Beruflich Dokumente

Kultur Dokumente

What Is A Pushbutton Switch?

Hochgeladen von

DoDuyBacOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

What Is A Pushbutton Switch?

Hochgeladen von

DoDuyBacCopyright:

Verfügbare Formate

Technical Explanation for Pushbutton Switches

CSM_PushbuttonSwitch_TG_E_1_1

Introduction

Sensors

What Is a Pushbutton Switch?

A Pushbutton Switch is a switch designed so that its contacts are opened and closed by depressing and releasing a pushbutton

on the Switch in the direction of its axis.

Switches

Safety Components

Classifications and Structures

Mounting Section

Pushbutton surface (illuminated surface)

Pushbutton

Transmits external

force/movement to the Switch.

Automation Systems

Mounting panel

Control Components

Used to secure the body of

the Switch to the mounting panel.

Relays

Pushbutton Switches come in two categories: lighted and non-lighted. The structure of a typical Lighted Pushbutton Switch is

shown below. Broadly speaking, Lighted Pushbutton Switches are made up of the 5 sections shown below. Non-lighted

Pushbutton Switches are made up of 4 sections, the 5 sections shown below less the light source.

Light Source

Controls the light indication.

Switch

Opens and closes electric circuit.

Motion / Drives

Pushbutton

Case

Protects internal mechanisms.

Movable

spring

Case

Energy Conservation Support /

Environment Measure Equipment

Movable

contacts

Movable

plate

Terminal

Structural diagram of Typical Lighted Pushbutton Switch (A16)

Operation

Power Supplies /

In Addition

Operations

Explanation

The pushbutton returns to its original position after it is released.

Alternate operation

The first time the pushbutton is pressed, an internal lock mechanism holds it in the same position.

The next time it is pressed, the lock is released and the pushbutton returns to its original position.

Push-pull operation

When the pushbutton is pressed, an internal lock mechanism holds it in the same position. The

pushbutton is returned to its original position when the pushbutton is pulled to release the lock.

Push-lock, turn-reset operation

When the pushbutton is pressed, an internal lock mechanism holds it in the same position. The

pushbutton is returned to its original position when the pushbutton is twisted to release the lock.

Others

Momentary operation

Common

Technical Explanation for Pushbutton Switches

Explanation of Terms

Term

Explanation

This term is used for switches that have more than one contact circuit. It indicates the difference in time or

position between the contacts when all the contacts of the switch are opened or closed in one operation.

LED lighting

LED-lighted models are lit with an LED installed in the base of the Pushbutton Unit.

The LED is mounted internally; it cannot be removed.

Switches

Simultaneity

Sensors

Chameleon lighting

Full-screen lighting in one of 3 colors: red, green, or orange. (Orange is produced by simultaneous illumination of red

and green.)

Safety Components

Incandescent lamp-lighted models are lit with an incandescent lamp.

The Lamp (i.e., the incandescent lamp) and the Pushbutton Unit can be separated.

Pushbutton

Unit

Pushbutton

Unit

Relays

Incandescent lamp

lighting

A16, M16

Control Components

Incandescent

lamp

Incandescent

lamp

A3P

Pushbutton

Unit

Automation Systems

LED lamp-lighted models use the same light source as incandescent lamp-lighted models, with an LED instead of a filament.

The Lamp (i.e., the LED lamp) and the Pushbutton Unit can be separated.

Pushbutton

Unit

Motion / Drives

LED-lamp lighting

LED lamp

Energy Conservation Support /

Environment Measure Equipment

A16, M16

LED lamp

A3P

Voltage Reduction

Unit

For 16-dia. A16 (M16)

models and 22-dia. A22

(M22)

models

Matrix mounting

Mounting several Switches in vertical and/or horizontal lines.

Horizontal

side-by-side mounting

Mounting Switches side-by-side with the long side of the Switch (rectangular models) horizontal.

Vertical side-by-side

mounting

Mounting Switches side-by-side with the long side of the Switch (rectangular models) vertical.

The Voltage Reduction Unit has a smoothing circuit and resistor, and lights the 24-VAC/

VDC LED lamp by applying 110 (or 220) VAC/VDC directly to the Lamp terminals.

