Beruflich Dokumente

Kultur Dokumente

ESCL-SOP-016, Work Instruction For WorkShop Operators

Hochgeladen von

adiqualityconsultOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ESCL-SOP-016, Work Instruction For WorkShop Operators

Hochgeladen von

adiqualityconsultCopyright:

Verfügbare Formate

Ref.

No: ESCL-SOP-016

EGBA SPLIT-CLAMPS LIMITED

Work Instruction for Workshop

Operators

Rev. No: 00

Issue Date:12th Nov, 2012

Page 1 of 5

WORK INSTRUCTION FOR WORKSHOP

OPERATORS

APPROVAL AND REVISION STATUS

Rev. No.

00

Issue Date

Revision

12/11/2012

Identification

First Issue

Prepared by

Reviewed

Approved by

Production

Manager

by

QHSE

Manager

Managing

Director

EGBA SPLIT-CLAMPS LIMITED

Ref. No: ESCL-SOP-016

Work Instruction for Workshop

Operators

Rev. No: 00

Issue Date:12th Nov, 2012

Page 2 of 5

CHANGE (S)/AMENDMENT (S)

The change(s)/amendment(s) noted below have been made and approved by the

Managing Director for issue.

Change/Amendment No.

Date

Page

Description of Change/Amendment

EGBA SPLIT-CLAMPS LIMITED

Work Instruction for Workshop

Operators

1.0

Ref. No: ESCL-SOP-016

Rev. No: 00

Issue Date:12th Nov, 2012

Page 3 of 5

PURPOSE

This work instruction is in place to ensure that operators are aware of the steps and

procedures in the use of process equipment.

Equipment in the workshop is specialized and technical. Operators are specifically

trained in the use of the engineering equipment. This instruction is general guidance

to supplement training given at technical levels.

2.0

SCOPE

This work instruction is applicable to workshop operators.

3.0

REFERENCES

ESCL Quality Manual (ESCL-QM-001)

NIS ISO 9001: 2008, Quality Management Systems Requirements.

NIS ISO 9000: 2005, Quality Management Systems - Fundamentals and Vocabulary

ESCL-SOP-009, Maintenance Procedure

Form 125, Job Card

4.0

TERMS AND DEFINITIONS

The following terms and definitions and the ones given in ESCL Quality Manual and

NIS ISO 9000:2005 apply.

4.1

ESCL: Egba Split-Clamps Limited

4.2

ISO: International Organization for Standardization

4.3

NIS: Nigerian Industrial Standard.

4.4

Egba: Local name for clamp

5.0

RESPONSIBILITIES AND AUTHORITY

5.1

Workshop Manager or his designee:

Responsibility for the receipt of client job

orders and opening of Job card (Form 125) and the allocation of job to the

Machine/Operators.

5.3

Workshop Operators: Responsibility for undertaking work tasks assigned to them in

accordance with associated drawings or samples.

EGBA SPLIT-CLAMPS LIMITED

Work Instruction for Workshop

Operators

5.4

Ref. No: ESCL-SOP-016

Rev. No: 00

Issue Date:12th Nov, 2012

Page 4 of 5

QHSE Manager, QC Inspector: Responsibility for quality control and assurance

activities.

6.0

PROCEDURES

6.1

General

1)

Ensure any personal protective equipment required is worn.

2)

Ensure you identify the isolation switch for the machine in case of emergency.

3)

Ensure pre-use checks are performed in line with appropriate maintenance

checklists and document Ref. No. ESCL-SOP-009.

6.2

Saw

1)

Tighten fully the material to saw ensuring it is firm and secure.

2)

Measure lengths to be cut and check the dimensions.

3)

Set saw to cut length measured.

4)

Observe whilst saw cuts to ensure the equipment is functioning correctly.

5)

Ensure that continuous lubrication of cutting is completed, if lubrication stops

shut off isolator for machine.

6)

Check dimensions of cut material when saw cut is complete.

