Beruflich Dokumente

Kultur Dokumente

12159

Hochgeladen von

NobodyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

12159

Hochgeladen von

NobodyCopyright:

Verfügbare Formate

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

WINTER 13 EXAMINATION

Model Answer

__

Important Instructions to examiners:

1) The answers should be examined by key words and not as word-to-word as given in the

model answer scheme.

2) The model answer and the answer written by candidate may vary but the examiner may try

to assess the understanding level of the candidate.

3) The language errors such as grammatical, spelling errors should not be given more

Importance (Not applicable for subject English and Communication Skills).

4) While assessing figures, examiner may give credit for principal components indicated in the

figure. The figures drawn by candidate and model answer may vary. The examiner may give

credit for any equivalent figure drawn.

5) Credits may be given step wise for numerical problems. In some cases, the assumed constant

values may vary and there may be some difference in the candidates answers and model answer.

6) In case of some questions credit may be given by judgement on part of examiner of relevant

answer based on candidates understanding.

7) For programming language papers, credit may be given to any other program based on

equivalent concept.

Q. 1 a) i) 1 mark per point

Framed Construction

Longitudinal members and cross

Frame less construction

members form the frame.

Heavy side members are eliminated and

floor is strengthened by cross member

and body, all are welded together.

Frame is up swept at rear and front to

used along with this type of construction

accumulate movement of the axle.

Eg. Tata, ashok leyland vehicles.

Body and frame are not integral units.

In some cases the sub frames are also

Eg. Small and medium cars, small buses

Body proper and frameless chassis

components are welded together to form

a rigid, integral unit for extra strength &

durability .

Stronger & Heavy construction

Higher impact resistance

Easier body repairs

Results in a light but stiff construction.

Less impact resistance

Repaires are expensive

Page 1 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

WINTER 13 EXAMINATION

Model Answer

__

Q. 1 a) ii) Sketch : 03 M , Labeling : 01 M

iii) The answer should reflect following key points. ( 04 M)

Aerodynamic shape of body reduces aerodynamic drag air resistance hence fuel

efficiency increases, Resistance to vehicle speed decreases.

Stream line of air flow around the vehicle should be continuous and separation of

boundary layer with its attendant vertices should be avoided. Skin drag coefficient

should be decreased by smooth and well polished body surface. This is achieved

with aerodynamic shape of body.

Aerodynamic shape of body reduces lift and pitching moment.

Lift is the vertical component of the resultant force caused by pressure distribution

on the vehicle body.

The lift acting vertically upward, tends to reduce the pressure between tyre and

ground. This causes loss of steering on front axle and loss of traction on rear axle.

Q. 1 a) iv) Battery Capacity :Is defined as amount of current it can deliver. It depends upon i) the number and area of

plate in cell and ii) quality of electrolyte present.

Page 2 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

Battery capacity decreases with decrease of temperature.

__

Battery Ratings :- Battery rating is determined by the current it can produce and the time

for which it can sustain this current.

Stating common battery ratings

Twenty hour rate (Ampere hour capacity)

Twenty minute rate.

Reserve capacity.

Cold rate (zero test).

( Definition 2 marks, stating ratings 2 marks )

Q1(b)

i) Rack and pinion type of gear box.

Construction:

The rack-and-pinion steering box has a pinion, connected to the steering column. This

pinion runs in mesh with a rack that is connected to the steering tie rods.

Both the pinion and the rack teeth are helical gears. Helical gearing gives smoother and

quieter operation for the driver.

Turning the steering wheel rotates the pinion, and moves the rack from side to side. Ball

joints at the end of the rack locate the tie-rods and allow movement in the steering and

suspension.

Mechanical advantage is gained by the reduction ratio. The value of this ratio depends on

the size of the pinion.

A small pinion gives light steering, but it requires many turns of the steering wheel to travel

from lock, to lock. A large pinion means the number of turns of the steering column is

reduced, but the steering is heavier to turn.

Page 3 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

Advantages:

WINTER 13 EXAMINATION

Model Answer

__

Provide low gear reduction for car.

Occupies less space and less number of linkages.

Uses: All most all small cars like maruti 800, Alto, Wagon R, Sweft Dezire, i10 etc houses this type

of steering gearbox.

( sketch : 02 M, working : 03 M, uses: 01 M)

ii) The answer should reflect the following salient areas of use. ( 02 M for each application))

Microprocessor is programmable device and can be used anywhere for developing electronic

circuit. this can be used as- 1. For performing logical operation 2. Arithmetical operation etc.

Microprocessors are used in many automotive systems: The electronic fuel injection system

uses an elaborate computerized control that takes into consideration engine conditions when

metering fuel and it's based on one or more microcontrollers. The system also controls spark

advance, EGR valve and other engine functions.

a) Motronic gasoline ignition system have a microprocessor based control system and

continuous correction of injected fuel quantity, ignition angle as well as air-fuel ratio

depending upon engine and external conditions. This ensures optimal engine

performance with minimum emission level. The main components are High pressure

fuel pump, injector on each cylinder, fuel rail and ECU.

ECU: Electronic Control unit consist of small programmed computer monitors and

performs that translates sensor signals in to command signals.

Various sensors employed are crankshaft speed sensor, camshaft speed sensor, knock

sensor, mass air flow sensor, manifold absolute pressure sensor, vehicle speed sensor

etc.

b) Natural gas motronic system: This type of system is installed on petrol and CNG Cars

function sin single ECU. It has advantages like,

i) at any time coordinated change can be made between petrol and CNG operation

without any jump in torque.

ii) lower cost

iii) greater potential for optimization.

c) Common Rail System: High pressure accumulator element called as rail is mounted on

engine block. This rail feeds all the injectors. The main components are low pressure

pump, high pressure pump, common rail and ECU.

d) The anti-lock brake system uses a microcontroller to compare the wheel speed when

brakes are applied and pulses the brakes when one or more wheel slips. In real-time

Page 4 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

computing systems, microprocessors are embedded in security devices such as the antilock braking system (ABS) that are widely used in modern automobiles.

