Beruflich Dokumente

Kultur Dokumente

Stability of Cyanocobalamine in Film-Coated Tablets

Hochgeladen von

NoemiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stability of Cyanocobalamine in Film-Coated Tablets

Hochgeladen von

NoemiCopyright:

Verfügbare Formate

Joiirnal of Pharmaceutical Sciences

1854

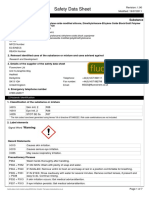

T A U L E VI-COMPARISON

OF ASPIRINTABLET

STABILITY TESTING

RESULTSA T 5 0 C . A N D 81-2%

HUMIDITY,

BASEDON THE DETERMINATION

OF ASPIRINAND SALICYLIC

ACIDCONTENTOF THE

RELATIVE

TABLETS=

Time,

Days

Aspirin Content

Based on Analysis

of Aspirin, %

Aspirin Content

Based on Analysis

of Salicylic Acid, yo

Error

Due to

Sublimation

of Salicylic Acid, %

0

15

30

45

60

98

100

99.1 f 0.038

98.4f 0.042

$7.2 f 0.123

97.1 f 0.178

95.0 f 0.288

100

99.1 f 0.028

98.8 0.215

98.7f 0.075

98.6 f 0.023

97.9 f 0.311

0

0

0.4

1.5

1.5

2.9

Each value is the average of 4 determinations recorded with f l standard deviation.

be interpreted as a trend toward equilibrium within

the tablet (2). Judging from the lower curve, no

such trend toward equilibrium is apparent. The

data pertaining t o Fig. 5 is summarized in Tahle

VI.

of gauging the stability of the formulation. A

method of analysis for aspirin with an accuracy of

a t least 1.5% was developed for application to

tasting of aspirin stability in solid dosage forms.

REFERENCES

SUMMARY AND CONCLUSIONS

Previously reported studies of the stability of

aspirin-containing solids have utilized the salicylic

acid content of the solids as a measure of aspirin

decomposition. The underestimation in the extent

of decomposition of the aspirin which can result

from such a practice is clearly demonstrated by

the results of the present work. The error can

be expected t o become increasingly serious with

storage time and the severity of the temperature

and humidity conditions under which the solids

are stored. This error can be circumvented by

employing a method of determining decomposed

aspirin which is independent of the loss of salicylic

acid from the solid due to sublimation. Since

aspirin was found not to sublime, the determination of its residual content in a solid is a valid means

(1) Nord. M.. Chcm. Enn.. 58. 157(1951).

(2) Leeson, L. J., and Mattocks, A. M., J . A m . Pharm.

Assoc.. Sci. E d . . 47. 329(1958).

(3) EdwaFdsL. j . T;ans.-Faraday SOC.46 723(1950).

(4) Garrett, E. R.: J . Org. Chem.. 26, &360~1961).

(5) Willard, H.H.. Merritt. L. L., and Dean, J. P . . Instrumental Methods of Analysis, 4th. ed., D. Van Nostrand.

Princeton, N.J., 1965, pp. 94-95.

Keypbrases

Aspirin stability-salicylic

acid sublimation

Salicylic acid sublimation-aspirin

tablets

Temperature eff ect-aspirin tablets stability

UV spectrophotometry-analysis

Stability of Cyanocobalamin in Film-Coated

Multivitamin Tablets

By JAMES T. JACOB, ROBERT J. NESSEL, and JACK BLODINGER

Multivitamin tablets containing each of two commercially available protected forms

of cyanocobalamin showed considerable loss of vitamin Blz after exposure to methanol vapor for 1 month at room temperature. Other solvents commonly used i n

film coating such as acetone, n-butanol, butyl acetate, isopropanol, and methylene

chloride did not affect the stability of vitamin B12. Tablets containing vitamins

B1, BIZ,ascorbic acid, and niacinamide, alone and i n combination with one another

after exposure to methanol vapor at room temperature showed considerable loss of

vitamin Blz only i n presence of ascorbic acid and/or niacinamide.

HERE ARE SEVERAL

reports in the literature

on the stability of cyanocobalamin (vitamin

Received June 13,1968, from the Product Development and

Service Laboratories, Merck & Co., Inc., Rahway, NJ 07065

Accepted for publication July 25, 1968.

Presented to the Industrial Pharmaceutical Technology

Section, APAA Academy of Pharmaceutical Sciences, Miami

Beach meeting, May 1968.

Biz) in liquid multivitamin preparations. Decomposition products of other vitamins, pH, heat,

and light can in most cases contribute t o the

degradation of vitamin BIZ. Feller and Macek

(1) reported that decomposition Of vitamin Biz

occurs at elevated temperatures in the presence

Vol. 57, No. 11, November 1968

of thiamine decomposition products. Doerge,

et al. ( 2 ) found that a thiol-containing degradation product of thiamine hydrochloride may be

responsible for the losses of vitamin BIZpotency

during storage. Bartilucci et al. ( 3 ) showed

that in liquid preparations, dehydroascorbic acid,

the first decomposition product of ascorbic acid,

caused greater instability of vitamin B I Z than

ascorbic acid.