7)

Transfer identification numbers.

8)

Confirm accuracy of dimensions with Quality Control Inspector and sign and

date job card.

6.3

Lathes, Vertical Borers, Drills & Milling Machines

1)

Tighten fully the material in chuck ensuring it is firm and secure.

2)

Use the lathe/mill/drill to cut/mill/drill materials to customer specification.

3)

Ensure continuous lubricant flow, if lubrication ceases isolate machine.

4)

Observe process continually.

5)

Check tolerances until specifications meet customers needs detailed on the Job

Card.

6)

Operator gauges/measures specification and confirms tolerances.

7)

Tolerances checked and gauged by QC Inspector to ensure specification is met.

8)

Job Card endorsed to confirm process completed.

9)

Manufacture released from machine.

EGBA SPLIT-CLAMPS LIMITED

Work Instruction for Workshop

Operators

6.4

Ref. No: ESCL-SOP-016

Rev. No: 00

Issue Date:12th Nov, 2012

Page 5 of 5

Welding

1)

Prepare the area for the welding operations.

2)

Confirm the availability of fire fighting equipment and determine an escape

route in case of fire during the operations.

3)

Clear any flammable materials away from the welding location.

4)

Clear any obstructions from within the area.

5)

Warn all in the vicinity that welding operations are going to commence.

6)

Visually check pipes and cylinders to ensure gas leakage and pipe runs are not

restricted.

7)

Confirm all components required for welding are at the site location before the

welding operations commence.

8)

Pre-heat components in accordance with safe operations and efficient

requirements for the welding process.

9)

Follow temperature of procedures in accordance with customer specification.

10)

Follow procedure determined by operating activities for ESCL Welding.

11)

Sign and date job card to confirm operation complete.

7.0

RECORDS

7.1

Maintenance checklist

7.2

Job card (Form 125)

Das könnte Ihnen auch gefallen

- Do's and Dont's Shop Floor PracticesDokument19 SeitenDo's and Dont's Shop Floor Practicessridharchebrolu50% (2)

- ESCL-SOP-011, Design and Development ProcedureDokument8 SeitenESCL-SOP-011, Design and Development Procedureadiqualityconsult100% (1)

- ESCL-SOP-019, Procedure For Control of Inspection, Measurement and Test EquipmentDokument5 SeitenESCL-SOP-019, Procedure For Control of Inspection, Measurement and Test EquipmentadiqualityconsultNoch keine Bewertungen

- ESCL-SOP-013, Outsourcing Procedure - Doc Rev 01Dokument6 SeitenESCL-SOP-013, Outsourcing Procedure - Doc Rev 01adiqualityconsult0% (2)

- ESCL SOP 010, Sales Marketing ProcedueDokument5 SeitenESCL SOP 010, Sales Marketing Procedueadiqualityconsult0% (1)

- UBD Lesson Plan in Computer EdDokument2 SeitenUBD Lesson Plan in Computer Edarenroferos89% (9)

- Technical Data Sheet: Ginthox Q-558Dokument3 SeitenTechnical Data Sheet: Ginthox Q-558LuuThiThuyDuongNoch keine Bewertungen

- Heat Straightening ProcedureDokument3 SeitenHeat Straightening ProcedurerzsoltNoch keine Bewertungen

- Welding Process: Work InstructionDokument6 SeitenWelding Process: Work Instructionmkcsekar100% (1)

- Skill Matrix WeldersDokument1 SeiteSkill Matrix WeldersRavikant Pandey100% (1)

- 983 - Welding Comprehensive ASME - Quality Plan Sample PDFDokument19 Seiten983 - Welding Comprehensive ASME - Quality Plan Sample PDFRhoteram VikkuNoch keine Bewertungen

- Google Ads Fundamentals Assessment Answers 2019Dokument38 SeitenGoogle Ads Fundamentals Assessment Answers 2019Lukacs Mark-ChristopherNoch keine Bewertungen

