Beruflich Dokumente

Kultur Dokumente

Prosper Gaslift

Hochgeladen von

kurtbkOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Prosper Gaslift

Hochgeladen von

kurtbkCopyright:

Verfügbare Formate

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

Gas Rate, GLR and Depth Sensitivities of Gas Lift Technique:

A Case Study

Pshtiwan Tahsin Mohammed Jaf

Petroleum Engineering Department,

Faculty of Engineering, Koya University, Kurdistan Region, Iraq

ABSTRACT

In petroleum industry, various problems may arise during production operations such as reduction in desired oil rate

due to water conning and lifting problems. Gas lift optimization is considered as a prestigious technique for preventing

such problems.

This work is carried out as a consequence of low production problems in one of the oil fields in Iraq. The name of the

field is not mentioned in this work due to the confidentiality of publication and well is named as JAF. Currently oil is

produced in JAF well through gas lift technique, while in other wells oil is produced by their own reservoir pressure.

Before implementing gas lift optimization, the average oil production rate for JAF well was around 1700 (bbl/day), with

relatively low drawdown pressure (psig) between average reservoir pressure and bottom-hole flowing pressure. Thus, to

optimize the production, this well is modelled in PROSPER program, through entering row field data of both reservoir

fluids properties and well testing data for PVT matching and generating IPR + VLP for the well.

In this paper, the JAF well has been modelled in PROSPER step by step. For VLP correlation comparison, Petroleum

Expert-2 was found very close to well test data for all vertical/tubing performance. While for matching pipe correlation

Beggs and Brill correlation is found the best fit correlation for production and flow line test. Design injection pressure

is inputted based on the available source supply and considering bubble point pressure as well.

The sensitivity results, through which maximum oil production rate is achieved as 2343 bbl/day for JAF well at gas lift

injection rate of l.75 MMscf/day.

In addition, maximum and optimum GLR for the well is determined under fixed injection rate of 1.35 scf/day of GasLift

gas rate based on the selected correlation for analysing injected GLR sensitivities and the result is 451 scf/stb for JAF

well.

Finally, optimum injection depths for fixed gas injection rate in MMscf/day for this well is obtained as 2250 ft.

Keywords

Gas Lift, Gas Rate, GLR, Depth, Optimization, Sensitivity, Pressure.

INTRODUCTION

1.1. Brief history

Field X is a super-giant field and mainly limestone reservoir with fold hydrocarbon trap (Anticline fold) and

its rock type is Dalmatic limestone which is characterized with natural fracture.

The reservoir petro-physical properties are ranged between (5-44) md for average permeability, between (13%

- 26%) for water saturation and between (18% - 27%) of average porosity in matrix. The oil column thickness

is about (60-90) meter with large gas cap and Aquifer, the estimated Gas oil contact at depth 600 ft MSL and

estimated oil water contact at 740 ft MSL.

For proceeding to produce from the field, it was planned to install a gas lift system for the wells which do not

produce in a desired rate relative to other high producer well. To meet the requirements demanded by the local

government.

1.2. Scope of Work and Paper Objectives

The objective of this paper is to analyze the oil production rate variation by implementing the gas lift artificial

method for a well named here as JAF of X field with two different domes. The work is performed by the

application of PROSPER software package.

Furthermore, the objective of this study is to provide some decision supporting document and evaluating each

of the scenarios in detail through using advanced software packages to match the data history and predict

simulation results. Consequently, simulations based on the field data will give an indication of what rates can

be produced and the different solutions will be recommended. A complete production analysis will be

138

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

developed by running a simulation program in PROSPER for individual well system and the maximum oil

production rate that could be achieved for the whole production system.

1.3. Pressure and Flow Rate Profile

Most of the wells are completed at a depth that should flow for a period of time after they begin put in

production. This will not be continuous because the energy will be spent and at some time there will not be

sufficient drive force to lift the fluid to the surface. Consequently, the well ceases to flow and the operating

company will be tempted to put the well on one of the forms of artificial lift to provide a good lifting energy

(Lake, 2010).

Figure 1 illustrates the reasons why it is required to lift the hydrocarbons artificially. Through looking at this

figure, wells normally can produce by their own reservoir pressure only for a specific period of time.

Figure 1: Pressure versus Flow Rate Profile (Lake, 2010).

Periodically, the required quantity of oil will not be achieved at the surface facilities, mainly because of the

following factors:

Low reservoir pressure

Heavy oil (high density fluids)

Scale liquid around the wellbore

Skin damage around wellbore

Poor completion and reservoir rock properties

Water conning

Therefore, the company will be tempted to optimize the production through the stimulation or by artificial lift

systems, for example, gas lift system (Hadiaman, 2011).

2. GAS LIFT METHOD

Gas lift is one of artificial lift methods, through which high pressure gas is injected continuously or

intermittently into the well through casing and U-Tubed to tubing. Thus, resulting in the reduction of the

hydrostatic pressure of the heavy column of the fluid and reducing bottom-hole flowing pressure. The purpose

of gas lift installation also to bring hydrocarbons to the surface at a desirable quantity while keeping the

bottom-hole pressure at a value that is small enough to provide high drawdown pressure within the reservoir

(Beggs, 2003)

Thus, gas lift method is where relatively high pressure gas is used as lifting agent through a mechanical

process. The installation of the gas lift system is required when the pressure of the reservoir is not quite

enough to maintain the oil production with sustainable economic return. This system is widely applicable for

the oil fields where the increasing water cut or decreasing reservoir pressure eventually causes well to cease

its natural flow (Ahmed and McKinney, 2004).

2.1. Gas Lift Optimization

The operation of the gas lift system is very similar to the normal production, because there is no any change in

the design configuration of the production system in terms of size and design. The artificial method will be

139

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

through lifting the fluid to reduce the bottom hole pressure as well as the hydrostatic pressure gradient on the

wellbore. A simplified diagram of a particular gas lift system is shown in the below figure (Guo, Lyons and

Ghalamber, 2007).

