Beruflich Dokumente

Kultur Dokumente

DCA 1 - Flame Spread Performance of Wood Products

Hochgeladen von

picottCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DCA 1 - Flame Spread Performance of Wood Products

Hochgeladen von

picottCopyright:

Verfügbare Formate

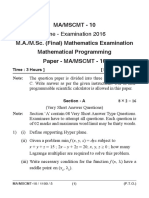

Flame Spread Performance of Wood Products

Wood and wood-based products are widely used

in interior wall, ceiling, and floor surfaces in all types

of buildings.

Appearance, acoustical qualities, and interior design versatility have made wood surfaces highly desired by architects, designers, and building occupants.

This publication briefly describes building code flame

spread regulations on products used in interior finish

and presents performance data on a range of wood

products.

Flame Spread Requirements

Most code requirements for wood interior finish

materials are expressed in terms of flame spread index

numbers. These values are determined in a standard

fire test which evaluates the surface burning characteristics of a material. Different maximum flame spread

indices are permitted depending upon building occupancy, location of the material in the building, and the

presence of sprinklers. Flame spread indices in this

publication are provided for wood materials that qualify for various building design requirements.

Test Method

The standard fire test used to evaluate flame

spread characteristics of wood building materials in

the United States is ASTM E-84, Standard Test

Method for Surface Burning Characteristics of Building Materials.

The test procedure exposes candidate materials in

a horizontal, rectangular tunnel 17 3/4" wide by 12" in

height and 25' long. The tunnel is equipped with two

gas burners at one end that direct a flame onto the surface of the test material under a controlled air flow.

Flame spreads along the surface of the material as the

test progresses. Distance of the flame travel and the

rate at which the flame front advances during a 10

Copyright 2008 American Forest & Paper Association, Inc.

FLAME SPREAD PERFORMANCE OF WOOD PRODUCTS

minute exposure determine the calculated flame spread

index.

To provide standard conditions for each test, the

tunnel is calibrated to an index of 0 for noncombustible materials and 100 for 23/32" red oak flooring. Indices for tested materials can range from 0 to over

1000.

Classification in Codes are:

Class

I or A

II or B

III or C

Flame Spread Range Example Locations

0-25

Enclosed vertical exits

26-75

Exit access corridors

76-200

Other rooms and areas

Wood Products

Lumber, plywood, and other wood-based materials

exhibit a relatively narrow range of flame spread. Differences result from factors such as density, thickness,

surface characteristics, and chemical constituents. If

the material is homogeneous, flame spread may be

considered nearly independent of material thickness at

thicknesses greater than 1/4".

Flame spread indices for a number of species of

lumber, plywood, particleboard, shakes, and shingles

are listed in Table 1. In products such as softwood and

hardwood plywood, the arrangement and type of components may also influence surface flame spread.

Some such products are described by face species and

core composition in Table 1. All ratings are based on

the ASTM E-84 test method.

Flame spread indices for a number of commercially available wood products with factory applied

overlay finishes are listed in Table 2. Factory finished

wall panels are typically tested and labeled to identify

the flame spread classification of the finished product.

Finish composition, adhesive, and finish thickness

may, however, affect flame spread.

As can be seen from the listed indices, most tested

wood products have a flame spread index less than

200, making them acceptable under current building

codes for a wide range of interior finish uses. Flame

spread indices for a range of proprietary wood-based

interior finish materials are also available from their

manufacturers. Commercially available fire retardant

treatments for wood and panel products can reduce

flame spread performance to an index of 25 or less.

Check with the manufacturer for flame spread index.

A smoke-developed index was also measured for

some of the wood products listed in Table 1 and Table

2. This index also has a value of 100 for red oak. None

of the products tested exceeded 450, a limiting value

commonly used in building code regulations.

While effort has been made to ensure the accuracy of the information in this publication, the

American Forest & Paper Association, and the Companies and Associations identified, do not

assume responsibility for the accuracy of the indices reported, the applicability or extension of

the reported flame spread values to specific products, or their acceptance for use in particular

applications. Includes updates through June 2008.

