Beruflich Dokumente

Kultur Dokumente

Isolation, Purification and Characterization of Mannanase From Bacillus Subtilis MAN-511

Hochgeladen von

IJSTEOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Isolation, Purification and Characterization of Mannanase From Bacillus Subtilis MAN-511

Hochgeladen von

IJSTECopyright:

Verfügbare Formate

IJSTE - International Journal of Science Technology & Engineering | Volume 2 | Issue 11 | May 2016

ISSN (online): 2349-784X

Isolation, Purification and Characterization of

Mannanase from Bacillus subtilis MAN-511

Dwi Retnaningtyas Utami

Student of Magister Program

Department of Food Science and Technology

Faculty of Agricultural Technology, Brawijaya University,

Malang. East Java

Aji Sutrisno

Lecturer

Department of Food Science and Technology

Faculty of Agricultural Technology, Brawijaya University,

Malang. East Java

Joni Kusnadi

Lecturer

Department of Food Science and Technology

Faculty of Agricultural Technology, Brawijaya University, Malang. East Java

Abstract

A bacterium, MAN-511 that produced extracellular mannanase, was isolated and identified as Bacillus subtilis on the basis of 16S

rDNA phylogenetic analysis. The enzyme was purified to apparent homogeneity by precipitasi ammonium sulfat 70% and

Sephadex G-75 chromatography procedures. The mannanase was purified 7.6 fold and specificity of 9.3 U/mg protein. SDS-PAGE

of the purified enzyme showed a single protein band of molecular mass 45.08 kDa. The mannanase activity from this strain had

optimum pH of 7.0, stable at a pH 6-7, optimum temperature at 30C and stable at 30-40C. In addition, crude mannanase

preparation were successfully employed for the degradation of glucomanan which has been proved by reduce of viscosity.

Keywords: Bacillus subtilis sp., Glucomannan, Mananase, Purification, Porang (Amorphophallus muelleri Blume)

________________________________________________________________________________________________________

I.

INTRODUCTION

-Mannanase is an important enzyme for the depolymerization of these polymers. It hydrolyzes the -1,4-linkages within the

mannan backbone, releasing mannooligosaccharides of various lengths [1]. Over the years, there has been increasing interest in

the potential application of -1,4-mannanases in various industrial processes. Hemicellulases, including -mannanase, play an

important role in the bioconversion of lignocellulose material. The coconut residue is a source of highly concentrated mannan

which can be hydrolyzed by mannan-degrading enzyme system to produce single-cell protein [2]. However, few above-mentioned

bacteria were isolated from environment containing polysaccharides such glucomannan, which brings in some problem like the

lower yield of the mannanases and higher production costs for industrial application [3]. To overcome these short comings, we

screened predominant microorganisms in soil of Amorphophallus konjac field to investigate new bacteria with high mannanase

activity. Furthermore, research indicated that this strain can produce extracellular enzyme to degrade glucomannan. This work

describes the isolation, purification and characterization of the extracellular mannanase from a newly isolated Bacillus subtilis

MAN-511.

II. MATERIAL AND METHODS

Chemicals and Media

Glucomannan, the media were consisted of 1% glucomannan, 0.5%pepton, 0.12%KH2PO4 and 0.02 % MgSO4.7H2O, 1.3% agar,

aquades, alcohol 70%, etanol 95%, KH2PO4, MgSO4.7H2O, CaCl2, MgCl2, FeSO4, CuSO4, NaCl, ZnCl2, BaCl2, Natrium acid,

EDTA, Na2CO3, citrat acid, glicerol, phenol, Na-metabisulfit, HCL 0,1N, 3,5dinitrosalisilat (DNS), congo red, buffer acetat pH

4-5, buffer phospat pH 6-7 and buffer Tris-HCL pH 8-9. Akrilamid (SIGMA), -merkaptoetanol, Bis-akrilamid, TEMED, APS,

Tris base, glicin, selofan, sephadex G-75.