Figure 2: Pressure relationships in a continuous gas lift (Guo, Lyons and Ghalamber, 2007)

2.2. Gas Lift Well Performance Analysis

Noda analysis is used to analyse the gas lift well performance, the following processes should be done to

analyse the system.

Select the operating gas lift to be analysed.

Select the node location that is most sensitive to change.

Develop the relationship between the inflow and flow of the node.

Calculate pressure drop versus flow rate for all components.

Determine the effect of changing characteristics of the selected node (gas lift valve).

Optimise the production system.

To follow the above mentioned steps, it is more convenient to allocate gas lift working valve as the posistion

of the node. Thus, the node pressure will be the pressure at the tubing exactly in the depth where the valve has

been installed symbolised as P v .

Hereby, the outflow and inflow would be:

Inflow into the node (at the gas lift valve depth)

(equ.1)

Where,

Pv is the pressure at the valve (psi)

Pres is the reservoir pressure (psi)

P res is the pressure difference across the reservoir (psi)

P tbg is the pressure difference across the tubing string (psi)

Outflow from the node;

(equ.2)

Where,

is the pressure at the valve (psi)

is the wellhead pressure (psi)

is the pressure difference across the tubing string (psi)

As the depth of gas injection point is changing with the type of design and at the same time there are more

than two valves usually installed into the wellbore. So, it is better to select the P wf as the node pressure. A

digram between the P wf and flow rate can be drawn, the effect of carrying out sensitive in the gas liquid ratio

140

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

will affect the outflow, but inflow will remain constant. This is because, the injection gas will affect the fluid

above valve only. The below figure illustrates more about the effect of changes in GLR.

Figure 3: Effect of gas rate on outflow (Beggs, 2003)

Increasing the GLR, the bottom hole flowing pressure decreases, consequently more liquid (oil) will be

delivered to the surface. The GLR has a limit, because the injection pressure should be designed in a manner

that will not affect the reservoir pressure, i.e. avoiding the reverse flow from the wellbore into the reservoir.

Furthermore, any extreme injection pressure might kill the well and stop the fluid flowing (Brown, 1984).

2.2.1. Gas Injection Rate

To determine the optimum gas rate, it is required to select a node in the reservoir while the gas lift valves are

also within the vertical system. The equations for inflow and outflow are expressed as follows:

(equ.3)

(equ.4)

Where,

Equation 3 is the inflow to the node and 4 is the outflow from the node (valve)

Pwf is the bottom-hole flowing pressure (psi)

is the reservoir pressure (psi)

is the seperator pressure (psi)

is the pressure difference within the reservoir (psi)

is the pressure difference within the flow line (psi)

is the pressure difference at the tubing above the GL valve (psi)

is the pressure difference at the tubing below the GL valve (psi)

The inflow into the node (

nd

will not be affected by the rate of

injection gas, but the downstream flow relative to the valve will be affected. Thus, the pressure drop across

flow line (

and pressure drop across tubing above valve will vary with the change of injected

GLR. Consequently, the different outflow line will be produced for each injected GLR (Economides, Hill and

Ehlig, 1994).

As shown in figure (3), the intersections of the inflow and outflow curves indicates the produced liquid for

different injected GLR. Equation (5) is used to determine gas injection rate for a continuous gas-lift, when the

system rate capacity is known (Beggs, 2003).

(equ.5)

Where,

is the gas injection rate (MMscf/day)

is desired liquid production rate (bbl/day)

141

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

is th producing gas-liquid ratio above point of gas injection (scf/bbl)

is the producing gas-liquid ratio below point of gas injection (scf/bbl)

Under static conditions, the pressure gradient in the tubing-casing annulus can be written as:

(equ.6)

Where,

P so : Surface operating pressure (psi) and P V : tubing pressure at the gas lift valve (psi)

: gas gravity (air=1) and

: True vertical depth to injection point (ft)

Zavg and Tag: Average compressibility factor and average temperature (R) respectively

2.2.2. Effect of Injection Gas Rate

Not only the required rate of injected gas should be calculated, but also the optimum amount of injection gas

should be determined through plotting a graph between the qgas-injection versus the qLiquid-produced as

shown in the figure (4) through which maximum amount of production rate should be avoided to reduce the

probability of killing the well. Nevertheless, the economical amount of injection rate can be touched through

the same graph to achieve a sustainable production system (Beggs, 2003).

Figure 4: Effect of Gas Injection Rate On Production (Beggs, 2003)

2.2.3. Effect of Injection Depth

The second category which should be considered is the depth of injection. For that reason, a graph would be

produced between gas injection rate versus qL-production with the corresponding injection depth. As a result,

different curves of production rate can be obtained with relative to the change in the depth of injection but at

constant injection rate. From figure (5) it is clear that by changing the depth for the same amount of injection

rate, the production rate will increase (Hall and Decker, 1995).

Figure 5: Effect of Injection Depth on Production (Beggs, 2003)

3.

WELL MODELLING In PROSPER

Modelling a gas lift system is easily provided by PROSPER simulator. PROSPER separates the various

aspects of the well that contribute to the overall production performance. After modelling each aspect, it has

the ability to verify them by performance matching. The purpose of performance matching is to make sure

142

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

those calculations and input data are in the right position. PROSPER is able to model a well in different

scenarios to obtain the upstream accurate information based on the surface data.

The below tables in the next pages are the key input data which required while modelling a continuous gas lift

system concerning a well. For example, in this paper JAF well has been brought into analysing and simulate

the effect of gas lift system on its production rate.

The row field data for this well have been brought for analysis in this paper. The well is being proposed to put

under gas lift optimisation, because its production rate declined to unwanted level.