Cyanocobalainin has been found Lu be stabilized in solid dosage forms, such as multivitamin

tablets by the incorporation of the vitamin in the

sugar coating, thus separating it from the other

active components. However, with the increasing use of film-coating, this method is not applicable. For this reason, the use of a protected

form of the vitamin is a necessity. Two such

forms commercially available are cyanocobalamin dispersed in gelatin' and cyanocobalamin

adsorbed on resin.

The process of film-coating involves spraying a

solution of a film-forming polymer in single or

mixed organic solvents onto the moving bed of

tablets or within a n air suspension column. The

solvents are then removed by intermittent drying

of the tablets. The total time for film-coating

varies, depending upon the type of film-forming

polymers and solvents used, thickness of the film,

number of tablets coated, and the process used.

It is quite possible for the solvent(s) to penetrate

into the tablet core during the long exposure.

Holl et al. (4) reported that tablets that were

film-coated with a solution of cellulose acetate

phthalate, even after considerable drying, retained residual amounts of acetone. Other solvents commonly used in film-coating are methanol, methylene chloride, chloroform, butanol,

and isopropanol.

Vitamin BI2dispersed in gelatin has shown very

good stability in uncoated multivitamin tablets.

However, because of an unexpected loss in potency observed when incorporated in tablets

that were film-coated, this investigation was

undertaken. The purpose of this investigation

was to determine whether the solvents used in

film-coating may be the cause of the aforementioned instability. For this study, solvent effects

were determined on two commercially available

protected cyanocobalamin forms.

EXPERIMENTAL

Materials-Acetone,a ascorbic acid, USP, butyl

a ~ e t a t e n-butyl

,~

alcohol,a chl~roform,~

1% cyano1 Marketed as Stabicote b y Merck & Co., Inc., Rahway,

N . J.

1 Marketed as Stablets by Chas. Pfizer & Co.. Inc., New

York, N . Y.

Reagent Grade, Merck % Co., Inc., Rahway, N. J.

4 Matheson, Coleman and Bell, Norwood, Ohio.

1855

TADLE

I-COMPOSITIONOF MULTIVITAMIN

TABLETS

Ingredient

Vitamin A acetate

Vitamin DZ

Thiamine mononitrate, USP

Riboflavin, USP

Ascorbic acida

Niacinamide"

&Calcium pantothenate, USI'

Cyanocobalaminb

Vitamin E succinate

Folic acid

Dicalcium phosphate

Microcrystalline cellulose"

Magnesium stearate

Stearic acid

Talc

Potency

per Tablet

5000 units

400 units

1.4 mg.

2 . 0 mg.

70.0 mg.

22.0 mg.

10.0 mg.

4 . 0 mcg.

15 units

0.1 mg.

20.0 mg.

30.0 mg.

2 . 5 mg.

5 . 0 mg.

10.0 mg.

In the form of Merpress-registered trademark or niacinamide ascorbate, Merck & Co., Inc. Rahway, N. J. Added

as 1% cyanocobalamin dispersed in gelatin; second batch

contained thesamequantityintheformof 1% cyanocobalamin

Marketed as Avicel by American Visadsorbed on resin.

cose Co., Marcus Hook, Pa.

(I

balamin dispersed in gelatin, 1% cyanocobalamin

adsorbed on resin, isopropyl alcohol,a anhydrous

methan01,~methylene chloride,a niacinamide, USP,

thiamine mononitrate, USP.

Preparation of Tablets-Two

1,000-tablet

batches of a full formula multivitamin were prepared by a direct compression method using 0.79-cm.

(6/le-in.) dies and standard concave punches on a

Manesty single-punch machine. One batch contained vitamin B12in the form of cyanocobalamin

dispersed in gelatin and the other, in the form of cyanocobalamin adsorbed on resin. The quantitative

formula is shown in Table I.

Immersion in Solvents-Ten tablets were immersed for exactly 60 sec. in a beaker containing each

of the following solvents: acetone, butyl acetate,

n-butyl alcohol, chloroform, isopropyl alcohol,

methyl alcohol and methylene chloride. The solvent

was then poured off, the tablets were air dried for

30 sec. and one-half of the tablets were stored at

room temperature and the rest a t 50'. After 1

month, the tablets were removed and were assayed

for vitamin B12 content.

Exposure to Solvent Vapors-Twenty multivitamin tablets were placed in loosely capped 20-ml.

amber bottles, and stored in desiccators containing

each of the solvents used in the immersion test at

room temperature. After storage for 1 month, the

tablets were assayed for vitamin Blz content.

Solubility Test-The dissolution of cyanocobalamin from the two protected forms in methanol was

determined as follows: 200 mg. of each powder was

weighed into 125-ml. amber colored conical flasks.

Fifty milliliters of anhydrous methanol yas added

and the flasks shaken on a mechanical shakefl for

48 hr. at room temperature. The solution was

filtered and the absorbance of the filtrate was measured a t 361 mp on a Cary I1 spectrophotometer using methanol as the reference solvent. The quantity

of dissolved cyanocobalamin was calculated from a

standard curve of cyanocobalamin solution in methanol.