Power Supplies /

In Addition

Others

Common

Technical Explanation for Pushbutton Switches

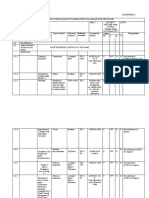

Terms Related to Operating Characteristics

Force

(torque)

Abbreviation

Unit

Definition

RF

N, Nm

The force (or torque) that must be applied to the pushbutton to

move it from the operating limit position back to the returned

position.

Total Travel Force (torque)

TTF

N, Nm

The force (or toque) on the pushbutton when it reaches the

stopper.

Free Position

FP

mm, ()

The position (or angle) of the pushbutton when there is no

external force applied to it.

Operating Position

OP

mm, ()

The position (or angle) of the pushbutton when the movable

contact changes from the free position state to the operating

position state due to an external force.

Release Position

RP

mm, ()

The position (or angle) of the pushbutton when the movable

contact changes from the operating position state to the free

position state due to the reduction of external force.

Total Travel Position

TTP

mm, ()

The position (or angle) of the pushbutton when it reaches the

stopper.

Set Position

SP

mm, ()

The position of an alternate operation pushbutton when it is in the

self-holding state, or the position (or angle) of a selector switch

when it is in the self-holding state.

Pretravel

PT

mm, ()

The distance (or angle) through which the pushbutton moves in

going from the free position to the operating position.

Overtravel

OT

mm, ()

The distance (or angle) through which the pushbutton moves in

going from the operating position to the operating limit position.

Movement Differential

MD

mm, ()

The distance (or angle) through which the pushbutton moves in

going from the operating position back to the returned position.

Total Travel

TT

mm, ()

The distance (or angle) through which the pushbutton moves in

going from the free position to the operating limit position.

Releasing Travel

RT

mm, ()

The distance (or angle) through which the pushbutton moves in

going from the returned position to the free position.

Lock Travel Alternate

LTA

mm, ()

The distance (or angle) through which the pushbutton moves in

going from the free position to the set position.

Travel

Automation Systems

Releasing Force (torque)

Control Components

N, Nm

Relays

OF

Safety Components

Operating Force (torque)

The force (or torque) that must be applied to the pushbutton to

move it from the free position to the operating position.

Switches

Position

Term

Sensors

Classification

Motion / Drives

RF

OF

TTF

FP

SP

PT

TT

Operating

position

RT

MD

OT

Operating

limit position

Terminal Symbols

LTA

Returned

position

Energy Conservation Support /

Environment Measure Equipment

Free position

FP

RP

OP

TTP

Set

position

Free

position

Contact Form

Meaning

COM

Common terminal

NC

Normally closed terminal

NO

Normally open terminal

Name

Double-throw

Contact form

Power Supplies /

In Addition

Symbol

NC

COM

NO

COM

NC

Normally opened

COM

NO

Double-break

NO

NO

NC

NC

Others

Normally closed

Common

Technical Explanation for Pushbutton Switches

Terms Related to IEC60947 and IEC60950

Term

Explanation

Sensors

No.

Rated operating

current (Ie)

Specified by the manufacturer on consideration of rated operating voltage (Ue), rated frequency, rated energizing time,

area of application, and type of enclosure protection.

Rated insulation

voltage (Ui)

Determined by creepage distance and the dielectric strength.

The maximum Ue value must not exceed the maximum Ui value.

If there is no Ui value specified, the maximum Ue value is taken as the Ui value.

Pollution degree

1. Either no pollutants are present, or only dried, non-conductive pollutants are present (e.g., clean rooms).

2. Basically, only non-conductive pollutants are present, or only transient conductivity occurs due to condensation

(indoor locations, such as offices).

3. Conductive pollutants are present, or non-conductive pollutants are present in locations where condensation is

expected (e.g., factories).

4. Conductivity due to impurities is a constant possibility, or conductivity is caused by conductive dust, rain, or snow

(e.g., outdoor locations).

Electric shock

protection class

Class I: These devices require grounding. Electric shock is prevented by basic insulation and charged parts that would

be subject to dangerously high voltages if the insulation was damaged, are grounded.

Class II: Electric shocks are prevented by double insulation or enforced insulation.

Class III: No countermeasures against electric shocks are required because the electric circuits in use operate in a lowenough voltage range.

PTI

Proof tracking index.

Specified CTI values (comparative tracking indices):

Materials satisfying the 175, 250, 300, 375, and 500 levels are denoted as PTI-175, PTI-250, PTI-300, PTI-375, and

PTI-500 respectively.