PVT data, IPR entry data, Downhole data (deviation survey and equipment) and well testing data (BHCIP,

BHFP and PI) for the well are provided. These data are arranged separately based on the PROSPER simulator

input requirement and all units will be field unit. This is to give better understanding on correlation and

matching with reality.

3.1.

Well Data

Table 1: PVT Data of the Reservoir Fluid

Parameters

Quantity

Units

Solution GOR

212

scf/stb

Oil Gravity (API)

34

API

Gas Gravity

0

Water Salinity

0

ppm

Gas Impurities

0

%

Bubble Point Pressure at MD temperature

950

psig

Oil FVF at MD Temperature and Pressure

1.138

stb/bbl

Oil Viscosity

1.34

cp

Table 2: IPR Data

Parameters

Reservoir Pressure

Reservoir Temperature

Water Cut

Total GOR

Measured Depth (MD)

ft

0

1670

Well Name

JAF

Quantity

1200

160

15

237

Units

psig

F

%

scf/stb

Table 3: Downhole Data

True vertical Depth (TVD)

ft

0

1670

Table4: Downhole Equipment

Tubing Dimensions

Casing Dimensions

ID

Depth

ID

Depth

(inches)

(ft RTKB)

(inches)

(ft RTKB)

3.5

950

7.00

990

Total Depth

(ft RTKB)

1670

Table5: Well Test Data

Test Type

Production

143

BHCIP

BHFP

pisg

1169

pisg

1010

Pshtiwan Tahsin Mohammed Jaf

Pressure

Rate

Differential

pisg

bopd

159

1700

Productivity

Index (PI)

stb/day/psi

9

Water

Cut

percent

15

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

3.2.

Outline of the Calculation Steps

The below flow chart illustrates an outline of the calculation processes that are required to model a system

analysis using PROSPER:

Figure 6: PROSPER outline calculation processes

4.

RESULTS, SENSITIVITIES ANDDISCUSSION

4.1.

System Capacity Prior to Gas Injection

PROSPER can calculate the system (VLP+IPR) or system capacity for each well before any gas being

injected. This gives an indication of the original well capacity to deliver hydrocarbons to the surface based on

the natural BHP.

The figure below is the plot between IPR versus VLP for the well, the intersection of these two curves is

called the solution point for the well.

144

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

Inflow (IPR) v Outflow (VLP) Plot (Well Number 1 13/06/2013 - 21:00:21)

1419.18

Solution Point

Liquid Rate 1794.9 (ST B/day)

Oil Rate 1525.6 (ST B/day)

Water Rate 269.2 (ST B/day)

Gas Rate0.36157 (MMscf/day)

Injection Depth 1895.0 (feet)

Solution Node Pressure1000.57 (psig)

dP Friction 21.28 (psi)

dP Gravity 824.36 (psi)

dP Total Skin

0 (psi)

dP Perforation

0 (psi)

dP Damage

0 (psi)

dP Completion

0 (psi)

Completion Skin

0

Total Skin

0

Wellhead Liquid Density 54.251 (lb/ft3)

Wellhead Gas Density0.55819 (lb/ft3)

Wellhead Liquid Viscosity 2.7201 (centipoise)

Wellhead Gas Viscosity

0.011861 (centipoise)

Wellhead Superficial Liquid Velocity 2.450 (ft/sec)

Wellhead Superficial Gas Velocity 6.912 (ft/sec)

Wellhead Z Factor 0.9748

Wellhead Interfacial T ension15.9217 (dyne/cm )

Wellhead Pressure 150.00 (psig)

Wellhead T em perature 128.66 (deg F)

First Node Liquid Density 54.251 (lb/ft3)

First Node Gas Density0.55819 (lb/ft3)

First Node Liquid Viscosity 2.7201 (centipoise)

First Node Gas Viscosity

0.011861 (centipoise)

First Node Superficial Liquid Velocity 2.450 (ft/sec)

First Node Superficial Gas Velocity 6.912 (ft/sec)

First Node Z Factor 0.9748

First Node Interfacial T ension15.9217 (dyne/cm )

First Node Pressure 150.00 (psig)

First Node T emperature 128.66 (deg F)

Pressure (psig)

1064.39

709.59

354.795

0

6.86707

1720.55

3434.22

5147.9

6861.58

Liquid Rate (STB/day)

Figure 7: Present

VLP Matching

IPR

PVT Method Black Oil

Top Node Pressure

1 50.00 (psig)

Branch

Fluid

Oil

Water Cut

15.000

(percent)

From this point, the below

table

of

System

Solution

Data

can

be

determined

priorInflow

to Type

gasSingle

liftHole

operation i.e.

Completion

Cased

Flow T ype Tubing

Bottom Measured Depth3 449.9 (feet)

Sand Control None

Well T ype Producer

Bottom T rue Vertical Depth3 449.9 (feet)

Gas Coning No

before injecting the Gaslift

into

the

well.

Artificial Lift Gas Lift (Continuous)

Surface Equipment Correlation Beggs and Brill

Lift Type No Friction Loss In Annulus

Reservoir M odel PI Entry

Vertical Lift Correlation Petroleum Experts 2

Predicting Pressure and T emperature (offshore)

Compaction Permeability Reduction Model No

Temperature Model Rough Approximation

Solution Node Bottom Node

Relative Permeability No

Company University of Salford

Left-Hand Intersection DisAllow

Absolute Open Flow (AOF)6867.1 (ST B/day)

Field Field A, Dome B

Reservoir Pressure

1200.00 (psig)

Location Kurdistan - North of Iraq

Reservoir T em perature200.00 (deg F)

Well Well Number 1

Water Cut15.000 (percent)

Analyst Farhad Khoshnaw

Date 10/06/2013

D:\Salford University\M asters Project\Simulation Results\2\1\Well Number 1.Out

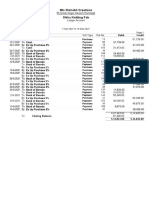

Table 6: Present Wells System Capacity

Parameters

Units

Liquid Rate

Oil Rate

Water Cut

Water Rate

Gas Rate

Solution Node

Pressure

STB/day

STB/day

percent

STB/day

MMscf/day

1795.4

1526.1

15

269.3

0.36168

psig

1000.51

In the subsequent analysis of Gas lift sensitivities after inject ion process, the changes in the above parameters;

more specifically increase in oil rate and reduction in solution node pressure should be observed and

discussed. These values which production engineers are more interested in, because the purpose of doing gas

lift for any well is to deliver more quantity of oil and reducing the bottom-hole pressure to increase the

drawdown pressure within the reservoir.

