Beruflich Dokumente

Kultur Dokumente

Strength Calculation

Hochgeladen von

Anonymous M8OLPIS7fQOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Strength Calculation

Hochgeladen von

Anonymous M8OLPIS7fQCopyright:

Verfügbare Formate

DOC. NO.

: 1041-D-001A

REV. NO. :

0

PAGE NO. :

2/166

- CONTENTS No. DESCRIPTION

PAGE

3

1. DESIGN DATA ------------------------------------------------------------------------------------4 ~ 5

2. SETTING SUMMARY -----------------------------------------------------------------------6 ~ 7

3. PRESSURE SUMMARY ------------------------------------------------------------------------

8 ~ 10

4. HYDROSTATIC TEST PRESSURE ------------------------------------------------------------------------

11

5. THICKNESS SUMMARY --------------------------------------------------------------------------------

12

6. NOZZLE SCHEDULE ----------------------------------------------------------------------------------

13

7. NOZZLE SUMMARY ----------------------------------------------------------------------------------14

8. WEIGHT SUMMARY ---------------------------------------------------------------------

15 ~ 30

9. PLATFORM & LADDER DATA CALCULATION --------------------------------------------------------------31

10. LIQUID LEVEL OF OPERATING ---------------------------------------------------------------------

32 ~ 41

11. SHELL & HEAD ------------------------------------------------------------------------------------42 ~ 77

12. NOZZLE NECK --------------------------------------------------------------------------------

13. WIND LOAD --------------------------------------------------------------------- 78 ~ 80

81 ~ 83

14. SEISMIC LOAD ---------------------------------------------------------------------

15. SUPPORT SKIRT UNDER EXTERNAL LOAD ------------------------------------------

84 ~ 85

86 ~ 88

16. BASE BLOCK CHECK ---------------------------------------------------------------------

89 ~ 101

17. LIFTING LUG & TAILING LUG CHECK -----------------------------------------------------------------102 ~ 107

18. BASE RING DESIGN CHECK ---------------------------------------------------------------------

19. DAVIT ---------------------------------------------------------------------

108 ~ 110

111 ~ 161

160

20. Analysis of Nozzle ---------------------------------------------------------------------

21. Stress calculation for supporting the vessel at horizontal position during shop test -------

162 ~ 166

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

3/166

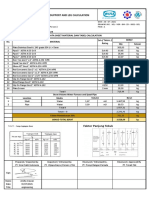

STRENGTH CALCULATION SHEET

FOR PRESSURE VESSEL

D E S I G N

D A T A

CODE

ASME SEC. VIII DIV.1 2007 ED. + 2009 ADD.

ITEM NO.

1041-D-001A

ITEM NAME

PROPYLENE FIRST FLASH DRUM

CODE STAMP

YES (ASME U)

SIZE(mmxmm) 2600 I.D x 7100 TL TO TL

TYPE

V-SKIRT

SHELL SIDE

UNIT

PROPYLENE

CAPACITY

42.4

M3

SPECIFIC GRAVITY

0.521

INT.

21 (2.059)

KG/CM 2.G(Mpa)

EXT.

N/A

KG/CM2.G(Mpa)

7.13 (0.699) (NORMAL)

KG/CM 2.G(Mpa)

KG/CM 2.G(Mpa)

SHOP

36.99 (3.627)

KG/CM2.G(Mpa)

FIELD

36.64 (3.593)

KG/CM2.G(Mpa)

87 / 87

11.3

11 3 (NORMAL)

28.18 (2.764)

KG/CM 2.G(Mpa)

AT SHELL

28.45 (2.79)

KG/CM 2.G(Mpa)

AT SHELL

M.A.E.P

KG/CM 2.G(Mpa)

M.D.M.T

-48

P.W.H.T

NO

CORROSION ALLOWANCE

0.0

MM

FULL / FULL

1.0 / 1.0

STRESS RELIEF (HEAD)

NO

INSULATION (COLD)

40

MM

FIRE PROOFING (IN/OUTSIDE)

50

MM

WIND VELOCITY

160 (ASCE 7-05)

KM/H

SEISMIC ZONE

IBC 2009, (I=1.25, R=3, Sds:0.284, Sd1:0.075)

2 :1 ELLIP

5120

MM

TEST

FULL WATER

MM

SHELL

SA240-316L

HEAD

SA240-316L

FLUID

DESIGN

PRESSURE

OPERATING

PNEUM. TEST

HYDRO. TEST

TEMPERATURE

DESIGN (INT./EXT.)

OPERATING

M.A.W.P

HOT & CORRODED

M.A.P

NEW & COLD

RADIOGRAPHY (SHELL/HEAD)

JOINT EFFICIENCY (SHELL/HEAD)

TYPE OF HEAD

DESIGN

LIQUID LEVEL

MATERIAL

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

4/166

Settings Summary

COMPRESS Build 7110

Units: MKS

Datum Line Location: -38.00 mm from bottom seam

Design

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Design or Rating:

Get Thickness from Pressure

Minimum thickness:

6.0 mm + C.A

Design for cold shut down only:

No

Design for lethal service (full radiography required):

No

Design nozzles for:

Larger of MAWP or MAP

Corrosion weight loss:

100% of theoretical loss

UG-23 Stress Increase:

1.00

Skirt/legs stress increase:

1.0

Minimum nozzle projection:

218 mm

Juncture calculations for > 30 only:

Yes

Preheat P-No 1 Materials > 1.25" and <= 1.50" thick:

Yes

UG-37(a) shell tr calculation considers longitudinal stress: No

Butt welds are tapered per Figure UCS-66.3(a).

Hydro/Pneumatic Test

Shop Hydrotest at user defined pressure

Test liquid specific gravity: 1.00

Field Hydrotest Pressure:

1.3 times vessel MAWP

Wind load present @ field: 75% of design

Maximum stress during test: 90% of yield

Required Marking - UG-116

UG-116(e) Radiography:

RT1

UG-116(f) Postweld heat treatment: None

Code Cases\Interpretations

Use Code Case 2547:

No

Apply interpretation VIII-1-83-66: Yes

Apply interpretation VIII-1-86-175: Yes

Apply interpretation VIII-1-83-115: Yes

Apply interpretation VIII-1-01-37: Yes

No UCS-66.1 MDMT reduction:

No

No UCS-68(c) MDMT reduction: No

Disallow UG-20(f) exemptions:

No

UG-22 Loadings

UG-22(a) Internal or External Design Pressure :

UG-22(b) Weight of the vessel and normal contents under operating or test conditions:

UG-22(c) Superimposed static reactions from weight of attached equipment (external loads):

UG-22(d)(2) Vessel supports such as lugs, rings, skirts, saddles and legs:

UG-22(f) Wind reactions:

UG-22(f) Seismic reactions:

UG-22(j) Test pressure and coincident static head acting during the test:

Note: UG-22(b),(c) and (f) loads only considered when supports are present.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

5/166

TABLE OF LOADING CASES AND LOAD COMBINATIONS

LOADS

DESIG CASE

THICKNESS

ALLOWABLE

STRESSES

WEIGHT

LIFTING

UNCORRODED

90% Y.S

ERECTED

UNCORRODED

90% Y.S

FUTURE

HYDRO

STATIC TEST

CORRODED

90% Y.S

OPERATING

CORRODED

PER ASME

SHOP

HYDROTEST

UNCORRODED

90% Y.S

SHUT DOWN

CORRODED

PER ASME

WIND

EARTHQUAKE

PRESSUR

TEMPERATUR

AMBIENT

AMBIENT

AMBIENT

DESIGN

AMBIENT

DESIGN

REMARK

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

6/166

Pressure Summary

Pressure Summary for Chamber bounded by BTM HEAD and TOP HEAD

Identifier

Design

( kg/cm2)

Design

( C)

MAWP

( kg/cm2)

MAP

( kg/cm2)

MDMT

( C)

MDMT

Exemption

Impact

Tested

TOP HEAD

21

87

29.06

29.06

-196

Note 1

No

Straight Flange on TOP HEAD

21

87

33.69

33.69

-196

Note 2

No

SHELL #1

21

87

34.53

34.56

-196

Note 2

No

SHELL #2

21

87

28.18

28.45

-196

Note 2

No

Straight Flange on BTM HEAD

21

87

33.42

33.69

-196

Note 2

No

BTM HEAD

21

87

28.76

29.06

-196

Note 1

No

TWO PHASE INLET (A1)

