Beruflich Dokumente

Kultur Dokumente

Boiler Operation

Hochgeladen von

Kevin TraynorCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Boiler Operation

Hochgeladen von

Kevin TraynorCopyright:

Verfügbare Formate

Sequence of Boiler Operation

Ch mode

Boiler in standby mode

Demand called for via room thermostat/timer

Pump runs activating primary flow switch then micro switch above from

NO to NC

Diverter valve remains in at rest position (central heating port open

only)

Printed circuit board sends voltage to fan

Fan runs ok

Air pressure switch activates from C and NC position over to C and NO

position (Sending signal back to Printed circuit board)

Overheat cut out thermostat is checked for closed circuit (continuous

circuit) Primary thermistor is also checked for correct thermal resistance

Spark generator and ignition electrode(s) ok

Gas valve energised and ignites ok (low rate)

Flame detection electrode ok (sparking finishes ionisation proved)

Gas valve ramps up to range rated set pressure (Controlled via the

thermistor and potentiometer at p.c.b)

Boiler control thermostat or room thermostat is satisfied or the timer shuts

down boiler

Fan and pump over run continue to dissipate residual heat (over run time

will vary)

Boiler returns to standby mode

Hot Water Mode

Boiler in standby mode

Demand called for activating hot water flow switch then micro switch

above from NO to NC (paddle, turbine, wheel or pressure differential type)

Pump runs-activating primary flow switch then micro switch above from

No to NC

Diverter valves internal hydraulics moves over from rest position

(central heating port open) to domestic hot water position (port to

secondary plate exchanger open only)

Note: not all models incorporate a diverter valve and plate to plate heat

exchanger, but instead utilise a twin pass main heat exchanger

Printed circuit board sends voltage to fan

Fan runs ok

Air pressure switch activates from C and NC position over to C and NO

position (sending signal back to Printed circuit board)

C/H and H/W overheat cut out thermostats are checked for closed circuit

(continuous circuit), primary and secondary thermistors are also checked

for correct thermal resistance

Spark generator and ignition electrode(s) ok

Gas valve energised and ignites ok (ignition rate)

Flame detection electrode ok (sparking finishes ionisation proved)

Gas valve modulates according to the water flow rate/ desired

temperature setting (controlled via the thermistor and potentiometer at

p.c.b)

Boiler shuts down when hot water demand is satisfied

Fan and pump over run continue to dissipate residual heat (over run time

will vary)

Boiler returns to standby mode

Please note: The above sequence of operation for both hot water and

central heating are not identical for every boiler out there, however, the

sequence of events will not progress any further forward, if there are no

feedback signals or if they are incorrect. See also our boiler servicing

procedure page.

Main Components

Boiler Check boiler manuals for details

Programmer

Ignition Electronic Pulse, Direct Spark, etc.

Heat Exchanger Single Pass or Crossflow.

Pump Speed (single, two speed, three speed), Modulating, Twin Pump,

etc.

Diverter Valve Diaphragm Pass, Wax Capsule, Electric, Venture.

Sometimes called a mid-position valve due to the mechanism of

diverting hot water from the boiler to either the radiators or the hot water

cylinder or both

Gas Valve Zero Governor, Automatic, Intermittent or Permanent Pilot.

Calorifier Cylinder and Coil or Plate.

Primary Flow Switch Pressure differential, Diaphragm, Reed.

Secondary Flow Switch Paddle Diaphragm, Diaphragm, Reed, Thermistor.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Absolute-Pressure Sensors: Micromechanics, Hybrid DesignDokument3 SeitenAbsolute-Pressure Sensors: Micromechanics, Hybrid Designc20get100% (2)

- Apelco Fishfinder 365Dokument83 SeitenApelco Fishfinder 365Ivan Campione100% (1)

- Ussocom 006Dokument52 SeitenUssocom 006RTSLLCNoch keine Bewertungen

- Tube Size (MM) : BS 6891 TableDokument2 SeitenTube Size (MM) : BS 6891 TableKevin TraynorNoch keine Bewertungen

- Underfloor Wheelset Lathe: Operating / Maintenance ManualDokument84 SeitenUnderfloor Wheelset Lathe: Operating / Maintenance ManualMinh Canh100% (1)

