Beruflich Dokumente

Kultur Dokumente

Method

Hochgeladen von

Arun MoorthyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method

Hochgeladen von

Arun MoorthyCopyright:

Verfügbare Formate

B.L.

KSAHYAP & SONS LTD

METHOD

STATEMENT

FOR CONSTRUCTION

ACTIVITIES

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

INDEX

METHOD STATEMENT FOR SETTING OUT OF THE BUILDING

LAYOUT.

METHOD STATEMENT FOR FOOTING EXCAVATION.

METHOD STATEMENT FOR EXCAVATION FOR WALL

FOUNDATION.

METHOD STATEMENT FOR CONCRETING WORKS.

METHOD STATEMENT FOR SHUTTERING WORKS.

METHOD STATEMENT FOR CUTTING, BENDING & PLACING

REINFORCEMENT.BARS.

METHOD STATEMENT FOR RANDOM RUBBLE STONE MASONRY

WORKS.

METHOD STATEMENT FOR BACK FILLING IN FOOTING PITS.

METHOD STATEMENT FOR EARTH FILLING WORKS FOR THE

PREPARATION OF SUB GRADE.

METHOD STATEMENT FOR 150MM THICK RUBBLE SOILING.

METHOD STATEMENT FOR COLUMNS.

METHOD STATEMENT FOR SLAB.

METHOD STATEMENT FOR SLAB SHUTTERING.

DESIGN STATEMENTS.

SHUTTERING DRAWINGS.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR SETTING OUT OF THE BUILDING LAYOUT

The setting out works is the most important activity in any execution work. It is called out in the

following way

1.The Points, which are forming the base line having certain defined references from

certain permanent structure, are established and protected from any disturbances.

2.

A theodolite having-at least count of one second is set at one of the points and is sited to any

other point to form a base line from where the offset and the angle to any point to the

proposed structure is considered.

3.

A point at a comfortable distance from the building grid which falls in the line showing the

distance from the base line is established and marked on masonry pillars is protected.

4.

Now from the above operation we have established a reference point for the structure.

5. The theodolite is then shifted to the above point and the first point is sited and is turned

to the defined angle to form a: lone parallel the grid line.

6. The above line is established and the point which from this line are marked on

pillars constructed in the above line.

7. The survey pillars are constructed at point's from where the distancelo the main point

can be measured by turning a line perpendicular to the line parallel to the grid line.

8. In the above' line, the distance to the points are measured and marked with paint so

that these points are nor removed easily.

9. The theodolite is the'set at a point established at a point from where the line already

established and the points in the other grid line, which is at a defined angle from the

previous line, Can be sited.

10. Now the new line is established and points. are marked as described earlier.

11. The theodolite is then shifted to the next point and the setting of the theodolite

establishing the points are continued till the starting point is sited and measured.

12. There, can be closing error and the error is distributed to all the points as a corrective

measure.

13. All the above points established which the reference for the proposed structure are

given due respect and are preserved undisturbed till the structure has come up to the

defined shape with the required accuracy.

,

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR EXCAVATION FOR WALL FOUNDATION

The excavation works of wall foundation are carried out in the following manner.

1. The area to be excavated is marked with lime powder giving due allowance for

working space.

2. The excavation is carried out manually by using hand tools.

3. The excavated earth which is good for filling works is spread at places required filling and

the unwanted earth is disposed off.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR CONCRETING WORKS

1. P.C.C

The earth surface at the location is made wet before receiving concrete P.C.C of

specified grade, is transported to the location in atransit mixer and is poured down inside

the formwork erected by means of chute. It is then leveled manually and finished to the

required standards by blowing with a rammer. Curing is done by allowing water to stay

above the PCC surface in the form of pond.

2.RCC FOORINGS

The PCC above which the following is to be casted is made wet. The RMC of the

specified grade is then position directly from the transit mixer into the forms erected in

position and is consolidated by vibrating properly internally with a needle vibrator. The

concrete surfaces are inspected after stripping of form works and if defects noticed are

rectified to the specification.

RCC COLUMN IN PLINTH/PEDESTALS

The surface to receive concrete is made wet and cement slurry is poured above the starter, which

is a construction junction. The- RMC received is unloaded tray made out of MS plates. The

concrete is then

mixed well properly to' form a uniform concrete free from segregation of

bigger aggreg-ates. It is then poured inside the forms manually to a layer of concrete to a

depth of 600mm. It is then consolidated, by using needle vibrator. Then the second layer of

concrete is poured and is vibrated. Similarly concreting is done to the required height. It is

cured 'for at least seven days by keeping the Hessian cloth wrapped around the column wet.

2. PLINTH BEAM

The SM surface above which the plinth beams rests are to be made wet. The RMC unloaded

over the MS span is mixed .well and is poured inside the forms. It is then consolidated by

means of a needle vibrator. Concrete is cured by keeping the Hessian cloth covering the beam

wet.