4.2.

Gas Lift Sensitivities

These sensitivities are adapted for specific application. For instance, the follow ing parameters can be modified

are related with inflow of the well. Thus any alterations in these parameters will affect the IPR curve rather

than VLP curve.

Reservoir Pressure and Reservoir Temperature

Productivity Index

Water Cut

Gas Oil Ratio (GOR), Water Oil Ration

145

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

Dissolved and Free GLR

On the other hand, the following parameters determine the outflow of any reservoir. For example, in the gas

lift application; where the node is indicated at the bottom of the well, any changes or modifications in the

below parameters can be considered while carrying out sensitivities.

Injection Depth

GRL Injected

Injection Depth

Total GOR

Gaslift Gas Injection Rate

Gaslift Gas Specific Gravity

Downhole Equipment, for example, Tubing/Pipe Diameter

Surface Equipment

In this paper, injected GLR, injection depth and Gaslift Gas Injection Rate sensitivities are tempted to find out

the effect of variation on the total oil production rate and bottom-hole flowing pressure (solution node

pressure). In all steps, the node pressure, water cut and design operating pressure are considered as constant.

Because Gaslift valves are already installed, thus no changes in valve position will be tried.

Finally the purpose of these sensitivities is to output an overall gas lift design system for the well. This will

include the trend of gas injection rate versus oil production rate and the position and number of gas lift valves.

4.2.1. Gaslift Gas Injection Rate

Through using PROSPER simulator different injection rate of the lifting gas can be analysed. This can be

done by selecting gas lift injection rate in the variable 1 of system 3 variables. For example, different injection

Sensitivity Plot (W ell Number 1 13/06/2013 - 19:38:43)

rates are tried from 0 to 2.25 MM scf/day, consequently, the below graph is plotted:

2 34 5.44

Oil Rate (STB/day)

2 14 0.48

1 93 5.53

1 73 0.58

1 52 5.63

0

0 .5 62 5

1 .1 25

Ga sli ft Gas Inj ecti on Rate

1 .6 87 5

2 .2 5

(MM scf/da y)

Figure 8: Gaslift Gas Injection Rate Sensitivities

From this graph, it is clear that any injection rate more than 1.687 MMscf/day will not change the liquid rate

(oil rate specifically) rather than increasing the pressure. By looking at the graph, the trend of the line is

remaining constant when gas is injected at a rate higher than 2.25 MMscf/day, thus 1.75 MMscf/day is the

maximum sensitivity of the well. However, this rate should be avoided, because only pressure will increase

and probably more gas will be produced than liquid. Table (7) summarises the data of above graph, through

which Optimum, maximum and Uneconomical injection rates are distinguished.

Table 7: Results of Injection Rate Sensitivities

Gas Injection Rate (MM scf/day)

Parameters

Optimum

Maximum

Uneconomical

0

0.25

0.5

0.75

1.0

1.250

1.500 1.750

2.000

2.250

Oil

Rate

1526.1

2113.2 2241.6 2283.4 2308.9 2325.9 2336.7 2342.9 2345.4 2345.1

(STB/day)

Sol. Node

1000.51 921.16 903.04 897.07 893.43 891.01 889.47 888.59 888.22 888.27

Press. (psig)

PV T Me tho d Bl a ck Oi l

First Nod e P re ssu re

1 50 .0 0 (psi g)

Infl ow T ype Si n gl e B ran ch

Flu i d Oi l

Bo ttom Me a su red Dep th

3 44 9.9 (fee t)

Co mp l eti on Ca sed Ho le

Flo w T yp e T u b in g

Bo ttom T ru e V erti ca l Dep th

3 44 9.9 (fee t)

Sa n d Co ntrol No n e

We l l T yp e Pro du ce r

Ga s Con i ng No

Su rface Eq u ip me nt Co rre l ati on Be g gs an d Bri l l

Arti fici al Li ft Ga s L i ft (Co nti nu ou s)

Ve

rtical

L

ift

Co

rre

la

ti

on

Pe

trol

eu

m

Exp

erts

2

L ift T ype No Fri cti o n Lo ss In A nn ul u s

Re servoi r M od el PI En try

Pre di cti n g Pre ssu re an d T emp e ra ture (o ffsho re)

First Nod e 1 X ma s T re

emp

0

(fee

t) on P erme a bi l ity Re du cti on Mod e l No

Co

acti

T e mp era tu re Mo de l Ro u gh A pp roxi mati o n

L ast Nod e 4 Casi ng 34 49(fee

.9 t)

Re l ati ve Pe rmea bi l i ty No

Co mp an y Un i ve rsi ty o f S al ford

Ab sol u te Op en Fl ow (A OF)6 81 2.0 (ST B/da y)

Fie l d Fie l d A, Do me B

Re servoi r P ressure

1 20 0.00 (psi g)

L ocati on Ku rdi stan - No rth of Ira q

Re servoi r T em pe rature2 00 .0 0 (de g F)

We l l We l l Numb e r 1

Wa ter Cu t1 5.00 0 (pe rce nt)