21

87

28.18

28.45

-196

Note 2

No

LIQIUD OUTLET (B1)

21

87

28.18

28.45

-48

Note 3

No

VAPOUR OUTLET (B2)

21

87

28.18

28.45

-196

Note 2

No

DRAIN (D)

21

87

28.18

28.45

-48

Note 4

No

LEVEL GAUGE (G1A)

21

87

28.18

28.45

-196

Note 5

No

LEVEL GAUGE (G1B)

21

87

28.18

28.45

-196

Note 5

No

LEVEL GAUGE (G2A)

21

87

28.18

28.45

-196

Note 5

No

LEVEL GAUGE (G2B)

21

87

28.18

28.45

-196

Note 6

No

LEVEL TRANSMITTER (L1A)

21

87

28.18

28.45

-196

Note 5

No

LEVEL TRANSMITTER (L1B)

21

87

28.18

28.45

-196

Note 7

No

LEVEL TRANSMITTER (L2A)

21

87

28.18

28.45

-196

Note 5

No

LEVEL TRANSMITTER (L2B)

21

87

28.18

28.45

-196

Note 5

No

LEVEL TRANSMITTER (L3A)

21

87

28.18

28.45

-196

Note 5

No

LEVEL TRANSMITTER (L3B)

21

87

28.18

28.45

-196

Note 7

No

MANWAY (M)

21

87

28.18

28.45

-196

Note 2

No

UTILITY CONNECTION (UC)

21

87

28.18

28.45

-196

Note 8

No

VENT (V)

21

87

28.18

28.45

-196

Note 9

No

RELIEF VAVLE (W)

21

87

28.18

28.45

-196

Note 10

No

Chamber design MDMT is -48 C

Chamber rated MDMT is -48 C @ 28.18 kg/cm2

Chamber MAWP was used in the MDMT determination

Chamber MAWP hot & corroded is 28.18 kg/cm2 @ 87 C

Chamber MAP cold & new is 28.45 kg/cm2 @ 21 C

This pressure chamber is not designed for external pressure.

Notes for MDMT Rating:

Note #

Exemption

Details

1.

Material Rated MDMT per UHA-51(d)(1)(a) = -196 C

2.

Rated MDMT per UHA-51(d)(1)(a) = -196 C

3.

Flange rating governs:

UCS-66(b)(1)(b)

4.

Flange rating governs:

Flange rated MDMT = -196 C

Bolts rated MDMT per Fig UCS-66 note (c) = -48 C

Per UHA-51(d)(1)(a)

5.

Impact test exempt per UHA-51(g)(coincident ratio = 0.0372)

6.

Impact test exempt per UHA-51(g)(coincident ratio = 0.03722)

7.

Impact test exempt per UHA-51(g)(coincident ratio = 0.03721)

8.

Impact test exempt per UHA-51(g)(coincident ratio = 0.08031)

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

7/166

9.

Impact test exempt per UHA-51(g)(coincident ratio = 0.28599)

10.

Impact test exempt per UHA-51(g)(coincident ratio = 0.25619)

Design notes are available on the Settings Summary page.

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

8/166

Hydrostatic Test

Shop test pressure determination for Chamber bounded by BTM HEAD and TOP HEAD based on user defined pressure

Shop test gauge pressure is 36.99 kgf/cm2 at 21 C

The shop test is performed with the vessel in the horizontal position.

Local test

pressure

kgf/cm2

Test liquid

static head

kgf/cm2

Stress

during test

kgf/cm2

Allowable

test stress

kgf/cm2

TOP HEAD

37.26

0.28

1,349.742

1,578.519

No

Straight Flange on TOP HEAD

37.26

0.28

1,293.298

1,578.519

No

Identifier

Stress

excessive?

SHELL #1

37.26

0.28

1,260.61

1,578.519

No

SHELL #2

37.26

0.28

1,532.329

1,578.519

No

Straight Flange on BTM HEAD

37.26

0.28

1,293.298

1,578.519

No

BTM HEAD

37.26

0.28

1,349.742

1,578.519

No

DRAIN (D)

37.12

0.13

413.784

2,340.247

No

LEVEL GAUGE (G1A)

37.01

0.02

1,350.134

2,340.247

No

LEVEL GAUGE (G1B)

37.01

0.02

1,350.134

2,340.247

No

LEVEL GAUGE (G2A)

37.09

0.1

1,353.136

2,340.247

No

LEVEL GAUGE (G2B)

37.09

0.1

1,353.136

2,340.247

No

LEVEL TRANSMITTER (L1A)

37.02

0.04

1,350.724

2,340.247

No

LEVEL TRANSMITTER (L1B)

37.02

0.04

1,350.724

2,340.247

No

LEVEL TRANSMITTER (L2A)

37.17

0.18

1,355.984

2,340.247

No

LEVEL TRANSMITTER (L2B)

37.17

0.18

1,355.984

2,340.247

No

LEVEL TRANSMITTER (L3A)

37.13

0.15

1,354.811

2,340.247

No

LEVEL TRANSMITTER (L3B)

37.13

0.15

1,354.811

2,340.247

No

LIQIUD OUTLET (B1)

37.14

0.16

1,501.594

2,340.247

No

MANWAY (M)

37.31

0.32

1,515.6

2,340.247

No

RELIEF VAVLE (W)

37.04

0.06

1,436.947

2,340.247

No

TWO PHASE INLET (A1)

37.3

0.32

1,243.403

2,340.247

No

UTILITY CONNECTION (UC)

37.04

0.05

1,351.333

2,340.247

No

VAPOUR OUTLET (B2)

37.15

0.17

1,430.047

2,340.247

No

VENT (V)

37.14

0.15

1,439.649

2,340.247

No

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

9/166

Notes:

(1) PL stresses at nozzle openings have been estimated using the method described in PVP-Vol. 399, pages 77-82.

(2) 1.5*0.9*Sy used as the basis for the maximum local primary membrane stress at the nozzle intersection PL.

(3) The zero degree angular position is assumed to be up, and the test liquid height is assumed to the top-most flange.

Field test pressure determination for Chamber bounded by BTM HEAD and TOP HEAD based on MAWP per UG-99(b)

Field hydrostatic test gauge pressure is 36.64 kgf/cm2 at 21 C (the chamber MAWP = 28.18 kgf/cm2)

The field test is performed with the vessel in the vertical position.

Identifier

TOP HEAD (1)

Local test

pressure

kgf/cm2

Test liquid

static head

kgf/cm2

UG-99

stress

ratio

UG-99

pressure

factor

Stress

during test

kgf/cm2

Allowable

test stress

kgf/cm2

36.76

0.12

1.30

1,331.487

1,578.519

Stress

excessive?

No

Straight Flange on TOP HEAD

36.76

0.12

1.30

1,275.806

1,578.519

No

SHELL #1

37

0.36

1.30

1,251.673

1,578.519

No

SHELL #2

37.46

0.82

1.30

1,540.465

1,578.519

No

Straight Flange on BTM HEAD

37.46

0.83

1.30

1,300.297

1,578.519

No

BTM HEAD

37.53

0.89

1.30

1,359.399

1,578.519

No

DRAIN (D)

37.62

0.98

1.30

419.374

2,340.247

No

LEVEL GAUGE (G1A)

36.77

0.13

1.30

1,341.465

2,340.247

No

LEVEL GAUGE (G1B)

36.79

0.15

1.30

1,342.066

2,340.247

No

LEVEL GAUGE (G2A)

36.77

0.13

1.30

1,341.465

2,340.247

No

LEVEL GAUGE (G2B)

36.99

0.35

1.30

1,349.431

2,340.247

No

LEVEL TRANSMITTER (L1A)

36.77

0.13

1.30

1,341.465

2,340.247

No

LEVEL TRANSMITTER (L1B)

36.98

0.34

1.30

1,349.048

2,340.247

No

LEVEL TRANSMITTER (L2A)

36.77

0.13

1.30

1,341.465

2,340.247

No

LEVEL TRANSMITTER (L2B)

36.79

0.15

1.30

1,342.066

2,340.247

No

LEVEL TRANSMITTER (L3A)

36.94

0.3

1.30

1,347.59

2,340.247

No

LEVEL TRANSMITTER (L3B)

36.98

0.34

1.30

1,349.048

2,340.247

No

LIQIUD OUTLET (B1)

37.65

1.01

1.30

1,522.021

2,340.247

No

MANWAY (M)

37.29

0.66

1.30

1,515.031

2,340.247

No

RELIEF VAVLE (W)

36.78

0.15

1.30

1,426.803

2,340.247

No

TWO PHASE INLET (A1)

36.81

0.17

1.30

1,226.984

2,340.247

No

UTILITY CONNECTION (UC)

36.97

0.34

1.30

1,348.957

2,340.247

No

VAPOUR OUTLET (B2)

36.69

0.05

1.30

1,412.146

2,340.247

No

VENT (V)

36.7

0.06

1.30

1,422.563

2,340.247

No

Notes:

(1) TOP HEAD limits the UG-99 stress ratio.