METHOD STATEMENT FOR SHUTTERING WORKS

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

1. P.C.0

The area where P.C.0 is to be laid is marked. The wooden runners to the required thickness free

from any twist or wrap are selected to from the sides of PCC. These are then joined by mailing

and supported properly to withstand the forces causing deviations while pouring the concrete.

Shuttering oil as recommended is applied to the surface of shuttering so as to make the

removal of forms easy without causing any damage to the concrete surface. The side shuttering

is kept for at least twelve hours and it removed without disturbing concrete casted.

2.RCC FOOTINGS

Frames of required dimension are made with wooden runners and Plywood boards are fixed

over the frames to form the side shutter. These shutters are then placed at the required position

and are fixed properly to form a box having inside dimension to the size and shape of RCC

footing.. it is then erected properly in position in plumb by rigid support by means of steel pipes

or wooden runner so that the position is not disturbed by lateral forces of vibration while

concreting. Shuttering oil is applied to the surface of Plywood as a releasing agent. The forms

are kept undisturbed for at least twelve hours after concreting. The shutters are then removed

without disturbing the structure.

3.RCC COLUMN IN PLINTHIPEDESTALS

Column pedestal starter in concrete which defines the location, size and shape are made to a

thickness 75 to 100 mm. The shutters of required dimension are made with plywood board

fixed above frames made out of wooden runners or steel frame. Shuttering oil is applied on the

surfaces. The shutters when fixed together will form a box confining the size and shape of the

column pedestal to be cast: It is then erected in position to plumb by referring the starter

defining the location of the column pedestal by giving support with MS props, so that the

location and the plumb are again checked immediately after concreting and if any deviations are

found it is then corrected by adjusting the support props. The shutters are kept undisturbed for at

least twenty four hours. The shutters are then, removed by taking care not to disturb the

structure.

4.RCC PLINTH BEAMS

Plinths beams to be cast above stone masonry and are in between two columns. The top level of

SSM is checked and is. corrected to the level proper methods if required. The shutters made out

of ply boards fixed over wooden frames are theri kept in position to from the side shutters after

applying shuttering oil. These shutters are then fixed in position by supporting with props. The

location and alignment is once again checked after the concrete pour and corrected if required.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR CUTTING, BINDING AND PLACING REINFORCEMENT

BARS

The bars received are made straight manually. The required length are then marked on the bar

with chalk pieces. It is then cut manually or with the help of shearing machine. It is then bend to

shape as required. These bars are carried to the place of erection and tide in position using MS

binding wire of specified thickness. The reinforcement is maintained in position by providing

cover blocks as specified. At places where the reinforcement is to be provided at top and

bottom of rafts, footing etc. chairs are provided to keep the bars in position. In ROC walls where

the reinforcements are at the faces of the wall it maintained in position providing spacers made

with bars.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR RANDOM RUBBLE STONE MASONRY WORKS

The stone masonry works are carried out as follows

1.

Stones of required sizes and river sand are stacked near the place of work

2.The surface of

PCC over which the masonry is to be done made clean and damp.

3.Cement sand mortar of specified proportion is prepared over a clean metal sheet.'

4.The area and -size of the masonry are marked by lying strings, which forms a guideline

for the mason working on this.

5.

A layer of sand mortar is placed is placed over the PCC the stones are laid in a staggered

manner to form a coarse of masonry.

6.

The voids are then packed with the mortar and the stone surfaces are made clean,

7.

A layer of sand mortar is again laid over the first layer of masonry and a course of masonry is

constructed.

8.

Similarly required courses of a masonry is build as per drawing and kept clean to received the

next day's works.

9.

Care is taken to provided through Stones (Header or Bond Stone) in each layer in a staggered

manner in such a way that one header comes in one square meter area.

10. The second stage of construction is started next day and if the final height of the same

section comes within

four coarse it is then finished to the required level properly and

keystones are provided for continuing with

11.

the next section.

The curing is done for at least seven days.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR BACKFILLING IN FOOTING PITS

The excavated pits for footing are backfilled after the completion of RCC works up to plinth in

the following manner.

1. The pit is cleared from all debris and wooden runners and nails etc. used for shuttering.

2. Water if found is pumped out of removed manually.

3. The approved earth for filling is then stacked near the pit and is filled in layers to a

thickness not more then 200mm.

4. The loose earth is then compacted mechanically by means of a plate compactor or

manually by ramming with the required tool.

5. Water is spread over to saturation and allowed for drying so that the entrapped air

escapes.

6. The surface is then rammed properly so as to get one layer of filled up earth.

7. The second layer is filled above the previous layer in the same way as explained earlier.

8. Similarly the required depth is made up and necessary tests are carried out to confirm the

required standards.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

M E T H O D S TATE M E N T F O R E A RTH F I L L I N G WORKS FOR THE PREPARATION

OF SUBGRADE

The following are the sequence of activities in the earth filling work for the preparation of sub

grade.

1. The existing ground levels are recorded.

2.

The area is cleared from all debris and vegetation.