The microprocessor detects motions and changes, that are relative to the surrounding or

environment of the security device and sends signals that correspond to the changes that

it detected.

Anti-lock brakes today use microprocessor technology to sense when the wheels are

about to lock up under braking, and then controls the brake pressure and timing to

prevent it.

Each wheel must be controlled independently, although only one axle of a multi-axle

configuration needs to be equipped with sensors. An exciter ring (sometimes referred to

as a tone ring) is installed on the inside of the hub.

A sensor reads the level of magnetism present as the teeth of the exciter ring pass it.

Since they don't touch, there is no wear or friction between them.

The sensors provide wheel speed information to the Electronic Control Unit (the ECU

or system brain). Input from the sensors is used to determine if a wheel is about to lock

during braking. If so, the system can release and apply the brake up to six times per

second through the modulator valve.

e) The radio uses specialized microcontrollers to track signal strength to tune the radio and

to lock in For example, Navigation systems provide information using microprocessors

and global positioning system (GPS) technology the memory buttons.

Page 5 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

Q. 2 a) sketch : 02 M , working : 02M

__

Construction :- There will be a lay shaft and splined main shaft. The dag clutches are

provided. They are free to slide as main shaft. The gears on lay shaft are fixed. All gears are

in constant mesh with corresponding gears on lay shaft.

Working : - when left dog clutch slides to left by means of selector mechanism, its teeth

are engaged with those on the clutch gear and we get the direct gear.

Same dag clutch, when slide to right makes contact with second gear.

Similarly movement of the right dog clutch to left results in lower gear and towards right in

reverse gear.

Double declutching: - for smooth engagement of dog clutches, it is necessary that speed of

main shaft gear and the sliding dog must be equal.

To obtain lower gear First clutch is disengaged and gears are brought to neutral position.

Then engage the clutch and press accelerator pedal for increases the speed of main shaft

gear, then disengage the clutch and dog clutch moves to required lower gear and engaged.

To obtain higher gear, driver has to wait with the gear in neutral till main shaft speed is

decreased sufficiently. Hence clutch is disengaged twice it is called double declutching.

Advantages :-

Page 6 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

Helical gears are used, quieter running.

__

High tongue transmission capacity.

Q. 2 b) ( any four points, 01 M for each point)

Single plate Clutch

It consists of flywheel, pressure plate,

Diaphragm clutch

To produce required pressure for

clutch plate with friction lining, along

engaging a conical spring called

with coil springs.

diaphragm is used.

It requires release of levers. Coil springs

are arranged circumferentially to provide

It requires no release of levers and

spring acts as series of levers.

axial force on the pressure plate.

Driver needs to exert high pressure to

pressure to hold clutch out of

hold clutch out of engagement.

engagement.

Less compact means of storing energy

compared to diaphragm clutch.

Coil spring has tendency to distort in

Load deflection curve is linear. With the

More compact means of storing energy

than coil spring.

transverse direction at high speeds.

Driver has not to exert as high a pedal

Less affected by centrifugal force, it

can withstand higher rotational speeds.

Load deflection curve is nonlinear.

wear of clutch facing, the springs have

When clutch face wears, force on plate

less deflection, they apply less force

gradually increases

against clutch plate

Page 7 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

Q. 2 c) sketch 03 marks labeling 01 mark

__

Q. 2 d) sketch : 02 marks description : 02 marks

Page 8 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

Working :

WINTER 13 EXAMINATION

Model Answer

__

It consists of worm of the end of steering rod. A nut is mounted on worm with two

sets of balls in the grooves of the worm in between the nut and worm.

The function of the bell is to reduce the friction between the worm and the nut. Nut

has number of teeth on outside which meshes with the teeth as worm wheel sector.

Drop arm is mounted on sector, which transfer the motion to steering arms through

linkages. When steering wheel turn, the balls in worm grove rolls, causes to nut slide

on the worm.

This linear motion of nut causes the wheel sector turn at an angle and actuate the

link rod through drop arm in desired steering of wheels.

Q. 2 e) (nomenclature : 02 M , specification : 02 M)

Specification of tyre :Tyres are specified on the basis of internationally recognized nomenclature :

An optional letter indicating intended tyre use ( P for passenger vehicle )

Width of tyre in mm.

A slash ie /

Aspect ratio as a percentage.

Nature of tyre carcass ( D-diagonals R for radial ply )

Diameter of wheel rim on which tyre is intended to fit in inches.

Load index.

Speed rating

Additional marks i.e traction, tread wear etc.

Page 9 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

WINTER 13 EXAMINATION

Model Answer

__

P205/75R1485H

Passenger car tyre, section width 205 mm.

Aspect ratio 75, radial ply, 14 inches rim wheel dia, load index 85, for maximum speed

130 mph or 210 kph.

Q. 2 f) sketch : 02 M, advantages : 02 M

Advantages over conventional metal springs.

1. A variable space for wheel deflection is put to optimum use by virtue of automatic

control device.

2. Change in head lamp alignment due to varying load are avoided.

3. Spring rate varies between the laden and unladen conditions as compared with

that of conventional steel springs. This reduces dynamic loading.

4. Improved standard of ride comfort and noise reduction.

Page 10 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

Q. 3 a) Explain the construction of steering linkages for independent front suspension with

neat sketches.

Sketch : 02 Marks

In the case of independent suspension, the two stub axles can move up or down independent

of each other due to which distance between ball joints ends of the two track and arms is

continuously varying. On account of this a single track rod cannot be used, instead three

track rods are used, the center portion being called the relay rod. Relay rod is connected at

one end to an idler arm supported on body structure and to the drop arm of the steering gear

at the other end through ball joints. The relay rod is restricted to move in horizontal plane

only. Movement in vertical plane is provided by the outer portion, viz, the tie rods about the

end ball joints, in case of conventional rigid axle suspension, the main axle beam ensures

the movement of stub axle in the horizontal plane only. In this there fore, there is no vertical

deflection of the suspension and hence there is no change in effective track rod length.