Assay Methods-The tablets were assayed for

vitamin contents using standard assay methods.

6

Burrel Wrist Action shaker, Pittsburgh, Pa.

1856

Journal of Pharmaceutical Sciences

TABLE

II-%

Loss OF VITAMIN Bl* FROM MULTIVITAMIN

TABLETS

EXPOSED

TO

VARIOUS

SOLVENT

VAPORSFOR 1 M O N T H

AT ROOMTEMPERATURE

Batch

No.

Acetone

No loss

No loss

la

2*

Butyl

Acetate

1:-Butanol

No loss

0.5

Chloroform

1.2

No loss

0.5

5.7

Contained Biz as 1%

' cyanocobalamin dispersed in gelatin.

RESULTS AND DISCUSSION

Immersion in Solvents-The time for immersion

of the tablets in the solvents was limited to 1 min.

so that the tablets would not be soaked with the solvents. The assay results showed little or no loss of

vitamin BIZpotency after storage either at room temperature or at 50' for 1 month. The concentration

of the solvents retained in the tablets may not have

been quite sufficient to cause any stability problem

for vitamin BIZ.

Exposure to Solvent Vapors-The tablets stored in

desiccators containing n-butyl alcohol, butyl acetate,

TABLE111- COMPOSITION^ AND POTENCY

Loss OF

INDIVIDUAL

VITAMINSFROM TABLETS

EXPOSEDTO

METHANOL

VAPOR FOR 1 MONTHAT

ROOMTEMPERATURE

-Potency

Batch

No.

3

4

5

6

7

BIZ,

mcg.

4.0b

4.OC

of Each TabletAscorbic NiacinAcid,

amide,

mg.

mg.

mg.

BI,

1.4

-

70.0

-

22.0

lsoprupanol

-.

yo

Loss

0.0

5.0

18.0

4.4

0.0

In addition to the vitamin, each tablet contained the same

quantities of excipients as in the multivitamin tablet (Table I )

and sufficient quantity of spray-dried lactose to adjust the

weight to t h a t of the multivitamin tablet.

As 1% cyanocobalamin dispersed in gelatin.

As 1% cyanocobalamin odsorbed on resin.

chloroform, isopropanol, and methylene chloride

showed no loss of vitamin BIZpotency, whereas tablets similarly exposed to methanol vapors showed

considerable loss (Table 11). Because of this loss,

the dissolution of cyanocobalamin in methanol from

its two protected forms was determined in order to

consider the possibility of extraction of vitamin B12

from the protective matrix into the tablet. Twentyfive percent of vitamin BIZdissolved in methanol from

the gelatin-dispersed form, while 55% of the vitamin

leached from the resin adsorbate. Exposure of the

two protected forms of vitamin BIZper se to methanol

vapor for 1 month showed no loss from the gelatindispersed form, whereas 20% loss was observed from

Contained

Methylene

Chloride

Methanol

No loss

N o loss

24.5

No loss

No loss

26.5

BI?as 1Yo cyanocobalamin adsnrbed on resin.

the resin adsorbate. This loss of vitamin BIZmay

be attributed to the fact that methanol vapor eapily

penetrated the resin adsorbate, which remained aJ a

powder, whereas the gelatin-dispersed powder solidilied in the bottle thereby preventing any penetration of methanol vapor. Since in aqueous solutions,

degradation products of ascorbic acid, especially dehydroascorbic acid, are known t o adversely affect the

stability of vitamin Blr (4).it was necessary to determine whether this or any other vitamin in presence of

methanol vapor may have any deleterious effect on

the stability of vitamin BIZ. For this purpose, tablets were prepared with ascorbic acid, niacinamide,

thiamine mononitrate, cyanocobalamin dispersed in

gelatin, and cyanocobalamin adsorbed on resin, alone

and in combination with one another. The potency

of each vitamin and the excipient quantities were

maintained at the same level as in the multivitamin

tablets except t h a t spray-dried lactose was used t o

adjust the weight to that of the multivitamin tablets. All tablets were formulated so as to be of same

size, weight, and hardness. These tablets were then

exposed t o methanol vapor by storage in desiccators

for 1 month a t room temperature.

A study of Table I11 shows that methanol vapor

did not cause an appreciable decrease in the potencies of protected vitamin B ~ (both

z

forms), ascorbic

acid, and niacinamide when these vitamins were

present alone in the tablets. The effect was more

pronounced on vitamin BI tablets which lost lS70 of

the vitamin (see Batch No. 5). Table I V shows t h a t

there was only a small loss of ascorbic acid, but its

presence in the tablet caused considerable loss of vitamin Biz. There was also a significant loss of vitamin

BI from the tablets (see Batch Nos. 10 and 11).

