Beruflich Dokumente

Kultur Dokumente

ITP For CW and ACW Piping Work

Hochgeladen von

Phong DoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ITP For CW and ACW Piping Work

Hochgeladen von

Phong DoCopyright:

Verfügbare Formate

VIETNAM OIL AND GAS GROUP

LONG PHU 1 POWER PROJECT MANAGEMENT BOARD

1.

EPC CONSORTIUM:

POWER MACHINES OJSC;

PETROVIETNAM TECHNICAL SERVICES CORPORATION - PTSC

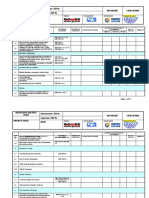

INSPECTION AND TEST PLANT (ITP)

FOR CW & ACW PIPING WORK

Document No: LP1-LLM-10XXX-QA-G1-PRO-0019

CONTRACTOR: PTSC

SUBCONTRACTOR: LLM

PREPARED BY

NAME

SIGN

DATE

APPROVED BY

NAME

SIGN

DATE

REVIEWED BY

NAME

SIGN

DATE

REVIEWED BY

NAME

SIGN

DATE

APPROVED BY

NAME

SIGN

DATE

LP1PP

PM-PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.: LP1-LLM10XXX-QA-G1-PRO-0019

Page: 2 of 16

ITP FOR CW & ACW PIPING WORK

Revision No.: A

Date: 10.Sep.16

REVISION COVER SHEET

NO.

1

REV.

A

CONTEN

CONTENT OF REVISION

Issue for Approval

DATE OF REVISION

10.Sep.2016

LP1PP

PM-PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.: LP1-LLM10XXX-QA-G1-PRO-0019

Revision No.: A

Page: 3 of 16

ITP FOR CW & ACW PIPING WORK

Date: 10.Sep.16

1.0

PURPOSE............................................................................................................................................................................2

2.0

SCOPE OF APPLICATION...........................................................................................................................................2

3.0

REFERENCE STANDARDS AND PROCEDURES............................................................................................2

4.0

ABBREVIATIONS...........................................................................................................................................................3

5.0

ITP FOR CW & ACW PIPING SYSTEM.................................................................................................................4

LP1PP

PM-PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.: LP1-LLM10XXX-QA-G1-PRO-0019

Page: 4 of 16

ITP FOR CW & ACW PIPING WORK

Revision No.: A

1.0

Date: 10.Sep.16

PURPOSE

The procedure inspection and test plan is a document which describes CONTRACTOR practice

and involvement during various phases of installation of CW and ACW Piping System. It

describes our control, inspection requirement, acceptance/ rejection criteria and inspection format

required.

2.0

SCOPE OF APPLICATION

This procedure covers all inspection point of the activities related to the works during preassembly, installation, testing, painting of CW & ACW Piping System.

3.0

3.1

REFERENCE STANDARDS AND PROCEDURES

AWWA M11: Steel Pipe A Guide for Design and Installation, Edition 4.

3.2

AWWA C203: Standard for Coal-Tar Protective Coatings and Linings for Steel Water

Pipelines - Enamel and Tape - Hot Applied.

3.3

AWWA C209: Standard for Cold-Applied Tape Coatings for Steel Water Pipe, Special

Sections, Connections, and Fittings.

3.4

AAWWA C210: Standard for Liquid-Epoxy Coating Systems for the Interior and Exterior of

Steel Water Pipelines.

3.5

CW & ACW Piping Drawings.

3.6

LP1-PTSC-10XXX-QA-G1-PRO-0003: Welding control procedure.

3.7

ASME section IX: Qualification standard for Welding, Brazing, and fusing procedures;

welders, brazers; and welding, brazing, and fusing operators.

3.8

NDE procedures.

3.9

Hydro Test Procedure.

LP1PP

PM-PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.: LP1-LLM10XXX-QA-G1-PRO-0019

Page: 5 of 16

ITP FOR CW & ACW PIPING WORK

Revision No.: A

4.0

Date: 10.Sep.16

ABBREVIATIONS

RT: Radiographic Test

PQR: Procedure Qualification Record

UT: Ultrasonic Test

ITP: Inspection & Test Plan

MT: Magnetic Particle Test

PWHT: Post Weld Heat Treatment

PT: Dye Penetrant Test

WQT: Welder Qualification Test

WPQT: Welding Procedure Qualification Test

NDE: Non-Destructive Testing

WPS: Welding Procedure Specification

N/A: Not Application

Legends:

I:

Subcontractor shall be responsible for undertaking the inspection or test and

generating the appropriate report and record.