Suitable Explanation 2M

b) Define the following term with suitable sketches.

i) Camber :Definition :- Camber is the tilt of the car wheels from the vertical. It is the angle

between tyre center line and vertical.

Page 11 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

( Def. 01 Mark)

__

Sketch : 01 Mark

ii) Caster :Defin :- The angle between the king pin center line ( or steering axis ) and the

vertical, in the plane of the wheel is called the caster angle. ( Def. 01 Mark)

Sketch : 01 Mark

C) Enlist colour codes used in Automobile wiring system.

For quick identification, insulations of various wires in a circuit are assigned

different colours. Various colour codes are in use for vehicle wiring. They are as

follows.

Page 12 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

Sr. No.

WINTER 13 EXAMINATION

Model Answer

Code

Colour

01

Black

02

Br

Brown

03

Green

04

Blue

05

Lb

Light Blue

06

Lg

Light Green

07

Orange

08

Red

09

Yellow

10

White

11

B/Y

Black / Yellow

12

L/W

Blue / White

13

R/B

Red / Black

__

Any 8 colour codes M for each -- 04 M

d) Explain the working of water temperature gauge with neat sketch. ( 02 marks for

sketch, 02 marks for explanation)

It is an important accessory provided on engine but very economical. It gives indication

of temperature of cooling water to the driver at all times. It helps the motorist to avoid

serious consequences because of clogging of thermostat. When thermostat is clogged,

this will stop the circulation of water and results in very high rise in engine temperature.

So it is a safeguard accessory against engine overheating and protect from damage.

The temperature gauges are of two types.

01. Bourdon tube type :

Page 13 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

This has a bourdon tube inside, which is connected by a capillary tube to the element,

containing some volatile liquid at suitable temperature and which is inserted in the

cooling water circuit at an appropriate point, generally on the engine side of the

thermostat. As the temperature of cooling water increases, the liquid in the element

evaporates and exerts its pressure in the capillary, which is further transmitted to the

Bourdon tube Due to this pressure, the bourdon tube tries to straighten out and thus

moves a pointer attached to it, to show higher temperature on scale.

02. Electrically operated type : (Note :- There are two types of water temperature gauge students can write

explanation any one gauge either Bourdon tube type OR electrical gauge )

e) Explain the head lamp of vehicle with neat sketch.

Headlights are provided at the front of the auto vehicles to enhance the visibility of

driver by illuminating the road during night driving. They are required to illuminate the

road with even intensity in the immediate vicinity and far ahead of the vehicles front.

These objectives are achieved by the use of optical devices such as reflector, prism, lens

in conjunction with the bulbs fitted with in the headlight assembly. This assembly

consists of the following main parts.

01) Reflector :- This is made of either glass, or metal having aluminized coating on its

concave surface. Due to its curved and highly polished surface it reflects all the rays

being radiated from the bulb into a strong beam parallel to its axis.

Page 14 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

02) Pre-Focus bulb or filament: - Here filament is placed at a particular point F called

the focal point of the reflector. If the filament is not located at focal point then the

reflected rays also will be non-parallel to the axis of the reflector and will deviate

from it.

03) Lens :- the powerful beam of reflected light produced combined by the filament and

the reflector is not sufficient for proper illumination of the road, also it is essential

that the driver feels an identical intensity of reflected light at all the points on the

road. Therefore a lens is used to achieve both the effects.

04) Prism :- This is a triangular glass piece used to bend the light rays to any required

angle which is suitable for road illumination.

Suitable description 02 M

Q. 04 a)

i) Explain the working of battery coil ignition system with neat sketch.

( 02 Marks for sketch, 02 Marks for explanation)

Working :- There are two basic circuits in the system viz, the primary and secondary

circuits. The battery, primary winding of the ignition coil, condenser and the contact

breaker from the primary circuit, whereas the secondary winding of the ignition coil, the

distributor and the spark plugs constitute the secondary circuit.

When the ignition switch is in the on position the current flowing in the primary

circuit will grow exponentially during the make period of the contact breaker. The

electromagnetic energy on account of this build up of current in the primary circuit is

Page 15 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

stored in the laminated iron core of the ignition coil. As the contact breaker points open,

the magnetic field built up by the growth of the current collapses and the energy stored

during the make period is collapses and the every stored during the make period is

projected into the secondary circuit. It is this energy, which is suddenly passed onto the

secondary, inducing an e.m.f. there. As a result a sudden voltage surge of very high

amplitude is produced in the secondary, causing a spark to occur at the spark plug

electrodes.

ii) Explain the manufacturers of Automobiles in India and their products ( Any

four , 01 mark for each)

Manufacturer

Products

1. Maruti Udyog

1. Maruti 800, alto, swift, wagon R

2. Bajaj Automobiles ltd.

2. Scooter, auto, tempo trax, tempo

traveler.

3. Tata

engg.

And

locomotive

3. Truck, tata safari sierra, Indica V2

company ltd (TELCO)

4. Mahindra and Mahindra ltd.

4. Jeep, car, bolero, scorpio, logan

5. Ashok Leyland ltd.

5. Ashok Leyland truck

6. Hindustan motor

6. Ambassador, lancer

7. Standard motor product of India

7. Van, bus.

ltd.

8. Swaraj Mazda Automobile ltd.

8. Swaraj mazda bus, tempo

iii) State the function of Bendix Drive in starting system with neat sketch.

Page 16 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

Sketch 2 M

WINTER 13 EXAMINATION

Model Answer

__

Bendix drives are the inertia drives in which the starter motor pinion is made to

engage or disengage with the toothed ring on the periphery of the engine flywheel.

When the motor starts, the armature shaft rotates causing the sleeve to rotate

and because the pinion cannot rotate due to unbalance weight, it moves axially towards

the motor till it is engaged with flywheel. Further movement of the pinion is prevented

by the collar attached on the sleeve and because of this pinion has to start rotating. As it

is also in mesh with the engine flywheel, the flywheel is rotated and the engine starts.