(2) PL stresses at nozzle openings have been estimated using the method described in PVP-Vol. 399, pages 77-82.

(3) 1.5*0.9*Sy used as the basis for the maximum local primary membrane stress at the nozzle intersection PL.

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

10/166

Corroded Hydrostatic Test

The shop test condition has not been investigated for the Chamber bounded by BTM HEAD and TOP HEAD.

Field test pressure determination for Chamber bounded by BTM HEAD and TOP HEAD based on MAWP per UG-99(b)

Field hydrostatic test gauge pressure is 29.35 kgf/cm2 at 21 C (the chamber MAWP = 22.58 kgf/cm2)

The field test is performed with the vessel in the vertical position.

Identifier

TOP HEAD (1)

Local test

pressure

kgf/cm2

Test liquid

static head

kgf/cm2

UG-99

stress

ratio

UG-99

pressure

factor

Stress

during test

kgf/cm2

Allowable

test stress

kgf/cm2

29.48

0.12

1.30

1,067.67

1,578.519

Stress

excessive?

No

Straight Flange on TOP HEAD

29.48

0.12

1.30

1,023.021

1,578.519

No

SHELL #1

29.71

0.36

1.30

1,005.277

1,578.519

No

SHELL #2

30.18

0.82

1.30

1,240.959

1,578.519

No

Straight Flange on BTM HEAD

30.18

0.83

1.30

1,047.512

1,578.519

No

BTM HEAD

30.25

0.89

1.30

1,095.581

1,578.519

No

DRAIN (D)

30.34

0.98

1.30

338.184

2,340.247

No

LEVEL GAUGE (G1A)

29.49

0.13

1.30

1,075.748

2,340.247

No

LEVEL GAUGE (G1B)

29.5

0.15

1.30

1,076.35

2,340.247

No

LEVEL GAUGE (G2A)

29.49

0.13

1.30

1,075.748

2,340.247

No

LEVEL GAUGE (G2B)

29.7

0.35

1.30

1,083.715

2,340.247

No

LEVEL TRANSMITTER (L1A)

29.49

0.13

1.30

1,075.748

2,340.247

No

LEVEL TRANSMITTER (L1B)

29.69

0.34

1.30

1,083.332

2,340.247

No

LEVEL TRANSMITTER (L2A)

29.49

0.13

1.30

1,075.748

2,340.247

No

LEVEL TRANSMITTER (L2B)

29.5

0.15

1.30

1,076.35

2,340.247

No

LEVEL TRANSMITTER (L3A)

29.65

0.3

1.30

1,081.874

2,340.247

No

LEVEL TRANSMITTER (L3B)

29.69

0.34

1.30

1,083.332

2,340.247

No

LIQIUD OUTLET (B1)

30.37

1.01

1.30

1,227.595

2,340.247

No

MANWAY (M)

30.01

0.66

1.30

1,219.153

2,340.247

No

RELIEF VAVLE (W)

29.5

0.15

1.30

1,144.278

2,340.247

No

TWO PHASE INLET (A1)

29.53

0.17

1.30

984.211

2,340.247

No

UTILITY CONNECTION (UC)

29.69

0.34

1.30

1,083.241

2,340.247

No

VAPOUR OUTLET (B2)

29.4

0.05

1.30

1,131.798

2,340.247

No

VENT (V)

29.41

0.06

1.30

1,140.225

2,340.247

No

Notes:

(1) TOP HEAD limits the UG-99 stress ratio.

(2) PL stresses at nozzle openings have been estimated using the method described in PVP-Vol. 399, pages 77-82.

(3) 1.5*0.9*Sy used as the basis for the maximum local primary membrane stress at the nozzle intersection PL.

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

11/166

Thickness Summary

Component

Identifier

Material

Diameter

(mm)

Length

(mm)

Nominal t

(mm)

Design t

(mm)

Total Corrosion

(mm)

Joint

E

Load

TOP HEAD

SA-240 316L

2,600 ID

682.3

32.3*

23.32

1.00

Internal

Straight Flange on TOP HEAD

SA-240 316L

2,600 ID

38

38

23.53

1.00

Internal

SHELL #1

SA-240 316L

2,600 ID

2,400

39

23.56

1.00

Internal

SHELL #2

SA-240 316L

2,600 ID

4,624

32

23.83

1.00

Internal

Straight Flange on BTM HEAD

SA-240 316L

2,600 ID

38

38

23.84

1.00

Internal

BTM HEAD

SA-240 316L

2,600 ID

682.3

32.3*

23.66

1.00

Internal

SKIRT

SA-240 316L

2,628 ID

2,168.7

11

2.2

0.55

Seismic

Nominal t:

Vessel wall nominal thickness

Design t:

Required vessel thickness due to governing loading + corrosion

Joint E:

Longitudinal seam joint efficiency

Head minimum thickness after forming

Load

internal:

Circumferential stress due to internal pressure governs

external:

External pressure governs

Wind:

Combined longitudinal stress of pressure + weight + wind governs

Seismic:

Combined longitudinal stress of pressure + weight + seismic governs

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

12/166

Nozzle Schedule

Materials

Nozzle

mark

Service

Size

Impact

Norm

Fine Grain

Pad

Impact

Norm

Fine Grain

A1

TWO PHASE INLET

380.40 IDx89.80

SA-182 F316L <= 125

Nozzle

No

No

No

N/A

N/A

N/A

N/A

WN A182 F316L Class 300

Flange

B1

LIQIUD OUTLET

247.70 IDx51.15

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

WN A105 Class 300

B2

VAPOUR OUTLET

380.40 IDx89.80

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

WN A182 F316L Class 300

DRAIN

102.30 IDx58.85

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

WN A182 F316L Class 300

G1A

LEVEL GAUGE

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

G1B

LEVEL GAUGE

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

G2A

LEVEL GAUGE

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

G2B

LEVEL GAUGE

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

L1A

LEVEL TRANSMITTER

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

L1B

LEVEL TRANSMITTER

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

L2A

LEVEL TRANSMITTER

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

L2B

LEVEL TRANSMITTER

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

L3A

LEVEL TRANSMITTER

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

L3B

LEVEL TRANSMITTER

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

MANWAY

583.60 IDx133.20

SA-182 F316L > 125

No

No

No

N/A

N/A

N/A

N/A

WN A182 F316L Class 300

UC

UTILITY CONNECTION

50.80 IDx16.65

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

LWN A182 F316L Class 300

VENT

97.10 IDx31.45

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

WN A182 F316L Class 300

RELIEF VAVLE

146.30 IDx36.85

SA-182 F316L <= 125

No

No

No

N/A

N/A

N/A

N/A

WN A182 F316L Class 300

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

13/166

Nozzle Summary

Reinforcement

Pad

Shell

Nozzle

mark

tn:

OD

(mm)

t

n

(mm)

Req t

n

(mm)

A1?

A2?