H:

Subcontractor is not allowed to proceed with the test/inspection unless a written

release is issued by the Employer and/or Contractor. Subcontractor shall submit

inspection notification to Contractor.

W:

Subcontractor can proceed with the test/inspection when Employer and/or

Contractor's inspector is not present at the notified time. Subcontractor shall submit

inspection notification to Contractor.

Subcontractor is requested to notify Contractor of the initial inspection date/time.

Subcontractor can proceed with the test/inspection when Employer and/or

IW:

Contractor's inspector is not present at the notified time. Subsequent test/inspection

will not be witnessed unless any deficiencies are found at the initial inspection.

S:

Subcontractor is not requested to notify Contractor. Employer and/or Contractor's

inspector will monitor manufacturing conditions, workmanship and test/inspection

during his visit or periodical inspection.

R:

Subcontractor is not requested to notify Contractor. Subcontractor shall perform the

required test/inspection and provide relevant documents such as certificate, report

and Quality Control record. This documents shall be submitted to Contractors

inspector for review.

LP1PP

PM-PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.: LP1-LLM10XXX-QA-G1-PRO-0019

Page: 6 of 16

ITP FOR CW & ACW PIPING WORK

Revision No.: A

Date: 10.Sep.16

5.0

ITP FOR CW & ACW PIPING SYSTEM

6.0

QC FORMS

6.1

LP1-CW-01

6.2

6.3

LP1-CW-03

6.4

LP1-CW-04

6.5

LP1-CW-05

6.6

LP1-CW-06

6.7

LP1-CW-07

6.8

LP1-CW-08

6.9

LP1-CW-09

6.10

LP1-CW-10

6.11

LP1-CW-11

6.12

LP1-CW-12

6.13

LP1-CW-13

P1-CW-02

Item

No.

Activity

Material Inspection

1.1

Quanity

1.2

Identification marking

1.3

Dimensions and sizes including

material grade

1.4

Visual check on damages

Reference

Documents

- Material Certificates

- Material Test Results

- Shop inspection

reports

- Material Control

Procedure

- Packing list

Method of

inspection

testing

Visual

examination

Acceptance Criteria

Freque

ncy

Verifying

Document

As per Packing List

100%

As per Packing List

100%

As per Approved

Drawing

100%

No defect

100%

LP1-CW-03

AWS D1.1

100%

WPS/PQR

100%

Welder

LP1-CW-01,

LP1-CW-02

Welder Qualification

2.1

WPS/PQR review

2.2

WQT

AWS D1.1

Review

Witness

LP1PP

PM-PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.: LP1-LLM10XXX-QA-G1-PRO-0019

Page: 7 of 16

ITP FOR CW & ACW PIPING WORK

Revision No.: A

Item

No.

Activity

Date: 10.Sep.16

Reference

Documents

Method of

inspection

testing

Acceptance Criteria

Freque

ncy

Verifying

Document

Certificates

Welding Inspection

Fit-up inspection:

- Edge preparation

3.1

3.2

4

Root gap

Roundness matching of two

pipes

Misalignment

WPS/PQR

AWS D1.1

Approved Drawings &

WPS

AWS D1.1

As per

Approved Drawings &

WPS

100%

LP1-CW-04

Review/

Witness

AWS D1.1

100%

WPS & PQR

Visual

examination

Measuring

As per Approved

Drawings

100%

LP1-CW-08

Visual

As per WPS, AWS

D1.1

100%

LP1-CW-05

Dimension and Final Inspection

4.1

Dimension inspection

Approved Drawings

4.2

Visual inspection of welding

WPS, AWS D1.1

Visual

examination

Measuring

NDE examination

5.1

Kerosene test for all site

circumferential weld seams

Approved Drawing

Visual

examination

No leak

100%

LP1-CW-07

5.2

RT applied for entire field butt

joint

API 1104

Approved Drawings

RT procedure

Review

As per API 1104

10%

LP1-CW-06

RT Films

5.3

Cleaning of internal pipe after

completion of all work

Witness

As required

100%

Bolt Torque check (if

applicable)

Witness

Bolt Manufacture or

Supply specification

& instruction

100%

LP1-CW-13

Records

Review

As per required

100%

Approved Drawing

Visual check

As per Approved

Drawing

100%

LP1-CW-10

Bolts & Nuts tightening

Hydrostatic test

7.1

Recording of all Pressure joints

weld NDE

7.2

Line system check for Hydro test

LP1PP

PM-PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.: LP1-LLM10XXX-QA-G1-PRO-0019

Page: 8 of 16

ITP FOR CW & ACW PIPING WORK

Revision No.: A

Item

No.