When the engine starts, it is the flywheel that rotates the pinion and because of its

bigger size, the flywheel rotates the pinion much faster than the armature with the result

that the pinion is backed out of mesh with the flywheel. ( 02 marks)

iv) Explain Constructional details of charging system used ,in automobile.

The function of charging system in an automobile is to generate, regulate and supply

electrical energy for charging the battery. The charging system consists of a generator

for converting mechanical energy from the engine into electrical energy, regulator to

control the amount of electrical energy so produced, a relay to regulate the flow of the

charging current from the generator to the battery and an ammeter or indicating lamp to

indicate whether the system is operating or not.

Page 17 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

WINTER 13 EXAMINATION

Model Answer

__

( Any one of the above figure should be considered, figure preferred, but not

essential)( sketch: 01 Mark, suitable description 03 Marks)

In the modern cars, the charging system consists of an alternator only.

An electromagnet is mounted on a shaft and is supplied current for its energisation

from a battery through the slip rings and brushes. In series with the stator winding are

two diodes which are connected to external circuit.

Frame or housing

This encloses the entire alternator assembly and is made of cast aluminum in two

pieces. Aluminum is light weight, non magnetic and has higher thermal conductivity so

as to keep the alternator assembly cool by more efficient transfer of heat.

Rotor :- The most common is the claw pole rotor which consist of an iron core

around the rotor shaft many turns of copper wire are wound over the core on both sides

of the rotor winding are thick metal plates bent over the winding with triangular fingers

called poles.

Slip rings and Brushes :- The current to the rotor winding is carried through the

copper slip rings and carbon brushes. The brushes ride the surface of the slip rings on

the rotor under spring tension provided by the brush holder.

Stator :- Three phase alternator is commonly used in automobiles. Between two

halves of the alternator casing is situated the stator consisting of three sets of winding

wound over a laminated iron core.

Q. 4 b ) i) Working of Differential :- ( 02 marks for working & 02 marks for function)

Page 18 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

Arrangement of differential is as shown in figure .The crown wheel is fixed with casing .The inner

ends of half shaft pass through the boss of differential case in which they are free to rotate. When

vehicle is going straight , there is no relative movement among different gear. The cage & inner

gear rotate as single unit & both half shaft revolve at same speed.

When vehicle is taking turn towards left, at this time there will be resistance to the motion of

left wheel. The restrictions observed are at n rpm. As outer wheel has to cover more distance than

inner wheel thus the resultant speed at right wheel be (N+n) rpm and left wheel be (N-n) rpm.

Q. 04 b) ii) Explain working of telescopic type of shock absorber with neat sketch.

Sketch:-

Working :- when a vehicle come across the bump, the bottom eye is moved

upwards, then the fluid below the piston must be displaced to the top side of the piston, the

fluid will now pass through the outer ring of hole in the piston by lifting the top disc against

the disc spring. But the volume above the piston is less due to piston rod. As such, fluid

from the bottom of the piston will also get displaced through inner ring of holes in the foot

valve and enter the reservoir space between the cylinder and outer tube so the fluid level in

the reservoir space will rise. When the cylinder moves down ward, fluid will be displaced

form the upper end of the cylinder to lower end through the inner ring of hole in the piston

Page 19 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

by opening the lower disc valve against coil spring because of the volume of the piston rod

that leaves the cylinder, the fluid will be drawn into the lower end of the cylinder from the

reservoir space through the outer ring of hole in the foot valve. This passing of fluid through

opening provides damping.

Sketch 2 M

Suitable description 2 M

Q. 5 a) ( sketch 03 Marks, description 05 Marks)

To simplify the operation of changing gear so that this can be done by every type of

operator, skilled or unskilled driver without occurrence of teeth clashes and their consequent

damage, synchromesh gear box is used.

Principle of these devices is to bring the speeds of both the engine driven and gear box

output shaft driven gear which are to be engaged to the same rotational speed for moving their dog

clutches or equivalent meshing unit into engagement readily and quietly. This gear box is similar

with constant mesh gear box that the gear on main shaft, lay shaft are in constantly mesh. In this a

synchromesh device is used instead of dog, which equalizes the speed by friction after which these

may be engaged smoothly. Sketch is shown in fig. A is the engine shaft having clutch gear B rotate

at engine speed, gear B, C, D, E are on main shaft and gear U1, U2, U3, U4 are the gear on layshaft

U5, is the intermediate gear. F1 and F2 are the synchromesh members free to slide on main shaft

Page 20 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Model Answer

Subject Code: 12159

__

which is spline internally. G1 and G2 are the ring shape member having internal teeth which fit onto

external teeth of member F1 and F2, K1 and K2, L1 and L2 are dog teeth on gear B, C, D, E, T1,

and T2 are the ball supported by spring. S1 and S2 are the forks. To obtain low gear member F2

moves toward left which causes the friction contact between the cone shape surface of gear D and

member F2. Similarly for second gear the member F1 and G1 slide to the right so that finally the

internal teeth on G1 are engaged with L1, then the drive to main shaft from gear B-U1-U2-gear CG1-F1 to spline. A direct gear is obtained by sliding member F1 toward left.

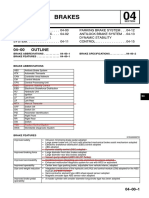

Q. 5 b) ( 01 mark for each point, 08 marks) alternative suitable points should be considered)

Disc Brake

Drum Brake

1. In drum brake, the friction occurs on

the internal surfaces from which

1. In disc brakes friction surfaces are

directly exposed to the cooling air.

heat can be dissipated only by

conduction.

2. Friction pads are flat.

2. Friction linings are curved.

3. There is no loss of efficiency due to

3. There is loss of efficiency due to

expansion.

expansion.

