Beruflich Dokumente

Kultur Dokumente

Compression Stiffeners

Hochgeladen von

ZsuzsaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Compression Stiffeners

Hochgeladen von

ZsuzsaCopyright:

Verfügbare Formate

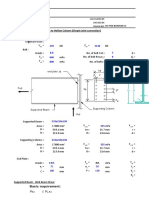

Resistance of unstiffened webs subject to compression

Actions (loading)

Design force :

FEd

kN

Resistance of unstiffened webs subject to concentrated load.

The compression resistance is assumed to be provided at the position of the concentrate

length of web that resists the compression depends on the dispersion of the force throug

plate and flange. If the web is inadequate in compression, a stiffener may be provided .

The area of web providing resistance to compression is given by the dispersion length sh

Figure below.

tfb=

sf=

tp=

tfc=

twc=

hc=

s=

mm

mm

mm

mm

mm

mm

mm

fywc=

N/mm2

The design resistance of an unstiffened column web in transverse compression is determined fro

but

where:

beff,c,wc= tfb+2sf+n(tfc+s)+sp

n

=

=

5

2+0.6be/(tfc+s)

Therefore,

be

Page 1 of 12

330287239.xlsx

0 mm

except at the end of a member

at the end of a member

n=

is the distance to the nearer end of the member from the end of the stiff

bearing

=

mm

is a reduction factor that takes account of the interaction with shear

For single sided joint

Avc=

mm2

Therefore,

twc

fy,wc

kwc

For no moment transferred through conn

is the thickness of the supporting web

is the yield strength of the column web

is a reduction factor, allowing for coexisting longitudinal compressive stress in th

The stress com,Ed is the sum of bending and axial design stresses in the column, f

design situation at the connection.

Conservatively, kwc could be taken as 0.7

=

is a reduction factor, allowing for plate buckling in the web

In which

=

E=

Therefore,

s =rc

=2a

Page 2 of 12

330287239.xlsx

###

0 mm

### Mpa

=

###

for rolled I and H column sections

for welded sections (a is the length of weld throat)

sf is the leg length of the fillet weld between the compression flange and the end p

Page 3 of 12

330287239.xlsx

sp =2tp

(provided that the dispersion line remains within the end plate)

Therefore,

Therefore

Fc,wc,Rd=

Therefore

###

0 kN

### kN

### kN

###

###

0 kN

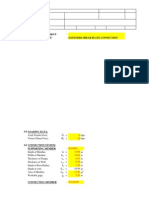

Compression stiffeners

Compression stiffeners should be provided symmetrically on either side of theweb and s

depth, as shown in Figure below.

bsg

bsn

ts

=

=

=

fy

The resistance of the effective stiffener cross section and the buckling resistance of the s

must be at least equal to the design force at the compression flange .

The effective stiffener section for buckling resistance comprises a cruciform made up of

web and the stiffeners on either side. The length of web considered to act as part of the

section is taken as 15twc either side of the stiffener.

where:

###

The width/thickness ratio of the stiffener outstand needs to be limited to prevent torsion

this can be achieved by observing the Class 3 limit for compression flange outstands. Th

bsg/ts

###

14

###

The effective area for buckling resistance is thus:

As,eff=

Page 4 of 12

330287239.xlsx

(30tw+ts)tw+2bsgts

### mm2

The second moment of area of the stiffener may be

taken as:

Is=

(2bsg+twc)3ts/12

0 mm4

Cross-sectional Resistance

The cross-sectional resistance of the effective compression stiffener section is:

=

0 kN

>

0 kN

For cross-sectional resistance, As,eff is the area of stiffener in contact with the flange plus

length of web given by dispersal from the beam flange.

As,eff=

2*bsn*ts+beff,c,wc*twc

0 mm2

Flexural Buckling Resistance

The flexural buckling resistance of the stiffener depends on its non-dimensional slendern

by:

where:

1=

93.9 =

l=

hw=

is=

Is/As,eff

###

###

0 mm

=

###

Therefore,

If the slenderness 0.2, the flexural buckling resistance of the compressions stiffener m

ignored (only the resistance of the cross-section needs to be considered).