Activity

Date: 10.Sep.16

Reference

Documents

Method of

inspection

testing

Acceptance Criteria

Freque

ncy

Verifying

Document

7.3

Clearing of Punch list before

hydro test which is related to

hydro test essential punch

LP1-CW-10

Hydro Test Procedure

Review

As Hydro Test

Procedure

100%

LP1-CW-11

7.4

Test Pack indicating Test

boundary limits in accordance

with Hydro test procedure

Approved Drawing

Review

As Hydro Test

Procedure

100%

7.5

Ensure availability of Calibrated

Pressure Gauges

Hydro test procedure

Calibration Certificate

Review

Not expiry

100%

Calibration

Certificate

7.6

Fill in complete system, check for

leak

Hydro test procedure

Witness

As Hydro test

procedure

100%

7.7

Pressure the system to hydrostatic

test pressure

Hydro test procedure

Witness

As Hydro test

procedure

100%

LP1-CW-09

7.8

Reduce the test pressure to

working pressure for inspection

Hydro test procedure

Witness

As Hydro test

procedure

100%

LP1-CW-09

Painting Procedure

Witness

As Painting Procedure

100%

As Painting

Procedure

8

8.1

9

Coating Inspection

Painting Inspection for CW pipe

Final piping inspection handing over for next activity

9.1

Punch list (if applicable)

Visual

Witness

Full

100%

LP1-CW-11

9.2

Check List for Before backfilling

Visual

Review

Full

100%

LP1-CW-12

Das könnte Ihnen auch gefallen

- 003 ITP UG PipingDokument4 Seiten003 ITP UG Pipingrvsingh70100% (1)

- Itp StructureDokument47 SeitenItp StructureMohammed Ady Ganjar100% (4)

- Itp Civil WorkDokument9 SeitenItp Civil WorkChristian Albert Sinaga RumajarNoch keine Bewertungen

- FM-16 Material Verification RecordDokument1 SeiteFM-16 Material Verification RecordBleep NewsNoch keine Bewertungen

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDokument1 SeiteStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNoch keine Bewertungen

- Organization Chart For Pipe Line Project 01Dokument1 SeiteOrganization Chart For Pipe Line Project 01MaherNoch keine Bewertungen

- Site Inspection and Test Plan For Tie-In Works: Subcontrac TorDokument24 SeitenSite Inspection and Test Plan For Tie-In Works: Subcontrac Torprabu palaniswamyNoch keine Bewertungen

- ITP C 005 (Structural Concrete)Dokument4 SeitenITP C 005 (Structural Concrete)segun ajibolaNoch keine Bewertungen

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Dokument37 SeitenIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNoch keine Bewertungen

- MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1Dokument13 SeitenMM ZTK 1a ZPQ Qua TPN 8055 Rev.a1sfd640Noch keine Bewertungen

- Material & Equipment Preservation Monitoring SheetDokument1 SeiteMaterial & Equipment Preservation Monitoring Sheetmoytabura96Noch keine Bewertungen

- Owner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionDokument5 SeitenOwner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionLuqman OsmanNoch keine Bewertungen

- ITP-FW For Civil & Building WorksDokument17 SeitenITP-FW For Civil & Building WorksRizki KresnaNoch keine Bewertungen

- Fabrication Erection and Installation Procedure For PipingDokument60 SeitenFabrication Erection and Installation Procedure For Pipinghasan_676489616Noch keine Bewertungen

- 039-Itp For Embedded Plate PDFDokument7 Seiten039-Itp For Embedded Plate PDFKöksal PatanNoch keine Bewertungen

- QA - QC Procedure For Construction - 3Dokument44 SeitenQA - QC Procedure For Construction - 3Samid MidmidNoch keine Bewertungen

- ItpDokument7 SeitenItpJose Sherin100% (1)