3. The selected suitable earth is dumped as heaps at places where filling works are to

be carried out.

4. The above loose soil is spread to a layer to a thickness not more than 200mm

manually or by mechanical means.

5. The dry filled up soil is compacted by rolling by means of Static Roller of 8 to 1ONIT

capacity.

6. Water is spread over these areas manually or by using a tanker to saturation.

7. The area where water has been spread is kept undisturbed for over four hours to allow the

water to percolate and release the entrapped air.

8. The area is again rolled for over one hour and water is spread as before.

9. The rolling, wetting and rolling are continued till satisfactory compaction is achieved.

10.The second layer of filling is started and the filling operation is carried out layer by layer till

the required level is achieved.

11.Finally the top level of filled up earth is observed and if any difference from the required

level noticed the same is build by filling at places in depression and cut into the

required level at places in elevation.

12.The final rolling is carried out and the density tests are carried out at different locations

to confirm the specified requirement.

13.The locations not satisfying the standard are treated as required to achieve the specified

standards.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR COLUMNS.

General

All works for shuttering, reinforcement and concreting of columns will be

undertaken by experienced workers under the supervisor/engineer.

Safety works will be always be ensured. All workers working at the top of the columns during

concerting will be provided with helmets, gloves and safety belts. A platform will prepared all

around the top of the column for easy movement of concreting/vibrating team.

Concrete will be done with crane buckets or manually.

6 For constructions at night adequate lighting and workmen will be maintained.

Detailed Procedure

Reinforcement

Bars of specified diameter will be straightened. Cut bend and placed in position as per

the approved construction drawings and bar bending Schedule. The steel will be lapped at

specified locations adequately. Care will be taken not to lap the bars at mid height of the

columns after erection of reinforcement in place stirrups will be prepared and positiOned cover

blocks will then be bound to the sides of stirrups.

Casting of Starters

This will be activity on columns which is to he taken up immediately after casting of

footings. Framework for starters will then be put in place. Formwork will be made of 4"x2"

wooden battens nailed together to square form. The height of starter will be minimum 75100mm.

Layout will again be checked after putting of starter form work to check for covers Alignment, Etc.

Concreting will be done using 40mm diameter needle vibrators. Care will be taken that the

vibrator needle does not touche the reinforcement or the sides of framework. After starter

concreting, shear keys will be made.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

Concrete will be placed manually, in steel pans or with crane buckets, and properly vibrated

continuously. Concreting will be done in layer Care will be taken to pour the concrete slowly,

so that the concrete does not accumulate heavily at the base of column. One supervisor will be

deputed at the base with wooden mallet to check any voids in concreting.

After concreting is complete, plumb and diagonals of the column will be again checked.

Post concreting

Deshuttering will be done after .24 hours of concreting. Any making good of the concrete surface

will be carried out as soon as forms are stripped. However approval will be requested prior to

making good of any defect in concreting.

-

After this the column will be wrapped fully ,with wet Hessian cloth for curing purpose. One

labour will be deputed full time for curing, to ensure that the concrete surface is always wet.

Curing will be done for at least seven days, after which Hessian will be removed.

As a final completion work, layout mortar, Concrete/mortar droppings at the base of the column

will be removed and finished smooth and clear.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR SLAB

GENERAL

1.All workers for shuttering, reinforcement and concreting of slab will be undertaken by

experienced workers under the supervision of a supervisor engineer.

2.Safety during the work will always be better to avoid any type of accident. All people

working during the work will wear safety helmet and gloves.

3.A ladder or proper approach will always be there to climb.the slab level.

4.Proper lightning arrangement will be provided there while working at slab /evel.at night.

5.Safety barcation will be made all around the slab at bottorri level and as well as top to

avoid any accident.

Detailed of Procedure.

As soon as the column reaches the required beam bottom level the activity of slab form work

will start.

Site at the ground floor will be made clean and no object will be their other then shuttering

material.

For first floor level slab ground will be made uniform/level and proper compact will be made

there to erect the staging for form work.

Staging will be erect at slab/beam area up to required height level.

At beam position M.S. span will be fix to the required length of the beam & it will be rest on

the staging made for that.

The above same exercise wily be made whenever beam is coming shown on the slab form

work drawing.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

Above span the wooden batten will be placed perpendicular the length of

the span.

Above the wooden batten fix on the MS span the beam bottom of that particular beam will

be placed along the length of the span. Proper fixing arrangement will be done with

beam bottom to the wooden batten.

Formwork leveling will be done to check the exact level of bottom level of beam.

Side of beam made of 12mm plywood will be fix, and it will rest on top of beam bottom

and it will fix with nailing.

After fixing the side it will extra supported with inclined batten as shown in the attached

sketch.

MS Span at 600c/c will be fixed in between two beam side support and proper nailing will

be done to fix the MS span and beam side.

On top of the ms span provided in between two beam side MS plate will be kept to

complete the slab form work.

Leveling of all work will be done as per the required level.