Relays

Safety Components

VAC: 120, 240, 380, 480, 500, 600

VDC: 125, 250, 440, 500, 600

Switches

Rated operating

voltage (Ue)

Meaning of first number

No.

Degree of protection for people

No penetration by any solid object Cannot be touched with the palm

with a diameter of 50 mm or more. of your hand.

Protects against vertical drops of

water.

No penetration by any solid object

with a diameter of 12.5 mm or

more.

Protects against drops of water

approaching at a maximum angle of

15 to the vertical.

No penetration by any solid object

Same as at left.

with a diameter of 2.5 mm or more.

Protects against sprinkled water.

No penetration by any solid object

Same as at left.

with a diameter of 1.0 mm or more.

Protects against water spray.

Protection against dust

No penetration by any object with a

Protects against water jet spray.

diameter of 1.0 mm or more.

Dustproof

No penetration by any object with a Protects against high-pressure

diameter of 1.0 mm or more.

water jet spray.

Cannot be touch with fingers.

No protection

Energy Conservation Support /

Environment Measure Equipment

No protection

Motion / Drives

IP

No protection

Meaning of second number

Degree of protection against

water

Automation Systems

Degree of protection against

solid materials

Control Components

IP- 1 2 (IEC60529)

Meaning of first number-Degree of protection against solid materials and people (See below.)

Meaning of second number-Degree of protection against water (See below.)

Power Supplies /

In Addition

Others

Common

Das könnte Ihnen auch gefallen

- Sales and MarketingDokument13 SeitenSales and MarketingSupriyadiNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Technocommercial OfferDokument14 SeitenTechnocommercial Offerkrish659Noch keine Bewertungen

- PLC Lab ManualDokument34 SeitenPLC Lab ManualDhiraj maliNoch keine Bewertungen

- How To Read Pump CurveDokument4 SeitenHow To Read Pump Curvebotaqi100% (6)

- Rotary Parking SystemDokument12 SeitenRotary Parking Systemanwar rekikNoch keine Bewertungen

- Electrical Protection System 1 To 150Dokument95 SeitenElectrical Protection System 1 To 150Anirban Bandyopadhyay50% (2)

- Relay Symbols and Device Numbers Selection From IEC 617-, IEEE C37.2-1991 and IEEE C37.2-1979Dokument14 SeitenRelay Symbols and Device Numbers Selection From IEC 617-, IEEE C37.2-1991 and IEEE C37.2-1979omvdNoch keine Bewertungen

- KXNSERIESDokument6 SeitenKXNSERIESJorge Martin Bejarano GonzalezNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Mechanical Electromechanical Switches and Relay and Other Interfacing DevicesDokument21 SeitenMechanical Electromechanical Switches and Relay and Other Interfacing DevicesRose Anne Delos SantosNoch keine Bewertungen

- PLC Lab ManualDokument27 SeitenPLC Lab ManualSneha100% (1)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Manual HipotDokument34 SeitenManual HipotOmar Marquez BonillaNoch keine Bewertungen

- P342 343 Generators ProtectionsDokument16 SeitenP342 343 Generators ProtectionshieudaininhNoch keine Bewertungen

- Actuator With Integral ControlDokument4 SeitenActuator With Integral Controlysr3ee6926Noch keine Bewertungen

- Power Devices: Selection Guide 2009Dokument80 SeitenPower Devices: Selection Guide 2009DoDuyBacNoch keine Bewertungen

- P SOA EA 70 Sample ItemsDokument4 SeitenP SOA EA 70 Sample ItemsEli_HuxNoch keine Bewertungen

- 18/07/2022 Java Homework-1: Core Java Test Papers - Day 1 (Class, Objects, Methods)Dokument13 Seiten18/07/2022 Java Homework-1: Core Java Test Papers - Day 1 (Class, Objects, Methods)praveen murugesanNoch keine Bewertungen

- F24 60manual (New)Dokument14 SeitenF24 60manual (New)Robert CumpaNoch keine Bewertungen

- Contador Hanyoung GE4Dokument4 SeitenContador Hanyoung GE4Juan Felipe Vieira Gaviria0% (1)

- SEMIKRONPowerSemiconductors PDFDokument466 SeitenSEMIKRONPowerSemiconductors PDFDoDuyBac0% (1)