- Rotating Itp 1Dokument4 SeitenRotating Itp 1abdul aziz100% (1)

- Itp Bored Pile Rev 1Dokument10 SeitenItp Bored Pile Rev 1Pandar HasibuhanNoch keine Bewertungen

- Quality Inspection FormDokument3 SeitenQuality Inspection FormTesfuNoch keine Bewertungen

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Dokument24 SeitenED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- ITP AllDokument1 SeiteITP AllMuhammadIqbalMughalNoch keine Bewertungen

- ITP SampleDokument2 SeitenITP Sampleeiman_zerep50% (2)

- Itp For Ug PipelineDokument3 SeitenItp For Ug PipelineJustin Alwar100% (1)

- Receiving Material Procedure CoverDokument1 SeiteReceiving Material Procedure Covergst ajahNoch keine Bewertungen

- Daily Welding Report PLD LogoDokument1 SeiteDaily Welding Report PLD Logonike_y2kNoch keine Bewertungen

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDokument1 SeitePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNoch keine Bewertungen

- Earthworks-Excavation: Owner: Client: Consultant: Main Contractor: Civil ContractorDokument1 SeiteEarthworks-Excavation: Owner: Client: Consultant: Main Contractor: Civil ContractorPrasanna KumarNoch keine Bewertungen

- ITP Installation of Boiler - R1Dokument14 SeitenITP Installation of Boiler - R1crys100% (4)

- External QC Inspection Request-Report FormDokument1 SeiteExternal QC Inspection Request-Report FormEdison WalitNoch keine Bewertungen

- Tank Erection Procedure: Note: This Is The Sample Document For The Related Job OnlyDokument5 SeitenTank Erection Procedure: Note: This Is The Sample Document For The Related Job Onlygeorge israelNoch keine Bewertungen

- ITP's and ITR's A Necessary - Monster - PDFDokument5 SeitenITP's and ITR's A Necessary - Monster - PDFshastri85Noch keine Bewertungen

- R057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor PackageDokument10 SeitenR057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor Packagedharwin100% (1)

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDokument10 SeitenDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNoch keine Bewertungen

- Piping Fabrication Installation QCP On SiteDokument1 SeitePiping Fabrication Installation QCP On SiteTarun PatelNoch keine Bewertungen

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDokument2 SeitenInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Itp - Rev eDokument36 SeitenItp - Rev ezaki_saddarNoch keine Bewertungen

- Format Punchlist PDFDokument27 SeitenFormat Punchlist PDFDuan Tokcer100% (2)

- Sample # 1Dokument3 SeitenSample # 1Clarence Ferro100% (1)

- Weld Identification Record FormDokument2 SeitenWeld Identification Record FormDimitris NikouNoch keine Bewertungen

- Itp For Storage TanksDokument7 SeitenItp For Storage TanksHamid MansouriNoch keine Bewertungen

- Fabrication Inspection Progress ReportDokument4 SeitenFabrication Inspection Progress ReportNorman MoralesNoch keine Bewertungen

- Itp For InsulationDokument14 SeitenItp For InsulationHytham El-NoubyNoch keine Bewertungen

- Inspection and Test Plan Format: GeneralDokument4 SeitenInspection and Test Plan Format: GeneralSABIR KHANNoch keine Bewertungen

- 025-ITP For Sewer & Drainage PDFDokument6 Seiten025-ITP For Sewer & Drainage PDFKöksal PatanNoch keine Bewertungen

- MKS 112 GEN AZ7 RQ 03 - A - Purchase Requisition For Painting MaterialsDokument21 SeitenMKS 112 GEN AZ7 RQ 03 - A - Purchase Requisition For Painting MaterialsĐiệnBiênNhâm100% (1)

- Welding Report For PipingDokument1 SeiteWelding Report For PipingRifki HasyaNoch keine Bewertungen

- Itp PaintingDokument14 SeitenItp PaintingNamta George100% (4)

- Request For Inspection FormDokument1 SeiteRequest For Inspection FormPHYRAK100% (1)

- Grati CCPP (Peaker) Extension Project 450Mw: Pt. Perusahaan Listrik Negara (Persero)Dokument29 SeitenGrati CCPP (Peaker) Extension Project 450Mw: Pt. Perusahaan Listrik Negara (Persero)Yurizal Firmansyah100% (1)