An a lyst Farha d K ho sh n aw

Da te 1 0/06 /20 13

D:\Sa l ford Uni versity\M asters Proj e ct\Si mu l ati on Re su l ts\2\1 \Wel l Nu mbe r 1 .Ou t

146

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

4.2.2. Injected GLR

In PROSPER simulator different injected GLR can be analysed. This can be done by selecting Injected GLR

in the variable 1 of system 3 variables. For example, different GORs are tried from 237 scf/STB to 1200

scf/STB, consequently, the below

graph isPlot

appeared:

Sensitivity

(W ell Number 1 13/06/2013 - 19:42:46)

2 34 4.54

Oil Rate (STB/day)

2 32 4.98

2 30 5.42

2 28 5.86

2 26 6.31

2 37

4 77 .7 5

7 18 .5

9 59 .2 5

1 20 0

GL R Inj e cte d (scf/STB)

Figure

Gas Injection GLR

Sensitivities 1 50 .0 0 (psi g)

PVT

Me tho d 9:

Bl a Gaslift

ck Oi l

First Nod e Pre ssu re

Infl ow Type Si n

i d Oi l

Bo ttom Me a su red Dep th

3 44 9.9 (fee t)

on Ca s

Table (8) summarises the data

ofFlu

above

through which

and

uneconomical

total GOR areSaCon dmpCol eti

Flo w

T yp

e Tu b ingraph,

g

Bo ttom Economical

T ru e Verti ca l Dep

th

3 44 9.9 (fee t)

ntrol No n

We l l T yp e Pro du ce r

Ga s Con i ng No

Su rface Eq u ip me nt Co rre l ati on Be g gs an d Bri l l

Arti

fici

al

Li

ft

Ga

s

L

i

ft

(Co

nti

nu

ou

s)

indicated. By looking at figureL ift(4.2),

it is clear that when injected

GLR > 400 scf/STB, the change in the Re

oilservoi r M od el PI E

Ve rtical L ift Co rre la ti on Pe trol eu m Exp erts 2

Type No Fri cti o n Lo ss In Ann ul u s

di cti n g Pre ssu re an d T emp e ra ture (o ffsho re)

Firsthave

Nod e 1

Xma

s T re

emp

0(fee

t) on Perme

Co

acti

a the

bi l itywell

Re du cti on Mod e l No

rate is insignificant. Thus

anytuPre

further

increasing

in the

no

impact

pressure

on

Te mp era

re

Mo de l Ro

u gh App roxi mati

o n injected GLR will

L ast Nod e 4 Casi ng 34 49(fee

.9 t)

Re l ati ve Pe rmea bi l i ty No

Co mp an y Un i ve rsi ty o f Sal ford

Ab sol u te Op en Fl ow (AOF)6 81 2

Fie

l d Fie l d A, Do me B

and the situation is tending to be

uneconomical.

Re servoi r Pressure

1 20 0.

L ocati on Ku rdi stan - No rth of Ira q

Re servoi r T em pe rature2 00 .

Wa ter Cu t1 5.0

We l l We l l Numb e r 1

An a lyst Farha d Kho sh n aw

Da te 1 0/06 /20 13

D:\Sa l ford Uni versity\M asters Proj e ct\Si mu l ati on Re su l ts\2\1 \Wel l Nu mbe r 1 .Ou t

Table 8: Results of Injection GLR Sensitivities

Injected GLR (scf/STB)

Parameters Economical

Uneconomical

237

344

451

558

665

772

879

Oil

Rate

2869.9 2302.1 2324.0 2336.8 2343.1 2344.5 2342.3

(STB/day)

Sol. Node

899.51 894.40 891.27 889.45 888.55 888.35 888.67

Press. (psig)

986

1093

1200

2337.2 2329.7

2320.5

889.40 890.46

891.78

4.2.3. Injection Depth Sensitivity

Various injection depths for the same injection gas can be analysed. This is done by selecting gas lift injection

rate in variable 1 of system 3 variables and injection depth in variable 2.

As shown in the figure below of injection sensitivities, the deeper injection of Gaslift gas rate leads to increase

the oil rate/or liquid rate. This happens because, when gas injected at deeper point, this will result in further

reduction in oil column density inside the vertical tubing. As a result of lightening the fluid, the hydrostatic

pressure will reduce, hence the BHP. In the design consideration of any gas lift system; there is a limit of

injection depth which is just above tubing shoe.

147

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com

July 2015, Volume 3, Issue 7, ISSN 2349-4476

Sensitivity Plot (Well Number 1 13/06/2013 - 19:41:40)

3002.71

2

2

Injection Depth

2

1

2630.55

(feet)

Curve 0 = 1985

Curve 1 = 2550.5

Curve 2 = 3116

Oil Rate (STB/day)

2258.39

1886.23

1514.07 2

1

0

0

0.5625

1.125

1.6875

2.25

Gaslift Gas Injection Rate (MM scf/day)

Figure 10: Sensitivity Effect

of Injection150.00

Depth

on Oil Rate

PVT Method Black Oil

First Node Pressure

(psig)

Type Single Branch

Fluid Oil

Bottom

Measured

Depth

3449.9 (feet)

Below table are theFlowsensitivity

results

for

the

JAF

well,

to

the

same

injection

rate in Inflow

MMscf/day,

at three

Completion

Cased Hole

T ype Tubing

Bottom T rue Vertical Depth

3449.9 (feet)

Sand Control None

Well

T

ype

Producer

different injection Artificial

depths

of

ft;

consequently,

the

oil

rate

proportionally

increased

with

increasing

depth

of

Gas

Coning

No

Lift Gas Lift (Continuous) Surface Equipment Correlation Beggs and Brill

Vertical Lift Correlation Petroleum Experts 2

Lift Type No Friction Loss In Annulus

Reservoir M odel PI Entry

injection.