Extra supporting from bottom will be done where ever required.

Cleaning of all slab form work will be done to remove all dust.

Shuttering oil will be applied on top.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

Reinforcement

Bars of -specified diameter will be straightened cut bend and placed in

position as per the approved construction drawing and bar bending schedule.

The reinforcement will lap at the specified location adequately,

While fixing the reinforcement at site first beam main reinforcement fixing

will be done after that the stirrups of required die and dimension will be

positioned.

Cover block will be then kept at position

After binding the beam reinforcement slab reinforcement will be fix there.

Cover block will then kept.

Concretin

On the approval of concrete will start with necessary equipment.

Concrete first will be placed at the column beam junction and then in

the beam position. While concreting vibrator will be used.

Concreting will be done in layer..

After pouring the concrete in the beam concrete will be done in slab

area. at slab. One supervisor and one engineer will always be there while concreting

Post concreting

Curing of slab will be done for seven days.

Deshuttering will be done for slab bottom after seven days and for beam

bottom 14 days.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

DESIGN STATEMENT

DEAD WEIGHT OF SHUTTERING MATERIALS AND LOAD CARRYING CAPACITY

SI.

No

Description

Weight

Load carrying

capacity when

placed

Props Male 65 (bottom)

Female 60 (top)

1.8Kgs.

15Kgs.

55 Kgs.

12 Kgs.

1.65 Tons

Acrow san

MS Shuttering sheet

with Angie frame.

4.

10.

11.

High Pressure Micro

Film faced shuttering

20 Kgs.

1.80 Tons

Horizontal

Position

Req. for one

has EF 1.3

9.0 x 8.0 =

72.0 m2

54 Nos.

26 Nos.

100 Nos.

Total load

carrying

capacity

Total weight

of steel &

concrete.

89.10 T

. 46.80 T

100.0 T

100 M2

PI

.

Wooden Battens/

8kgs/rmt 2 . 4 x 1 . 2

100.M

Runners 4"x3"/2"x3"

5.5kg/m

200 M

Nails 4",3" & 2" long

80 kgs.

1.050 T

Steel

for

Beam 1.050.

Tons

300x750x9.0x3 Nos.

0.700

0.700 T

Tons

Steel for Slab 9.0x8.0

1.665 T

1.665 EF 2.3

Concrete Beam

22.39 T

750x750x8.0x2 Nos.

Concrete Beam

15.11 T

300x750x9.0x3 Nos.

Concrete Slab

35.82 T

9.0x80M

23.44 T

15.81 T

37.49 T

Total Weight of RCC - M Tons*

Total Load Carrying

Capacity of Shuttering M Tons

Including F/S

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

METHOD STATEMENT FOR SLAB SHUTTERING

A. Preparation of Base.

1. Filling area is leveled and same is compacted properly.

2. The height available between filled up level and shuttering bottom is measured.

3. As per requirement, the minor level is made up by filling or scraping.

4. Either solid block or. ISMC or wooden runners below the prop are provided in

order to reduce the stress on the filled up soil.

5. Props are checked whether is has proper base, if not rectify it or replace it.

B. Beam Shuttering.

Shuttering for Peripheral Beams.

1. The bottom of the beam shuttering is marked in each columns according to the

depth indicated by Consultant.

2. APS unit are lined, up along the beam alignment as per the spacing. required.

3. Acrow. Span are mounted over the APS unit abutting the columns.

4. Cross runners 4"x3" are laid with required spacing over the already mounted

Acrow Span.

5. Now, Beam bottom with adequate back up timber shall be temporarily spread.

6. Beam Bottom shall now be, aligned, leveled in its proper position and it is nailed

to the cross runner.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

Shuttering for Internal Beams

1. All above procedure shall remain same except, the support shall be with Props,

2. Now, the beam sides shall be fixed to the beam bottom considering the slab

thickness,

3. Alignments are verticality sides vertical & horizontal are nailed for positioning

Acrow Span.

C. Shuttering for Slab.

1. Acrow Spans are checked individually for stability & damages if found are

rejected forthright. 2. Acrow Spans are extended up to 3.5 m length so that it sits

over extra runner provided to the sides of the..beams.

3. Acrow Spans are aligned properly and the ends of the span are nailed with the

beam side runner.

4. Now, the spans are ready to take the Floor Forms.

5. The Floor Forms are laid over the. Acrow Span in such a way that the joints of the

forms are in one line, which on Deshuttering will look presentable at the bottom.

6. The middle screw of Acrow Span is tightened properly.

7. Now the levels of each Floor Forms is checked by thread and gauging method & a

cross check is also made with leveling instrument.

8. The Joints of Floor Forms are covered with adhesive tape in order to restrict the

slurry leakage.

9. After checking levels & alignment of the entire Shuttering system oil is applied

over centering, which would enable trouble free Deshuttering:

10. Clearance is now given for the Bar bending team for placing reinforcement.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

Formwork

Formwork activity will start the next day of pouring of starters. Prior to erection of

formwork, the starter layout will be again cross-checked by the deputed engineer.