Nom t

(mm)

Design t

(mm)

User t

(mm)

Width

(mm)

Corr

(mm)

A /A

a r

(%)

t

pad

(mm)

A1

560

89.8

8.33

Yes

Yes

39

32

N/A

N/A

158.9

B1

350

51.15

8.33

Yes

Yes

32.3*

28.55

N/A

N/A

128.4

B2

560

89.8

8.33

Yes

Yes

32.3*

28.45

220

58.85

3.06

Yes

Yes

12.7

3.06

11.11

N/A

N/A

141.3

N/A

N/A

1206.5

G1A

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

G1B

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

G2A

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

G2B

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

L1A

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

L1B

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

L2A

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

L2B

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

L3A

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

L3B

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

850

133.2

8.33

Yes

Yes

32

32

N/A

N/A

108.4

UC

84.1

16.65

4.8

Yes

Yes

39

N/A

N/A

N/A

Exempt

160

31.45

5.27

Yes

Yes

32.3*

28.45

N/A

N/A

183.9

220

36.85

7.16

Yes

Yes

39

32

N/A

N/A

132.6

Nozzle thickness

Req tn:

Nozzle thickness required per UG-45/UG-16

Nom t:

Vessel wall thickness

Design t: Required vessel wall thickness due to pressure + corrosion allowance per UG-37

User t:

Local vessel wall thickness (near opening)

Aa:

Area available per UG-37, governing condition

Ar:

Area required per UG-37, governing condition

Corr:

Corrosion allowance on nozzle wall

Head minimum thickness after forming

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

14/166

Weight Summary

Weight ( kg) Contributed by Vessel Elements

Component

Metal

Metal

New*

Insulation &

Supports

Corroded*

Lining

Piping

+ Liquid

Operating

Liquid

Test

Liquid

TOP HEAD

2,109.3

2,109.3

65.1

2,545.3

SHELL #1

6,120.9

6,120.9

163.9

1,266.6

12,762.3

SHELL #2

9,675.3

9,675.3

12,814.7

24,596.4

BTM HEAD

2,153.4

2,153.4

1,329.4

2,552.5

0

SKIRT

1,587.7

1,587.7

BASE BLOCK

575.6

575.6

TOTAL:

22,222.1

22,222.1

229

15,410.7

42,456.5

* Shells with attached nozzles have weight reduced by material cut out for opening.

Weight ( kg) Contributed by Attachments

Component

Nozzles &

Flanges

Body Flanges

New

Packed

Beds

Ladders &

Platforms

Trays &

Supports

Rings &

Clips

Vertical

Loads

New

Corroded

TOP HEAD

342.8

342.8

Corroded

0

1,686.3

SHELL #1

488.7

488.7

700

1,860.8

320.9

SHELL #2

1,262.3

1,262.3

2,343.1

2,724*

BTM HEAD

225.6

225.6

37.7

350

SKIRT

1,698.6

BASE BLOCK

19.9

TOTAL:

2,319.4

2,319.4

700

7,626.5

340.8

3,074*

* This number includes vertical loads which are not present in all conditions.

Vessel operating weight, Corroded: 51,881 kg

Vessel operating weight, New:

51,881 kg

Vessel empty weight, Corroded:

36,382 kg

Vessel empty weight, New:

36,382 kg

Vessel test weight, New:

78,880 kg

Vessel center of gravity location - from datum - lift condition

Vessel Lift Weight, New: 27,751 kg

Center of Gravity:

3,150.52 mm

Note: Vessel lift weight includes weight of insulation supports as they are assumed to be shop installed.

Vessel Capacity

Vessel Capacity** (New):

42,297 liters

Vessel Capacity** (Corroded): 42,297 liters

**The vessel capacity does not include volume of nozzle, piping or other attachments.

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

15/166

Distance from platform base to datum:

Platform attached to:

Platform start angle:

Platform end angle:

Platform shell clearance:

Platform width:

Platform projected length:

Platform wind force coefficient:

Platform/Ladder #1

-500 mm

SKIRT

300.00 degrees

145.00 degrees

Lc = 150 mm

W = 1,200 mm (1.20 m)

L = 2,700 mm (2.70 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

8.91 m

h = 1,270 mm (1.27 m)

11970.95 mm (11.97 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

-2,300 mm

150.00 degrees

35.00 kg/m

1,800 mm (1.80 m)

Platform & railing weight:

Ladder weight:

Total weight:

1635.63 kg

63.00 kg

1698.63 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp

= 152.4 mm

Railing effective height:

Hr

= 243.84 mm

Angle subtended by ends of platform:

Angle = 205.00

Length from vessel center line to platform outer edge: R

= 2,675 mm

Platform projected length:

Le P = 2 * R

= 2 * 2,675

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

16/166

Front Railing projected length:

Rear Railing projected length:

Platform projected area:

Front Railing projected area:

Rear Railing projected area:

Total projected area:

=

Le FR =

=

Le RR =

=

=

Ae P =

=

=

Ae FR =

=

=

Ae RR =

=

=

Ae

=

=

=

5,350 mm

Le P

5,350 mm

Le FR - 2 *R*sin((360 - angle) / 2) + W*sin((360 - angle) / 2)*2

5,350 - 2*2,675*sin((360 - 205.00) / 2) + 1,200*sin((360 - 205.00) / 2)*2

2,469.93 mm

Hp * Le P

152.4 * 5,350

8,153.4 cm2

Hr * Le FR

243.84 * 5,350

13,045.44 cm2

Hr * Le RR

243.84 * 2,469.93

6,022.67 cm2

Ae P + Ae FR + Ae RR

8,153.4 + 13,045.44 + 6,022.67

27,221.51 cm2

Local wind pressure:

Pw

= (qz*G) = 871.57 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 871.57 * 2.00 * 27,221.51 * 0.101972

= 483.86 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

17/166

Distance from platform base to datum:

Platform attached to:

Platform start angle:

Platform end angle:

Platform shell clearance:

Platform width:

Platform projected length:

Platform wind force coefficient:

Platform/Ladder #2

1,300 mm

SHELL

125.00 degrees

210.00 degrees

Lc = 150 mm

W = 1,200 mm (1.20 m)

L = 1,350 mm (1.35 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

3.71 m

h = 1,270 mm (1.27 m)

6378.83 mm (6.38 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

-500 mm

120.00 degrees

35.00 kg/m

1,800 mm (1.80 m)

Platform & railing weight:

Ladder weight:

Total weight:

715.44 kg

63.00 kg

778.44 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp

= 152.4 mm

Railing effective height:

Hr

= 243.84 mm

Angle subtended by ends of platform:

Angle = 85.00

Length from vessel center line to platform outer edge: R

= 2,682 mm

Platform projected length:

Le P = 2*R*sin( Angle / 2 )

= 2*2,682*sin( 85.00 / 2 )

= 3,623.87 mm

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

18/166

Front Railing projected length:

Rear Railing projected length:

Platform projected area:

Front Railing projected area:

Rear Railing projected area:

Total projected area:

Le FR =

=

Le RR =

=

=

Ae P =

=

=

Ae FR =

=

=

Ae RR =

=

=

Ae

=

=

=

Le P

3,623.87 mm

W*sin( Angle / 2 )*2

1,200*sin(85.00 / 2)*2

1,621.42 mm

Hp * Le P

152.4 * 3,623.87

5,522.77 cm2

Hr * Le FR

243.84 * 3,623.87

8,836.43 cm2

Hr * Le RR

243.84 * 1,621.42

3,953.66 cm2

Ae P + Ae FR + Ae RR

5,522.77 + 8,836.43 + 3,953.66

18,312.87 cm2

Local wind pressure:

Pw

= (qz*G) = 871.57 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 871.57 * 2.00 * 18,312.87 * 0.101972

= 325.51 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

19/166

Distance from platform base to datum:

Platform attached to:

Platform start angle:

Platform end angle:

Platform shell clearance:

Platform width:

Platform projected length:

Platform wind force coefficient:

Platform/Ladder #3-1

1,900 mm

SHELL

340.00 degrees

27.00 degrees

Lc = 150 mm

W = 1,200 mm (1.20 m)

L = 1,350 mm (1.35 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

2.05 m

h = 1,270 mm (1.27 m)

4600.06 mm (4.60 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

1,900 mm

120.00 degrees

35.00 kg/m

0 mm (0.00 m)

Platform & railing weight:

Ladder weight:

Total weight:

422.42 kg

0.00 kg

422.42 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp

= 152.4 mm

Railing effective height:

Hr

= 243.84 mm

Angle subtended by ends of platform:

Angle = 47.00

Length from vessel center line to platform outer edge: R

= 2,682 mm

Platform projected length:

Le P = 2*R*sin( Angle / 2 )

= 2*2,682*sin( 47.00 / 2 )

= 2,138.89 mm

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

20/166

Front Railing projected length:

Rear Railing projected length:

Platform projected area:

Front Railing projected area:

Rear Railing projected area:

Total projected area:

Le FR =

=

Le RR =

Ae P =

=

=

Ae FR =

=

=

Ae RR =

=

=

Ae

=

=

=

Le P

2,138.89 mm

0 mm

Hp * Le P

152.4 * 2,138.89

3,259.67 cm2

Hr * Le FR

243.84 * 2,138.89

5,215.47 cm2

Hr * Le RR

243.84 * 0

0 cm2

Ae P + Ae FR + Ae RR

3,259.67 + 5,215.47 + 0

8,475.14 cm2

Local wind pressure:

Pw

= (qz*G) = 871.57 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 871.57 * 2.00 * 8,475.14 * 0.101972

= 150.65 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

21/166

Distance from platform base to datum:

Platform attached to:

Platform start angle:

Platform end angle:

Platform shell clearance:

Platform width:

Platform projected length:

Platform wind force coefficient:

Platform/Ladder #3-2

1,900 mm

SHELL

27.00 degrees

77.00 degrees

Lc = 150 mm

W = 1,600 mm (1.60 m)

L = 1,750 mm (1.75 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

3.19 m

h = 1,270 mm (1.27 m)

5889.55 mm (5.89 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

-500 mm

52.00 degrees

35.00 kg/m

2,400 mm (2.40 m)

Platform & railing weight:

Ladder weight:

Total weight:

625.18 kg

84.00 kg

709.18 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp

= 152.4 mm

Railing effective height:

Hr

= 243.84 mm

Angle subtended by ends of platform:

Angle = 50.00

Length from vessel center line to platform outer edge: R

= 3,082 mm

Platform perpendicular projected length:

Le P = (W + Rvessel + Lc) - (Rvessel + Lc)*cos(Angle / 2)

= (1,600 + 1,332 + 150) - (1,332 + 150)*cos(50.00 / 2)

= 1,738.85 mm

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

22/166

Total Perpendicular projected area:

Ae

= Le P * (Hp + 2 * Hr)

= 1,738.85 * (152.4 + 2 * 243.84)

= 11,130.04 cm2

Local wind pressure:

Pw

= (qz*G) = 871.57 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 871.57 * 2.00 * 11,130.04 * 0.101972

= 197.84 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

23/166

Distance from platform base to datum:

Platform attached to:

Platform start angle:

Platform end angle:

Platform shell clearance:

Platform width:

Platform projected length:

Platform wind force coefficient:

Platform/Ladder #3-3

1,900 mm

SHELL

77.00 degrees

115.00 degrees

Lc = 150 mm

W = 1,200 mm (1.20 m)

L = 1,350 mm (1.35 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

1.66 m

h = 1,270 mm (1.27 m)

4178.77 mm (4.18 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

1,900 mm

120.00 degrees

35.00 kg/m

0 mm (0.00 m)

Platform & railing weight:

Ladder weight:

Total weight:

353.02 kg

0.00 kg

353.02 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp

= 152.4 mm

Railing effective height:

Hr

= 243.84 mm

Angle subtended by ends of platform:

Angle = 38.00

Length from vessel center line to platform outer edge: R

= 2,682 mm

Platform perpendicular projected length:

Le P = (W + Rvessel + Lc) - (Rvessel + Lc)*cos(Angle / 2)

= (1,200 + 1,332 + 150) - (1,332 + 150)*cos(38.00 / 2)

= 1,280.74 mm

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

24/166

Total Perpendicular projected area:

Ae

= Le P * (Hp + 2 * Hr)

= 1,280.74 * (152.4 + 2 * 243.84)

= 8,197.77 cm2

Local wind pressure:

Pw

= (qz*G) = 871.57 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 871.57 * 2.00 * 8,197.77 * 0.101972

= 145.72 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

25/166

Distance from platform base to datum:

Platform attached to:

Platform start angle:

Platform end angle:

Platform shell clearance:

Platform width:

Platform projected length:

Platform wind force coefficient:

Platform/Ladder #4-1

4,750 mm

SHELL

162.00 degrees

225.00 degrees

Lc = 150 mm

W = 1,500 mm (1.50 m)

L = 1,650 mm (1.65 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

3.68 m

h = 1,270 mm (1.27 m)

6278.88 mm (6.28 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

4,750 mm

0.00 degrees

35.00 kg/m

0 mm (0.00 m)

Platform & railing weight:

Ladder weight:

Total weight:

709.17 kg

0.00 kg

709.17 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp

= 152.4 mm

Railing effective height:

Hr

= 243.84 mm

Angle subtended by ends of platform:

Angle = 63.00

Length from vessel center line to platform outer edge: R

= 2,982 mm

Platform projected length:

Le P = 2*R*sin( Angle / 2 )

= 2*2,982*sin( 63.00 / 2 )

= 3,116.18 mm

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

26/166

Front Railing projected length:

Rear Railing projected length:

Platform projected area:

Front Railing projected area:

Rear Railing projected area:

Total projected area:

Le FR =

=

Le RR =

=

=

Ae P =

=

=

Ae FR =

=

=

Ae RR =

=

=

Ae

=

=

=

Le P

3,116.18 mm

W*sin( Angle / 2 )*2

1,500*sin(63.00 / 2)*2

1,567.5 mm

Hp * Le P

152.4 * 3,116.18

4,749.06 cm2

Hr * Le FR

243.84 * 3,116.18

7,598.5 cm2

Hr * Le RR

243.84 * 1,567.5

3,822.18 cm2

Ae P + Ae FR + Ae RR

4,749.06 + 7,598.5 + 3,822.18

16,169.74 cm2

Local wind pressure:

Pw

= (qz*G) = 963.18 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 963.18 * 2.00 * 16,169.74 * 0.101972

= 317.63 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

27/166

Distance from platform base to datum:

Platform attached to:

Platform start angle:

Platform end angle:

Platform shell clearance:

Platform width:

Platform projected length:

Platform wind force coefficient:

Platform/Ladder #4-2

4,750 mm

SHELL

225.00 degrees

355.00 degrees

Lc = 150 mm

W = 1,200 mm (1.20 m)

L = 2,700 mm (2.70 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

5.67 m

h = 1,270 mm (1.27 m)

8485.26 mm (8.49 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

1,300 mm

0.00 degrees

35.00 kg/m

3,450 mm (3.45 m)

Platform & railing weight:

Ladder weight:

Total weight:

1062.44 kg

120.75 kg

1183.19 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp

= 152.4 mm

Railing effective height:

Hr

= 243.84 mm

Angle subtended by ends of platform:

Angle = 130.00

Length from vessel center line to platform outer edge: R

= 2,682 mm

Platform projected length:

Le P = 2*R*sin( Angle / 2 )

= 2*2,682*sin( 130.00 / 2 )

= 4,861.44 mm

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

28/166

Front Railing projected length:

Rear Railing projected length:

Platform projected area:

Front Railing projected area:

Rear Railing projected area:

Total projected area:

Le FR =

=

Le RR =

=

=

Ae P =

=

=

Ae FR =

=

=

Ae RR =

=

=

Ae

=

=

=

Le P

4,861.44 mm

W*sin( Angle / 2 )*2

1,200*sin(130.00 / 2)*2

2,175.14 mm

Hp * Le P

152.4 * 4,861.44

7,408.83 cm2

Hr * Le FR

243.84 * 4,861.44

11,854.12 cm2

Hr * Le RR

243.84 * 2,175.14

5,303.86 cm2

Ae P + Ae FR + Ae RR

7,408.83 + 11,854.12 + 5,303.86

24,566.81 cm2

Local wind pressure:

Pw

= (qz*G) = 963.18 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 963.18 * 2.00 * 24,566.81 * 0.101972

= 482.58 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

29/166

Distance from platform base to datum:

Platform attached to:

Platform orientation:

Platform offset:

Platform width:

Platform length:

Platform wind force coefficient:

Platform/Ladder #5

8,100 mm

TOP HEAD

0.00 degrees

1,500 mm

W = 3,000 mm (3.00 m)

L = 3,000 mm (3.00 m)

Cf = 2.00

Floor grating unit weight:

Floor grating area:

Railing height:

Railing length:

Railing unit weight:

150.00 kg/m

9.00 m

h = 1,270 mm (1.27 m)

12000.00 mm (12.00 m)

25.00 kg/m

Distance from ladder start to datum:

Ladder angle:

Ladder unit weight:

Ladder length:

4,750 mm

0.00 degrees

35.00 kg/m

3,350 mm (3.35 m)

Platform & railing weight:

Ladder weight:

Total weight:

1650.00 kg

117.25 kg

1767.25 kg

Included in vessel lift weight:

No

Present when vessel is empty:

Yes

Present during hydrotest:

Yes

Platform Wind Shear Calculation

Method and assumptions taken from Wind Loads and Anchor Bolt Design for Petrochemical Facilities, ASCE, 1997.