Table V shows that tablets containing vitamins

BI-Blpniacinamide combinations had little or no loss

of either vitamin B, or niacinamide in presence of

methanol vapor. Only one batch (Batch No. 16)

lost a substantial amount of vitamin BIZ. The large

loss of vitamin B1 did not cause any stability problem for vitamin B1t when these two vitamins were

present together in the tablet (see Batch Nos. 12 and

13). Since this study was limited only t o the assay

of vitamin contents after exposure to methanol vapors, no attempt was made t o isolate the degradative

products of the vitamins, especially those of ascorbic

TABLE

IV- COMPOSITION^ A N D POTENCY

Loss OF VITAMINS

FROM B I - B l r A ACID

~ ~ ~ ~ ~ ~ ~

TABLETS

EXPOSED

TO METHANOL

VAPOR FOR 1 MONTHAT ROOMTEMPERATURE

Batch

NO.

8

9

10

11

BI, mg.

1.4

1.4

Potency of Each Tablet

Ascorbic Acid,

BIZ,mcg.

mg.

.-

4.0b

4.OC

1.06

4.OC

70.0

70.0

70.0

70.0

yo Loss---

7

-

Ascorbic Acid

B1

B12

17.6

13.0

11.5

19.4

7.3

17.0

__

.~

3.7

8.1

5.2

3.0

I n addition to the vitamins, each tablet contained the same amount of excipients as in the multivitamin tablets (Table I )

As 1% cyanocobalamin

and sufficientquantity of spray-dried lactose to adjust the weight to that of the multivitamin tablet.

dispersed i n gelatin.

As 1 % cyanocobalamin adsorbed on resin.

Vol. 57, No. 11, November 1968

1857

TABLEV-COMPOSITION"AND POTENCY

Loss OF VITAMINSFROM B I - B l r N ~ ~ ~ ~ ~ ~

TABLETS

EXPOSED

TO METHANOL

VAPOR FOR 1 MONTH

AT ROOM

TEMPERATURE

BI, mg.

12

13

14

15

16

1.4

1.4

1.4

1.4

1.4

Potency of Each TabletNiacinamide,

BIZ,mcg.

m(t.

Batch

No.

4.0b

4.OC

4.0b

4.0"

22.0

22.0

22.0

% Lass

,

BI

12.6

14.2

0.0

1.1

1.1

Biz

Niacinamide

2.4

4.9

4.9

14.6

0.0

3.8

4.0

In addition to the vitamin, each tablet contained the same quantities of excipients a s in t h e multivitamin tablet (Table 1)

and sufficient quantity of spray-dried lactose t o adjust the weight to t h a t of the multivitamin tablet.

As 1% cyanocohalamin

As 1% cyanocobalamin adsorbed on resin.

dispersed in gelatin.

'

acid and vitamin B1. No quantitative relationship

between loss of vitamin B11 and loss of other vitamins

could be observed. Nevertheless, it is quite apparent that methanol vapor when allowed to penetrate

multivitamin tablets can cause loss of potency of individual vitamins, especially vitamins B1 and BIZ.

It can be postulated that methanol vapor causes degradation of either ascorbic acid or vitamin B1, or

both, the degradation products of which in turn influence stability of vitamin Bn. This fact should be

taken into consideration when methanol is used as a

solvent in film coating of multivitamin tablets.

REFERENCES

(1) Feller, 3. A.. and Macek, T.

Sci. Ed.. 44,662(1955).

J., J . A m . Phorm. A.ssoc.,

(2) Doerge, R. F., Ravin, L. J., and Caldwell, H. C., J .

Phorm. Sci., 54,1038(1965).

(3) Bartilucci, A. J.. DiGirolamo. R.. and Eisen, H., J . A m .

Phorm. Assoc., Scr. Ed.. 47,42(1958).

(4) Holl, W. W., Michaels, T. P., and Sinotte. L. P., J .

Phorm. Sci., 52, 817(1963).

Keyphrases

Cyanocobalamin (vitamin BI,)-stability

Film-coated multivitamin tablets-vitamin

BlZstability

Methanol vapor effect-vitamins

BI, B12

stability

Ascorbic acid effect-vitamins Bl, BIZstability

Fluorometric Determination of Norgestrel

and Structurallv Related Steroids

d

By L. F. CULLEN, J. G. RUTGERS, P. A. LUCCHESI,

a n d G. J. PAPARIELLO

A sensitive procedure, based on sulfuric acid-induced fluorescence, has been develon-4-en-3oped for the analysis of norgestrel (dl-13-ethyl-l7cr-ethinyl-l?-hydroxy

one) in tablets of low dosage, i.e., 15-75 mcg. Optimum conditions for korescence

have been established and the fluorescent properties of structurally related steroids

studied to determine the selectivity of the reaction and mechanism of fluorescence

formation. The reaction is specific for A4-3-ketosteroids which have both a 178hydroxyl and 17~r-alkylor alkyne substitution and A1.8P(10)-tziene-3-ol

steroids.