Isolation of Microorganisms

Soil and glucomannan were put into Erlenmeyer and incubated at 37C, 48 hours. Plate containing glucomannan (1% glucomannan,

0.5%pepton, 0.12%KH2PO4 and 0.02 % MgSO4.7H2O, and 1.3% agar). After 24 h, the colony was picked out and stained with

congo red. The colony with clear zone was selected for further experiment.

All rights reserved by www.ijste.org

83

Isolation, Purification and Characterization of Mannanase from Bacillus subtilis MAN-511

(IJSTE/ Volume 2 / Issue 11 / 011)

Phylogenetic analysis by 16S rRNA of the MAN-511

The PCR was performed to amplify the 16S rRNA coding region, using two oligonucleotide primers, 5'

GGTTACCTTGTTACGACTT - 3' and 5' AGAGTTTGATCCTGGCTCAG - 3'. The PCR products were subcloned into Applied

Biosystems GeneAmp PCR System 9700. Sequencing was performed with 96-well sequencer (Applied Biosystem 3130 Genetic

Analyzer), in Sequencing Laboratory, Biologi Molecular Eijkman ABI Prism 3100 Genetic Analyzer Sequencing Chemistry Guide

(ABI PN 4315831). Homology alignment was performed with the MEGA 6 program.

Enzyme Production

The bacterial culture was first amplified at 37C in liquid medium and then grown on a defined agar medium, using 1% (w/vl)

glucomanan as carbon source. Colonies grown on this agar medium were first amplified by vigorous shaking at 37C in 25 mL

liquid medium. The overnight cultures were then further amplified under identical conditions in 250 mL of the same medium until

growth had reached stationary phase (18h). After centrifugation at 8500 rpm for 15 min, the bacterial pellet was gently transferred

into buffer citrate acid pH 6. Maximum hemicellulase activities occurred within 48 h and were monitored as described below.

Purification of the Mannanase.

Ammonium Sulfate [(NH4)2SO4] Fractionation and Dialysis

A volume of one litre of crude mannanase was taken initially and then the required quantity of ammonium sulfate was added

slowly to obtain various saturation levels (40%-80%). Proteins were precipitated and then separated by centrifugation at 8500 rpm

4C for 15 min. The separated proteins were then dissolved in a minimum amount of 0.05 M citrat buffer (pH 6) and refrigerated

for further analysis. Precipitated proteins were transferred into a dialysis tube using a micropipette and dialyzed against citrat buffer

(0.05 M, pH 6) at 4C. Dialysis was conducted overnight and the buffer was changed several times to increase the efficiency of the

dialysis.

Filtration Gel chromatography

The dialyzed enzyme was loaded onto a filtration gel column (1 60 cm) equilibrated with citrate buffer (0.05 M, pH 6) and the

column was washed with the same buffer. The enzyme bound to sephadex G-75 was eluted with a buffer (50 mM, pH 6). Fractions

were collected at a flow rate of 4 min/mL, and fractions (1 ml) were collected. All fractions were checked for protein (A280) and

-mannanase activities (A540).

Zymogram Analysis and Molecular Mass Determination by SDS-PAGE

Protein bands were stained with Coomassie Brilliant Blue. For zymogram analysis, a substrate gel was prepared by adding 1%

agarose to a 1% glucomanan solution and heating until the agarose dissolved. After electrophoresis, the native gel was placed on

the substrate gel. The two gels were then incubated at 50C for 3 h followed by staining of the substrate gel using 0.1% (w/v)

Congo red solution for 20 min. The gel was destained using 2 M NaCl for 15 min. Electrophoresis was done on 12% gel and the

separated protein band was detected by Coomassie blue staining. The separating gel consisted of 12% polyacrylamide and the

stacking gel consisted of 30% polyacrylamide. The sample (25 l) and 25 l of sample buffer with 50 mM Tris HCl (pH 6.8), 10%

SDS, 0.1% bromophenol blue, -mercaptoethanol, and glycerol were loaded into the well. Molecular mass markers were purchased

from Biosains, University of Brawijaya Malang-Indonesia.and were run parallel to the samples.