4. Less weight than drum brakes.

4. More weight than disc brake.

5. Better anti-fade characteristics than

5. Less anti-fade characteristics than

drum brake.

6. Simple in design than drum brake.

7. It contains small number of parts to

wear.

8. Easy to replace friction pads.

disc brake.

6. Complicated in design than disc

brake.

7. It contains large number of parts,

chances of wear is more.

8. Difficult to replace curved friction

linings.

Page 21 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

Q. 5 C)( Function 02 marks, components 02 marks,sketch 02 marks & construction 02 marks)

Battery is the main part of the electrical system in an automobile. Without battery,

engine cannot be started with the starting motor. The battery supplies current to various part

of the automobile vehicle such as for starting motor, ignition system, head and tail light,

brake light, to wiper and other accessories.

Components of battery :

1) Container 2) Plates and grids 3) Separator

4) Cell cover 5) Cell Connector

Construction :Container :- It is constructed in single piece and made of acid resistant of hard rubber or

plastic or bituminous composition. It is divided by partitions into compartments for

individual cell. Ribs are there at the bottom of each compartment. Battery plates rest on

these ribs.

Grids and Plates :- Plates are made of lead alloy containing 6 to 8% antimony which gives

them resistant to corrosion and gives strength and rigidity. Number of plates of positive and

negative types and separetators are there in a cell positive plates are kept one less than the

negative plate.

Page 22 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

Separator :- Separators are placed between the negative and positive plates. This prevents

the positive and negative plates from direct contact with each other. They are porous to

permit electrolyte to circulate between the plates. They are made of wood, spun glass,

porous glass, porous rubber sheet etc.

Cell Cover :- each cell is sealed by a cover of hard rubber through which the positive and

negative terminals are projected. Cover has an opening for filling the electrolyte and a filler

cap is provided with an air vent to escape the gases.

Electrolyte :- Electrolyte is a chemically pure sulphuric acid diluted with distilled water. It

consist of 40% sulphuric acid and 60% distilled water.

Cell connectors :- connector straps connect the negative and positive terminal post of the

adjacent cell just above the cell cover.

Q. 6 A) The automobiles are classified as follows. ( any four points, 01 mark for each- 04 M)

1. According to use :- Auto cycle or moped, car & jeep buses and trucks.

2. According to capacity: - Heavy transport vehicle Trucks & buses.

Light transport vehicle Car, Jeep Minibus.

3. According to fuel :- Petrol vehicle, Diesel Vehicle Gas Vehicle, Solar Vehicle.

4. According to wheels :- Two wheeler, there wheeler, four wheeler six wheeler.

5. According to drive :- Left hand drive, Right hand drive front wheel drive, Rear wheel

drive ,all wheel drive.

6. According to transmission :- Conventional gear box, semiautomatic gear box. Automatic

gear box.

7. According to suspension system :- conventional (Rigid ) system, Independent system.

8. According to engine fitting :- Front engine, Rear engine, transverse under floor engine.

Page 23 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

Q. 6 B) Overdrive :-( 02 marks for sketch, 02 marks for description)

__

This is a device that helps the propeller shaft to rotate faster than the engine in the

transmission. By employing this engine speed can be reduced by 20 to 25 % allowing high

cruising at low engine speed. So advantage of this is to increase engine life, improve fuel

consumption also reduce noise and vibration. It increases gear ratio available by fitting it to

intermediate gear. It can be operated automatically or manually. It reduces engine wear and

tear because of driven road speed, the engine speed is less. It is easy for engagement and

disengagement.

Q. 6 C) Transfer Case :- ( 02 marks for use ,02 marks for sketch)

Page 24 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

Subject Code: 12159

WINTER 13 EXAMINATION

Model Answer

__

It enables the driver to

i)

Drive in two wheel drive on highway or shift to four wheel drive for cross country

operation.

ii)

To drive in high gear or low gear as required obviously low gear is used for cross

country driving.

There are two output shafts, one going to the front axle and the second going to rear

axle.

Q. 6 D) Necessity of wheel alignment :1. Provides an easier direction control to the vehicle.

2. Minimum tyre wear.

3. Stability to the vehicle while negotiating a curve.

4. Parallel rolling of front wheels moving straight.

(01 Mark)

Necessity of Wheel Balancing :- Due to improvements in engine, handling as well as in

body aerodynamic it is becoming possible for automobiles to operate at higher and higher

speeds every year.

At high speeds, an unbalanced wheel assembly can create vibrations which are transmitted

to the body through suspension components, causing annoyance to the driver and passenger.

Therefore it is necessary to balance the wheel assemblies properly in order to eliminate such

vibrations.

( 01 mark)

Procedure of wheel balancing :- This can be done by using electronic balancer

1. Lift the front wheels on hydraulic jack such that the wheel is freely rotated.

2. Arrange the spinner, which carries the balancer equipment.

3. Move the balancer into position to point to strobe light at the wheel.

Page 25 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

4. Position the pickup magnet in contact with a clean flat surface on the front suspension

as closed to the wheel as possible.

5. Apply the reference mark on the wheel cap on the tyre.

6. Shift the balancer to position I

7. Start the wheel by hand, snap on the switch of the spinner, motor and hold the spinner

pulley against the tyre tread to revup the wheel.

8. Repeat the above inspection procedure and note maximum needle reading on meter

dial.