- DBCC and SP CommandsDokument5 SeitenDBCC and SP Commandssirisha715Noch keine Bewertungen

- R35 DetailedDokument2 SeitenR35 DetailedStuar Tencio0% (1)

- Measuring & Test EquipmentDokument12 SeitenMeasuring & Test EquipmentPalkesh TrivediNoch keine Bewertungen

- Welding Machine ChecklistDokument34 SeitenWelding Machine ChecklistShahid BhattiNoch keine Bewertungen

- SOP Workshop Hy FinalDokument4 SeitenSOP Workshop Hy FinalanbuNoch keine Bewertungen

- PWHT Request 169-31853Dokument1 SeitePWHT Request 169-31853Syed Mahmud Habibur RahmanNoch keine Bewertungen

- Environment Management System ManualDokument5 SeitenEnvironment Management System ManualtoanvmpetrologxNoch keine Bewertungen

- DR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07Dokument13 SeitenDR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07SasaNoch keine Bewertungen

- Work Instruction GalDokument31 SeitenWork Instruction Galjasminnee100% (1)

- Material Rejection ReportDokument4 SeitenMaterial Rejection ReportMunazar HussainNoch keine Bewertungen

- Safety Procedure TemplateDokument23 SeitenSafety Procedure Templatejylim89Noch keine Bewertungen

- Hindustan Hydraulics EHPsh25 PDFDokument4 SeitenHindustan Hydraulics EHPsh25 PDFshyam_ink50% (2)

- BSI Standards Publication: BS EN IEC 60974-1:2018+A1:2019Dokument20 SeitenBSI Standards Publication: BS EN IEC 60974-1:2018+A1:2019Global QualityNoch keine Bewertungen

- API Audit Planning GuidanceDokument3 SeitenAPI Audit Planning GuidanceTasha RamisettiNoch keine Bewertungen

- Gate & Globe PDFDokument0 SeitenGate & Globe PDFZoebairNoch keine Bewertungen

- 39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0Dokument59 Seiten39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0JakesNoch keine Bewertungen

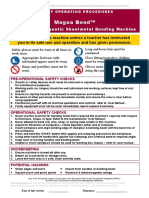

- Magna Bend SopDokument1 SeiteMagna Bend SopClarkKent Fabro Batucan0% (1)

- Master List of InstrumentsDokument35 SeitenMaster List of Instrumentskrichenaraj6931100% (1)

- Transamerican Manufacturing Group: Document Title: Weld Standards, SteelDokument16 SeitenTransamerican Manufacturing Group: Document Title: Weld Standards, SteelQuoc VinhNoch keine Bewertungen

- Safety Inspection Report: KLL (I)Dokument1 SeiteSafety Inspection Report: KLL (I)Ega NugrahaNoch keine Bewertungen

- Sop Hydraulic Punch and ShearDokument1 SeiteSop Hydraulic Punch and ShearBorislav VulićNoch keine Bewertungen

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDokument4 SeitenBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNoch keine Bewertungen

- Procedure Progress ISO 3834 2 PDFDokument3 SeitenProcedure Progress ISO 3834 2 PDFKumar DNoch keine Bewertungen

- Process Validation 1Dokument1 SeiteProcess Validation 1tayyab100% (1)

- Gmaw PDFDokument169 SeitenGmaw PDFsalman GtrNoch keine Bewertungen

- Flame Straightening S355Dokument9 SeitenFlame Straightening S355Anonymous oI04sS100% (1)

- Inspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationDokument3 SeitenInspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationKhaled GamalNoch keine Bewertungen

- S-OS-21-01 Hand Tool Inspection RegisterDokument1 SeiteS-OS-21-01 Hand Tool Inspection RegisterCharles Lamb100% (1)

- Welder Qualification Test - WQT by ITPI-IWESDokument1 SeiteWelder Qualification Test - WQT by ITPI-IWESsanul mulyNoch keine Bewertungen