For > 0.2, the flexural buckling resistance is given by:

where:

=

=

Page 5 of 12

330287239.xlsx

0.49

###

Therefore,

###

###

### kN

###

###

0 kN

Weld to Column Flange

The stiffener is normally fabricated with a bearing fit to the inside of the column flange. I

the weld to the flange need only be a nominal (6 mm leg length) fillet weld. If a bearing

possible, the welds should be designed to carry the force in the stiffeners.

Page 6 of 12

330287239.xlsx

position of the concentrated load. The

spersion of the force through the end

tiffener may be provided .

by the dispersion length shown on the

mpression is determined from:

pt at the end of a member

e end of a member

ber from the end of the stiff

Page 7 of 12

330287239.xlsx

tion with shear

nt transferred through connection

nal compressive stress in the column

gn stresses in the column, for the

Page 8 of 12

330287239.xlsx

ession flange and the end plate

Page 9 of 12

330287239.xlsx

hin the end plate)

0 kN

either side of theweb and should be full

mm

mm

mm

Mpa

buckling resistance of the stiffener

flange .

es a cruciform made up of a length of

idered to act as part of the stiffener

e limited to prevent torsional buckling;

ession flange outstands. Thus:

###

Page 10 of 12

330287239.xlsx

iffener section is:

FALSE

ontact with the flange plus that of a

s non-dimensional slenderness, given

the compressions stiffener may be

considered).

Page 11 of 12

330287239.xlsx

###

side of the column flange. In this case

gth) fillet weld. If a bearing fit is not

he stiffeners.

Page 12 of 12

330287239.xlsx

Das könnte Ihnen auch gefallen

- Connections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)Dokument5 SeitenConnections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)travis8zimmermannNoch keine Bewertungen

- End Plate Conn. To Hollow Col. EC2Dokument26 SeitenEnd Plate Conn. To Hollow Col. EC2Raymond SabadoNoch keine Bewertungen

- Cranebeam v1 2 AramadaDokument1 SeiteCranebeam v1 2 AramadaronyNoch keine Bewertungen

- Types of Tension Member Design For Axial TensionDokument450 SeitenTypes of Tension Member Design For Axial TensionJeve MilitanteNoch keine Bewertungen

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDokument29 SeitenPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENoch keine Bewertungen

- Specification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsDokument9 SeitenSpecification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsMr Incognito100% (1)

- Structural Steel Design Project: Calculation SheetDokument14 SeitenStructural Steel Design Project: Calculation SheetJoey Johnson100% (2)

- Corbel Design AllenDokument3 SeitenCorbel Design Allenmanoj_structureNoch keine Bewertungen

- Steel Grillage Fondation: Presented byDokument12 SeitenSteel Grillage Fondation: Presented byAbhishek ChaurasiaNoch keine Bewertungen

- AISC-Extended Shear Plate ConnectionDokument7 SeitenAISC-Extended Shear Plate ConnectionMuthukumaran SivalingamNoch keine Bewertungen

- Prof M G Gadgil Building Designed As Per Old Code and IS 16700-2017 PDFDokument128 SeitenProf M G Gadgil Building Designed As Per Old Code and IS 16700-2017 PDFankit kadamNoch keine Bewertungen

- Calculation Sheet: Design of Splice For BeamDokument6 SeitenCalculation Sheet: Design of Splice For BeamTOM YEENoch keine Bewertungen

- Double Angle ConnectionDokument8 SeitenDouble Angle ConnectionrunkirNoch keine Bewertungen

- Braking Test: Vehicle Laboratory 2Dokument20 SeitenBraking Test: Vehicle Laboratory 2Steven SullivanNoch keine Bewertungen