- Technical Training of 5G Networking DesignDokument32 SeitenTechnical Training of 5G Networking DesignThanh Hoang100% (5)

- Types of Switches and Their ApplicationsDokument26 SeitenTypes of Switches and Their ApplicationsSiddhant H (siddu)100% (2)

- Manual de Usuario - Fluidoterapia ES y INGDokument114 SeitenManual de Usuario - Fluidoterapia ES y INGjames lopezNoch keine Bewertungen

- Form - 8932E BELT DRIVE PDFDokument130 SeitenForm - 8932E BELT DRIVE PDFDoDuyBacNoch keine Bewertungen

- A Review On Various Transformer Testing SystemsDokument4 SeitenA Review On Various Transformer Testing Systemsijsret100% (1)

- UT130 Manual 1Dokument4 SeitenUT130 Manual 1soka2030Noch keine Bewertungen

- Electropneumatics - 1Dokument46 SeitenElectropneumatics - 1abyzenNoch keine Bewertungen

- Al Tech Right TimerDokument9 SeitenAl Tech Right Timermr eNoch keine Bewertungen

- Emergency SwitchDokument2 SeitenEmergency SwitchTrend TubeNoch keine Bewertungen

- 3VT4Dokument17 Seiten3VT4PhanNamNoch keine Bewertungen

- A Brief Introduction To Essential Substation ComponentsDokument16 SeitenA Brief Introduction To Essential Substation ComponentsMuhammed MekkiNoch keine Bewertungen

- Emergency Stop Examples Sistema Ver 100Dokument16 SeitenEmergency Stop Examples Sistema Ver 100Wer AdNoch keine Bewertungen

- Valtek Beta Positioners: For Control ValvesDokument8 SeitenValtek Beta Positioners: For Control Valvesابزار دقیقNoch keine Bewertungen

- Valtek XL Series High Performance Positioner: For Control ValvesDokument8 SeitenValtek XL Series High Performance Positioner: For Control ValvesRifadli GatesNoch keine Bewertungen

- Questions and AnswersDokument15 SeitenQuestions and AnswersMahtab GhummanNoch keine Bewertungen

- Time Delay Relays - Application Data: DefinitionDokument9 SeitenTime Delay Relays - Application Data: DefinitionReethu ParavadaNoch keine Bewertungen

- Switches: Selecting A SwitchDokument9 SeitenSwitches: Selecting A SwitchRadu DelaAfumatiNoch keine Bewertungen

- Yokogawa WT110 Digital Power MeterDokument204 SeitenYokogawa WT110 Digital Power MeterCristian BandilaNoch keine Bewertungen

- Instrukcja XT 546 - WWW - Ebmia.plDokument3 SeitenInstrukcja XT 546 - WWW - Ebmia.plAwdhesh Singh BhadoriyaNoch keine Bewertungen

- PT31 Smart Pressure Transmitter Operation ManualDokument51 SeitenPT31 Smart Pressure Transmitter Operation ManualAlu menzikenNoch keine Bewertungen

- Toshiba VFS9Dokument12 SeitenToshiba VFS9PùbùdùPathirathnaNoch keine Bewertungen

- TRL27 Installation Instructions - IL04910003EDokument2 SeitenTRL27 Installation Instructions - IL04910003Ericardo_ro_4Noch keine Bewertungen

- 1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00Dokument71 Seiten1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00kmpoulos100% (1)

- PG 5310Dokument32 SeitenPG 5310vyadunandana0% (1)

- VMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsDokument6 SeitenVMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsjjcanoolivaresNoch keine Bewertungen

- Cz-k1p Dataseet KeyenceDokument8 SeitenCz-k1p Dataseet KeyenceErnesto AlonsoNoch keine Bewertungen

- Een 11 Midterm Lec3Dokument67 SeitenEen 11 Midterm Lec3Miggy VelasquezNoch keine Bewertungen

- On Off Level Control ProcessDokument16 SeitenOn Off Level Control ProcessAndrew NabilNoch keine Bewertungen

- Methodology: Design SpecificationDokument10 SeitenMethodology: Design SpecificationEfryl LapinaNoch keine Bewertungen

- Proximity Sensor Terminology: Break Function (N.C., Normally Closed) Protection Degree Installation NotesDokument5 SeitenProximity Sensor Terminology: Break Function (N.C., Normally Closed) Protection Degree Installation Notespata nahi hai mujeNoch keine Bewertungen