9. Repeat the check as directed previously. If the wheel is still out of balance, proceed

with the balance procedure, till the meter needle remains in the green area. ( 02 marks)

Q. 6 E)

01 mark for sketch

Page 26 of 27

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

(Autonomous)

(ISO/IEC - 27001 - 2005 Certified)

WINTER 13 EXAMINATION

Subject Code: 12159

Model Answer

__

A Macpherson, an engineer, developed a single wishbone with a telescopic strut

type suspension system. In this system, there is a telescopic strut type shock absorber, a

single arm and a diagonal stay. A strut is fixed to the body structure at the upper end

through a flexible mounting and a lower part of the strut is connected at the bottom by a

joint to the lower arm. The lower part of the strut also carries the stub axle, which in turn

carries the wheel. The steering motion is supplied to the lower part of the strut and it turns

the whole strut. A coil spring and a hydraulic damper surround the upper part of the strut

which takes care of the road roughness shocks and vibration. ( 02 marks)

Name of vehicles in which this type of suspension is used Maruti Zen, maruti alto Maruti

Swift. ( any two names, 01 mark)

Page 27 of 27

Das könnte Ihnen auch gefallen

- The Four Walls: Live Like the Wind, Free, Without HindrancesVon EverandThe Four Walls: Live Like the Wind, Free, Without HindrancesBewertung: 5 von 5 Sternen5/5 (1)

- Product Design and DevelopmentDokument14 SeitenProduct Design and Developmentapi-279168957Noch keine Bewertungen

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDokument28 SeitenBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledCordillera St. JosephNoch keine Bewertungen

- Time: 03 Hours Maximum Marks: 100 Instructions To CandidatesDokument2 SeitenTime: 03 Hours Maximum Marks: 100 Instructions To CandidatesAa BbNoch keine Bewertungen

- Product Design and DevelopmentDokument8 SeitenProduct Design and DevelopmentAnonymous d6EtxrtbNoch keine Bewertungen

- Bortole M Design Control Robotic Exoskeleton Gait Rehabilitation Tesis Master PDFDokument95 SeitenBortole M Design Control Robotic Exoskeleton Gait Rehabilitation Tesis Master PDFMuizzuddin RosliNoch keine Bewertungen

- Vehicle Layout Transmission SystemsDokument38 SeitenVehicle Layout Transmission SystemsKhan Liyaqat100% (1)

- Springs (Compatibility Mode)Dokument50 SeitenSprings (Compatibility Mode)srwickedsunnyNoch keine Bewertungen

- Manpower Development For Technological ChangesDokument6 SeitenManpower Development For Technological ChangesKRITIKA NIGAMNoch keine Bewertungen

- Departments PDFDokument408 SeitenDepartments PDFAshlin AugustyNoch keine Bewertungen

- A Progress Report On Design and Development of MEMS Based SensorDokument3 SeitenA Progress Report On Design and Development of MEMS Based Sensorarun14089Noch keine Bewertungen

- Advanced IC EngineDokument6 SeitenAdvanced IC EngineThulasi RamNoch keine Bewertungen

- Engineering Entrepreneurship Key to Nigerian EconomyDokument12 SeitenEngineering Entrepreneurship Key to Nigerian EconomyAnonymous tSYkkHToBP100% (1)

- 2016 IA-HEV BOOK Web PDFDokument339 Seiten2016 IA-HEV BOOK Web PDFVMarochiNoch keine Bewertungen

- Machine vision systems for real-time inspectionsDokument30 SeitenMachine vision systems for real-time inspectionsAnudeep VeeranNoch keine Bewertungen

- Parabolic Solar CollectorDokument9 SeitenParabolic Solar CollectorWise manNoch keine Bewertungen

- Chapter 1 Units and StandardsDokument26 SeitenChapter 1 Units and Standardsra malNoch keine Bewertungen

- Prototyping: Presented by Pradeep PandeyDokument16 SeitenPrototyping: Presented by Pradeep PandeyPradeep Kumar PandeyNoch keine Bewertungen

- CAD Drawing M1911ADokument59 SeitenCAD Drawing M1911AAngela Uselton100% (1)

- Design and ManufacturingDokument49 SeitenDesign and ManufacturingThulasi Doss100% (2)

- HRM AssignmentDokument6 SeitenHRM Assignmentanilkumar5292Noch keine Bewertungen

- Beam EngineDokument37 SeitenBeam EngineTanviNoch keine Bewertungen

- 15me835 PLCM Module 1Dokument15 Seiten15me835 PLCM Module 1prashanth prabhuNoch keine Bewertungen

- Soft Robots Modeling A Structured OverviewDokument21 SeitenSoft Robots Modeling A Structured Overview维尔Noch keine Bewertungen

- 3D PrintingDokument18 Seiten3D PrintingkishanNoch keine Bewertungen

- Hawassa University Designs Automatic Emergency Braking SystemDokument25 SeitenHawassa University Designs Automatic Emergency Braking SystemYosef TesfayeNoch keine Bewertungen

- Executive SummaryDokument11 SeitenExecutive SummaryNitish Kumar SinghNoch keine Bewertungen

- Coil SpringDokument14 SeitenCoil SpringLeti HanajNoch keine Bewertungen

- Chapter 4 - Advanced Programming TechniquesDokument3 SeitenChapter 4 - Advanced Programming TechniquesRitesh SharmaNoch keine Bewertungen

- Human Resource ManagementDokument63 SeitenHuman Resource ManagementAbegail NuylanNoch keine Bewertungen

- Automobile PDFDokument58 SeitenAutomobile PDFjaycee68Noch keine Bewertungen

- TYPES OF ORGANISATION STRUCTURES EXPLAINEDDokument35 SeitenTYPES OF ORGANISATION STRUCTURES EXPLAINEDVijayBhasker VeluryNoch keine Bewertungen

- Organization Study ReportDokument44 SeitenOrganization Study ReportGovind ChowdharyNoch keine Bewertungen

- DOME-I Unit 1 - GDokument17 SeitenDOME-I Unit 1 - GGautam GunjanNoch keine Bewertungen

- Types of Production SystemsDokument34 SeitenTypes of Production SystemsAnuradha GaikwadNoch keine Bewertungen

- Industrial ManagementDokument10 SeitenIndustrial ManagementHimanshu GautamNoch keine Bewertungen

- Product Design and DevelopmentDokument16 SeitenProduct Design and DevelopmentTedy ThomasNoch keine Bewertungen

- Report On Tesla Model 3 (Rough)Dokument7 SeitenReport On Tesla Model 3 (Rough)Sadia Sultana LikhanNoch keine Bewertungen