American Wood Council

FLAME SPREAD PERFORMANCE OF WOOD PRODUCTS

Table 1

Reported Flame Spread Indices

Material1

LUMBER

Birch, Yellow

Cedar, Alaska Yellow

Cedar, Pacific Coast Yellow

Cedar, Port Orford

Cedar, Western Red

Cedar, Western Red

Cherry 3/4"

Cottonwood

Cypress

Elm 3/4"

Fir, Douglas

Fir, Douglas 3/4" flooring

Fir, Amabilis (Pacific Silver)

Fir, White

Gum, Red

Hem-Fir Species Group5

Hemlock, West Coast

Larch, Western

Maple (flooring)

Oak, Red or White

Oak, Red 3/4"

Oak, White 3/4"

Pecan 3/4"

Pine, Eastern White

Pine, Idaho White

Pine, Idaho White

Pine, Lodgepole

Pine, Northern White

Pine, Ponderosa4

Pine, Ponderosa

Pine, Red

Pine, Southern Yellow

Pine, Sugar

Pine, Western White

Poplar, Yellow

Redwood

Redwood 3/8"

Spruce, Engelmann

Spruce, Northern

Spruce, Sitka

Spruce, Western

Walnut

Walnut 3/4"

ORIENTED STRAND BOARD,

(Exterior Glue6)

5/16"

7/16"

1/2"

3/4"

ASTM E-84

Flame

2

Spread

Source3

105-110

UL

50

HPVA2

78

CWC

60

HPVA2

70

HPVA

73

CWC

76

HPVA

115

UL

145-150

UL

76

HPVA

70-100

UL

83-98

WEY

69

CWC

65

HPVA2

140-155

UL

60

HPVA2

60-75

WEY, UL

45

HPVA2

104

CWC

100

UL

84

HPVA

77

HPVA

84

HPVA

85

CWC

72

HPVA

82

WEY

98

WEY

120-215

UL

105-230

UL

115

HPVA2

142

CWC

130-195

UL

95

HPVA2

75

UL

170-185

UL

70

UL

102

UL

55

HPVA2

65

UL

74

CWC

100

UL

130-140

UL

101

HPVA

WAFERBOARD

127-138

86-150

74-172

147-158

Copyright 1997, 1998, 2001, 2002, 2008

American Forest & Paper Association, Inc.

APA2

APA2

APA2

APA2

Material1

ASTM E-84

Flame

2

Spread

Source3

SOFTWOOD PLYWOOD (Exterior Glue6)

Cedar 3/8"

Douglas Fir 1/4"

Douglas Fir 5/16"

Douglas Fir 3/8"

Douglas Fir 1/2"

Douglas Fir 5/8"

Hemlock 3/8"

Southern Pine 1/4"

Southern Pine 3/8"

Southern Pine 5/8"

Redwood 3/8"

Redwood 5/8"

70-95

150

115-155

110-150

130-150

95-130

75-160

95-110

100-105

90

95

75

APA

APA

APA

APA

APA

APA

APA

APA

APA

APA

UL

UL

HARDWOOD PLYWOOD7

Ash 3/4" - Particleboard Core

Birch 1/4" - Douglas Fir Veneer Core

Birch 1/4" - Fuma Veneer Core

Birch 3/4" - Douglas Fir Veneer Core

Birch 3/4" - High Density Veneer Core

Birch 3/4" - Particleboard Core

Birch 3/4" - MDF Core

Honduras Mahogany 3/4" - Particleboard Core

Lauan 11/64"

Lauan 1/4"

Oak 1/4" - Douglas Fir Veneer Core

Oak 3/4" - MDF Core

134

135-173

127

114

114

124

134

105

167

150

153

123

HPVA

HPVA

HPVA

HPVA

HPVA

HPVA

HPVA

HPVA

NIST

HPVA

HPVA

HPVA

156

200

135

156

153

168

145

88-98

HPVA

UL

HPVA

NIST

NIST

UL

UL

APA2

140

125

120

UL

HPVA

HPVA

11/16"