- EL Meaure MeterDokument40 SeitenEL Meaure MeterRangasamyNoch keine Bewertungen

- 3VT4 Molded Case PDFDokument17 Seiten3VT4 Molded Case PDFAnonymous clMeE4g70Noch keine Bewertungen

- DTA Manual UsuarioDokument12 SeitenDTA Manual Usuario99lea99Noch keine Bewertungen

- DTB ManualDokument13 SeitenDTB ManualJorge BurbanoNoch keine Bewertungen

- Digital Motor Protection RelayDokument16 SeitenDigital Motor Protection RelaySukant Kumar MohantyNoch keine Bewertungen

- Numarator Cta 4Dokument2 SeitenNumarator Cta 4Paun AlNoch keine Bewertungen

- Programmable Logic Controller (PLC) and AutomationDokument27 SeitenProgrammable Logic Controller (PLC) and AutomationJeeva RajNoch keine Bewertungen

- Manual Fan VerticeDokument20 SeitenManual Fan VerticeDoaa MetwallyNoch keine Bewertungen

- SCR w5 enDokument10 SeitenSCR w5 enAji Beni LastomoNoch keine Bewertungen

- 4.PLC I-O Devices and PeripheralsDokument34 Seiten4.PLC I-O Devices and PeripheralsEmmanuel MatutuNoch keine Bewertungen

- Switches 25Dokument7 SeitenSwitches 25Anchal sandhuNoch keine Bewertungen

- Digital Multimeter: Instruction ManualDokument26 SeitenDigital Multimeter: Instruction ManualelectronicsandbooksNoch keine Bewertungen

- Group 2 Written ReportDokument22 SeitenGroup 2 Written ReportNiña TorralbaNoch keine Bewertungen

- 2 - ComponentsDokument61 Seiten2 - ComponentsEdogawa ConanNoch keine Bewertungen

- DeltaDokument13 SeitenDeltaNguyễn Minh CườngNoch keine Bewertungen

- Substation Protection DevicesDokument14 SeitenSubstation Protection DevicesnikcsitNoch keine Bewertungen

- Chassis 449ZA: Nokia Display Products Oy P.O.Box 14 FIN - 24101 Salo, FinlandDokument66 SeitenChassis 449ZA: Nokia Display Products Oy P.O.Box 14 FIN - 24101 Salo, FinlandZoran ŠušakNoch keine Bewertungen

- Push Button Catalog en YwDokument32 SeitenPush Button Catalog en YwbasslaborielNoch keine Bewertungen

- Automatic Transfer Switch (ATS) - Contactor-Based: Technical Data TD01602018EDokument24 SeitenAutomatic Transfer Switch (ATS) - Contactor-Based: Technical Data TD01602018EUrsula JohnsonNoch keine Bewertungen

- 1-GX Wks2 Advanced Na Eng-ADokument67 Seiten1-GX Wks2 Advanced Na Eng-ADoDuyBacNoch keine Bewertungen

- 1-MELSEC-L Basics Na EngDokument61 Seiten1-MELSEC-L Basics Na EngDoDuyBacNoch keine Bewertungen

- 307-316 Gooood Pid TemperatureDokument10 Seiten307-316 Gooood Pid TemperatureDoDuyBacNoch keine Bewertungen

- Hi - Speed - Igbt MITSU PDFDokument15 SeitenHi - Speed - Igbt MITSU PDFDoDuyBacNoch keine Bewertungen

- REH984b - 04a GOOOOOD TROUBLE SHOOTING IGBT PDFDokument16 SeitenREH984b - 04a GOOOOOD TROUBLE SHOOTING IGBT PDFDoDuyBacNoch keine Bewertungen

- REH984b - 04a GOOOOOD TROUBLE SHOOTING IGBT PDFDokument16 SeitenREH984b - 04a GOOOOOD TROUBLE SHOOTING IGBT PDFDoDuyBacNoch keine Bewertungen

- Igbt - Note - e MITSUBISHI PDFDokument76 SeitenIgbt - Note - e MITSUBISHI PDFDoDuyBacNoch keine Bewertungen