Any discrepancy, error, mistake in operation quality, alignment (Le. the column

starter should not get skewed) will be informed immediately to the clients Engineerin-charge, who will advise necessary action

Column forrnwork will be made of 12mrn shuttering plywood. The ply face will be

stiffened with 3" x 2" wooden battens all around at the edges. And internal supportstiffeners with 3" x 2" wooden battens (horizontal & vertical). Spacing of internal

stiffeners will be as per the formwork design drawings. Care will be taken to ensure

that the battens "sit" on the face of the plywood to prevent bulging.

The joint at the junction of two-ply pieces will be strengthened with an additional

batten.

The surfacing of ply (inner face) will be applied with form releasing oil of approved

make,

The column will then be tightened with tie rods fixed at regular intervals. Props

jacks will be supported at regular intervals on sides to keep the formwork in exact

position. Verticality and alignment will then be checked. After this the client's

Engineer-in-charge will be requested to review and approve the column, and sign on

the pour card.

Concreting

On approval of column form work, access platform will be. created up to'the top to

allow workmen to stand on top proceed with concreting. 1 No of vibrator with 40

mm diameter needle will be deputed on top of the access tower. 1 No. of vibrator

will be kept at the base as a standby.

Prior to placing of concrete, rich cement slurry will be poured into the column for

better bonding of new and old concrete.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

B.L.KSAHYAP & SONS LTD

D. Final Check before Concreting Commences.

1. AU props are checked for its rigidity, and ensure proper wedges are provided

below in tight position.

2. The gaps if found any of the Shuttering joints shalr be closed by plywood or GI

Sheets.

3. Bracing for all vertical Units shall be provided with horizontal ledger/ pipes by

clamping it using swivel couplers.

4. Proper cleaning of the shuttering surface for dust, Leaves, Cement, Residues,

Papers etc., shall be ensured by using Air blower, Vacuum Cleaner and watering.

Note:Any need arises for construction joint, the some shall be discussed with consultant's

site team and such location shall be provided with offset runners, which will give

proper key for the subsequent concrete.

Regional Office: 4th floor, West Wing, Soul Space Paradigm, Near Innovative Multiplex, Outer Ring Road, Bangalore 560 037

Corporate Office: B-1/E-23, Extension, Mohan Co-op, Industrial Estate, Mathura Road, New Delhi 110044.

Das könnte Ihnen auch gefallen

- Concrete Casting Preparation For PourDokument4 SeitenConcrete Casting Preparation For PourJedNoch keine Bewertungen

- Method Statement FOR Concreting Work: ProjectDokument6 SeitenMethod Statement FOR Concreting Work: ProjectKelvin LauNoch keine Bewertungen

- Method of Statement - Junction ChamberDokument9 SeitenMethod of Statement - Junction ChamberLaksri JayathilakeNoch keine Bewertungen

- Method Statement Striking FormworkDokument3 SeitenMethod Statement Striking FormworkSurya HeriwijayaNoch keine Bewertungen

- Method Statement For Excavation & BackfillingDokument5 SeitenMethod Statement For Excavation & BackfillingPaul LadjarNoch keine Bewertungen

- 006-Sample Method Statement Structure New WorksDokument4 Seiten006-Sample Method Statement Structure New WorksS.C.Satish ChanderNoch keine Bewertungen

- TEC-036400 - MET-DoR-003a (Method Statement For Concrete Crack Repairing by Concresive 2200&concresive - 1Dokument8 SeitenTEC-036400 - MET-DoR-003a (Method Statement For Concrete Crack Repairing by Concresive 2200&concresive - 1Micheal B HaizenNoch keine Bewertungen

- Ms Block WorksDokument3 SeitenMs Block WorksjaladeepNoch keine Bewertungen

- Workmanship On Building SitesDokument28 SeitenWorkmanship On Building SitesSa Reddi100% (1)

- Earthwork Excavation-Method StatementDokument4 SeitenEarthwork Excavation-Method StatementKhaled AbdelbakiNoch keine Bewertungen

- Method Statement Base Slab Concreting: Page 1 of 8Dokument8 SeitenMethod Statement Base Slab Concreting: Page 1 of 8J. Kumar Infraprojects LtdNoch keine Bewertungen

- Method Statement - Concreting WorkDokument4 SeitenMethod Statement - Concreting WorkArnold Roy ManaloNoch keine Bewertungen

- Methodology Statement Retrofitting of HVE Pedestal Supports - 1678233623Dokument7 SeitenMethodology Statement Retrofitting of HVE Pedestal Supports - 1678233623Francis GonzalesNoch keine Bewertungen

- Structural Loading of Fire Engine On Access WayDokument3 SeitenStructural Loading of Fire Engine On Access Wayleodegarioporral100% (1)

- De-Watering Method StatementDokument1 SeiteDe-Watering Method StatementSupun SandaruwanNoch keine Bewertungen

- SECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralDokument4 SeitenSECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralJojolasNoch keine Bewertungen

- Method Statement For General Concrete Work and Cutting Bending of Steel ReinforcementDokument4 SeitenMethod Statement For General Concrete Work and Cutting Bending of Steel ReinforcementSandip PaulNoch keine Bewertungen

- Method Statement For Trial LoadingDokument5 SeitenMethod Statement For Trial LoadingPunithan PunithanNoch keine Bewertungen

- ITT - Statement of ComplianceDokument3 SeitenITT - Statement of ComplianceAtif RizviNoch keine Bewertungen

- Method Statement Steel Structure 1 4 Meg PDFDokument26 SeitenMethod Statement Steel Structure 1 4 Meg PDFemeka2012Noch keine Bewertungen

- Mahaweli Water Security Investment Program Site EstablishmentDokument26 SeitenMahaweli Water Security Investment Program Site EstablishmentAmila Priyadarshana DissanayakeNoch keine Bewertungen

- Water RecDokument9 SeitenWater RecToyEn MEgatNoch keine Bewertungen

- Method Statement-EarthworkDokument2 SeitenMethod Statement-EarthworkChung May LynnNoch keine Bewertungen

- General Civil Work Method Statement For RoadsDokument3 SeitenGeneral Civil Work Method Statement For RoadsKaram MoatasemNoch keine Bewertungen

- Lean Concrete MOSDokument9 SeitenLean Concrete MOSebrahimlinda25619Noch keine Bewertungen

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDokument4 SeitenKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezNoch keine Bewertungen

- Method Statement ConbextraGPDokument7 SeitenMethod Statement ConbextraGPsinambeladavidNoch keine Bewertungen

- Method Statement For Earthwork Cutting and FillingDokument8 SeitenMethod Statement For Earthwork Cutting and FillingABDO ALLIANoch keine Bewertungen

- Safe bikes - Operators wearing helmetsDokument6 SeitenSafe bikes - Operators wearing helmetsZeljkoNoch keine Bewertungen

- Inspection, Good Construction Practices, Workmanship and Codal ProvisionsDokument31 SeitenInspection, Good Construction Practices, Workmanship and Codal ProvisionsThiyagarajan TiguNoch keine Bewertungen

- Earthworks and RoadworksDokument9 SeitenEarthworks and RoadworkswagwahkiabatheNoch keine Bewertungen

- Method Statement For PilingDokument2 SeitenMethod Statement For Pilinggilbert850507100% (1)

- Method Statement IFIDokument17 SeitenMethod Statement IFIHaitham M A Bechara0% (1)

- Method Statement - Crack Control Joint For CCB RC WallDokument7 SeitenMethod Statement - Crack Control Joint For CCB RC WallReza RosenoNoch keine Bewertungen

- Method Statement For ConstructionDokument8 SeitenMethod Statement For ConstructionTin DanNoch keine Bewertungen

- Method Statement (PAIP 400)Dokument4 SeitenMethod Statement (PAIP 400)Shafiq MustapaNoch keine Bewertungen

- Method Statement PDFDokument9 SeitenMethod Statement PDFDon Clerance Denzil WeerakkodyNoch keine Bewertungen

- Structured Method Statement For Concrete Repair - 6Dokument15 SeitenStructured Method Statement For Concrete Repair - 6m.umarNoch keine Bewertungen

- Mos DrainageDokument3 SeitenMos DrainageaniesbaekNoch keine Bewertungen

- Quality Assurance and Quality Control PlanDokument6 SeitenQuality Assurance and Quality Control PlanTia KurniawatiNoch keine Bewertungen

- Method Statement for Slab Ground Floor ConstructionDokument11 SeitenMethod Statement for Slab Ground Floor ConstructiondeviesrigatiNoch keine Bewertungen

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Dokument19 SeitenMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinNoch keine Bewertungen

- MS For Rehabilitation of Clear Water ReserviorDokument3 SeitenMS For Rehabilitation of Clear Water ReserviorMhando IgnasNoch keine Bewertungen

- Method StatementDokument2 SeitenMethod Statementsafiuedin0% (1)

- Multiplex Vertical Structures Method StatementDokument7 SeitenMultiplex Vertical Structures Method StatementAdel SaqqaNoch keine Bewertungen

- Carpet Floorring-Method StatementDokument6 SeitenCarpet Floorring-Method StatementAli Bouchakor0% (1)

- Method Statement - Structural ConcreteDokument7 SeitenMethod Statement - Structural Concretearif_rubinNoch keine Bewertungen

- 12 WI FormworkDokument9 Seiten12 WI FormworkSafdar AliNoch keine Bewertungen

- Precast Concrete Pipe Culvert InstallationDokument4 SeitenPrecast Concrete Pipe Culvert InstallationDanny NguNoch keine Bewertungen