140

UL

3/4"

3/4"

3/4"

1"

SHAKES and SHINGLES

Western Red Cedar Shakes 1/2"

Western Red Cedar Shingles 1/2"

140

140

130

90

HPVA

HPVA

HPVA

UL

69

49

HPVA

HPVA

PARTICLEBOARD

3/16" (Aromatic Cedar Flakeboard)

3/8"

1/2"

1/2"

5/8"

11/16"

3/4"

3/4"(Exterior Glue5)

MEDIUM DENSITY FIBERBOARD - MDF

3/8"

7/16"

5/8"

NOTE: Table 1 footnotes on next page.

American Forest & Paper Association

FLAME SPREAD PERFORMANCE OF WOOD PRODUCTS

Table 1 Footnotes.

1 Thickness of material tested is one-inch nominal except where indicated.

2 The ASTM E-84 test method has been revised a number of times during the years referenced by the source reports. However, the E-84 test apparatus has

changed little over this period. Slightly different flame spread indices, usually lower, result when recent E-84 flame spread calculation techniques are applied to

older wood product data. These changes in flame spread indices are not sufficient to change the flame spread class for the wood products described in this report.

3 Sources:

APA APA-The Engineered Wood Association, Research Reports 128, Revised, August 1979.

APA2 APA-The Engineered Wood Association Test Results.

CWC Fire Safety Design in Buildings, Canadian Wood Council, 1996.

HPVA Hardwood Plywood and Veneer Association, Test Reports, 202, 203, 335, 336, 337, 592, and 596; Special flame spread performance tests, Aug. 1974;

T9234, T9237, T9317, T9344, T9354, May 1995; T9422, T9430, T9431, T9453, T9665, Feb/July 1997.

HPVA2 Hardwood Plywood and Veneer Association, March/April 1995; October/December 2000; June 2008.

NIST National Institute of Standards and Technology (formerly National Bureau of Standards), Technical Notes 879 and 945.

UL Underwriter's Laboratory, UL 527, May 1971; Subject 723, Assignment 71SC509, Mar 15 &16,1971; Assignment 84NK1898, File R10917, Mar 9, 1984.

WEY Weyerhaueser Fire Laboratory, 1973, 1987, January & February 1988.

4 Average of 18 tests was 154 with three values over 200.

5 The Hem-Fir Species Group represents six species: Californian Red Fir, Grand Fir, Nobel Fir, Pacific Silver Fir, Western Hemlock, and White Fir. The reported flame spread index represents a product containing a mixture of these species. When lumber is from a single species refer to the specific species flame

spread index.

6 Exposure 1 or exterior. Average of 22 tests was 128.

7 Flame spread of plywood is affected by the species of the face veneer but can also be influenced by the species of the underlying core veneer. Various panel

constructions involving certain core species show a relatively high degree of variability and potential to yield flame spread values above 200. Panel constructions involving cores of aspen, sumauma, yellow poplar and white fir have exhibited this behavior with average flame spread indices ranging from 78 to 259.

Other factors, in addition to species, including material and process variables related to specific manufacturers can also affect flame spread. Thus, for plywood

panels with certain core species, test data from the actual manufacturer is particularly important in establishing the flame spread classification of the product.

Copyright 1997, 1998, 2001, 2002, 2007, 2008 American Forest & Paper Association, Inc.