- 62-P-90Rev A Method Statement For Oxygen Line FabricationDokument13 Seiten62-P-90Rev A Method Statement For Oxygen Line FabricationAsadAliAliNoch keine Bewertungen

- ITP For Civil WorksDokument15 SeitenITP For Civil WorksNoor A Qasim100% (8)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDokument18 Seiten046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNoch keine Bewertungen

- ITP For Pipeline Construction Table 1Dokument3 SeitenITP For Pipeline Construction Table 1wahyu100% (2)

- NCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestDokument1 SeiteNCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestCharles KingNoch keine Bewertungen

- Inspection Test Plan For Pipeline JobsDokument6 SeitenInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNoch keine Bewertungen

- TP-01Hydrostatic Test Cover SheetDokument4 SeitenTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Itp For Fabrication Steel Structure of Warehouse and WorkshopDokument6 SeitenItp For Fabrication Steel Structure of Warehouse and WorkshopPhong Do100% (1)

- FQPDokument9 SeitenFQPtushar647Noch keine Bewertungen

- 5) Economizer - Lifting SequencesDokument1 Seite5) Economizer - Lifting SequencesPhong DoNoch keine Bewertungen

- Vv31b4-001-B-100!8!001 Method Statement For Fireproofing of Structural Steel Structures & Equipment With Interkote 1460Dokument54 SeitenVv31b4-001-B-100!8!001 Method Statement For Fireproofing of Structural Steel Structures & Equipment With Interkote 1460Phong DoNoch keine Bewertungen

- Boiler Erection ManualDokument51 SeitenBoiler Erection ManualPhong Do100% (1)

- Erection Guidelines For 500 MW Boiler Pressure PartsDokument150 SeitenErection Guidelines For 500 MW Boiler Pressure Partsyanloyan80% (5)

- LP1 TKZ 10XXX M M1a Man 8405 CDokument27 SeitenLP1 TKZ 10XXX M M1a Man 8405 CPhong DoNoch keine Bewertungen

- Presentation UzbekistanDokument9 SeitenPresentation UzbekistanPhong DoNoch keine Bewertungen

- RT ProcedureDokument25 SeitenRT ProcedurePhong Do100% (2)

- LP1 TKZ 10XXX M M1a Man 8405 CDokument27 SeitenLP1 TKZ 10XXX M M1a Man 8405 CPhong DoNoch keine Bewertungen

- Itp For Fabrication Steel Structure of Warehouse and WorkshopDokument6 SeitenItp For Fabrication Steel Structure of Warehouse and WorkshopPhong Do100% (1)

- KP2 Coalbunker SV Report For Week 48 Update On 30-NovDokument246 SeitenKP2 Coalbunker SV Report For Week 48 Update On 30-NovPhong DoNoch keine Bewertungen

- Approval Status of Hyundai Welding ConsumableDokument9 SeitenApproval Status of Hyundai Welding ConsumablePhong DoNoch keine Bewertungen

- Astm 262 PDFDokument19 SeitenAstm 262 PDFiyam75% (4)

- Element Loading Sequence in Air PreheaterDokument21 SeitenElement Loading Sequence in Air PreheaterPhong DoNoch keine Bewertungen

- F462-79 (2007) Standard Consumer Safety Specification For Slip-Resistant Bathing FacilitiesDokument7 SeitenF462-79 (2007) Standard Consumer Safety Specification For Slip-Resistant Bathing FacilitiesPhong DoNoch keine Bewertungen

- Iso 4624 PDFDokument15 SeitenIso 4624 PDFRajan Steeve50% (2)

- Henry Dee Taking Off Beme For Office Building of 40m October 2016Dokument257 SeitenHenry Dee Taking Off Beme For Office Building of 40m October 2016Henry DiyokeNoch keine Bewertungen

- F455A E-Dynamic - F455RA E-DynamicDokument24 SeitenF455A E-Dynamic - F455RA E-Dynamicmatej1992Noch keine Bewertungen

- Firedoor ProductsDokument2 SeitenFiredoor Productsmozzer6969Noch keine Bewertungen

- Fencing, Compound Wall and Gate (Pranoti) - 1Dokument36 SeitenFencing, Compound Wall and Gate (Pranoti) - 1MG100% (1)

