our Registration Quick Guide.) You also can contact your Risk Control consultant or email Ask-RiskControl@travelers.com.

travelers.com

The Travelers Indemnity Company and its property casualty affiliates. One Tower Square, Hartford, CT 06183

The information provided in this document is intended for use as a guideline and is not intended as, nor does it constitute, legal or professional advice. Travelers does not

warrant that adherence to, or compliance with, any recommendations, best practices, checklists, or guidelines will result in a particular outcome. In no event will Travelers or

any of its subsidiaries or affiliates be liable in tort or in contract to anyone who has access to or uses this information. Travelers does not warrant that the information in this

document constitutes a complete and finite list of each and every item or procedure related to the topics or issues referenced herein. Furthermore, federal, state or local

laws, regulations, standards or codes may change from time to time and the reader should always refer to the most current requirements. This material does not amend, or

otherwise affect, the provisions or coverages of any insurance policy or bond issued by Travelers, nor is it a representation that coverage does or does not exist for any

particular claim or loss under any such policy or bond. Coverage depends on the facts and circumstances involved in the claim or loss, all applicable policy or bond

provisions, and any applicable law.

2008-2013 The Travelers Indemnity Company. All rights reserved. Travelers and the Travelers Umbrella logo are registered trademarks of The Travelers Indemnity

Company in the U.S. and other countries. 396

PAGE 6

Das könnte Ihnen auch gefallen

- Welding Safety Policy ProcedureDokument16 SeitenWelding Safety Policy ProcedureIkyegh IshaNoch keine Bewertungen

- Tool Box SubjectsDokument70 SeitenTool Box Subjectsrajeshsabitha80100% (5)

- Workshop - Risk AssessmentDokument7 SeitenWorkshop - Risk AssessmentJeganeswaran100% (1)

- Safety Department Checklist FormatDokument32 SeitenSafety Department Checklist Formatrockyvinoo100% (18)

- 22 Safety ChecklistsDokument30 Seiten22 Safety ChecklistsIrvys G. Juarez Dordi100% (2)

- Angle Grinder ChecklistDokument4 SeitenAngle Grinder Checklistshakti123456789Noch keine Bewertungen

- Safety Inspection ChecklistDokument5 SeitenSafety Inspection ChecklistAnuj Kjoy67% (3)

- Ag ExtensionDokument101 SeitenAg ExtensionWaren LlorenNoch keine Bewertungen

- Crane Hoist Sling Safety ProgramDokument14 SeitenCrane Hoist Sling Safety Programomar sadiqNoch keine Bewertungen

- Implementing Global Human Resources PDFDokument486 SeitenImplementing Global Human Resources PDFme.atulNoch keine Bewertungen

- Confined Space Entry Risk AssessmentDokument9 SeitenConfined Space Entry Risk Assessmentkoketso0% (1)

- Monthly Forklift Inspection Checklist OHS PR 009 FM 01 0412Dokument1 SeiteMonthly Forklift Inspection Checklist OHS PR 009 FM 01 0412cmrig74100% (2)

- Arc Welding - JSADokument6 SeitenArc Welding - JSAdroffilcz27Noch keine Bewertungen

- Equipment Operating ProcedureDokument5 SeitenEquipment Operating ProcedurezaizamNoch keine Bewertungen

- Tool Box Talk MeetingsDokument5 SeitenTool Box Talk MeetingsSusyenSihiteNoch keine Bewertungen

- Toolbox Talk - Workshop Safety General RulesDokument3 SeitenToolbox Talk - Workshop Safety General Rules260380sdNoch keine Bewertungen

- PPE Hazard Assessment Certification FormDokument4 SeitenPPE Hazard Assessment Certification FormHaleem Ur Rashid BangashNoch keine Bewertungen

- Office Safety ChecklistDokument3 SeitenOffice Safety ChecklistJaijeev Pali100% (1)

- Manufacturing Plant Audit ChecklistDokument6 SeitenManufacturing Plant Audit ChecklistAnurag SrivastavaNoch keine Bewertungen

- Facility Inspection ChecklistDokument9 SeitenFacility Inspection ChecklistdesignselvaNoch keine Bewertungen

- Daily Montly Checklist 04JUN2007Dokument9 SeitenDaily Montly Checklist 04JUN2007tomiNoch keine Bewertungen

- Site Visitor Management PlanDokument8 SeitenSite Visitor Management Planhanshul sisodiyaNoch keine Bewertungen

- Paint Booth ChecklistDokument3 SeitenPaint Booth ChecklistAkhtar Quddus100% (1)

- Machinery ChecklistDokument2 SeitenMachinery Checklistmike_day90% (31)