Predicting Pressure and T emperature (offshore)

First Node 1 Xmas T ree

0(feet)

Compaction

Permeability Reduction Model No

Temperature Model Table

Rough Approximation

Last Node 4 Casing

3449.9

(feet)

9: Injection Depth Sensitivity

Result

on the Well

Relative Permeability No

Company University of Salford

Absolute Open Flow (AOF)6812.0 (ST B/day)

Field Field A, Dome B

Reservoir Pressure

1200.00 (psig)

Optimum

Maximum

Location Kurdistan - NorthPROSPER

of Iraq

Reservoir T em perature200.00 (deg F)

Well Well Number 1

Water Cut15.000 (percent)

Parameters

Calculated

Injection

Injection

Analyst Farhad Khoshnaw

Date 10/06/2013

Injection

Sensitivity

Sensitivity

D:\Salford University\M asters Project\Simulation

Results\2\1\Well

Number 1.Out Sensitivity

Injection Depth (ft)

1985

2250

3116

Gas Injection Rate (MM scf/day) 1.750

1.750

1.750

Oil Rate (bopd)

2390.2

2692.6

2999.9

Solution Node Pressure (psi)

881.84

837.34

790.18

5.

CONCLUSION

Before implementing gas lift optimisation, the average oil production rate (bbl/day) for this well was around

1700 (bbl/day), with relatively low drawdown pressure (psig) between average reservoir pressure and bottomhole flowing pressure. Thus, to optimise the production, these wells are modelled in PROSPER program,

through entering row field data of both reservoir fluids properties and well testing data for PVT matching and

generating IPR and VLP for each well.

The well is modelled in PROSPER step by step for VLP correlation comparison, Petroleum Expert-2 was

found very close to well test data for all vertical/tubing performance. While for matching pipe correlation

Beggs and Brill correlation is found the best fit correlation for production and flow line test. Design injection

pressure is inputted based on the available source supply and considering bubble point pressure as well.

The sensitivity results, through which maximum oil production rates are achieved as 2343 bbl/day at gas lift

injection rate of l.75 MMscf/day. In addition, maximum and optimum GLR for the well is determined under

fixed injection rate of 1.35 scf/day of GasLift gas rate based on the selected correlation for analysing injected

GLR sensitivities and the result was; 451 scf/stb. And finally, an optimum injection depth for the fixed gas

injection rate in MMscf/day for the well is obtained as 2250 ft.

148

Pshtiwan Tahsin Mohammed Jaf

Inte rnational Journal of Engineering Technology, Manage ment and Applied Sciences

www.ijetmas.com July 2015, Volume 3, Issue 7, ISSN 2349-4476

6.

1.

2.

3.

4.

5.

6.

7.

8.

REFERENCES

Ahmed, T., and McKinney, P. D. (2004). Advanced Reservoir Engineering. Oxford : Gu lf Professional Publishing

is an imprint of Elsevier.

Beggs, H. D. (2003). Production Optimization Using Nodal Analysis. Oklaho ma: OGCI and Petroskills

Publications.

Bro wn, K. E. (1984). The Technology of Artificial Methods (Vol. Vo lu me 4). Tu lsa: PennWell Publishing

Co mpany.

Economides, J. M ., Hill, D. A., and Ehlig-Econo mides, C. (1994). Petroleum Production Systems. New Jersy:

Prentice Hall PTR.

GUO, B., LYONS, W. C., and GHALAM BOR, A. (2007). Petroleum Production Engineering. Elsevier Science

and Technology Books.

Hadiaman, F. (2011). GAS LIFT OPERATION, BEST PRACTICE, AN D PERFORMANCE. WLS: Totalattitude.

Hall, J. W., and Decker, K. L. (1995). Gas -1ift Unloading and Operating Simulation as Appliedd to Mandrel

Spacing and Valve Design. SPE 29450, 63-78.

Lake, L. W. (2010). Petroleum Engineering Handbook (Vol. Vo lu me IV). ZULIA, VENEZUELA : MERCADO

NEGRO.

149

Pshtiwan Tahsin Mohammed Jaf

Das könnte Ihnen auch gefallen

- Working Guide to Reservoir Rock Properties and Fluid FlowVon EverandWorking Guide to Reservoir Rock Properties and Fluid FlowBewertung: 3 von 5 Sternen3/5 (1)

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesVon EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesNoch keine Bewertungen

- Fundamentals of Gas Lift Engineering: Well Design and TroubleshootingVon EverandFundamentals of Gas Lift Engineering: Well Design and TroubleshootingBewertung: 5 von 5 Sternen5/5 (2)

- 1 - Introduction To Nodal AnalysisDokument35 Seiten1 - Introduction To Nodal AnalysisLuis Marcio AvendañoNoch keine Bewertungen

- 03 - Oil Well IPRDokument90 Seiten03 - Oil Well IPRMohammad Kazemi67% (6)

- Nodal AnalysisDokument24 SeitenNodal AnalysisSuhail Al-serriNoch keine Bewertungen

- Well Test - GeramiDokument203 SeitenWell Test - Geraminwosu_dixon100% (1)

- Kick ToleranceDokument3 SeitenKick TolerancePunam KapoorNoch keine Bewertungen

- Production Optimization: January 21, 2016Dokument45 SeitenProduction Optimization: January 21, 2016Farhad Ali SafiNoch keine Bewertungen

- Ongc &: Oil Well Production TestingDokument35 SeitenOngc &: Oil Well Production TestingDayanand Singh100% (1)

- Well TestingDokument20 SeitenWell TestingSaa D ShamimNoch keine Bewertungen

- Nodal AnalysisDokument44 SeitenNodal AnalysisAbigail Park100% (2)

- Introduction To Well TestingDokument39 SeitenIntroduction To Well TestingzazoNoch keine Bewertungen

- Total Well Management IIDokument14 SeitenTotal Well Management IIEdgar Tellez100% (1)