Platform depth:

Hp = 213.36 mm

Railing effective height:

Hr

= 243.84 mm

Platform diagonal length:

Ld

Platform projected area:

Ae P

=

=

=

=

=

=

sqr(L2 + W2)

sqr(3,0002 + 3,0002)

4,242.64 mm

Hp * Ld

213.36 * 4,242.64

9,052.1 cm2

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

30/166

Front Railing projected area: Ae FR =

=

=

Rear Railing projected area: Ae RR =

=

=

Total projected area:

Ae =

=

=

Hr * Ld

243.84 * 4,242.64

10,345.26 cm2

Hr * Ld

243.84 * 4,242.64

10,345.26 cm2

Ae P + Ae FR + Ae RR

9,052.1 + 10,345.26 + 10,345.26

29,742.61 cm2

Local wind pressure:

Pw

= (qz*G) = 1,042.42 Pa

Wind shear:

Vp

= Pw * Cf * Ae * MetricFactor

= 1,042.42 * 2.00 * 29,742.61 * 0.101972

= 632.31 kgf

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

31/166

HHLL

Location from datum

5120 mm

Operating Liquid Specific Gravity 0.521

Test liquid specific gravity

1

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

32/166

TOP HEAD

ASME Section VIII, Division 1, 2007 Edition, A09 Addenda Metric

Ellipsoidal Head

Component:

Material Specification:

SA-240 316L (II-D Metric p.70, ln. 14)

Material Rated MDMT per UHA-51(d)(1)(a) = -196 C

Internal design pressure: P = 21 kgf/cm2 @ 87 C

Static liquid head:

Ps= 0 kgf/cm2 (SG=0.521, Hs=0 mm Operating head)

Pth= 0.2772 kgf/cm2 (SG=1, Hs=2773.82 mm Horizontal test head)

Ptv= 0.1189 kgf/cm2 (SG=1, Hs=1190 mm Vertical test head)

Corrosion allowance:

Inner C = 0 mm

Outer C = 0 mm

Design MDMT = -48C

No impact test performed

Rated MDMT = -196C

Material is not normalized

Material is not produced to fine grain practice

PWHT is not performed

Do not Optimize MDMT / Find MAWP

Radiography:

Category A joints Head to shell seam -

Full UW-11(a) Type 1

Full UW-11(a) Type 1

new = 2,109.3 kg

corr = 2,109.3 kg

Estimated weight*:

new = 2,502.4 liters

corr = 2,502.4 liters

Capacity*:

* includes straight flange

= 2600 mm

Inner diameter

Minimum head thickness

= 32.3 mm

Head ratio D/2h

= 2 (new)

Head ratio D/2h

= 2 (corroded)

Straight flange length Lsf

= 38 mm

Nominal straight flange thickness tsf = 38 mm

weight: 65.0556 kg

Insulation thk*:

40 mm

density: 200 kg/m3

0 mm

individual weight: 0 kg

total weight: 0 kg

Insulation support ring spacing:

* includes straight flange if applicable

Results Summary

The governing condition is internal pressure.

Minimum thickness per UG-16

= 1.5 mm + 0 mm = 1.5 mm

Design thickness due to internal pressure (t)

= 23.32 mm

Maximum allowable working pressure (MAWP) = 29.06 kgf/cm2

Maximum allowable pressure (MAP)

= 29.06 kgf/cm2

Design thickness for internal pressure, (Corroded at 87 C) UG-32(d)(1)

t

=

P*D / (2*S*E - 0.2*P) + Corrosion

=

21*2,600 / (2*1,172.673*1 - 0.2*21) + 0

=

23.32 mm

The head internal pressure design thickness is 23.32 mm.

Maximum allowable working pressure, (Corroded at 87 C) UG-32(d)(1)

P

=

2*S*E*t / (D + 0.2*t) - Ps

=

2*1,172.673*1*32.3 / (2,600 +0.2*32.3) - 0

=

29.06 kgf/cm2

The maximum allowable working pressure (MAWP) is 29.06 kgf/cm2.

Maximum allowable pressure, (New at 21 C) UG-32(d)(1)

P

=

2*S*E*t / (D + 0.2*t) - Ps

=

2*1,172.673*1*32.3 / (2,600 +0.2*32.3) - 0

=

29.06 kgf/cm2

The maximum allowable pressure (MAP) is 29.06 kgf/cm2.

% Forming strain - UHA-44(a)(2)(b)

EFE =

(75*t / Rf)*(1 - Rf / Ro)

=

(75*38 / 461)*(1 - 461 / )

=

6.1822%

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

33/166

Straight Flange on TOP HEAD

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Straight Flange

Material specification:

SA-240 316L (II-D Metric p. 70, ln. 14)

Rated MDMT per UHA-51(d)(1)(a) = -196 C

Internal design pressure: P = 21 kg/cm2 @ 87 C

Static liquid head:

Ps = 0 kg/cm2

(SG = 0.521, Hs = 0 mm,Operating head)

Pth = 0.28 kg/cm2 (SG = 1, Hs = 2773.82 mm, Horizontal test head)

Ptv = 0.12 kg/cm2 (SG = 1, Hs = 1228 mm, Vertical test head)

Corrosion allowance

Inner C = 0 mm

Outer C = 0 mm

Design MDMT = -48 C

No impact test performed

Rated MDMT = -196 C

Material is not normalized

Material is not produced to Fine Grain Practice

PWHT is not performed

Radiography:

Longitudinal joint Full UW-11(a) Type 1

Circumferential joint Full UW-11(a) Type 1

Estimated weight New = 96.1 kg

corr = 96.1 kg

Capacity

New = 201.75 liters corr = 201.75 liters

ID

= 2,600 mm

Length Lc = 38 mm

t

= 38 mm

Insulation thk:

40 mm

density:

200 kg/m3

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 21*1,300 / (1,172.67*1.00 - 0.60*21) + 0

= 23.53 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,172.67*1.00*38 / (1,300 + 0.60*38) - 0

= 33.69 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,172.67*1.00*38 / (1,300 + 0.60*38)

= 33.69 kg/cm2

% Forming strain - UHA-44(a)(2)(a)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*38 / 1,319)*(1 - 1,319 / )

=

1.4405%

Design thickness = 23.53 mm

The governing condition is due to internal pressure.

The cylinder thickness of 38 mm is adequate.

Thickness Required Due to Pressure + External Loads

Allowable Stress

Before

UG-23 Stress

Pressure P

Condition

Increase ( kg/cm2)

( kg/cm2)

St

Sc

Temperature

( C)

Corrosion

C (mm)

Operating, Hot &

Corroded

21

1,172.7

746.2

87

Operating, Hot &

New

21

1,172.7

746.2

87

Hot Shut Down,

Corroded

1,172.7

746.2

87

Hot Shut Down,

New

1,172.7

746.2

87

Empty, Corroded

1,172.7

823.5

21

Empty, New

1,172.7

823.5

21

Hot Shut Down,

1,172.7

746.2

87

Weight:

Load

Wind

Req'd Thk

Due to

Tension

(mm)

0 kg

Req'd Thk Due to

Compression

(mm)

11.58

11.54

Seismic 11.59

11.54

Wind

11.58

11.54

Seismic 11.59

11.54

Wind

0.02

0.09

Seismic 0.02

0.09

Wind

0.02

0.09

Seismic 0.02

0.09

Wind

0.02

0.08

Seismic 0.02

0.08

Wind

0.02

0.08

Seismic 0.02

0.08

Weight

0.07

0.07

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

34/166

Corroded, Weight &

Eccentric Moments

Only

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

35/166

SHELL #1

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Material specification:

Rated MDMT per UHA-51(d)(1)(a) = -196 C

Cylinder

SA-240 316L (II-D Metric p. 70, ln. 14)

Internal design pressure: P = 21 kg/cm2 @ 87 C

Static liquid head:

Ps

Pth

Ptv

0.02 kg/cm2 (SG = 0.521, Hs = 458 mm,Operating head)

(SG = 1, Hs = 2773.82 mm, Horizontal test

0.28 kg/cm2

head)

0.36 kg/cm2 (SG = 1, Hs = 3628 mm, Vertical test head)