- Ofs Permit To Work FormDokument2 SeitenOfs Permit To Work FormZ Babar KhanNoch keine Bewertungen

- Work Shop TRA Tyre MaintenanceDokument13 SeitenWork Shop TRA Tyre MaintenanceTarik MunafNoch keine Bewertungen

- Lathe SopDokument2 SeitenLathe SopDilip Kumar K100% (1)

- Compressed Gas Cylinders ChecklistDokument2 SeitenCompressed Gas Cylinders ChecklistPerwez21100% (1)

- Mig Welding Work JSA HSE ProfessionalsDokument2 SeitenMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- H S ChecklistDokument17 SeitenH S ChecklistkhajaimadNoch keine Bewertungen

- Ladder Inspection ChecklistDokument1 SeiteLadder Inspection ChecklistzulfactNoch keine Bewertungen

- Safety Inspection Checklist Hand Tools PDFDokument1 SeiteSafety Inspection Checklist Hand Tools PDFHtun Soe100% (5)

- Hazards Associated With Plant and Equipment (Including Non-Powered Plant and Hand Tools)Dokument7 SeitenHazards Associated With Plant and Equipment (Including Non-Powered Plant and Hand Tools)وأكثرهم كارهونNoch keine Bewertungen

- Contoh Workplace Inspection Procedure and Checklist PDF 1.1MBDokument10 SeitenContoh Workplace Inspection Procedure and Checklist PDF 1.1MBmae_blurNoch keine Bewertungen

- Facility Inspection ChecklistDokument2 SeitenFacility Inspection ChecklistDexter QuébecNoch keine Bewertungen

- Safety Inspection FormDokument5 SeitenSafety Inspection Formraymondhthomas100% (1)

- Working at Height Check ListDokument1 SeiteWorking at Height Check ListVimal SinghNoch keine Bewertungen

- Welding Checklist 9195Dokument3 SeitenWelding Checklist 9195Michael PenaNoch keine Bewertungen

- WPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingDokument4 SeitenWPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingMohamed RizwanNoch keine Bewertungen

- Safe Working PracticesDokument7 SeitenSafe Working PracticesDiana ParkerNoch keine Bewertungen

- Checklist For Rope Suspended Platform HSE OCP 16Dokument1 SeiteChecklist For Rope Suspended Platform HSE OCP 16Mohamed KamalNoch keine Bewertungen

- Monthly Camp Inspection FormDokument22 SeitenMonthly Camp Inspection FormvijithNoch keine Bewertungen

- Lab Audit FormDokument6 SeitenLab Audit Formmahesh90600Noch keine Bewertungen

- Safty ProgramDokument27 SeitenSafty ProgramMohamed ReezaNoch keine Bewertungen

- SWP Welder Gas Metal Arc AS560Dokument2 SeitenSWP Welder Gas Metal Arc AS560Amirul Haris100% (1)

- Portacabin Office-InspectionDokument4 SeitenPortacabin Office-Inspectionikponmwonsa100% (2)

- Inspection Checklists - Sample Checklist For Manufacturing Facilities - OSH AnswersDokument6 SeitenInspection Checklists - Sample Checklist For Manufacturing Facilities - OSH Answersshahira100% (1)

- What Is An Example of An Inspection Checklist For A Manufacturing FacilityDokument7 SeitenWhat Is An Example of An Inspection Checklist For A Manufacturing FacilityaKureishi100% (1)

- Chillers Sequence of OperationDokument23 SeitenChillers Sequence of OperationAshraf TurkyNoch keine Bewertungen

- Iso 10245-2-2014 PDFDokument16 SeitenIso 10245-2-2014 PDFalejandroNoch keine Bewertungen

- Order Fulfilment PDFDokument21 SeitenOrder Fulfilment PDFSaikumar SelaNoch keine Bewertungen

- Machinery Inspection ChecklistDokument3 SeitenMachinery Inspection ChecklistYuva samaj sewa TrustNoch keine Bewertungen

- Hazards ChecklistDokument7 SeitenHazards ChecklistRemeras TartagalNoch keine Bewertungen

- SAP CloudDokument512 SeitenSAP CloudyabbaNoch keine Bewertungen

- Android Project ReportDokument38 SeitenAndroid Project ReportSahil Adlakha57% (7)

- Machinery Inspection ChecklistDokument3 SeitenMachinery Inspection ChecklistIvan Dave TorrecampoNoch keine Bewertungen

- Jsa PDFDokument5 SeitenJsa PDFVAMSINoch keine Bewertungen

- Bandsaw Daily Inspection Checklist 001Dokument2 SeitenBandsaw Daily Inspection Checklist 001Mohamad Afif100% (1)

- Work at Heights Self Assessment SheetDokument4 SeitenWork at Heights Self Assessment SheetBalogun IsaacNoch keine Bewertungen