- PROSPER Complete 2Dokument1.725 SeitenPROSPER Complete 2Mohamad Zamri100% (1)

- Well TestingDokument21 SeitenWell TestingOvaid Mehmood100% (1)

- Well TestingDokument8 SeitenWell TestingMahmoud El Shorafa100% (5)

- Well Testing Schlumberger GlossaryDokument18 SeitenWell Testing Schlumberger GlossaryDiana La Cruz100% (1)

- Introduction To Well Performance and MethodsDokument40 SeitenIntroduction To Well Performance and MethodsShagun Devshali100% (2)

- Flowing and Gas Lift Performance Gilbert 1954Dokument32 SeitenFlowing and Gas Lift Performance Gilbert 1954cakewater86% (7)

- Note Calc PWRI InjectivityDokument9 SeitenNote Calc PWRI InjectivityDoddy VallentynoNoch keine Bewertungen

- Fracture GradientsDokument36 SeitenFracture Gradientszapspaz100% (1)

- Advanced Artificial Lift Methods - PE 571Dokument29 SeitenAdvanced Artificial Lift Methods - PE 571Ruben Chirinos OlivaresNoch keine Bewertungen

- Well Test ProblemsDokument9 SeitenWell Test ProblemsArash Nasiri100% (1)

- Nodal Analysis SummaryDokument7 SeitenNodal Analysis SummaryaliyahfitNoch keine Bewertungen

- Well Problem IdentificationDokument16 SeitenWell Problem IdentificationMichel zakhariaNoch keine Bewertungen

- Lecture 1 Reservoir DeliverabilityDokument36 SeitenLecture 1 Reservoir DeliverabilitySInowrita100% (2)

- Production Petroleum SoftwareDokument48 SeitenProduction Petroleum SoftwareMohamed TarekNoch keine Bewertungen

- 1 - Nodal AnalysisDokument39 Seiten1 - Nodal Analysisweldsv1Noch keine Bewertungen

- Introduction To Well Testing and Interpretation: WCP1 CourseDokument51 SeitenIntroduction To Well Testing and Interpretation: WCP1 Courserabahnali75% (12)

- Ipr VLPDokument67 SeitenIpr VLPDhiaa LaMiNoch keine Bewertungen

- Gas Well Testing, MDGC PDFDokument106 SeitenGas Well Testing, MDGC PDFanggityaNoch keine Bewertungen

- Well Test AnalysisDokument138 SeitenWell Test AnalysisDaniel Sinkot100% (1)

- Asphaltenes Problems and SolutionsDokument36 SeitenAsphaltenes Problems and SolutionsRuben Dario Rodriguez Lopez50% (2)

- Advanced Well TestingDokument91 SeitenAdvanced Well TestingBendali MehdiNoch keine Bewertungen

- Flowing Well PerformanceDokument57 SeitenFlowing Well PerformanceTogoumas Djide100% (4)

- Streamline Numerical Well Test Interpretation: Theory and MethodVon EverandStreamline Numerical Well Test Interpretation: Theory and MethodNoch keine Bewertungen

- Production OptimizationDokument36 SeitenProduction OptimizationLawrence MbahNoch keine Bewertungen

- Introduction To NODAL AnalysisDokument47 SeitenIntroduction To NODAL AnalysisAmin Elfatih100% (2)

- Prosper® Tutorial 05: Modelling A Multilateral Dry Gas ProducerDokument72 SeitenProsper® Tutorial 05: Modelling A Multilateral Dry Gas ProducerPedro Marquez100% (1)

- Hagedorn Brown CorrelationDokument14 SeitenHagedorn Brown CorrelationRoyan100% (1)

- Bottom Hole PressureDokument12 SeitenBottom Hole PressurebrayangtNoch keine Bewertungen

- Spe 120632 MS PDokument0 SeitenSpe 120632 MS PMagaña AuryNoch keine Bewertungen

- Prosper® Tutorial 08: Modelling A Gas Well With Connected PipelineDokument9 SeitenProsper® Tutorial 08: Modelling A Gas Well With Connected PipelinePedro MarquezNoch keine Bewertungen

- Artificial Lift MethodsDokument10 SeitenArtificial Lift MethodsMohamed Nazeer Mohd IsmailNoch keine Bewertungen

- Well Test AnalysisDokument23 SeitenWell Test Analysisleong_guoNoch keine Bewertungen

- Bottomholemodaloil PCDokument6 SeitenBottomholemodaloil PCKimiko ShopNoch keine Bewertungen

- DF7 - Vertical Lift PerformanceDokument2 SeitenDF7 - Vertical Lift Performanceadnan0307100% (1)

- Pore Pressure PredictionDokument62 SeitenPore Pressure PredictionDheeraj KumarNoch keine Bewertungen

- Gas Lift WellfloDokument39 SeitenGas Lift WellfloJuan Guillermo Restrepo Cano100% (1)

- Methods for Petroleum Well Optimization: Automation and Data SolutionsVon EverandMethods for Petroleum Well Optimization: Automation and Data SolutionsNoch keine Bewertungen

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceVon EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNoch keine Bewertungen

- Air and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHVon EverandAir and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHNoch keine Bewertungen

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- Microbial Enhancement of Oil Recovery - Recent AdvancesVon EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNoch keine Bewertungen

- PCP VenezuelaDokument6 SeitenPCP VenezuelakurtbkNoch keine Bewertungen

- Stuctured Product SlidesDokument12 SeitenStuctured Product SlideskurtbkNoch keine Bewertungen

- Associated Gas Utilization Via MiniGTL Jan 2014 UpdateDokument37 SeitenAssociated Gas Utilization Via MiniGTL Jan 2014 Updatekurtbk100% (1)

- Marginal Field DevelopmentDokument56 SeitenMarginal Field DevelopmentkurtbkNoch keine Bewertungen