- Method Statement All-Hbc PDFDokument62 SeitenMethod Statement All-Hbc PDFĐoàn Anh ĐứcNoch keine Bewertungen

- MS-001-Form Work, Reinforcement Steel & Concrete WorksDokument12 SeitenMS-001-Form Work, Reinforcement Steel & Concrete WorksFrancis Phillip CapistranoNoch keine Bewertungen

- Structured Method Statement For Concrete Repair - 2Dokument10 SeitenStructured Method Statement For Concrete Repair - 2m.umarNoch keine Bewertungen

- MS For BackfillingDokument3 SeitenMS For BackfillingShan THALANoch keine Bewertungen

- Method StatementDokument4 SeitenMethod StatementRichmond SantiagoNoch keine Bewertungen

- Work Method Statement For Plain and Reinforced Cement Concrete PCCDokument2 SeitenWork Method Statement For Plain and Reinforced Cement Concrete PCCBhargav BbvsNoch keine Bewertungen

- Methodology of Earth WorksDokument8 SeitenMethodology of Earth WorksMartinNoch keine Bewertungen

- Method Statement For Construction - Method Statement - Non Suspended SlabDokument3 SeitenMethod Statement For Construction - Method Statement - Non Suspended SlabKellyNoch keine Bewertungen

- Concreting MethodologyDokument2 SeitenConcreting Methodologyervnglen08Noch keine Bewertungen

- Method of Statement For HDPE Pipe InstallationDokument2 SeitenMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- Casting Box Girder Segments - tcm45-342871Dokument3 SeitenCasting Box Girder Segments - tcm45-342871AuYongTheanSengNoch keine Bewertungen

- Curriculum Vita1sad IIDokument2 SeitenCurriculum Vita1sad IIArun MoorthyNoch keine Bewertungen

- Curriculum Vitae: M.PrakashDokument2 SeitenCurriculum Vitae: M.PrakashArun MoorthyNoch keine Bewertungen

- Staff Allocation ChartDokument1 SeiteStaff Allocation ChartArun MoorthyNoch keine Bewertungen

- 2 ResumeDokument2 Seiten2 ResumeArun MoorthyNoch keine Bewertungen

- Annexure F' Specimen Declaration of Applicant For Obtaining A Passport in Lieu of Lost/ Damaged PassportDokument2 SeitenAnnexure F' Specimen Declaration of Applicant For Obtaining A Passport in Lieu of Lost/ Damaged PassportArun MoorthyNoch keine Bewertungen

- Affidavit by The StudentDokument2 SeitenAffidavit by The StudentArun MoorthyNoch keine Bewertungen

- Geetha LakshmiDokument2 SeitenGeetha LakshmiArun MoorthyNoch keine Bewertungen

- Affidavit by Parents and StudentDokument7 SeitenAffidavit by Parents and StudentArun MoorthyNoch keine Bewertungen

- Bike NocDokument1 SeiteBike NocArun MoorthyNoch keine Bewertungen

- Account Activation LetterDokument1 SeiteAccount Activation LetterArun MoorthyNoch keine Bewertungen

- Corn FoodsDokument2 SeitenCorn FoodsArun MoorthyNoch keine Bewertungen

- GST Not ApplicableDokument1 SeiteGST Not ApplicableArun MoorthyNoch keine Bewertungen

- Chemistry Project Work by Rihana.IDokument2 SeitenChemistry Project Work by Rihana.IArun MoorthyNoch keine Bewertungen

- Schedule of Rates - 2011-12Dokument170 SeitenSchedule of Rates - 2011-12Raja SekharNoch keine Bewertungen

- Quote Chakkravarthy IIDokument1 SeiteQuote Chakkravarthy IIArun MoorthyNoch keine Bewertungen

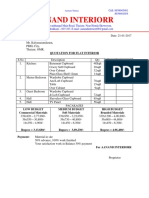

- Loganathan Vilas Interior WorkDokument2 SeitenLoganathan Vilas Interior WorkArun MoorthyNoch keine Bewertungen

- PayslipDokument1 SeitePayslipArun MoorthyNoch keine Bewertungen

- Chandran ResumeDokument2 SeitenChandran ResumeArun MoorthyNoch keine Bewertungen

- Flat Interior WorkDokument1 SeiteFlat Interior WorkArun Moorthy100% (1)

- Flat Interior Work 2Dokument1 SeiteFlat Interior Work 2Arun MoorthyNoch keine Bewertungen

- Affidavit Cum IndemnityDokument4 SeitenAffidavit Cum IndemnityArun Moorthy50% (2)

- Lease AgreementDokument1 SeiteLease AgreementArun MoorthyNoch keine Bewertungen

- MP Certificate for PAN CardDokument1 SeiteMP Certificate for PAN CardreddygrNoch keine Bewertungen

- KalyanasundaramDokument1 SeiteKalyanasundaramArun MoorthyNoch keine Bewertungen

- Affidavit ParentDokument2 SeitenAffidavit ParentArun MoorthyNoch keine Bewertungen