- Adjustable Stair-Climbing Trolley for Load TransportDokument19 SeitenAdjustable Stair-Climbing Trolley for Load Transportaniket patil100% (1)

- EEE 212 - Infix to Postfix ConversionDokument2 SeitenEEE 212 - Infix to Postfix ConversionbayentapasNoch keine Bewertungen

- Flowcharting ExplainedDokument8 SeitenFlowcharting ExplainedBagus SuryandaruNoch keine Bewertungen

- Trend Change Into Rolling Stock Maintenance by Car-BuilderDokument19 SeitenTrend Change Into Rolling Stock Maintenance by Car-BuilderADBI EventsNoch keine Bewertungen

- Case StudyDokument2 SeitenCase StudyAnam ShoaibNoch keine Bewertungen

- Multi Track Pit Traverser Vs 2 Track SSC Surface TraverserDokument16 SeitenMulti Track Pit Traverser Vs 2 Track SSC Surface TraverserAmin PaniwalaNoch keine Bewertungen

- Tesla's Quality Challenges 1Dokument16 SeitenTesla's Quality Challenges 1dolapoNoch keine Bewertungen

- Honors Electric Vehicles 2019 CourseDokument8 SeitenHonors Electric Vehicles 2019 CourseSawai PareshNoch keine Bewertungen

- EHU-601 Industrial ManagementDokument214 SeitenEHU-601 Industrial Managementvivek.birla100% (1)

- OMF551-Product Design and DevelopmentDokument17 SeitenOMF551-Product Design and DevelopmentRAMANI PRIYA0% (1)

- Customer Interaction ManagementDokument34 SeitenCustomer Interaction ManagementSandeep MoharanaNoch keine Bewertungen

- Exoskeleton Chairless ChairDokument31 SeitenExoskeleton Chairless ChairNithin PradeepNoch keine Bewertungen

- Autonomous Lawnmower ConceptDokument10 SeitenAutonomous Lawnmower ConceptKeeganNoch keine Bewertungen

- Tutor Finder App Report - Find Private Tutors EasilyDokument35 SeitenTutor Finder App Report - Find Private Tutors EasilyarjNoch keine Bewertungen

- LINE FOLLOWING ROBOT Without Microcontrollers.Dokument11 SeitenLINE FOLLOWING ROBOT Without Microcontrollers.حمایت علی قریشیNoch keine Bewertungen

- Manufacturing SystemsDokument14 SeitenManufacturing SystemsPradeep Kumar MehtaNoch keine Bewertungen

- Evolution OSCMDokument1 SeiteEvolution OSCMsanzitNoch keine Bewertungen

- Introduction of Mechanical EngineeringDokument5 SeitenIntroduction of Mechanical EngineeringMuhamad Eko FebriansyahNoch keine Bewertungen

- Book Review You Can Win - Shiv KheraDokument11 SeitenBook Review You Can Win - Shiv Kheraarun19740% (1)

- Decoding The Dna of Toyota's Production SystemDokument7 SeitenDecoding The Dna of Toyota's Production SystemBiswajit PrustyNoch keine Bewertungen

- PrefaceDokument49 SeitenPrefaceManish RajakNoch keine Bewertungen

- Entrepreneurship Development Programs 2003Dokument22 SeitenEntrepreneurship Development Programs 2003Bharat Choudhary100% (1)

- 12157Dokument24 Seiten12157NobodyNoch keine Bewertungen

- 2-5-1 Jazz Scale ExercisesDokument2 Seiten2-5-1 Jazz Scale Exercisesμιχαλης καραγιαννης83% (6)

- 2-5-1 Jazz Scale ExercisesDokument2 Seiten2-5-1 Jazz Scale Exercisesμιχαλης καραγιαννης83% (6)

- Music Sheet Bateman Trevor Scarborough Fair 26015Dokument4 SeitenMusic Sheet Bateman Trevor Scarborough Fair 26015Carol PereiraNoch keine Bewertungen

- Ivanova T F Novy Orfoepicheskiy Slovar RusskoDokument907 SeitenIvanova T F Novy Orfoepicheskiy Slovar RusskoNobodyNoch keine Bewertungen

- 12156Dokument27 Seiten12156NobodyNoch keine Bewertungen

- 12158Dokument16 Seiten12158NobodyNoch keine Bewertungen

- 12160Dokument22 Seiten12160NobodyNoch keine Bewertungen

- FDokument21 SeitenFNobodyNoch keine Bewertungen

- Document 1Dokument1 SeiteDocument 1NobodyNoch keine Bewertungen

- 12155Dokument25 Seiten12155NobodyNoch keine Bewertungen

- 12154Dokument20 Seiten12154NobodyNoch keine Bewertungen

- !!!catia V5R12 Mechanical Design Solutions 1Dokument2.065 Seiten!!!catia V5R12 Mechanical Design Solutions 1api-26678597100% (2)

- Past Continuous Tense ExercisesDokument2 SeitenPast Continuous Tense ExercisesNobodyNoch keine Bewertungen

- MangloreDokument1 SeiteMangloreNobodyNoch keine Bewertungen

- Trades Math Workbook PDFDokument32 SeitenTrades Math Workbook PDFDiyaNegiNoch keine Bewertungen

- An Industrial Visit Report to Anjani Cement PlantDokument9 SeitenAn Industrial Visit Report to Anjani Cement PlantNobodyNoch keine Bewertungen

- Shell Case Study PDFDokument2 SeitenShell Case Study PDFNobody100% (1)

- Chip PoemDokument1 SeiteChip PoemNobodyNoch keine Bewertungen

- Elements-Of-Urban-DesignDokument9 SeitenElements-Of-Urban-DesignNobodyNoch keine Bewertungen

- URBAN SIGNAGE AND SYMBOLSDokument9 SeitenURBAN SIGNAGE AND SYMBOLSNobodyNoch keine Bewertungen