- Weld Repair AWS D1.1Dokument3 SeitenWeld Repair AWS D1.1Hemant PatelNoch keine Bewertungen

- Design Change Note 1Dokument1 SeiteDesign Change Note 1Oladimeji TaiwoNoch keine Bewertungen

- GP Handling The WeaponDokument2 SeitenGP Handling The WeaponBeder MirjanNoch keine Bewertungen

- Work Instructions - Gas CuttingDokument2 SeitenWork Instructions - Gas Cuttingvivek sureshNoch keine Bewertungen

- Shell Rolling Report 1Dokument6 SeitenShell Rolling Report 1Hanuman RaoNoch keine Bewertungen

- Quality Manual Revision L Edition 2Dokument32 SeitenQuality Manual Revision L Edition 2shifa100% (1)

- Ajts QCP Fab Format Rev 01Dokument4 SeitenAjts QCP Fab Format Rev 01Pradip DabhiNoch keine Bewertungen

- Tqm-7 QC ToolsDokument124 SeitenTqm-7 QC ToolsZubair Mohamed100% (2)

- Bearing Housing Assembly Procedure EXTERNALDokument10 SeitenBearing Housing Assembly Procedure EXTERNALAlejandroZegarraNoch keine Bewertungen

- SOP - 03C Rev 1 Weld Shop PDFDokument9 SeitenSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- Prof. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMDokument43 SeitenProf. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMKeristiyantoNoch keine Bewertungen

- API Spec Q1 9th Edition - Mandatory Documented Procedures: No. Clause No. DescriptionDokument1 SeiteAPI Spec Q1 9th Edition - Mandatory Documented Procedures: No. Clause No. Descriptionzae nuddinNoch keine Bewertungen

- Wi (2) Powder CoatingDokument9 SeitenWi (2) Powder CoatingMalathi ISONoch keine Bewertungen

- NIP - Weld Check SheetDokument1 SeiteNIP - Weld Check SheetAlanka Prasad100% (2)

- Dimensional Control ProcedureDokument12 SeitenDimensional Control ProcedureBethel NdifonNoch keine Bewertungen

- 0606 Supplier Evaluation FormDokument4 Seiten0606 Supplier Evaluation FormSmitesh VangalwarNoch keine Bewertungen

- Bash-P General CatalogueDokument123 SeitenBash-P General CatalogueAri Rizki RivaldoNoch keine Bewertungen

- Motor Vehicle Log BookDokument3 SeitenMotor Vehicle Log BookkabirNoch keine Bewertungen

- Clauses IATF16949 2016Dokument2 SeitenClauses IATF16949 2016Javier BustamanteNoch keine Bewertungen

- NCR TemplateDokument4 SeitenNCR TemplateJennifer BradleyNoch keine Bewertungen

- IS 13834 Part 5Dokument6 SeitenIS 13834 Part 5SourabhAdikeNoch keine Bewertungen

- Calibration ValidationDokument12 SeitenCalibration ValidationAlberto LobonesNoch keine Bewertungen

- ESCL SOP 009, Maintenance ProcedureDokument6 SeitenESCL SOP 009, Maintenance Procedureadiqualityconsult100% (1)

- ESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsDokument6 SeitenESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsadiqualityconsultNoch keine Bewertungen

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDokument5 SeitenCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNoch keine Bewertungen

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDokument9 SeitenMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- ESCL-SOP-017, Procedure For Control of Workshop-Project OperationsDokument8 SeitenESCL-SOP-017, Procedure For Control of Workshop-Project Operationsadiqualityconsult100% (1)

- ESCL-SOP-020, Technical Specification For Egba Split-Sleeve ClampsDokument8 SeitenESCL-SOP-020, Technical Specification For Egba Split-Sleeve ClampsadiqualityconsultNoch keine Bewertungen