- Staircase Design: 8.28kN/m 15.57kN/mDokument3 SeitenStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNoch keine Bewertungen

- Design of Column BasesDokument9 SeitenDesign of Column Basesdarshanakp100% (1)

- AISC (LRFD) Shear Connection - Cleat AngleDokument14 SeitenAISC (LRFD) Shear Connection - Cleat AngleMANOJNoch keine Bewertungen

- End Plate Moment ConnectionDokument3 SeitenEnd Plate Moment ConnectionIndustry Standard Structural DesignNoch keine Bewertungen

- Bolted ConnectionsDokument3 SeitenBolted ConnectionsandreiroscaNoch keine Bewertungen

- Circular WeldDokument12 SeitenCircular WeldJohn Paul UmaliNoch keine Bewertungen

- AISC LRFD Column DesignDokument4 SeitenAISC LRFD Column Designwinlugue3059Noch keine Bewertungen

- Calculation For Base Plate ConnectionDokument85 SeitenCalculation For Base Plate ConnectionpriantomoNoch keine Bewertungen

- Weld StrengthDokument9 SeitenWeld StrengthRUDHRA DHANASEKAR50% (2)

- Circular WeldDokument12 SeitenCircular WeldJohn Paul UmaliNoch keine Bewertungen

- Steel Design - LRFD AISC Steel Manual 13th Edition Bolted ConnectionsDokument4 SeitenSteel Design - LRFD AISC Steel Manual 13th Edition Bolted ConnectionsRangga SatriaNoch keine Bewertungen

- Design of Shear KeyDokument13 SeitenDesign of Shear KeyRonnie SmithNoch keine Bewertungen

- Steel ConnectionsDokument83 SeitenSteel ConnectionsMEPNoch keine Bewertungen

- Week 6 Lecture Material - WatermarkDokument59 SeitenWeek 6 Lecture Material - WatermarkVaibhav SharmaNoch keine Bewertungen

- Base Plate & BoltsDokument3 SeitenBase Plate & BoltsarvnndNoch keine Bewertungen

- Beam Columns Example - Is 800Dokument7 SeitenBeam Columns Example - Is 800anil97232Noch keine Bewertungen

- Splice Connection Beam Wide FlangeDokument2 SeitenSplice Connection Beam Wide Flangejoneru 04Noch keine Bewertungen

- Plate GirderDokument11 SeitenPlate GirderAfia S HameedNoch keine Bewertungen

- Base Plate Design ExampleDokument74 SeitenBase Plate Design ExampleNiko NištićNoch keine Bewertungen

- RAM Connection Input With CommentsDokument6 SeitenRAM Connection Input With CommentsAhmed Saeed OokaNoch keine Bewertungen

- Bolt Design For Steel Connections As Per AISCDokument24 SeitenBolt Design For Steel Connections As Per AISCDjordjeDj100% (1)

- Ec3 Steel Design JointDokument2 SeitenEc3 Steel Design JointneverreturnNoch keine Bewertungen

- Design of Long Wall: Tank Full and No Soil PressureDokument6 SeitenDesign of Long Wall: Tank Full and No Soil PressureAshoka YadavNoch keine Bewertungen

- Steel I Beam Web Shear CapacityDokument1 SeiteSteel I Beam Web Shear CapacityArjun RajaNoch keine Bewertungen

- Reference For Shear ConnectionDokument7 SeitenReference For Shear ConnectionmaheshbandhamNoch keine Bewertungen

- 41-Pile FoundationDokument56 Seiten41-Pile Foundationsharif uddinNoch keine Bewertungen

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDokument4 SeitenShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNoch keine Bewertungen

- Brace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Dokument44 SeitenBrace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Antonio LópezNoch keine Bewertungen

- Slab Design of Partially Fixed Circular SlabDokument4 SeitenSlab Design of Partially Fixed Circular SlabBithika DattaNoch keine Bewertungen