- Aalborg Universitet: Wu, Rui Blaabjerg, Frede Wang, Huai Liserre, Marco Iannuzzo, FrancescoDokument8 SeitenAalborg Universitet: Wu, Rui Blaabjerg, Frede Wang, Huai Liserre, Marco Iannuzzo, FrancescoDoDuyBacNoch keine Bewertungen

- Pm100cva120 - e IGBT PDFDokument6 SeitenPm100cva120 - e IGBT PDFDoDuyBacNoch keine Bewertungen

- Fusing IGBT Based Inverters 2001 PCIM PDFDokument9 SeitenFusing IGBT Based Inverters 2001 PCIM PDFDoDuyBacNoch keine Bewertungen

- Vector Brochure PDFDokument11 SeitenVector Brochure PDFDoDuyBacNoch keine Bewertungen

- IGBT - ApplicationManual - E GOOOOOD TO UNDERSTANDING PDFDokument16 SeitenIGBT - ApplicationManual - E GOOOOOD TO UNDERSTANDING PDFDoDuyBacNoch keine Bewertungen

- VVT Sensor PDFDokument4 SeitenVVT Sensor PDFDoDuyBac100% (1)

- Office 2013 Activation ProcedureDokument2 SeitenOffice 2013 Activation ProcedureChandra KanthNoch keine Bewertungen

- Driving To Outcomes - Success Plans & ScorecardsDokument59 SeitenDriving To Outcomes - Success Plans & Scorecardshkulkarni100% (1)

- Eraspec Bro en WebDokument6 SeitenEraspec Bro en WebDavcons ConsultoresNoch keine Bewertungen

- Beer Filtration With Diatomite - Imerys PDFDokument4 SeitenBeer Filtration With Diatomite - Imerys PDFLeandro ChSanzNoch keine Bewertungen

- Linux Administration: Unit 1Dokument59 SeitenLinux Administration: Unit 1DerenNoch keine Bewertungen

- Shop Management Buyer Kit JobBOSSDokument11 SeitenShop Management Buyer Kit JobBOSSGirish Khanna Veshala0% (1)

- Model QAP For Plates1Dokument3 SeitenModel QAP For Plates1tarun kaushalNoch keine Bewertungen

- JST Connector Catalogue Vol 120eDokument535 SeitenJST Connector Catalogue Vol 120etiago alexandreNoch keine Bewertungen

- Forti WebDokument7 SeitenForti WebYoussef HbilateNoch keine Bewertungen

- 0-By CPU - MT6571 - EMMC - 04-24-2023-18-37-04Dokument2 Seiten0-By CPU - MT6571 - EMMC - 04-24-2023-18-37-04abubakar qassimNoch keine Bewertungen

- Micro Personal GPS Tracker User ManualDokument6 SeitenMicro Personal GPS Tracker User ManualGarage Lifestyle BVGNoch keine Bewertungen

- Arrow Product OverviewDokument13 SeitenArrow Product OverviewRafael Zurita100% (1)

- The Platform of EverythingDokument51 SeitenThe Platform of EverythingSi Pham QuocNoch keine Bewertungen

- Liebert-HPC S 006 022-TS-EN-EMEA-273571Dokument54 SeitenLiebert-HPC S 006 022-TS-EN-EMEA-273571Breno ETCENGENHARIANoch keine Bewertungen

- Capr-Ii 2013Dokument46 SeitenCapr-Ii 2013Pramod DhaigudeNoch keine Bewertungen

- DG 03 001-E 04-03 ARGOSDokument35 SeitenDG 03 001-E 04-03 ARGOSrickyNoch keine Bewertungen

- WMC LAB Manual - 2022Dokument98 SeitenWMC LAB Manual - 2022U20EC131SANKALP PRADHAN SVNITNoch keine Bewertungen

- Samsung Eric-Ve-R r1.0Dokument43 SeitenSamsung Eric-Ve-R r1.0Tintaytoner ZumpangoNoch keine Bewertungen

- SNA AssignmentDokument42 SeitenSNA AssignmentSuzan DahitNoch keine Bewertungen

- 2N5038 ZalecanyDokument2 Seiten2N5038 ZalecanyEdzNoch keine Bewertungen

- Nonfiction Reading Test GarbageDokument5 SeitenNonfiction Reading Test GarbageYuri DunlaoNoch keine Bewertungen

- 7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DataDokument7 Seiten7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DatasoltaniNoch keine Bewertungen