Corrosion allowance

Inner C = 0 mm

Design MDMT = -48 C

Rated MDMT = -196 C

Radiography:

No impact test performed

Material is not normalized

Material is not produced to Fine Grain Practice

PWHT is not performed

Longitudinal joint Top circumferential joint Bottom circumferential joint -

Estimated weight New = 6,120.9 kg

Capacity

ID

Length

=

Lc

t

=

Insulation thk:

corr = 6,120.9 kg

2,600

mm

2,400

mm

39 mm

40 mm

density:

Design thickness, (at 87 C) UG-27(c)(1)

=

=

=

P*R / (S*E - 0.60*P) + Corrosion

21.02*1,300 / (1,172.67*1.00 - 0.60*21.02) + 0

23.56 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

=

=

=

S*E*t / (R + 0.60*t) - Ps

1,172.67*1.00*39 / (1,300 + 0.60*39) - 0.02

34.53 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

=

=

=

S*E*t / (R + 0.60*t)

1,172.67*1.00*39 / (1,300 + 0.60*39)

34.56 kg/cm2

% Forming strain - UHA-44(a)(2)(a)

EFE

Full UW-11(a) Type 1

Full UW-11(a) Type 1

Full UW-11(a) Type 1

New = 12,742.3 liters corr = 12,742.3 liters

=

Outer C = 0 mm

(50*t / Rf)*(1 - Rf / Ro)

(50*39 / 1,319.5)*(1 - 1,319.5 / )

1.4778%

Design thickness = 23.56 mm

The governing condition is due to internal pressure.

The cylinder thickness of 39 mm is adequate.

200 kg/m3

Weight:

163.9 kg

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

36/166

Thickness Required Due to Pressure + External Loads

Pressure P (

kg/cm2)

Condition

Operating, Hot & Corroded

Operating, Hot & New

Hot Shut Down, Corroded

Hot Shut Down, New

Empty, Corroded

Empty, New

Hot Shut Down, Corroded, Weight & Eccentric

Moments Only

21

21

Allowable

Stress Before

UG-23 Stress

Increase (

kg/cm2)

St

Sc

1,172.7

749.8

1,172.7

1,172.7

1,172.7

1,172.7

1,172.7

1,172.7

749.8

749.8

749.8

827.4

827.4

749.8

Temperature (

C)

87

87

87

87

21

21

87

Corrosion C

(mm)

Load

Req'd Thk Due to

Tension (mm)

Req'd Thk Due to

Compression (mm)

Wind

11.6

11.36

Seismic

11.63

11.34

Wind

11.6

11.36

Seismic

11.63

11.34

Wind

0.01

0.37

Seismic

0.03

0.41

Wind

0.01

0.37

Seismic

0.03

0.41

Wind

0.01

0.33

Seismic

0.03

0.37

Wind

0.01

0.33

Seismic

0.03

0.37

Weight

0.17

0.28

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

37/166

SHELL #2

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Material specification:

Rated MDMT per UHA-51(d)(1)(a) = -196 C

Cylinder

SA-240 316L (II-D Metric p. 70, ln. 14)

Internal design pressure: P = 21 kg/cm2 @ 87 C

Static liquid head:

Ps

Pth

Ptv

0.26 kg/cm2 (SG = 0.521, Hs = 5082 mm,Operating head)

(SG = 1, Hs = 2773.82 mm, Horizontal test

0.28 kg/cm2

head)

0.82 kg/cm2 (SG = 1, Hs = 8252 mm, Vertical test head)

Corrosion allowance

Inner C = 0 mm

Design MDMT = -48 C

Rated MDMT = -196 C

Radiography:

No impact test performed

Material is not normalized

Material is not produced to Fine Grain Practice

PWHT is not performed

Longitudinal joint Top circumferential joint Bottom circumferential joint -

Estimated weight New = 9,675.3 kg

Capacity

ID

Length

Lc

t

corr = 9,675.3 kg

New = 24,550.17 liters corr = 24,550.17 liters

=

=

=

2,600

mm

4,624

mm

32 mm

Design thickness, (at 87 C) UG-27(c)(1)

t

=

=

=

P*R / (S*E - 0.60*P) + Corrosion

21.26*1,300 / (1,172.67*1.00 - 0.60*21.26) + 0

23.83 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

=

=

=

S*E*t / (R + 0.60*t) - Ps

1,172.67*1.00*32 / (1,300 + 0.60*32) - 0.26

28.18 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

=

=

=

S*E*t / (R + 0.60*t)

1,172.67*1.00*32 / (1,300 + 0.60*32)

28.45 kg/cm2

% Forming strain - UHA-44(a)(2)(a)

EFE

Outer C = 0 mm

(50*t / Rf)*(1 - Rf / Ro)

(50*32 / 1,316)*(1 - 1,316 / )

1.2158%

Design thickness = 23.83 mm

The governing condition is due to internal pressure.

The cylinder thickness of 32 mm is adequate.

Full UW-11(a) Type 1

Full UW-11(a) Type 1

Full UW-11(a) Type 1

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

38/166

Thickness Required Due to Pressure + External Loads

Pressure P (

kg/cm2)

Condition

Operating, Hot & Corroded

Operating, Hot & New

Hot Shut Down, Corroded

Hot Shut Down, New

Empty, Corroded

Empty, New

Hot Shut Down, Corroded, Weight & Eccentric

Moments Only

21

21

Allowable

Stress Before

UG-23 Stress

Increase (

kg/cm2)

St

Sc

1,172.7

722.6

1,172.7

1,172.7

1,172.7

1,172.7

1,172.7

1,172.7

722.6

722.6

722.6

798.1

798.1

722.6

Temperature (

C)

87

87

87

87

21

21

87

Corrosion C

(mm)

Load

Req'd Thk Due to

Tension (mm)

Req'd Thk Due to

Compression (mm)

Wind

11.74

10.96

Seismic

11.81

10.89

Wind

11.74

10.96

Seismic

11.81

10.89

Wind

0.14

1.03

Seismic

0.21

1.14

Wind

0.14

1.03

Seismic

0.21

1.14

Wind

0.14

0.93

Seismic

0.15

0.94

Wind

0.14

0.93

Seismic

0.15

0.94

Weight

0.42

0.58

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

39/166

Straight Flange on BTM. HEAD

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Straight Flange

Material specification:

SA-240 316L (II-D Metric p. 70, ln. 14)

Rated MDMT per UHA-51(d)(1)(a) = -196 C

Internal design pressure: P = 21 kg/cm2 @ 87 C

Static liquid head:

Ps = 0.27 kg/cm2 (SG = 0.521, Hs = 5120 mm,Operating head)

Pth = 0.28 kg/cm2 (SG = 1, Hs = 2773.82 mm, Horizontal test head)

Ptv = 0.83 kg/cm2 (SG = 1, Hs = 8290 mm, Vertical test head)

Corrosion allowance

Inner C = 0 mm

Outer C = 0 mm

Design MDMT = -48 C

No impact test performed

Rated MDMT = -196 C

Material is not normalized

Material is not produced to Fine Grain Practice

PWHT is not performed

Radiography:

Longitudinal joint Full UW-11(a) Type 1

Circumferential joint Full UW-11(a) Type 1

Estimated weight New = 96.1 kg

corr = 96.1 kg

Capacity

New = 201.75 liters corr = 201.75 liters

ID

= 2,600 mm

Length Lc = 38 mm

t

= 38 mm

Insulation thk:

40 mm

density:

200 kg/m3

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 21.27*1,300 / (1,172.67*1.00 - 0.60*21.27) + 0

= 23.84 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,172.67*1.00*38 / (1,300 + 0.60*38) - 0.27

= 33.42 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,172.67*1.00*38 / (1,300 + 0.60*38)

= 33.69 kg/cm2

% Forming strain - UHA-44(a)(2)(a)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*38 / 1,319)*(1 - 1,319 / )

=

1.4405%

Design thickness = 23.84 mm

The governing condition is due to internal pressure.

The cylinder thickness of 38 mm is adequate.