A two-step mechanism is tentatively explained on the basis of the effects of temperature, time, initial acid concentration, and subsequent dilution with water on

fluorogen development. Specificity of the method with respect to the analysis of intact norgestrel in the presence of its photochemical and thermal degradation products was demonstrated by comparison to quantitative thin-layer chromatography

values. This procedure has been automated to permit unit dose analysis. This

automated procedure is capable of analyzing 1 5 samples per hour with a relative

standard deviation of f1.4 percent at the 50-mcg. level.

of a new, extremely potent

progestational steroid, norgestrel (dl-13-ethyl17a-ethinyl-17-hydroxygon-4-en-3-0ne)~

and subsequent formulation of this steroid in tablets of

HE SYNTHESIS

Received M a y 22,1968,from Wyeth Laboratories. Philadelphia. P A 19101

Accepted for publication August 5. lY6S.

low dosage, i.e., 15-75 mcg. per tablet, had presented a challenging analytical problem. A sensitive, accurate, and rapid procedure was desired

for content iiniforinity testing of the dosage form.

Steroids Structurally related to norgestrel,

having a characteristic A*-3-keto group in the

Das könnte Ihnen auch gefallen

- STABILITYDokument10 SeitenSTABILITYNishamolKSNoch keine Bewertungen

- Stability Indicating LC Method For The Determinati PDFDokument7 SeitenStability Indicating LC Method For The Determinati PDFFebby da costaNoch keine Bewertungen

- Cara Membuat Minyak Rambut Pomade PDFDokument9 SeitenCara Membuat Minyak Rambut Pomade PDFSandri SimbolonNoch keine Bewertungen

- Azeotrope AssignmentDokument2 SeitenAzeotrope AssignmentKamran Zeb100% (1)

- Bahan SyllabusDokument2 SeitenBahan SyllabusShantamNoch keine Bewertungen

- Vodafone Interview Questions - 75 Interview Questions and AnswersDokument3 SeitenVodafone Interview Questions - 75 Interview Questions and AnswersKIISHAN DARJI0% (1)

- Parametri Per L'equazione Di Antoine Ed Altre ProprietàDokument1 SeiteParametri Per L'equazione Di Antoine Ed Altre ProprietàAlberto NovelloNoch keine Bewertungen

- Continued Process VerificationDokument4 SeitenContinued Process VerificationAbdul KalimNoch keine Bewertungen

- Pi 053 1 Hbel Qa PDFDokument7 SeitenPi 053 1 Hbel Qa PDFM. S. ChikkamaniNoch keine Bewertungen

- Modulus of Elasticity of PVB-2Dokument2 SeitenModulus of Elasticity of PVB-2songyanxinNoch keine Bewertungen

- AnDokument4 SeitenAnBidyasagar TalukdarNoch keine Bewertungen

- Manufacturing of StyreneDokument1 SeiteManufacturing of StyreneNornadiahnadhirah MdNadzriNoch keine Bewertungen

- Solubility Parameter Cellulose Esters PDFDokument3 SeitenSolubility Parameter Cellulose Esters PDFcaioltbgNoch keine Bewertungen

- Parsol® HS - DSMDokument2 SeitenParsol® HS - DSMdian100% (1)

- Product Proposal - Hair WaxDokument23 SeitenProduct Proposal - Hair WaxMilany Anne LuayNoch keine Bewertungen

- Web Application Authentication Cheat SheetDokument1 SeiteWeb Application Authentication Cheat SheetVishal Garg100% (1)

- Pinch Analysis For Cumene ProductionDokument1 SeitePinch Analysis For Cumene ProductionCarlos FrançaNoch keine Bewertungen

- Health Base CriteriaDokument4 SeitenHealth Base Criteriatimex59Noch keine Bewertungen

- Molecular Weight of Carbopol and PemulenDokument3 SeitenMolecular Weight of Carbopol and PemulenMawarniNoch keine Bewertungen

- Tarea Extracción LiquidoDokument3 SeitenTarea Extracción Liquidovanessa ramosNoch keine Bewertungen

- Egc DehDokument8 SeitenEgc DehNur Asni NurNoch keine Bewertungen

- EFFECT OF LICORICE Glycyhrriza Glabra Linn., A SKIN WHITENING AGENT ON BLACK MDokument10 SeitenEFFECT OF LICORICE Glycyhrriza Glabra Linn., A SKIN WHITENING AGENT ON BLACK MNi Made sri Santika dewiNoch keine Bewertungen

- Stabilization of Serum Albumin by Anti-Inflammatory DrugsDokument8 SeitenStabilization of Serum Albumin by Anti-Inflammatory DrugsJariyah AmiliaNoch keine Bewertungen

- Reagents.: Materials and MethodsDokument6 SeitenReagents.: Materials and Methodsedal_108Noch keine Bewertungen

- TBuOCl PreparationDokument4 SeitenTBuOCl PreparationKaren González SilvaNoch keine Bewertungen

- P 4780 PisDokument2 SeitenP 4780 Pisabhi200291Noch keine Bewertungen

- Stability of Hydrocortisone, Nifedipine, and Nitroglycerine Compounded Preparations For The Treatment of Anorectal ConditionsDokument5 SeitenStability of Hydrocortisone, Nifedipine, and Nitroglycerine Compounded Preparations For The Treatment of Anorectal ConditionsedzaNoch keine Bewertungen

- Lin 05 FoodadditcontamDokument9 SeitenLin 05 Foodadditcontamforward websiteNoch keine Bewertungen