Determination of Protein Content

Protein content was determined by the method of Bradford (1976) [4]. Standard curve was plotted using Bovine serum albumin

(Sigma, U.SA.).

Assay for Mannanase Activity

1% (w/v) glucomanan dissolved in 0.05 M citrate buffer at pH 6 was used as the substrate mixture. 1 mL of the substrate mixture

was added to 1ml of the crude enzyme solution and incubated in a water bath at 30C for 30 minutes. Afterwards 1mL of

dinitrosalicylic acid (DNS) was added to 0.5 mL of each enzyme substrate mixture and boiled for 15 minutes. The absorbance

of the mixture was thereafter measured at 540 nm in a spectrophotometer. The amount of mannose released was determined by the

method of Miller, (1959). One unit of mannanase was defined as the amount of mannanase that released 1 micromole of mannose

in one millimeter of the reaction mixture under the assay conditions.

Biochemical Characterization of -Mannanase

Determination of optimum pH and pH stability

The optimum pH of enzyme activity was examined at pH 4.0-9.0 under standard assay conditions. 0.05M of buffers were used

citrate (pH 4.0-9.0). The enzyme reaction was incubated at 30C for 30 min in the presence of 1% glucomanan dissolved in the

buffers. The effect of pH on enzyme stability was determined using the same buffer system in the pH range of 4.0-9.0. Then, the

remaining enzyme activity was measured (A 540 nm).

Determination of Optimum Temperature and Temperature Stability

The effect of temperature on enzyme activity was performed at temperatures ranging from 30-60C in 0.05M citrat buffer at

optimum pH for 30 min. Thermal stability of the enzyme was determined at various temperatures in 0.05M buffer at optimal pH

for 30 min. Then, the remaining enzyme activity was measured (A 540 nm).

All rights reserved by www.ijste.org

84

Isolation, Purification and Characterization of Mannanase from Bacillus subtilis MAN-511

(IJSTE/ Volume 2 / Issue 11 / 011)

Viscosity Measurements

Viscosity of glucomanan liquid was measured with a viscometer. Each measurement was repeated three times. For the

determination of the relationship between specific fluidity of glucomanan and the released reducing sugars during hydrolysis by

crude enzyme mannanases of Bacillus subtilis MAN-511, a 1% (w/v) solution of glucomanan in 0.05M citrate buffer pH 6 was

incubated with 1.8 U ml1 mannanase activity at 30C. The decrease in the viscosity was monitored. The released reducing sugars

were determined using the DNS method (A 540 nm).

III. RESULTS AND DISCUSSION

Strain Properties and Identification

The strain used in the present study, Bacillus subtilis MAN-511 was isolated from soil enriched with glucomanan. This strain was

a Gram-positive bacil shaped bacterium. The partial nucleotide sequence of the 16S rDNA gene, corresponding to the region from

1,500 bp. The phylogenetic tree based on the analysis of the 16S rDNA sequences are shown in Fig. 1. Therefore, the culture was

used for further experimental studies.

gi|930246407|gb|KR108289.1| Bacillus cereus strain SG2 16S ribosomal RNA gene, partial sequence

gi|930420549|gb|KT818807.1| Bacillus cereus strain TV4 16S ribosomal RNA gene, partial sequence

gi|930174180|gb|KR997601.1| Bacillus cereus strain DCRUST BT YW-6 16S ribosomal RNA gene, partial sequence

gi|930174177|gb|KR997598.1| Bacillus cereus strain DCRUST BT SS-2 16S ribosomal RNA gene, partial sequence

gi|929996740|gb|KT206229.1| Bacillus thuringiensis strain BAPE1 16S ribosomal RNA gene, partial sequence

gi|930697006|emb|LN880132.1| Uncultured Streptomyces sp. partial 16S rRNA gene, clone W3S30

gi|929049967|gb|KT758610.1| Bacillus anthracis strain HQB817 16S ribosomal RNA gene, partial sequence

gi|927371366|gb|KT462573.1| Bacillus sp. PS2(2015) 16S ribosomal RNA gene, partial sequence

m2

gi|950834956|gb|KT216601.1| Bacillus subtilis strain LAHP3-4 16S ribosomal RNA gene, partial sequence