- Pinned Base Plates 18Dokument1 SeitePinned Base Plates 18pawkomNoch keine Bewertungen

- Roof TrussDokument4 SeitenRoof TrussShamie Dela Cruz CaldeaNoch keine Bewertungen

- Here: Mat Foundation Design Spreadsheet PDFDokument2 SeitenHere: Mat Foundation Design Spreadsheet PDFbiniamNoch keine Bewertungen

- Madvi Ko Behjna HaiDokument7 SeitenMadvi Ko Behjna Haibhavyakumar26Noch keine Bewertungen

- 1.design For Shear For Prestressed ConcreteDokument34 Seiten1.design For Shear For Prestressed ConcretealexNoch keine Bewertungen

- Design of Stiffeners Under LoadsDokument2 SeitenDesign of Stiffeners Under Loadsmadasamya20Noch keine Bewertungen

- Chapter 2 - Shear Design SP 17-09-07Dokument37 SeitenChapter 2 - Shear Design SP 17-09-07Alex FerrariNoch keine Bewertungen

- SHEARDokument11 SeitenSHEARJen Burdeos100% (1)

- Concrete CalculationDokument10 SeitenConcrete CalculationKaye Ibañez CastilloNoch keine Bewertungen

- Shear Design of BeamDokument46 SeitenShear Design of BeamNeha ChauhanNoch keine Bewertungen

- Reinforced Concrete Beam DesignDokument8 SeitenReinforced Concrete Beam DesignLindy Kho100% (1)

- Reinforced Concrete Beam DesignDokument8 SeitenReinforced Concrete Beam DesignEngr Alam Shah FarooqiNoch keine Bewertungen

- Chapter V - 1 - Design of Deep Flexural MemberDokument56 SeitenChapter V - 1 - Design of Deep Flexural Memberpemeliharaan pi3Noch keine Bewertungen

- Chpt4Torsion in RCMembers (F) CDokument13 SeitenChpt4Torsion in RCMembers (F) CIsmail A Ismail100% (1)

- Chapter 9Dokument23 SeitenChapter 9Mahfuzur RahmanNoch keine Bewertungen

- 2.1 Bolts GeneralDokument54 Seiten2.1 Bolts GeneralIyrin JohnNoch keine Bewertungen

- Fundamentals 1-24Dokument5 SeitenFundamentals 1-24marklloydcanda30Noch keine Bewertungen

- Axle Fracture of An ICE3 High Speed Train - 2013 - Engineering Failure AnalysisDokument16 SeitenAxle Fracture of An ICE3 High Speed Train - 2013 - Engineering Failure AnalysisArimateia SoaresNoch keine Bewertungen

- Clayton, 1992, Earth-Pressures On Backfilled-Retaining-WallsDokument9 SeitenClayton, 1992, Earth-Pressures On Backfilled-Retaining-Wallsprisciliano1Noch keine Bewertungen

- Final Assignment: Geotechnical Earthquake Engineering Professor: Ikuo Towhata Name: Phaknakhone RATTANA ID: 37-117008 Submitted Dated: 27 A Gust 2011Dokument2 SeitenFinal Assignment: Geotechnical Earthquake Engineering Professor: Ikuo Towhata Name: Phaknakhone RATTANA ID: 37-117008 Submitted Dated: 27 A Gust 2011Thắng HồNoch keine Bewertungen

- Me472 Failure Analysis and DesignDokument2 SeitenMe472 Failure Analysis and DesignSreehari SNoch keine Bewertungen

- Chapter 5 Principal Stresses PDFDokument61 SeitenChapter 5 Principal Stresses PDFcoded coderNoch keine Bewertungen

- EN1992 2 ManciniDokument138 SeitenEN1992 2 Mancinidragos_bogdan1974Noch keine Bewertungen

- Additional Calculation For Folding DoorDokument14 SeitenAdditional Calculation For Folding DoorNoman AliNoch keine Bewertungen