- Senior Project Article and Project Proposal PresentationDokument7 SeitenSenior Project Article and Project Proposal PresentationSoumitree MazumderNoch keine Bewertungen

- SP Paper 1Dokument9 SeitenSP Paper 1mellaNoch keine Bewertungen

- A Comparative Study of Phytochemicals Antioxidant Potential and Free Radical Scavenging Activity of Psidium Guajava and Malus DomesticaDokument9 SeitenA Comparative Study of Phytochemicals Antioxidant Potential and Free Radical Scavenging Activity of Psidium Guajava and Malus DomesticaChérie XuanzaNoch keine Bewertungen

- Flavonoids From and Their Antioxidant Activities: Vernonia AmygdalinaDokument4 SeitenFlavonoids From and Their Antioxidant Activities: Vernonia AmygdalinatirahmNoch keine Bewertungen

- Pharmaceutical Development and Compatibility Studies On Cytarabine InjectionDokument4 SeitenPharmaceutical Development and Compatibility Studies On Cytarabine InjectionAmit KhuntNoch keine Bewertungen

- GPAT 2023 Question Paper Shift 1Dokument7 SeitenGPAT 2023 Question Paper Shift 1kiran sonawaneNoch keine Bewertungen

- Materials and MethodsDokument8 SeitenMaterials and MethodsVenkatesh BidkikarNoch keine Bewertungen

- Ampicillin PDFDokument3 SeitenAmpicillin PDFdoxelaudioNoch keine Bewertungen

- Fems Microbiology Letters - 2006 - Schoefer - A Fluorescence Quenching Test For The Detection of Flavonoid TransformationDokument4 SeitenFems Microbiology Letters - 2006 - Schoefer - A Fluorescence Quenching Test For The Detection of Flavonoid TransformationRodos LaboratoriesNoch keine Bewertungen

- Formulation and Evaluation of Mucoadhesive Microcapsules of RifampicinDokument5 SeitenFormulation and Evaluation of Mucoadhesive Microcapsules of RifampicinIOSR Journal of PharmacyNoch keine Bewertungen

- Method Development and Validation of Afatinib in Bulk and Pharmaceutical Dosage Form by Uvspectroscopic MethodDokument7 SeitenMethod Development and Validation of Afatinib in Bulk and Pharmaceutical Dosage Form by Uvspectroscopic MethodBaru Chandrasekhar RaoNoch keine Bewertungen

- Stability Data - ConcordDokument127 SeitenStability Data - Concordтатьяна васильковаNoch keine Bewertungen

- Garner 1994Dokument4 SeitenGarner 1994Daniel GuérinNoch keine Bewertungen

- FarmasiDokument2 SeitenFarmasiSHAFANA PUTRI -Noch keine Bewertungen

- Pyronin Y Aldrich)Dokument2 SeitenPyronin Y Aldrich)SæhrímnirNoch keine Bewertungen

- Afhs1102 0197Dokument7 SeitenAfhs1102 0197Wisnu WardhanaNoch keine Bewertungen

- Application: Reversed-Phase HPLC Separation of Water-Soluble Vitamins On Agilent ZORBAX Eclipse Plus ColumnsDokument8 SeitenApplication: Reversed-Phase HPLC Separation of Water-Soluble Vitamins On Agilent ZORBAX Eclipse Plus ColumnsThanh Thanh Hai LeNoch keine Bewertungen

- 1 PBDokument6 Seiten1 PBhatet77570Noch keine Bewertungen

- Chen 1990Dokument5 SeitenChen 1990wahyu rizaldiNoch keine Bewertungen

- Stability Study of Thymoquinone, Carvacrol and Thymol Using HPLC-UV and LC-ESI-MSDokument18 SeitenStability Study of Thymoquinone, Carvacrol and Thymol Using HPLC-UV and LC-ESI-MSFilip MartinovićNoch keine Bewertungen

- Determination of Water-Soluble Vitamins in Infant Milk by High-Performance Liquid Chromatography PDFDokument7 SeitenDetermination of Water-Soluble Vitamins in Infant Milk by High-Performance Liquid Chromatography PDFGiangNoch keine Bewertungen

- Cyanocobalamine 1Dokument4 SeitenCyanocobalamine 1ainun endarwatiNoch keine Bewertungen

- Ijpsr10 01 08 04 PDFDokument11 SeitenIjpsr10 01 08 04 PDFStephanie FigueroaNoch keine Bewertungen

- Paracetamol 1Dokument4 SeitenParacetamol 1Jeremiah Justus MNoch keine Bewertungen

- International Journal of Pharmtech ResearchDokument8 SeitenInternational Journal of Pharmtech ResearchnurpurbasariNoch keine Bewertungen

- Jurnal Stabilitas Suhu PCTDokument7 SeitenJurnal Stabilitas Suhu PCTAdnanNoch keine Bewertungen

- Total Amino Acids AOAC 2018.06 Pre PrintDokument17 SeitenTotal Amino Acids AOAC 2018.06 Pre PrintDuy Tien NguyenNoch keine Bewertungen

- Disolusi Sildenafil (15 MNT, Min 85%)Dokument9 SeitenDisolusi Sildenafil (15 MNT, Min 85%)Katarina KatarinaNoch keine Bewertungen