0.005

Fig. 1: Phylogenetic tree based on 16S rDNA sequences, showing the positions of strain MAN-511 and other Bacillus subtilis species.

Production of the Mannanase

The newly isolated Bacillus subtilis MAN-511 produced maximum level of extracellular mannanase during growth on 1%

glucomannan at 37C. To the best of our knowledge, this is the report on the production of -mannanase Bacillus subtilis WY34

[5]. Similarly, Bacillus subtilis NM-39 produced mannanase at 37C with locust bean gum as the substrate [6]. Other Bacillus

subtilis strains isolated so far produced maximum mannanases at below 50C [7]. Some Bacillus subtilis strains can produce

mannanases at up to 45C [8,9]. Five -mannanases were secreted by Sclerotium rolfsii when cultivated in glucomannan [6].

Bacillus sp. KK01 produced four -mannanases in the culture medium [4].

Purification of the Mannanase

The purification results are summarized in Table 1. 7.6-fold purification of the mannanase were obtained (Fig. 2A). The specific

activity determined using glucomannan as substrate was 15 U/mg protein. The enzyme was also confirmed to be mannanase by

zymogram analysis by congo red staining (Fig. 2B). The apparent molecular mass of mannanase (45.08 kDa) from Bacillus subtilis

MAN-511 is similar to that of mananase from Bacillus subtilis WY34 was 39,6 kDa [5], Bacillus subtilis KU -1 was 40 kDa [8].

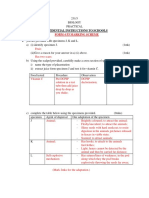

Table 1

Purification of mannanase from the isolated Bacillus subtilis MAN-511

Purification Step

Total Activity (mol/min)

Total Protein (mg)

Specific Activity (mol/min/mg)

Crude extract

(NH4)2SO4

(70%)

Sephadex G-75

370

188

1,97

Yield

(%)

100

72,2

17,9

4,03

19,51

2,04

15,3

1,02

15

4,13

7,61

Purification (fold)

1

All rights reserved by www.ijste.org

85

Isolation, Purification and Characterization of Mannanase from Bacillus subtilis MAN-511

(IJSTE/ Volume 2 / Issue 11 / 011)

Fig. 2: SDS-PAGE and zymogram for mannanase from Baciluus subtilis MAN-511. Lane M, marker proteins; lane A, purified mannanase;

lane B, zymogram of purified mannanase.

Temperature and pH optimal and stabilities

The optimal temperature for -mannanase activity was 30C (Fig. 3A). The mannanase was optimally active at 30- 65C from

Bacillus circulans NT 6.7 at 45C [13], Bacillus subtilis WY34 at 65 C [5], Bacillus stearothermophilus at 70 C [12] Bacillus

subtilis KU -1 at 50 [8], Bacillus sp. MG-33 at 65 C [10]. The enzyme was stable up to 30-40C, but about activity was lost at

50C after 1 h of incubation (Fig. 3B). The optimal pH for -mannanase activity was pH 7.0 (Fig. 4A). The enzyme showed stability

within the pH range of 6.0-7.0 (Fig. 4B). This thermostability is comparable to those reported for several mannanases from the

Bacillus subtilis WY34 [9], Paenibacillus illinoisensis ZY-08 [11], Bacillus sp.MG-33 [10], Bacillus subtilis KU-1 [8], Bacillus

stearothermophilus [11], Bacillus licheniformis at pH 7 [12], Bacillus circulans NT6.7 at pH 6 [14], Bacillus stearothermophilus

at pH 6.5 [12], Trichoderma reesei C-30 at pH 5 [15], Vibrio sp strain MA-138 at pH 6,5 [16].