American Wood Council

FLAME SPREAD PERFORMANCE OF WOOD PRODUCTS

Table 2

Reported Flame Spread Indices of Factory Finished Products

1

Material

ASTM-84 Flame Spread

PARTICLEBOARD

5/32" Factory Finished Printed

116-178

5/32" Paper Overlay

159-176

5/32" Vinyl Overlay

180

1/4" Vinyl Overlay

127

3/8" Vinyl Overlay

130

1/2" Vinyl Overlay

175

5/8" Vinyl Overlay

100

MEDIUM DENSITY FIBREBOARD (MDF)

3/16" Factory Finished Printed

167

1/4" Vinyl Overlay

121

HARDBOARD

1/8" Paper Overlay

155-166

1/8" Vinyl Overlay

164

3/16" Vinyl Overlay

148

HARDWOOD PLYWOOD

Cherry 1/4" Factory Finished

160

Elm 1/4" Factory Finished

130-145

Hickory 1/4" Factory Finished

140

Lauan 1/4" Factory Finished Printed

99-141

Lauan 1/4" Vinyl Overlay

120

Lauan 3.6mm Factory Finished Printed

123-191

Lauan 3.6mm Vinyl Overlay

108-158

Lauan 3.6mm Paper Overlay

132-190

Maple 1/4" Factory Finished

155

Oak 1/4" Factory Finished

125-185

Pecan 1/4" Factory Finished

145-150

Pine 1/4" Factory Finished

120-140

Walnut 1/4" Factory Finished

138-160

SOFTWOOD PLYWOOD

1/4" Douglas Fir w/Medium Density Overlay2 140

3/8" Douglas Fir w/Medium Density Overlay3 110

3/8" Douglas Fir w/High Density Overlay3

110

4

ORIENTED STRAND BOARD, WAFERBOARD (Exterior Glue )

3

7/16" Phenolic Paper Overlay

150-155

Copyright 1997, 1998, 2001, 2002, 2008 American Forest & Paper Association, Inc.

Table 2 Footnotes.

1

2

3

4

Source: Hardwood Plywood and Veneer Association Test Records, except as noted.

Canadian Wood Council, Fire Safety Design in Buildings, 1996.

APA - The Engineered Wood Association Test Results.

Exposure 1 or exterior.

American Forest & Paper Association

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- GuidewireClaimCenter Performance TestPlanDokument18 SeitenGuidewireClaimCenter Performance TestPlanshanthan117Noch keine Bewertungen

- NASA ERAST Program Develops High-Altitude UAVsDokument17 SeitenNASA ERAST Program Develops High-Altitude UAVsEgz AguilarNoch keine Bewertungen

- Elevator Installation Contract - 2022 - CNMDokument5 SeitenElevator Installation Contract - 2022 - CNMsolid groupNoch keine Bewertungen

- A Practical Introductory Guide On Using Satellite Technology For CommunicationsDokument15 SeitenA Practical Introductory Guide On Using Satellite Technology For CommunicationsJohan PrinslooNoch keine Bewertungen

- SLTRT Service Level Testing Reporting ToolDokument110 SeitenSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- SYMAP UsersManual E PDFDokument98 SeitenSYMAP UsersManual E PDFRafaqatAliNoch keine Bewertungen

- Serviceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapsDokument11 SeitenServiceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapspicottNoch keine Bewertungen

- Creep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperDokument5 SeitenCreep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Add Info B-82974EN 01Dokument3 SeitenAdd Info B-82974EN 01Charles JacobNoch keine Bewertungen

- Lateral Displacement Ductility of Reinforced Concrete Flat PlatesDokument9 SeitenLateral Displacement Ductility of Reinforced Concrete Flat PlatespicottNoch keine Bewertungen

- Modeling of Concrete Damage: Aci Structural Journal Technical PaperDokument12 SeitenModeling of Concrete Damage: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Shear Resistance of Connections Between Reinforced Concrete Linear Precast ElementsDokument34 SeitenShear Resistance of Connections Between Reinforced Concrete Linear Precast ElementspicottNoch keine Bewertungen

- Strength Evaluation of Shotcrete Repaired Beams: Aci Structural Journal Technical PaperDokument5 SeitenStrength Evaluation of Shotcrete Repaired Beams: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Membrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperDokument10 SeitenMembrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Nonlinear Finite Element Analysis of Reinforced Concrete MembranesDokument10 SeitenNonlinear Finite Element Analysis of Reinforced Concrete MembranespicottNoch keine Bewertungen