Thickness Required Due to Pressure + External Loads

Allowable Stress

Before UG-23 Stress

Pressure

P

Condition

Increase ( kg/cm2)

( kg/cm2)

St

Sc

Temperature

( C)

Corrosion

C (mm)

Operating, Hot &

Corroded

21

1,172.7

746.2

87

Operating, Hot &

New

21

1,172.7

746.2

87

Hot Shut Down,

Corroded

1,172.7

746.2

87

Hot Shut Down,

New

1,172.7

746.2

87

Empty, Corroded

1,172.7

823.5

21

Empty, New

1,172.7

823.5

21

Hot Shut Down,

Corroded, Weight &

1,172.7

746.2

87

Weight:

Load

Req'd Thk

Due to

Tension

(mm)

0 kg

Req'd Thk Due to

Compression

(mm)

11.75

10.96

Seismic 11.82

10.89

Wind

11.75

10.96

Seismic 11.82

10.89

Wind

Wind

0.15

Seismic 0.23

1.11

Wind

0.15

Seismic 0.23

1.11

Wind

0.9

0.15

Seismic 0.17

0.92

Wind

0.9

0.15

Seismic 0.17

0.92

Weight

0.55

0.39

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

40/166

Eccentric Moments

Only

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

41/166

BTM. HEAD

ASME Section VIII, Division 1, 2007 Edition, A09 Addenda Metric

Ellipsoidal Head

Component:

SA-240 316L (II-D Metric p.70, ln. 14)

Material Specification:

Material Rated MDMT per UHA-51(d)(1)(a) = -196 C

Internal design pressure: P = 21 kgf/cm2 @ 87 C

Static liquid head:

Ps= 0.3004 kgf/cm2 (SG=0.521, Hs=5770 mm Operating head)

Pth= 0.2772 kgf/cm2 (SG=1, Hs=2773.82 mm Horizontal test head)

Ptv= 0.8933 kgf/cm2 (SG=1, Hs=8940 mm Vertical test head)

Corrosion allowance:

Inner C = 0 mm

Outer C = 0 mm

Design MDMT = -48C

No impact test performed

Rated MDMT = -196C

Material is not normalized

Material is not produced to fine grain practice

PWHT is not performed

Do not Optimize MDMT / Find MAWP

Radiography:

Category A joints Head to shell seam -

Full UW-11(a) Type 1

Full UW-11(a) Type 1

new = 2,153.4 kg

corr = 2,153.4 kg

Estimated weight*:

new = 2,502.4 liters

corr = 2,502.4 liters

Capacity*:

* includes straight flange

= 2600 mm

Inner diameter

Minimum head thickness

= 32.3 mm

Head ratio D/2h

= 2 (new)

Head ratio D/2h

= 2 (corroded)

Straight flange length Lsf

= 38 mm

Nominal straight flange thickness tsf = 38 mm

weight: 65.0556 kg

Insulation thk*:

40 mm

density: 200 kg/m3

0 mm

individual weight: 0 kg

total weight: 0 kg

Insulation support ring spacing:

* includes straight flange if applicable

Results Summary

The governing condition is internal pressure.

Minimum thickness per UG-16

= 1.5 mm + 0 mm = 1.5 mm

Design thickness due to internal pressure (t)

= 23.66 mm

Maximum allowable working pressure (MAWP) = 28.76 kgf/cm2

Maximum allowable pressure (MAP)

= 29.06 kgf/cm2

Design thickness for internal pressure, (Corroded at 87 C) UG-32(d)(1)

t

=

P*D / (2*S*E - 0.2*P) + Corrosion

=

21.3*2,600 / (2*1,172.673*1 - 0.2*21.3) + 0

=

23.66 mm

The head internal pressure design thickness is 23.66 mm.

Maximum allowable working pressure, (Corroded at 87 C) UG-32(d)(1)

P

=

2*S*E*t / (D + 0.2*t) - Ps

=

2*1,172.673*1*32.3 / (2,600 +0.2*32.3) - 0.3

=

28.76 kgf/cm2

The maximum allowable working pressure (MAWP) is 28.76 kgf/cm2.

Maximum allowable pressure, (New at 21 C) UG-32(d)(1)

P

=

2*S*E*t / (D + 0.2*t) - Ps

=

2*1,172.673*1*32.3 / (2,600 +0.2*32.3) - 0

=

29.06 kgf/cm2

The maximum allowable pressure (MAP) is 29.06 kgf/cm2.

% Forming strain - UHA-44(a)(2)(b)

EFE =

(75*t / Rf)*(1 - Rf / Ro)

=

(75*38 / 461)*(1 - 461 / )

=

6.1822%

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

42/166

TWO PHASE INLET (A1)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) = 39 mm

Leg41 =

Note: Per UW-16(b) minimum inside corner radius r = min [1 / 4*t , 3 mm] = 3 mm

1

Located on:

SHELL #1

Liquid static head included:

0 kgf/cm2

Nozzle material specification:

SA-182 F316L <= 125 (II-D Metric p. 70, ln. 10)

Nozzle longitudinal joint efficiency:

Flange description:

16 inch Class 300 WN A182 F316L

Bolt Material:

SA-193 B8M 2 Bolt 25 < t <= 32 (II-D Metric p. 356, ln. 12)

Flange rated MDMT:

-196C

(Per UHA-51(d)(1)(a))

Liquid static head on flange:

0 kgf/cm2

ASME B16.5 flange rating MAWP:

36.86 kgf/cm2 @ 87C

ASME B16.5 flange rating MAP:

42.22 kgf/cm2 @ 21C

ASME B16.5 flange hydro test:

64.24 kgf/cm2 @ 21C

Gasket Description:

Flexitallic Spiral Wound CGI 316L S.S.

PWHT performed:

No

Circumferential joint radiography:

Full UW-11(a) Type 1

Nozzle orientation:

180

Local vessel minimum thickness:

39 mm

Nozzle center line offset to datum line:

6,738.15 mm

End of nozzle to shell center:

1,700 mm

Nozzle inside diameter, new:

380.4 mm

Nozzle wall thickness, tn:

89.8 mm

Nozzle minimum wall thickness:

13 mm

Nozzle corrosion allowance:

0 mm

Projection available outside vessel, Lpr:

214.95 mm

Projection available outside vessel to flange face, Lf:

Reinforcement Calculations for Internal Pressure

361 mm

UG-37 Area Calculation Summary (cm2)

2

For P = 28.18 kg /cm @ 87 C

f

The opening is adequately reinforced

UG-45

Nozzle Wall

Thickness

Summary

(mm)

The nozzle

passes UG-45

9 mm

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

43/166

A

required

A

available

A1

A2

A3

A5

A

welds

120.5789

194.6538

27.7774

166.0661

--

--

0.8103

treq

8.33

UG-41 Weld Failure Path Analysis Summary

The nozzle is exempt from weld strength calculations per

UW-15(b)(1)

UW-16 Weld Sizing Summary

Weld description

Nozzle to shell fillet (Leg41)

Required weld

throat size (mm)

Actual weld

throat size (mm)

6.3

Status

weld size is adequate

tmin

13

DOC. NO. : 1041-D-001A

REV. NO. :

0

PAGE NO. :

44/166

LIQIUD OUTLET (B1)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) = 32.3 mm

Leg41 =

Note: Per UW-16(b) minimum inside corner radius r = min [1 / 4*t , 3 mm] = 3 mm

1

Located on:

BTM HEAD

Liquid static head included:

0.3618 kgf/cm2

Nozzle material specification:

SA-182 F316L <= 125 (II-D Metric p. 70, ln. 10)

Nozzle longitudinal joint efficiency:

Flange description:

10 inch Class 300 WN A105

Bolt Material:

SA-193 B7 Bolt <= 64 (II-D Metric p. 348, ln. 33)

Flange rated MDMT:

-48C

(UCS-66(b)(1)(b))

Liquid static head on flange:

0.3635 kgf/cm2

ASME B16.5 flange rating MAWP:

48.45 kgf/cm2 @ 87C

ASME B16.5 flange rating MAP:

52.11 kgf/cm2 @ 21C

ASME B16.5 flange hydro test:

78.52 kgf/cm2 @ 21C

Gasket Description:

Flexitallic Spiral Wound CGI 321 S.S.

PWHT performed:

No

Circumferential joint radiography:

Full UW-11(a) Type 1

Nozzle orientation:

180

Calculated as hillside:

No

Local vessel minimum thickness:

32.3 mm

End of nozzle to datum line:

-1,863 mm

Nozzle inside diameter, new:

247.7 mm

Nozzle wall thickness, tn:

51.15 mm

Nozzle minimum wall thickness:

12.7 mm

Nozzle corrosion allowance:

0 mm