- ESCL SOP 014, Materials Store Control ProcedureDokument5 SeitenESCL SOP 014, Materials Store Control ProcedureadiqualityconsultNoch keine Bewertungen

- ESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsDokument6 SeitenESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsadiqualityconsultNoch keine Bewertungen

- ESCL-SOP-012, Procurement Control ProcedureDokument7 SeitenESCL-SOP-012, Procurement Control ProcedureadiqualityconsultNoch keine Bewertungen

- ESCL-SOP-011, Design and Development Procedure - Doc Rev 01Dokument6 SeitenESCL-SOP-011, Design and Development Procedure - Doc Rev 01adiqualityconsultNoch keine Bewertungen

- ESCL-SOP-015, Procedure For Production of Egba Split-Sleeve ClampsDokument12 SeitenESCL-SOP-015, Procedure For Production of Egba Split-Sleeve Clampsadiqualityconsult100% (1)

- ESCL SOP 013, Outsourcing ProcedureDokument7 SeitenESCL SOP 013, Outsourcing ProcedureadiqualityconsultNoch keine Bewertungen

- ESCL SOP 009, Maintenance ProcedureDokument6 SeitenESCL SOP 009, Maintenance Procedureadiqualityconsult100% (1)

- Form 127, Client FeedbackDokument2 SeitenForm 127, Client FeedbackadiqualityconsultNoch keine Bewertungen

- ESCL-QSP-003, Internal Quality Audit ProcedureDokument7 SeitenESCL-QSP-003, Internal Quality Audit ProcedureadiqualityconsultNoch keine Bewertungen

- ESCL SOP 008, Admin Human Resources ProcedureDokument8 SeitenESCL SOP 008, Admin Human Resources Procedureadiqualityconsult100% (1)

- ESCL-QSP-006, Preventive Action ProcedureDokument5 SeitenESCL-QSP-006, Preventive Action ProcedureadiqualityconsultNoch keine Bewertungen

- ESCL-QSP-004, Procedrue For Control of Nonconforming ProductDokument6 SeitenESCL-QSP-004, Procedrue For Control of Nonconforming Productadiqualityconsult100% (1)

- ESCL-QSP-005, Corrective Action ProcedureDokument6 SeitenESCL-QSP-005, Corrective Action Procedureadiqualityconsult100% (1)

- ESCL-QSP-002, Records Control ProcedureDokument6 SeitenESCL-QSP-002, Records Control Procedureadiqualityconsult100% (1)

- ESCL-QSO-001, Documents Control ProcedureDokument7 SeitenESCL-QSO-001, Documents Control ProcedureadiqualityconsultNoch keine Bewertungen

- Contract Review Record AmendmentDokument1 SeiteContract Review Record AmendmentadiqualityconsultNoch keine Bewertungen

- Form 128, Calibration Status LogDokument1 SeiteForm 128, Calibration Status LogadiqualityconsultNoch keine Bewertungen

- Form 102, Documents Distribution RecordDokument2 SeitenForm 102, Documents Distribution RecordadiqualityconsultNoch keine Bewertungen

- Form 122, Supplier EvaluationDokument2 SeitenForm 122, Supplier EvaluationadiqualityconsultNoch keine Bewertungen

- Form 109, Corrective-Preventive Action LogDokument2 SeitenForm 109, Corrective-Preventive Action LogadiqualityconsultNoch keine Bewertungen

- Form 119, Breakdown Maintenance RecordDokument2 SeitenForm 119, Breakdown Maintenance RecordadiqualityconsultNoch keine Bewertungen

- Form 104, Document TransmittalDokument1 SeiteForm 104, Document TransmittaladiqualityconsultNoch keine Bewertungen

- Form 105, Internal Quality Audit RecordDokument2 SeitenForm 105, Internal Quality Audit RecordadiqualityconsultNoch keine Bewertungen

- OOP in C++ - Lecture 5Dokument11 SeitenOOP in C++ - Lecture 5zaibakhan8Noch keine Bewertungen