Fig. 3: Effect of temperature on mannanase activity (A) and stability (B). For determination of thermal stability.

Fig. 4: Effects of pH on mannanase activity (A) and stability (B). The effect of pH on mannanase activity was monitored at 60C

All rights reserved by www.ijste.org

86

Isolation, Purification and Characterization of Mannanase from Bacillus subtilis MAN-511

(IJSTE/ Volume 2 / Issue 11 / 011)

Hydrolysis of Glucomanan by Mananase from Bacillus subtilis MAN-511

The rate of glucomanan hydrolysis by mananase was rapid and linier the periode to 30 min, viscosity of glucomanan liquid was

decreased from 3.875 cpa.s to 510 cpa.s (86,8 %).Result from the hydrolysis study showed that this enzyme has a strong potential

to be use to decrease high viscosity from glucomanan without causing any pollution as compared to the use of toxic inorganic

acids.

Fig. 5: Hydrolysis of Glucomanan by Mananase from Bacillus subtilis MAN-511at pH 7 and 30C

IV. CONCLUSION

The mannanase activity from this strain had optimum pH of 7.0, stable at a pH 6-7, optimum temperature at 30C and stable at 3040C, the purified enzyme showed of molecular mass was 45.08 kDa.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

Franco, P. F., H. M. Ferreira, and E. X. F. Filho. (2004). Production and characterization of hemicellulase activities from Trichoderma harzianum strain T4.

Biotechnol. Appl. Biochem. 40: 255-259.

Hossain MZ, Abe J, and Hizukuri S. (1996) Multiple forms of -mannanase from Bacillus sp. KK01. Enzyme Microb Technol 18, 95-98.

Schiradi C and De rose M (2002) The production of biocatalysts and biomolecules from extremophiles. Trends Biotechnol 20, 515-521.

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal

Biochem 72, 248-254.

Jiang Z, Wei Y, Li D, Li L, Chai P, and Kusakabe I (2006) High-level production, purification and characterization of a thermostable -mannanase from the

newly isolated Bacillus subtilis WY34. Carbohydrate Polymers 66, 88-96.

Mendoza NS, Arai M, Kawaguchi T, Cubol FS, Panerio EG, and Yoshida T (1994) Isolation of mannan-utilizing bacteria and the culture conditions for

mannanase production. World J Microbiol Biotechnol 10, 51-54.

Khanongnuch C, Asada K, Tsuruga H, Ooi T, Kinoshita S, and Lumyong S (1998) -Mannanase and xylanase of Bacillus subtilis 5H active for bleaching

of crude pulp. J Ferment Bioeng 86, 461-466.

Zakaria MM, Yamamoto S, and Yagi T (1998) Purification and characterization of an endo-1,4--mannanase from Bacillus subtilis KU-1. FEMS Microbiol

Lett 158, 25-31.

Stalbrand H, Siika-aho M, Tenkanen M, and Viikari L (1993) Purification and characterization of two -mannanases from Trichoderma reesei. J Biotechnol

29, 229-242.

Meenakshi, Singh G, Bhalla A, Hoondal GS (2010) Solid state fermentation and characterization of partially purified thermostable mannanase from Bacillus

sp. MG-33. Bioresources 5(3):16891701

Lee, Y.S., Y. Zhou, Park, I.H., Chandra, M.R.G.S., Ahn, S.C, dan Choi Y.L. (2010). Isolation and Purification of Thermostable -Mannanase from

Paenibacillus illinoisensis ZY-08. J. Korean Soc. Appl. Biol. Chem. 53(1), 1-7

Talbot G and Sygusch J (1990) Purification and characterization of thermostable -mannanase and -galactosidase from Bacillus stearothermophilus. Appl

Environ Microbiol 56, 3505-3510.