- HIRAC - Work at Height TemplateDokument8 SeitenHIRAC - Work at Height Templateputra2azanNoch keine Bewertungen

- Standard Operating ProcedureDokument55 SeitenStandard Operating Procedureboy tryadi100% (1)

- Weekly Tower Light Check ListDokument1 SeiteWeekly Tower Light Check ListpjosesmNoch keine Bewertungen

- Personal Protective Equipment: Safety AlertDokument3 SeitenPersonal Protective Equipment: Safety Alerteffendi100% (1)

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDokument1 SeiteHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (3)

- Index: Cv. Dira Utama SejahteraDokument12 SeitenIndex: Cv. Dira Utama SejahteraFreshop SurabayaNoch keine Bewertungen

- Genie-Making Sense of MEWPSDokument11 SeitenGenie-Making Sense of MEWPSd. donlonNoch keine Bewertungen

- Inspeksi SMK3Dokument30 SeitenInspeksi SMK3Ulva YuliantiNoch keine Bewertungen

- Pangasinan State University Urdaneta Campus Urdaneta CityDokument11 SeitenPangasinan State University Urdaneta Campus Urdaneta CityNephtali Pinos-anNoch keine Bewertungen

- Sensotronic Brake Control ReportDokument19 SeitenSensotronic Brake Control ReportDeekshaomarNoch keine Bewertungen

- Application For Getting ISBN Number in IndiaDokument3 SeitenApplication For Getting ISBN Number in IndiamahamayaNoch keine Bewertungen

- Chapter 3Dokument74 SeitenChapter 3Berhane KifleNoch keine Bewertungen

- OpTransactionHistory02 12 2019Dokument4 SeitenOpTransactionHistory02 12 2019Vijay KumarNoch keine Bewertungen

- Release 6.0: Technical Solution ManualDokument14 SeitenRelease 6.0: Technical Solution ManualcosconorNoch keine Bewertungen

- hh400 Handheld Scanner Data Sheet en A4Dokument2 Seitenhh400 Handheld Scanner Data Sheet en A4Haris WahyuNoch keine Bewertungen

- Amazon Product Review - Ipynb - ColaboratoryDokument7 SeitenAmazon Product Review - Ipynb - ColaboratoryThomas ShelbyNoch keine Bewertungen

- How To Configure An Anybus Controlnet Adapter/Slave Module With Rsnetworx For ControlnetDokument26 SeitenHow To Configure An Anybus Controlnet Adapter/Slave Module With Rsnetworx For ControlnetEcaterina IrimiaNoch keine Bewertungen

- Hp81110a ImpulsatoreDokument132 SeitenHp81110a Impulsatorejack11rossiNoch keine Bewertungen

- Concrete Pump TPIDokument1 SeiteConcrete Pump TPIWakil AhmadNoch keine Bewertungen

- Washing Machine: Service ManualDokument66 SeitenWashing Machine: Service ManualFernando AlmeidaNoch keine Bewertungen

- Carpool App Case StudyDokument2 SeitenCarpool App Case StudyLuh CheeseNoch keine Bewertungen

- Laptop Sebagai Teman Siswa: Laptop As Students' FriendDokument1 SeiteLaptop Sebagai Teman Siswa: Laptop As Students' Friendtigor lianda manik07Noch keine Bewertungen

- Pbdocs Traktoren Zetor 117 41 Forterra eDokument1 SeitePbdocs Traktoren Zetor 117 41 Forterra eZoran RajčevićNoch keine Bewertungen

- Firmware Upgrade Guide enDokument4 SeitenFirmware Upgrade Guide enPau CorellaNoch keine Bewertungen

- Implementing Accounting HubDokument258 SeitenImplementing Accounting HubNarendra ReddyNoch keine Bewertungen

- Key Responsibility AreasDokument6 SeitenKey Responsibility AreasSubodh YadavNoch keine Bewertungen

- Vessel Technical BrochureDokument26 SeitenVessel Technical BrochureMonica IorgulescuNoch keine Bewertungen

- Zed-F9K: High Precision Dead Reckoning With Integrated IMU SensorsDokument2 SeitenZed-F9K: High Precision Dead Reckoning With Integrated IMU SensorsStevan ZupunskiNoch keine Bewertungen

- IT Module 4Dokument2 SeitenIT Module 4Crizele Joy LagudaNoch keine Bewertungen

- Time Table Spring 2022-2023 V2Dokument3 SeitenTime Table Spring 2022-2023 V2moad alsaityNoch keine Bewertungen

- CV - Qian YihaoDokument19 SeitenCV - Qian Yihaodestri_742053763Noch keine Bewertungen