- Stiffness Analysis of Parallel Leaf-Spring Flexures: RZ Direction Can Be Approximated Based On CDokument4 SeitenStiffness Analysis of Parallel Leaf-Spring Flexures: RZ Direction Can Be Approximated Based On CmdrehmerNoch keine Bewertungen

- Winkler Curved Beam TheoryDokument21 SeitenWinkler Curved Beam TheoryMuluken TemesgenNoch keine Bewertungen

- 48th Floor Initial Punchlist For Other ContractorDokument16 Seiten48th Floor Initial Punchlist For Other ContractorBenhur CasasNoch keine Bewertungen

- Calculation For Operating Platform-043-Plf-31004: Tangguh Expansion - Project ExecuteDokument112 SeitenCalculation For Operating Platform-043-Plf-31004: Tangguh Expansion - Project ExecuteRiesang Wirawan Probogumilang100% (2)

- Lab Report: Design of Concrete Structures (ENG466)Dokument11 SeitenLab Report: Design of Concrete Structures (ENG466)Amrit AcharyaNoch keine Bewertungen

- Carillo Rod Bolts Tech InfoDokument1 SeiteCarillo Rod Bolts Tech Infoagrandi12Noch keine Bewertungen

- ELECTRIC LAYOUT-ModelDokument1 SeiteELECTRIC LAYOUT-Modelmanasa manasaNoch keine Bewertungen

- Redbook Vol2part1Dokument92 SeitenRedbook Vol2part1ChadNoch keine Bewertungen

- BSA Stationary Concrete Pumps Esmart Brochure INDokument4 SeitenBSA Stationary Concrete Pumps Esmart Brochure INajeet ranaNoch keine Bewertungen

- Erifon HD603HP Series MacDermid OffshoreDokument2 SeitenErifon HD603HP Series MacDermid OffshoreVictor RomeroNoch keine Bewertungen

- COC BuildingDokument1 SeiteCOC Buildingrolando dionisioNoch keine Bewertungen

- Roof Purlin Design: 1. Constructive SchemeDokument35 SeitenRoof Purlin Design: 1. Constructive SchemeCristian ScutaruNoch keine Bewertungen

- Steam O&MDokument28 SeitenSteam O&MmadiNoch keine Bewertungen

- Lab 2 - Tensile Testing of MetalsDokument8 SeitenLab 2 - Tensile Testing of MetalsMoey RenNoch keine Bewertungen

- Method Statement For Conduit Installation Including Accessories PVC & GIDokument17 SeitenMethod Statement For Conduit Installation Including Accessories PVC & GIgangadharan000100% (1)

- Unit 4Dokument17 SeitenUnit 4sandeepNoch keine Bewertungen

- Passive Design: Strategies in ArchitectureDokument9 SeitenPassive Design: Strategies in ArchitectureUmang KayasthaNoch keine Bewertungen

- Minturn 100 Block Design Standards and GuidelinesDokument27 SeitenMinturn 100 Block Design Standards and GuidelinesJohn LaConteNoch keine Bewertungen

- Sand Cushion: 1. IntroductionDokument2 SeitenSand Cushion: 1. Introductionlokesh nandinaNoch keine Bewertungen

- Sae J246 2000 (En)Dokument23 SeitenSae J246 2000 (En)Oh No PotatoNoch keine Bewertungen

- 7 Safety PlanDokument17 Seiten7 Safety PlanAhmed GamalNoch keine Bewertungen

- Engineering Utilities 2: Engr. Ervin John D. Melendres InstructorDokument24 SeitenEngineering Utilities 2: Engr. Ervin John D. Melendres InstructorStephanie CanibanNoch keine Bewertungen

- Hydrostatic Test Procedure: Project No: 14481Dokument6 SeitenHydrostatic Test Procedure: Project No: 14481Ahmad MohammadNoch keine Bewertungen

- Mathcad - PART II Ceiling (ICU) 20200602 (Update) - 2Dokument418 SeitenMathcad - PART II Ceiling (ICU) 20200602 (Update) - 2BQ HeNoch keine Bewertungen

- Flow Coeffi Cients: Catalog # 77-1006ADokument8 SeitenFlow Coeffi Cients: Catalog # 77-1006AFelipe Gamboa GálvezNoch keine Bewertungen

- TOR For Dilapidation SurveyDokument3 SeitenTOR For Dilapidation Surveysayuti_yusofNoch keine Bewertungen