Zhang J, He Z, Hu K. (2000). Purification and characterization of -mannanase from Bacillus licheniformis for industrial use. Biotechnology Letters 22:13751378.

Phothichitto, K. (2006). Isolation and Characterization of Mannanase Producing Microorganism. Graduate School, Kasetsart University. Thailand

Atac IA, Hodist R, Kristufek D, Kubicek CP. (1993). Purification and characterization of a -Mannanase of Trichorderma reesei C-30. Appl Microbiol

Biotechnol 39:58-62.

Tamaru, Y., T. Araki, H. Mori., H. Amagoi and T. Morishita, (1995). Purification and characterization of an extracellular 1-4-mannanase from a marine

bacterium, Vibrio sp. Strain MA-138. Applied Environ. Microbiol., 61: 4454-4458.

All rights reserved by www.ijste.org

87

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Design and Analysis of Magneto Repulsive Wind TurbineDokument7 SeitenDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDokument9 SeitenEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDokument6 SeitenDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDokument7 SeitenPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Mixture of Experts Model For ExtubationDokument4 SeitenA Mixture of Experts Model For ExtubationIJSTENoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDokument5 SeitenAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Onerider The Bike TaxiDokument3 SeitenOnerider The Bike TaxiIJSTENoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Technology Advancement For Abled PersonDokument9 SeitenTechnology Advancement For Abled PersonIJSTENoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDokument6 SeitenUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDokument6 SeitenWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENoch keine Bewertungen

- Privacy Preserving: Slicer Based SchemeDokument3 SeitenPrivacy Preserving: Slicer Based SchemeIJSTENoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDokument6 SeitenResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENoch keine Bewertungen

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDokument5 SeitenAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Duplicate Detection Using AlgorithmsDokument3 SeitenDuplicate Detection Using AlgorithmsIJSTENoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- An Implementation of Matlab Based Platform For The Evaluation of Modulation Techniques Using Multiuser MIMO-OFDM For Visible Light Communications Using MatlabDokument5 SeitenAn Implementation of Matlab Based Platform For The Evaluation of Modulation Techniques Using Multiuser MIMO-OFDM For Visible Light Communications Using MatlabIJSTENoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Study On The Properties of Aerated Concrete Incorporating Fly Ash and Rubber PowderDokument6 SeitenStudy On The Properties of Aerated Concrete Incorporating Fly Ash and Rubber PowderIJSTENoch keine Bewertungen

- Coupled Shear Wall: A ReviewDokument2 SeitenCoupled Shear Wall: A ReviewIJSTE100% (1)

- 5 Enzymes: 0610 BiologyDokument9 Seiten5 Enzymes: 0610 BiologyAbdul HadiNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Jump To Navigation Jump To Search: For Other Uses, SeeDokument19 SeitenJump To Navigation Jump To Search: For Other Uses, SeeDanny FentomNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Biochemistry Anabolism of Lipids: Principal Investigator Dr. Sunil Kumar Khare, ProfessorDokument10 SeitenBiochemistry Anabolism of Lipids: Principal Investigator Dr. Sunil Kumar Khare, Professorninafatima allamNoch keine Bewertungen

- Vegetative Propagation Cape BiologyDokument11 SeitenVegetative Propagation Cape BiologyOrlanda EllisNoch keine Bewertungen

- Cardiorespiratory EnduranceDokument38 SeitenCardiorespiratory EnduranceHilarion Vidal OlimpoNoch keine Bewertungen

- Tissue Reactions Report Draft For ConsultationDokument315 SeitenTissue Reactions Report Draft For ConsultationMichaelAndreasNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 7 Endemic Centers - MathodologyDokument21 Seiten7 Endemic Centers - MathodologyMirza ČelebičićNoch keine Bewertungen

- Daniel Pimley - Representations of The Body in AlienDokument37 SeitenDaniel Pimley - Representations of The Body in AlienVerbal_KintNoch keine Bewertungen