- Spe 75133Dokument9 SeitenSpe 75133kurtbkNoch keine Bewertungen

- Pipeline Construction ScorecardDokument4 SeitenPipeline Construction ScorecardkurtbkNoch keine Bewertungen

- Evaporative Rates of A SpillDokument3 SeitenEvaporative Rates of A SpillkurtbkNoch keine Bewertungen

- Coveccion ForzadaDokument6 SeitenCoveccion ForzadakurtbkNoch keine Bewertungen

- WG's Process Engineers' Codes StandardsDokument18 SeitenWG's Process Engineers' Codes StandardskurtbkNoch keine Bewertungen

- B 07 S 01Dokument219 SeitenB 07 S 01kurtbkNoch keine Bewertungen

- Infra-View LitDokument2 SeitenInfra-View LitGavinsiauNoch keine Bewertungen

- Pengaruh Skarifikasi Dan Hormon Giberelin (Ga) Terhadap Daya Kecambah Dan Pertumbuhan Bibit Palem Putri (Veitchia Merillii)Dokument8 SeitenPengaruh Skarifikasi Dan Hormon Giberelin (Ga) Terhadap Daya Kecambah Dan Pertumbuhan Bibit Palem Putri (Veitchia Merillii)Adi IndraNoch keine Bewertungen

- Academic Calendar Odd Sem 2020-21Dokument1 SeiteAcademic Calendar Odd Sem 2020-21NAMRATA SHARMANoch keine Bewertungen

- ACT Lab ManualDokument6 SeitenACT Lab ManualkanjiaevNoch keine Bewertungen

- 1-P1 P9-AIAG CQI-9 Pre 3rdDokument12 Seiten1-P1 P9-AIAG CQI-9 Pre 3rdSaravanan MNoch keine Bewertungen

- Math 216 SyllabusDokument4 SeitenMath 216 Syllabusdoney_78100% (1)

- Heijunka 1Dokument15 SeitenHeijunka 1navin.rohilla7564Noch keine Bewertungen

- Unit 8 Migration: 8.0 ObjectivesDokument10 SeitenUnit 8 Migration: 8.0 ObjectivesSatyanshNoch keine Bewertungen

- SET B ExamDokument21 SeitenSET B ExamDhon ValeNoch keine Bewertungen

- How To Install Kali Linux 2Dokument36 SeitenHow To Install Kali Linux 2ᎦᏂᎯᎦᎲ ᏦᎯᏁᎿᏂNoch keine Bewertungen

- Alice in Wonderland Literary AnalysisDokument5 SeitenAlice in Wonderland Literary AnalysisRica Jane Torres100% (1)

- Five Codes of Barthes in Shahraz's Story A Pair of Jeans: A Post-Structural AnalysisDokument14 SeitenFive Codes of Barthes in Shahraz's Story A Pair of Jeans: A Post-Structural Analysismuhammad faheemNoch keine Bewertungen

- Installation Manual MaldivesDokument23 SeitenInstallation Manual MaldivesutaiuliancatalinNoch keine Bewertungen

- Ge7 ModDokument5 SeitenGe7 Modaldo galloNoch keine Bewertungen

- Using Engineering and Management Principles For Better Patient Care Nikhil BalakrishnanDokument345 SeitenUsing Engineering and Management Principles For Better Patient Care Nikhil BalakrishnanYendy ReyesNoch keine Bewertungen

- Starters: Grammar Unit 11Dokument8 SeitenStarters: Grammar Unit 11andres lNoch keine Bewertungen

- Characterization of Metallized Biaxially Oriented Polypropylene FilmDokument10 SeitenCharacterization of Metallized Biaxially Oriented Polypropylene FilmLaboratory Plant 7Noch keine Bewertungen

- Giancoli - Physics SolutionsDokument1 SeiteGiancoli - Physics Solutionspo4xx0% (1)

- Philippine Business For Social Progress: A Case StudyDokument52 SeitenPhilippine Business For Social Progress: A Case StudySynergos InstituteNoch keine Bewertungen

- Participatory Irrigation Sector Project (Pisp)Dokument35 SeitenParticipatory Irrigation Sector Project (Pisp)Maman Rustaman100% (1)

- FM Station ProposalDokument10 SeitenFM Station ProposalCedric De Lara Conol100% (2)

- Aa - Spec - 538011 Medium Voltage Induction MotorsDokument32 SeitenAa - Spec - 538011 Medium Voltage Induction Motorsjonodo89Noch keine Bewertungen

- How To Solder A Through-Hole Component: InstructablesDokument6 SeitenHow To Solder A Through-Hole Component: InstructablesBobKatNoch keine Bewertungen

- SR5 TOOL Adept Powers List + Description, CompiledDokument5 SeitenSR5 TOOL Adept Powers List + Description, Compiledvwp09705Noch keine Bewertungen

- Lesson Plan Week 1 The Eve of The Viking AgeDokument3 SeitenLesson Plan Week 1 The Eve of The Viking AgeIsaac BoothroydNoch keine Bewertungen

- Eisi - Company & Product Profile (2022)Dokument29 SeitenEisi - Company & Product Profile (2022)Loui BarciaNoch keine Bewertungen

- Proposal Cafe Janji JiwaDokument24 SeitenProposal Cafe Janji JiwaIbamz SiswantoNoch keine Bewertungen

- M/s Rishabh Creations Sikka Knitting FabDokument1 SeiteM/s Rishabh Creations Sikka Knitting FabVarun AgarwalNoch keine Bewertungen

- A Study On The Socio Economic Impact of Deforestation Upon The Tribal Villagers in Galudih, East Singhbhum, JharkhandDokument11 SeitenA Study On The Socio Economic Impact of Deforestation Upon The Tribal Villagers in Galudih, East Singhbhum, JharkhandEditor IJTSRDNoch keine Bewertungen