- Strength of Concrete On An Extremely Small Bearing Area: Aci Structural Journal Technical PaperDokument9 SeitenStrength of Concrete On An Extremely Small Bearing Area: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Strength of Reinforced Concrete Corbles With Fibers: Aci Structural Journal Technical PaperDokument8 SeitenStrength of Reinforced Concrete Corbles With Fibers: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Torsion in Concrete Deep Beams With An Opening: Aci Structural Journal Technical PaperDokument6 SeitenTorsion in Concrete Deep Beams With An Opening: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Torsional Response of Reinforced Fibrous Concrete Beams: Aci Structural Journal Technical PaperDokument9 SeitenTorsional Response of Reinforced Fibrous Concrete Beams: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Angetal Circolari PDFDokument15 SeitenAngetal Circolari PDFCiro AscioneNoch keine Bewertungen

- Interaction of Concrete and Curved Reinforcement As Applied To Construction PracticeDokument29 SeitenInteraction of Concrete and Curved Reinforcement As Applied To Construction PracticepicottNoch keine Bewertungen

- Repair of Fire-Damaged Reinforced Concrete Columns: Aci Structural Journal Technical PaperDokument6 SeitenRepair of Fire-Damaged Reinforced Concrete Columns: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Softened Truss Model Theory For Shear and Torsion: Aci Structural Journal Technical PaperDokument12 SeitenSoftened Truss Model Theory For Shear and Torsion: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- High-Strength Concrete Deep Beams With Effective Span and Shear Span VariationsDokument9 SeitenHigh-Strength Concrete Deep Beams With Effective Span and Shear Span VariationspicottNoch keine Bewertungen

- Modeling Nonlinear Bond-Slip Behavior For Finite Element Analyses of Reinforced Concrete StructuresDokument6 SeitenModeling Nonlinear Bond-Slip Behavior For Finite Element Analyses of Reinforced Concrete StructurespicottNoch keine Bewertungen

- Response of Reinforced Concrete Columns To Simulated Seismic LoadingDokument10 SeitenResponse of Reinforced Concrete Columns To Simulated Seismic LoadingpicottNoch keine Bewertungen

- Durability of Some Glass Fiber Reinforced Cement CompositesDokument7 SeitenDurability of Some Glass Fiber Reinforced Cement CompositespicottNoch keine Bewertungen

- Cracking Load For A Wind-Loaded Reinforced Concrete Cooling TowerDokument8 SeitenCracking Load For A Wind-Loaded Reinforced Concrete Cooling TowerpicottNoch keine Bewertungen

- Air Entrainment in The Presence of Superplasticizers: Aci Journal Technical PaperDokument6 SeitenAir Entrainment in The Presence of Superplasticizers: Aci Journal Technical PaperpicottNoch keine Bewertungen

- The Performance of Epoxy-Coated Shear Reinforcement: Aci Structural Journal Technical PaperDokument7 SeitenThe Performance of Epoxy-Coated Shear Reinforcement: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Flexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WasteDokument7 SeitenFlexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WastepicottNoch keine Bewertungen

- Computer-Aided Concrete Mix Proportioning: Aci Journal Technical PaperDokument6 SeitenComputer-Aided Concrete Mix Proportioning: Aci Journal Technical PaperpicottNoch keine Bewertungen

- Performance of High-Strength Concrete Corbels: Aci Structural Journal Technical PaperDokument9 SeitenPerformance of High-Strength Concrete Corbels: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Effect of High-Strength Concrete Columns On The Behavior of Slab-Column ConnectionsDokument8 SeitenEffect of High-Strength Concrete Columns On The Behavior of Slab-Column ConnectionspicottNoch keine Bewertungen

- Flexural Strength of Externally Prestressed Concrete BridgesDokument11 SeitenFlexural Strength of Externally Prestressed Concrete BridgespicottNoch keine Bewertungen

- Seismic Assessment of The Santa Monica Viaduct Bent Details: Aci Structural Journal Technical PaperDokument12 SeitenSeismic Assessment of The Santa Monica Viaduct Bent Details: Aci Structural Journal Technical PaperpicottNoch keine Bewertungen