- Indian Hindu Baby Names GuideDokument113 SeitenIndian Hindu Baby Names Guidevenkateshsj100% (2)

- NirmalaDokument2 SeitenNirmalaArun MoorthyNoch keine Bewertungen

- Driver Antecent LetterDokument1 SeiteDriver Antecent LetterArun MoorthyNoch keine Bewertungen

- ToDokument1 SeiteToArun MoorthyNoch keine Bewertungen

- DateDokument1 SeiteDateArun MoorthyNoch keine Bewertungen

- Asphalt Concrete PavingDokument10 SeitenAsphalt Concrete Pavingsethu1091Noch keine Bewertungen

- Graphene Will Change The Way We LiveDokument1 SeiteGraphene Will Change The Way We LiveGeorge CuniaNoch keine Bewertungen

- Oring Guide Europe Ord 5712ukDokument0 SeitenOring Guide Europe Ord 5712ukramchandra rao deshpandeNoch keine Bewertungen

- Cebex 112 Mortar Plasticiser Improves Workability & YieldDokument2 SeitenCebex 112 Mortar Plasticiser Improves Workability & YieldMel AdNoch keine Bewertungen

- Surkhet Rate 2072 073Dokument88 SeitenSurkhet Rate 2072 073Mishal Limbu100% (1)

- Polycoat RbeDokument2 SeitenPolycoat RbejovindhaNoch keine Bewertungen

- Coating For The Protection of Steel StructureDokument17 SeitenCoating For The Protection of Steel StructureMohamed Abdel SamieNoch keine Bewertungen

- Insulation Materials Spec Chart Updated For Winter 2016 TICDokument2 SeitenInsulation Materials Spec Chart Updated For Winter 2016 TICMustafa AmroNoch keine Bewertungen

- Sandeep ThesisDokument67 SeitenSandeep Thesiskuldeep100% (1)

- SPECAA22421Dokument4 SeitenSPECAA22421SURJIT SINGHNoch keine Bewertungen

- Variation in Cement Properties and Its Effect on Concrete QualityDokument7 SeitenVariation in Cement Properties and Its Effect on Concrete QualityTran Huynh NamNoch keine Bewertungen

- General Specification - Roads and BridgesDokument165 SeitenGeneral Specification - Roads and BridgesEnea BogdanNoch keine Bewertungen

- Material Submittal - ConsultantDokument40 SeitenMaterial Submittal - Consultantm13naserraja75% (4)

- Bil TechDokument10 SeitenBil TechAbhishek JainNoch keine Bewertungen

- M4 Ep PDFDokument2 SeitenM4 Ep PDFjunaid112Noch keine Bewertungen

- Detalle de Caja Da RegistroDokument2 SeitenDetalle de Caja Da RegistroCarlos VasquezNoch keine Bewertungen

- Maseedupadu EstimateDokument63 SeitenMaseedupadu EstimateD.V.Srinivasa RaoNoch keine Bewertungen

- Urea Formaldehyde ResinDokument5 SeitenUrea Formaldehyde ResinSarah Katrina Veliganilao SalvacionNoch keine Bewertungen

- Aeng 261 - Paes 320Dokument47 SeitenAeng 261 - Paes 320lennahfe19100% (1)

- FLEXIPRO - BrochureDokument2 SeitenFLEXIPRO - Brochurebeck.26Noch keine Bewertungen

- West Bengal Schedule Rates of Building Works 2015Dokument399 SeitenWest Bengal Schedule Rates of Building Works 2015Arunashish Mazumdar75% (8)

- Flexi Arch Presentation - Precast ArchesDokument66 SeitenFlexi Arch Presentation - Precast ArchesdsadsNoch keine Bewertungen

- Mortars in Norway From The Middle Ages To The 20th Century: Con-Servation StrategyDokument8 SeitenMortars in Norway From The Middle Ages To The 20th Century: Con-Servation StrategyUriel PerezNoch keine Bewertungen

- Pollution Prevention and Cleaner Technology in Textile IndustryDokument18 SeitenPollution Prevention and Cleaner Technology in Textile IndustryPratik DeogekarNoch keine Bewertungen

- HVAC VRF Installation Method StatementDokument8 SeitenHVAC VRF Installation Method StatementFrancis Mayowa Ezekiel100% (2)

- Technical Specifications for Fire Safety EquipmentDokument26 SeitenTechnical Specifications for Fire Safety EquipmentRinku MishraNoch keine Bewertungen

- MODIFIED OATH HIVE PLANSDokument5 SeitenMODIFIED OATH HIVE PLANSScott GrantNoch keine Bewertungen

- Nitocote EP175: High Performance, Solvent Based Epoxy Resin CoatingDokument4 SeitenNitocote EP175: High Performance, Solvent Based Epoxy Resin CoatingVenkata Raju KalidindiNoch keine Bewertungen

- TEADITDokument1 SeiteTEADITTurbo Snail RNoch keine Bewertungen