- Estabilidad AciclovirDokument4 SeitenEstabilidad AciclovirDiana Vasquez SanchezNoch keine Bewertungen

- Kenawy Et Al 2005 Biologically Active Polymers Modification and Anti Microbial Activity of Chitosan DerivativesDokument17 SeitenKenawy Et Al 2005 Biologically Active Polymers Modification and Anti Microbial Activity of Chitosan DerivativesBharti PahujaNoch keine Bewertungen

- Artigo - Stability Characteristics of Cannabidiol For The Design of Pharmacological, Biochemical and Pharmaceutical Studies - 2020 PDFDokument24 SeitenArtigo - Stability Characteristics of Cannabidiol For The Design of Pharmacological, Biochemical and Pharmaceutical Studies - 2020 PDFVinicius MajorNoch keine Bewertungen

- International Journal of PharmacyDokument6 SeitenInternational Journal of Pharmacygthic.underNoch keine Bewertungen

- 2011 Hunyadi Et Al PLoS ONEDokument10 Seiten2011 Hunyadi Et Al PLoS ONENoemiNoch keine Bewertungen

- 2008 Tóth Et Al J.Nat - Prod. 26-OH SilvirDokument3 Seiten2008 Tóth Et Al J.Nat - Prod. 26-OH SilvirNoemiNoch keine Bewertungen

- Jurand 1973Dokument10 SeitenJurand 1973NoemiNoch keine Bewertungen

- Rosenkrantz 1988Dokument12 SeitenRosenkrantz 1988NoemiNoch keine Bewertungen

- Lewis 2004Dokument162 SeitenLewis 2004NoemiNoch keine Bewertungen

- 2023 Tóth Et Al Minor Ecdy BBB JNatProdDokument7 Seiten2023 Tóth Et Al Minor Ecdy BBB JNatProdNoemiNoch keine Bewertungen

- 2012 Martins Et Al J.Med - Chem.Dokument10 Seiten2012 Martins Et Al J.Med - Chem.NoemiNoch keine Bewertungen

- Geber 1975Dokument9 SeitenGeber 1975NoemiNoch keine Bewertungen

- Antibody Response To Sars-Cov-2 Infection in Humans: A Systematic ReviewDokument27 SeitenAntibody Response To Sars-Cov-2 Infection in Humans: A Systematic ReviewNoemiNoch keine Bewertungen

- Science of The Total Environment: Alfonso BalmoriDokument5 SeitenScience of The Total Environment: Alfonso BalmoriNoemiNoch keine Bewertungen

- Finnigan 1948Dokument8 SeitenFinnigan 1948NoemiNoch keine Bewertungen

- Electromagnetic Pollution Alert: Microwave Radiation and Absorption in Human Organs and TissuesDokument19 SeitenElectromagnetic Pollution Alert: Microwave Radiation and Absorption in Human Organs and TissuesNoemiNoch keine Bewertungen

- Ac and VaccineDokument15 SeitenAc and VaccineMayaLunaNoch keine Bewertungen

- Short CommunicationDokument4 SeitenShort CommunicationNoemiNoch keine Bewertungen

- Amberlite Irp64Dokument5 SeitenAmberlite Irp64NoemiNoch keine Bewertungen

- Hypoxia-Induced Coronary Flow Changes in The Perfused Rat Heart: Effects of High L-Carnitine ConcentrationsDokument5 SeitenHypoxia-Induced Coronary Flow Changes in The Perfused Rat Heart: Effects of High L-Carnitine ConcentrationsNoemiNoch keine Bewertungen

- Acetyl - Carnitine Treatment in Minimal Hepatic EncephalopathyDokument8 SeitenAcetyl - Carnitine Treatment in Minimal Hepatic EncephalopathyNoemiNoch keine Bewertungen

- L-Carnitine in Omnivorous Diets Induces An Atherogenic Gut Microbial Pathway in HumansDokument16 SeitenL-Carnitine in Omnivorous Diets Induces An Atherogenic Gut Microbial Pathway in HumansNoemiNoch keine Bewertungen

- Process Design Special EditionDokument105 SeitenProcess Design Special EditionNoemiNoch keine Bewertungen

- Effect of Dietary Carnitine Isomers and 7-Butyrobetaine On L-Carnitine Biosynthesis and Metabolism in The Rat1-2Dokument8 SeitenEffect of Dietary Carnitine Isomers and 7-Butyrobetaine On L-Carnitine Biosynthesis and Metabolism in The Rat1-2NoemiNoch keine Bewertungen

- Ivermectin ToxicityDokument8 SeitenIvermectin ToxicityNoemiNoch keine Bewertungen

- Dietary Supplement GMP.2012Dokument314 SeitenDietary Supplement GMP.2012333cubi333100% (3)

- Ivermectin GABA - Binding SiteDokument13 SeitenIvermectin GABA - Binding SiteNoemiNoch keine Bewertungen

- Acrivastine StabilityDokument8 SeitenAcrivastine StabilityNoemiNoch keine Bewertungen