- TL 9000 and CMMI ComparisonDokument28 SeitenTL 9000 and CMMI Comparisonsatya_14uNoch keine Bewertungen

- Excel Macro TrainingDokument21 SeitenExcel Macro Trainingapi-373800783% (6)

- Installation Instructions (Corrected)Dokument1 SeiteInstallation Instructions (Corrected)Sicein SasNoch keine Bewertungen

- PCTV Nanostick DVB-T: Big TV Experience in Small PackageDokument1 SeitePCTV Nanostick DVB-T: Big TV Experience in Small PackageShaik Mohammed HaikhalNoch keine Bewertungen

- HR Table For CreateDokument4 SeitenHR Table For CreateMadhuriNoch keine Bewertungen

- Virtual RealityDokument20 SeitenVirtual RealityAkash SolankiNoch keine Bewertungen

- Focp Important Question in Unit IV and Unit VDokument3 SeitenFocp Important Question in Unit IV and Unit VSurendran RajNoch keine Bewertungen

- How To Load Worker Data Using HDLDokument41 SeitenHow To Load Worker Data Using HDLpriyanka_ravi14Noch keine Bewertungen

- B Vs C TestDokument7 SeitenB Vs C TestSiva Subramaniam M BNoch keine Bewertungen

- Accuguard 8 Server For RDX - Release NotesDokument2 SeitenAccuguard 8 Server For RDX - Release NotesRicardo BarrazaNoch keine Bewertungen

- 1999-07 The Computer Paper - BC EditionDokument138 Seiten1999-07 The Computer Paper - BC EditionthecomputerpaperNoch keine Bewertungen

- Remote Procedure CallsDokument104 SeitenRemote Procedure CallsxenonyodaNoch keine Bewertungen

- Misc-Revision SDokument121 SeitenMisc-Revision SYang ZhouNoch keine Bewertungen

- Lecture 1 - HCI IntroDokument32 SeitenLecture 1 - HCI IntroSulaman AhmadNoch keine Bewertungen

- Project 2 Computer ScienceDokument9 SeitenProject 2 Computer SciencethedonutpirateNoch keine Bewertungen

- Getting Started With Workforce Timekeeper A Guide For ManagersDokument56 SeitenGetting Started With Workforce Timekeeper A Guide For ManagerscswigerNoch keine Bewertungen

- NC PRGDokument9 SeitenNC PRGNAGU2009Noch keine Bewertungen

- Computer Science & Engineering: Apex Institute of Technology Bachelor of Engineering (Information Security)Dokument10 SeitenComputer Science & Engineering: Apex Institute of Technology Bachelor of Engineering (Information Security)RavleenNoch keine Bewertungen

- ETSE Zeiss True Position Bore PatternDokument29 SeitenETSE Zeiss True Position Bore PatternCarlos García HernándezNoch keine Bewertungen

- Communication in The WorkplaceDokument25 SeitenCommunication in The WorkplaceApoorv Goel100% (1)

- Anna University MBA - All Year, Semester Syllabus Ordered Lecture Notes and Study Material For College StudentsDokument69 SeitenAnna University MBA - All Year, Semester Syllabus Ordered Lecture Notes and Study Material For College StudentsM.V. TVNoch keine Bewertungen

- "A Study On Cash Flow Analysis in Hetero Drugs - LTD": Master of Business AdministrationDokument7 Seiten"A Study On Cash Flow Analysis in Hetero Drugs - LTD": Master of Business AdministrationNarendra MuppasaniNoch keine Bewertungen

- Information Request PDFDokument2 SeitenInformation Request PDFrengkujeffry5323Noch keine Bewertungen

- Alexander Amini, PHD: EducationDokument5 SeitenAlexander Amini, PHD: EducationFirdaus BambooNoch keine Bewertungen

- Polynomials FunctionsDokument6 SeitenPolynomials FunctionsJerson Yhuwel100% (2)