- Yield States and Stress-Strain Relationships in A Natural Plastic Clay. Graham, Noonan, and Lew (1983)Dokument15 SeitenYield States and Stress-Strain Relationships in A Natural Plastic Clay. Graham, Noonan, and Lew (1983)Jesus GonzalezNoch keine Bewertungen

- Damage and Plasticity For Concrete BehaviorDokument16 SeitenDamage and Plasticity For Concrete BehaviorJosé Antonio Cornetero UrpequeNoch keine Bewertungen

- Chapter 1Dokument18 SeitenChapter 1ephNoch keine Bewertungen

- 1971 Casagrande On Liquefaction Phenomena, Report of LectureDokument8 Seiten1971 Casagrande On Liquefaction Phenomena, Report of Lecturea_nikro0% (1)

- FEMA 451 Compl - Struct Analysis Performance-BasedDokument85 SeitenFEMA 451 Compl - Struct Analysis Performance-BasedGeorge Sanches100% (2)

- Design of Knuckle JointDokument26 SeitenDesign of Knuckle Jointvikasporwal2605100% (2)

- Parámetros en GeotecniaDokument20 SeitenParámetros en Geotecniahad18052010Noch keine Bewertungen

- A Case History On Design, Construction, and Performance of Stone Column PDFDokument10 SeitenA Case History On Design, Construction, and Performance of Stone Column PDFSuthan PooranampillaiNoch keine Bewertungen

- Understanding Loss Modulus and Tan DeltaDokument7 SeitenUnderstanding Loss Modulus and Tan DeltaJohn BenedictNoch keine Bewertungen

- Design of Steel Structure-1Dokument30 SeitenDesign of Steel Structure-1separveenjangra100% (1)

- An Analytical and Experimental Study of Stretch Flanging N.-M. W O and M. L. WennerDokument13 SeitenAn Analytical and Experimental Study of Stretch Flanging N.-M. W O and M. L. Wenner0511018Noch keine Bewertungen

- FHWA Design and Construction of Stone Columns Vol.1 ExtraDokument46 SeitenFHWA Design and Construction of Stone Columns Vol.1 ExtranoordenNoch keine Bewertungen

- Stress CorrosionDokument13 SeitenStress CorrosionAbhinav GuptaNoch keine Bewertungen

- 9201 CVRMDokument275 Seiten9201 CVRMAjayvidyanand SharmaNoch keine Bewertungen

- Concordia University: MECH 390 - Mechanical Engineering Design ProjectDokument58 SeitenConcordia University: MECH 390 - Mechanical Engineering Design ProjectAlexander Rueda OrduzNoch keine Bewertungen

- Seismicity of Metro ManilaDokument2 SeitenSeismicity of Metro ManilaKiel CruzNoch keine Bewertungen

- Physical and Mechanical Properties of Dental MaterialsDokument104 SeitenPhysical and Mechanical Properties of Dental Materialsdiwakar2100% (1)

- Slides of SFRCDokument5 SeitenSlides of SFRCjhony06Noch keine Bewertungen

- Problem Set No. 2Dokument2 SeitenProblem Set No. 2Kristoffer YapanaNoch keine Bewertungen

- Hollow Core DiaphragmDokument10 SeitenHollow Core DiaphragmJaher WasimNoch keine Bewertungen

- School of Architecture and Design Architecture Department Fall 2020-2021Dokument3 SeitenSchool of Architecture and Design Architecture Department Fall 2020-2021death armyNoch keine Bewertungen

- Investigating Seismic Behavior of Horizontally Curved RC Bridges With Different Types of Irregularity in Comparison With Equivalent Straight BridgesDokument18 SeitenInvestigating Seismic Behavior of Horizontally Curved RC Bridges With Different Types of Irregularity in Comparison With Equivalent Straight Bridgesgrobardogroba1211Noch keine Bewertungen

- Ashby ChartDokument6 SeitenAshby ChartArjul AkramNoch keine Bewertungen