- Biology f4t2 Pp3 MsDokument4 SeitenBiology f4t2 Pp3 MssamuwelNoch keine Bewertungen

- LASA Blood SamplingDokument4 SeitenLASA Blood SamplinggursinNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- What Is A Good FriendDokument16 SeitenWhat Is A Good FriendAndii Nyezha Noeroel KealbeyNoch keine Bewertungen

- Bronsted QA Set D Bio 1 GuideDokument9 SeitenBronsted QA Set D Bio 1 GuideBaguma Michael100% (1)

- Coffee Leaf Rust - NutmanDokument20 SeitenCoffee Leaf Rust - NutmanKalpana TanguturiNoch keine Bewertungen

- "The Food Chain" Comprensión Lectora InglésDokument9 Seiten"The Food Chain" Comprensión Lectora InglésAna Basterra100% (18)

- Bio ElectrodesDokument26 SeitenBio ElectrodesSharok Nancy JoshuvaNoch keine Bewertungen

- Herbs and Herbal Constituents Active Against Snake BiteDokument14 SeitenHerbs and Herbal Constituents Active Against Snake BiteSundara Veer Raju MEDNoch keine Bewertungen

- Bakir 2017Dokument12 SeitenBakir 2017fragariavescaNoch keine Bewertungen

- Ad For AdmDokument365 SeitenAd For AdmAshmeet PradhanNoch keine Bewertungen

- Menstrual Cycle and Its Physiology Mechanism Pathophysiology and Clinical SignificanceDokument2 SeitenMenstrual Cycle and Its Physiology Mechanism Pathophysiology and Clinical SignificanceRoyd KabweNoch keine Bewertungen

- Check List: Serra Do Urubu, A Biodiversity Hot-Spot For Angiosperms in The Northern Atlantic Forest (Pernambuco, Brazil)Dokument25 SeitenCheck List: Serra Do Urubu, A Biodiversity Hot-Spot For Angiosperms in The Northern Atlantic Forest (Pernambuco, Brazil)SôniaRodaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ex. 5 DNA Extraction PDFDokument3 SeitenEx. 5 DNA Extraction PDFAlyssa Pauline PalacioNoch keine Bewertungen

- Pharmaceutical Organic ChemistryDokument2 SeitenPharmaceutical Organic ChemistryPankaj KushwahNoch keine Bewertungen

- Phylum PoriferaDokument4 SeitenPhylum PoriferaMA. LYN CASIPENoch keine Bewertungen

- Invigilation Time Table 2022Dokument3 SeitenInvigilation Time Table 2022ThomasNoch keine Bewertungen

- Biol 102 Fruits AssignmentsDokument8 SeitenBiol 102 Fruits AssignmentsMohsin AliNoch keine Bewertungen

- EPPO StandardsDokument12 SeitenEPPO StandardsSarai Olmedo CruzNoch keine Bewertungen

- John Toland - Pantheisticon PDFDokument246 SeitenJohn Toland - Pantheisticon PDFAlexander Elder100% (2)

- Why Abiogenesis Is ImpossibleDokument17 SeitenWhy Abiogenesis Is ImpossibleshljnjNoch keine Bewertungen

- Ess - Final SUBJECT OUTLINEDokument15 SeitenEss - Final SUBJECT OUTLINEYosi AdriyantoNoch keine Bewertungen

- Cystatin-C AU400 480 640 680 2700Dokument2 SeitenCystatin-C AU400 480 640 680 2700Nghi NguyenNoch keine Bewertungen

- 10% Human: How Your Body's Microbes Hold the Key to Health and HappinessVon Everand10% Human: How Your Body's Microbes Hold the Key to Health and HappinessBewertung: 4 von 5 Sternen4/5 (33)

- Masterminds: Genius, DNA, and the Quest to Rewrite LifeVon EverandMasterminds: Genius, DNA, and the Quest to Rewrite LifeNoch keine Bewertungen