- Bond Stress-Slip Response of Reinforcing Bars Embedded in FRC Matrices Under Monotonic and Cyclic LoadingDokument12 SeitenBond Stress-Slip Response of Reinforcing Bars Embedded in FRC Matrices Under Monotonic and Cyclic LoadingpicottNoch keine Bewertungen

- Ma-Mscmt-10 J16Dokument5 SeitenMa-Mscmt-10 J16Dilip BhatiNoch keine Bewertungen

- Describe The Physical Properties of Propylene Glycols.: PrintDokument4 SeitenDescribe The Physical Properties of Propylene Glycols.: PrintKaarthicNatarajanNoch keine Bewertungen

- The NT Insider: Writing Filters Is Hard WorkDokument32 SeitenThe NT Insider: Writing Filters Is Hard WorkOveja NegraNoch keine Bewertungen

- Figure 6-1. Frame Accessories Battery Figure 6-1. Frame Accessories BatteryDokument31 SeitenFigure 6-1. Frame Accessories Battery Figure 6-1. Frame Accessories BatteryalopezvillavicencioNoch keine Bewertungen

- GDCF 2 240 - 2nd - 01 10Dokument2 SeitenGDCF 2 240 - 2nd - 01 10edgardomichligNoch keine Bewertungen

- Oral and Practical Tests: MechanicDokument19 SeitenOral and Practical Tests: MechanicHugo AlmeidaNoch keine Bewertungen

- LMS Adaptive FiltersDokument14 SeitenLMS Adaptive FiltersalialibabaNoch keine Bewertungen

- Extrusion-Spheronization Process Variables and CharacterizationDokument57 SeitenExtrusion-Spheronization Process Variables and CharacterizationKhanh Le0% (1)

- Otago:Polytechnic: National Diploma in Drinking Water AssessmentDokument33 SeitenOtago:Polytechnic: National Diploma in Drinking Water AssessmentThomas CollinsNoch keine Bewertungen

- Tek 10-03Dokument4 SeitenTek 10-03Thai DamNoch keine Bewertungen

- Hybrid or Standard?: Why The Urge To "Go Green"Dokument20 SeitenHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonNoch keine Bewertungen

- Price Quotation: Quote/Project Description Ref. Details: Project DetailDokument3 SeitenPrice Quotation: Quote/Project Description Ref. Details: Project DetailAhmad AyyoubNoch keine Bewertungen

- Mktech Is1-19Hd & Receptor: Receptor PVR de Satelit Si Semnal Terestru Raport de TestareDokument7 SeitenMktech Is1-19Hd & Receptor: Receptor PVR de Satelit Si Semnal Terestru Raport de TestareAlexander WieseNoch keine Bewertungen

- Pure Chem p2 - 26pgDokument26 SeitenPure Chem p2 - 26pgJhomer CrespoNoch keine Bewertungen

- Linthwaite: Conservatio N AreaDokument26 SeitenLinthwaite: Conservatio N Areabill baileyNoch keine Bewertungen

- PARTSDokument10 SeitenPARTSTestrooteNoch keine Bewertungen

- Human-Environment InteractionDokument3 SeitenHuman-Environment Interactionapi-299100358Noch keine Bewertungen

- FD FX Brochure Update 072020Dokument9 SeitenFD FX Brochure Update 072020Alex PomaNoch keine Bewertungen

- TSB 1106 - MFY Starter Solenoid - ChangeDokument1 SeiteTSB 1106 - MFY Starter Solenoid - ChangeChrisMNoch keine Bewertungen

- Custom Validation ExampleDokument4 SeitenCustom Validation ExampleAbdul Bais StanikzaiNoch keine Bewertungen

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsDokument6 SeitenStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009Noch keine Bewertungen

- Datasheet SharePlexDokument2 SeitenDatasheet SharePlexBruno PóvoaNoch keine Bewertungen

- Emergency CallDokument6 SeitenEmergency CallNugrohoNoch keine Bewertungen