- 8th Grade Ela Summer PacketDokument4 Seiten8th Grade Ela Summer PacketNobodyNoch keine Bewertungen

- Hunter Zolomon - Wikipedia, The Free Encyclopedia PDFDokument7 SeitenHunter Zolomon - Wikipedia, The Free Encyclopedia PDFNobodyNoch keine Bewertungen

- PRTG Report 2072 - Report - Created 2015-06-18 12-06-30 (2015-06-18 00-00 - 2015-06-18 00-00) UTCDokument2 SeitenPRTG Report 2072 - Report - Created 2015-06-18 12-06-30 (2015-06-18 00-00 - 2015-06-18 00-00) UTCNobodyNoch keine Bewertungen

- Pedro Antunes, Nuno Guimar Aes, Javier Segovia, Jesus CardenosaDokument9 SeitenPedro Antunes, Nuno Guimar Aes, Javier Segovia, Jesus CardenosaNobodyNoch keine Bewertungen

- BallsDokument1 SeiteBallsNobodyNoch keine Bewertungen

- Benchmarking Red Ribbon vs Goldilocks BakeriesDokument4 SeitenBenchmarking Red Ribbon vs Goldilocks BakeriesNobody100% (3)

- RC Time Constant Experiment ResultsDokument2 SeitenRC Time Constant Experiment ResultsNobodyNoch keine Bewertungen

- Sribd PT.2Dokument1 SeiteSribd PT.2NobodyNoch keine Bewertungen

- Manual: Please Use It Often Reading. Let's Keep The Manual in The CarDokument12 SeitenManual: Please Use It Often Reading. Let's Keep The Manual in The Carmohd rudy azuanNoch keine Bewertungen

- Section One: Reading ComprehensionDokument3 SeitenSection One: Reading ComprehensionHou HouNoch keine Bewertungen

- Catalogo Tokico 2012Dokument316 SeitenCatalogo Tokico 2012Андрей СилаевNoch keine Bewertungen

- Project Report ON: "A Study of Consumer Behaviours and Satisfaction With Hyundai Motors"Dokument105 SeitenProject Report ON: "A Study of Consumer Behaviours and Satisfaction With Hyundai Motors"Mayank AgrawalNoch keine Bewertungen

- Honda ListDokument8 SeitenHonda Listmoderncorporation402Noch keine Bewertungen

- Remote Functions PDFDokument14 SeitenRemote Functions PDFBenz Aio Calachua AraujoNoch keine Bewertungen

- Nissan Car Fault Codes DTCDokument1.060 SeitenNissan Car Fault Codes DTCnanteza florenceNoch keine Bewertungen

- Circuito Electrico Volqueta de Bajo Perfil DuxDokument1 SeiteCircuito Electrico Volqueta de Bajo Perfil DuxMarvin Tejerina GarfiasNoch keine Bewertungen

- Car Workshops in Petaling JayaDokument8 SeitenCar Workshops in Petaling JayaNavin CheckerzNoch keine Bewertungen

- Volvo TruckDokument21 SeitenVolvo TruckJOAONoch keine Bewertungen

- Fj180V Kai: Owner, S ManualDokument11 SeitenFj180V Kai: Owner, S ManualThong KimNoch keine Bewertungen

- Factors Affecting Knocking in Si Engines PDFDokument2 SeitenFactors Affecting Knocking in Si Engines PDFFrancisco0% (1)

- 49-57 CarDokument149 Seiten49-57 CartruckshopNoch keine Bewertungen

- Modelling, Simulations, and Optimisation of Electric Vehicles For Analysis of Transmission Ratio SelectionDokument15 SeitenModelling, Simulations, and Optimisation of Electric Vehicles For Analysis of Transmission Ratio SelectionKyla WindartaNoch keine Bewertungen

- 2004 KX125 Racing TuningDokument5 Seiten2004 KX125 Racing Tuningdinamik2t100% (1)

- ME 6404 Thermal Engineering UNIT I Question BankDokument8 SeitenME 6404 Thermal Engineering UNIT I Question BankRiyaz haja MohideenNoch keine Bewertungen

- Bajaj Diesel Maxima Z C+ +xwide Bs4Dokument84 SeitenBajaj Diesel Maxima Z C+ +xwide Bs4sparesbajajNoch keine Bewertungen

- Wheelchair Electrical ManualDokument36 SeitenWheelchair Electrical Manualxerox4512Noch keine Bewertungen

- Log WVWZZZ1KZBW221099 180170km 111952miDokument9 SeitenLog WVWZZZ1KZBW221099 180170km 111952miManjula GovindNoch keine Bewertungen

- MNPTP - 01 - 8-16A Ton IntroductionDokument20 SeitenMNPTP - 01 - 8-16A Ton IntroductionGlobal Teknik Abadi100% (1)

- Brake+system New ModelDokument30 SeitenBrake+system New ModelTimkenNoch keine Bewertungen

- 2003-2006 Scarabeo 500 PartsDokument87 Seiten2003-2006 Scarabeo 500 PartsRon TalayNoch keine Bewertungen

- TG 04Dokument35 SeitenTG 04chrideer100% (1)

- Steering Column Parts ListDokument20 SeitenSteering Column Parts ListNaimahSulistianingsihNoch keine Bewertungen

- Price List for Shock Absorbers and StrutsDokument4 SeitenPrice List for Shock Absorbers and StrutsMaracutaia GratisNoch keine Bewertungen

- TVS_Radeon_BSVI_WIRINGDokument4 SeitenTVS_Radeon_BSVI_WIRINGstarlinwooNoch keine Bewertungen

- General Pipe Cleaners General Root 66Dokument2 SeitenGeneral Pipe Cleaners General Root 66sugeyNoch keine Bewertungen

- Suzuki SX4 - BrochureDokument16 SeitenSuzuki SX4 - Brochurerazvan_matei100% (2)

- Auto Air Suspension PDFDokument22 SeitenAuto Air Suspension PDFPranjal Nimase100% (2)