- IVT Cleaning Validation IV 0Dokument87 SeitenIVT Cleaning Validation IV 0Noemi100% (7)

- Paraben Esters ReviewDokument11 SeitenParaben Esters ReviewNoemiNoch keine Bewertungen

- Continuing Process Verification - 1Dokument106 SeitenContinuing Process Verification - 1Noemi100% (1)

- Continuing Process Verification - 1Dokument106 SeitenContinuing Process Verification - 1Noemi100% (1)

- Mrsatreatment GuideDokument2 SeitenMrsatreatment GuideNoemiNoch keine Bewertungen

- Stability of Cyanocobalamine in Sugar Coated TabletsDokument8 SeitenStability of Cyanocobalamine in Sugar Coated TabletsNoemiNoch keine Bewertungen

- Who We Are: Case Study-Mahindra ChlorisDokument25 SeitenWho We Are: Case Study-Mahindra ChlorisSUNIDHI VERMANoch keine Bewertungen

- Masel Catalog - WiresDokument30 SeitenMasel Catalog - WiresOrtho OrganizersNoch keine Bewertungen

- Density MethodDokument5 SeitenDensity MethodMajed DawaNoch keine Bewertungen

- Plumbing Notes 1 PDFDokument57 SeitenPlumbing Notes 1 PDFhoneyvie53% (15)

- Nursing Care Plan PrenatalDokument5 SeitenNursing Care Plan PrenatalKim Galamgam100% (2)

- J.ultsonch.2014.08.022 InglesDokument48 SeitenJ.ultsonch.2014.08.022 InglesBrayan LuisNoch keine Bewertungen

- McQuay WHS ChillerDokument28 SeitenMcQuay WHS ChillerYorkist100% (1)

- Models - Bfc.li Battery Thermal 2d AxiDokument16 SeitenModels - Bfc.li Battery Thermal 2d AxijehadyamNoch keine Bewertungen

- tmpA3C2 TMPDokument11 SeitentmpA3C2 TMPFrontiersNoch keine Bewertungen

- ACTI-PLUS® 2818: Safety Data SheetDokument12 SeitenACTI-PLUS® 2818: Safety Data SheetCharbel WannesNoch keine Bewertungen

- (En GB) DBE 821 - 1.00Dokument7 Seiten(En GB) DBE 821 - 1.00Enio Miguel Cano LimaNoch keine Bewertungen

- REPORTDokument31 SeitenREPORTUnique Boss50% (2)

- 7 - Casing DesignDokument36 Seiten7 - Casing Designام فاطمة البطاط100% (1)

- TGA Supersoil 5lbDokument1 SeiteTGA Supersoil 5lbKatherine CampbellNoch keine Bewertungen

- Biological ManagementDokument27 SeitenBiological ManagementpatrickkayeNoch keine Bewertungen

- UO-II Chapter 4 (Adsorption)Dokument27 SeitenUO-II Chapter 4 (Adsorption)Ghaydah Hamed Rashid Al-AbriNoch keine Bewertungen

- A Tribological Study of Synchronizing Devices UsedDokument7 SeitenA Tribological Study of Synchronizing Devices UsedthisisjineshNoch keine Bewertungen

- Netting Analysis of Composite Pressure VesselsDokument3 SeitenNetting Analysis of Composite Pressure VesselsPratyu Ch100% (1)

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDokument15 SeitenWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistssbiasotoNoch keine Bewertungen

- High Voltage Cable JointingDokument7 SeitenHigh Voltage Cable Jointingscrapmail9Noch keine Bewertungen

- NTSE Stage 1 State Level Model Paper 10Dokument30 SeitenNTSE Stage 1 State Level Model Paper 10Om Prakash100% (1)

- Cut Diet Lean MassDokument62 SeitenCut Diet Lean Masspakzeeshan167% (3)

- Hydro Silk Fluid Englisch 06 2020Dokument1 SeiteHydro Silk Fluid Englisch 06 2020Saman KhalidNoch keine Bewertungen

- Additional Pressure and Temperature Switch Application InformationDokument2 SeitenAdditional Pressure and Temperature Switch Application InformationJean GonzalezNoch keine Bewertungen

- Chemical Changes LabDokument5 SeitenChemical Changes LabGildardo SalazarNoch keine Bewertungen

- CH 2 Chemical Bonding ICSE Solutions Class 10 ChemistryDokument18 SeitenCH 2 Chemical Bonding ICSE Solutions Class 10 ChemistrylionelkenethNoch keine Bewertungen

- Lecture 3 GlycosidesDokument18 SeitenLecture 3 Glycosidessami ullahNoch keine Bewertungen

- LBR 2014 - ReDokument62 SeitenLBR 2014 - ReEugen XhaferajNoch keine Bewertungen

- Datasheet Z-PrimercoatDokument1 SeiteDatasheet Z-PrimercoatСтанислав ПодольскийNoch keine Bewertungen

- Industrial Materials: Instructed By: Dr. Sajid ZaidiDokument13 SeitenIndustrial Materials: Instructed By: Dr. Sajid ZaidiarulmuruguNoch keine Bewertungen