- Bms & Hvac SystemDokument41 SeitenBms & Hvac SystemHirushan Menuka100% (2)

- (Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFDokument534 Seiten(Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFপ্রিয়দীপ প্রিয়মNoch keine Bewertungen

- Chapter 6-Agitated LiquidDokument48 SeitenChapter 6-Agitated LiquidAhmad SiddiqNoch keine Bewertungen

- IONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11Dokument3 SeitenIONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11dhiaa mohammedNoch keine Bewertungen

- Costiuc Silvia - Culas in Oltenia - CNHC 2011Dokument25 SeitenCostiuc Silvia - Culas in Oltenia - CNHC 2011trancalina100% (1)

- Cold Water Storage CisternDokument7 SeitenCold Water Storage CisternKevin TraynorNoch keine Bewertungen

- Gas RateDokument8 SeitenGas RateKevin TraynorNoch keine Bewertungen

- Robinson Willey Firegem Visa 2-4Dokument10 SeitenRobinson Willey Firegem Visa 2-4Kevin TraynorNoch keine Bewertungen

- PMOS RunsheetDokument3 SeitenPMOS Runsheetkrishna_singhalNoch keine Bewertungen

- Robotics Answer KeyDokument4 SeitenRobotics Answer KeyChad ValenciaNoch keine Bewertungen

- Commsys 2 2012 4Dokument47 SeitenCommsys 2 2012 4AnuNoch keine Bewertungen

- Net Positive Suction HeadDokument4 SeitenNet Positive Suction Headjorge alarconNoch keine Bewertungen

- Vastu Tips For CareerDokument2 SeitenVastu Tips For CareerBeyond ThoughtsNoch keine Bewertungen

- UCO General BrochureDokument2 SeitenUCO General BrochureSam LamNoch keine Bewertungen

- Fluid Mechanics Subjective QuestionsDokument3 SeitenFluid Mechanics Subjective QuestionsCrewdex ProNoch keine Bewertungen

- CAD (ME2155) Lab ManualDokument18 SeitenCAD (ME2155) Lab Manualharishj93Noch keine Bewertungen

- Mine Design and SchedulingDokument10 SeitenMine Design and SchedulingLeandro FagundesNoch keine Bewertungen

- Supports For Pipelines 1758uk 7-03-15 PDFDokument46 SeitenSupports For Pipelines 1758uk 7-03-15 PDFAndor MolitoriszNoch keine Bewertungen

- Commissioning Report Generator - SAMPLEDokument5 SeitenCommissioning Report Generator - SAMPLEMax JohnNoch keine Bewertungen

- Saudi Technical Trade Test - Welder CategoryDokument4 SeitenSaudi Technical Trade Test - Welder CategoryshabashakkimNoch keine Bewertungen

- Frame RelayDokument33 SeitenFrame RelayDilsha AshrafNoch keine Bewertungen

- Efecto de La Temperatura Del Hipoclorito de SodioDokument4 SeitenEfecto de La Temperatura Del Hipoclorito de SodioMarriano DarinoNoch keine Bewertungen

- Polymer PhysicsDokument9 SeitenPolymer PhysicslotannaNoch keine Bewertungen

- Projection Achievement ReportDokument8 SeitenProjection Achievement ReportPskaruppiah KarupsNoch keine Bewertungen

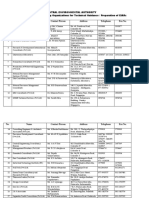

- New Consultant List 20177 For Cea Website 10.02.2016Dokument4 SeitenNew Consultant List 20177 For Cea Website 10.02.2016hxian.y9333Noch keine Bewertungen

- Durehete 1055Dokument5 SeitenDurehete 1055alextentwenty100% (1)

- Traffic Engineering Bachelor of Science in Civil EngineeringDokument22 SeitenTraffic Engineering Bachelor of Science in Civil EngineeringDaisy AstijadaNoch keine Bewertungen

- Polyken 1600 High TempDokument2 SeitenPolyken 1600 High TempKyaw Kyaw AungNoch keine Bewertungen